space manufacturing on:

[Wikipedia]

[Google]

[Amazon]

Space manufacturing or In-space manufacturing (ISM in short) is the fabrication, assembly or integration of tangible

Space manufacturing or In-space manufacturing (ISM in short) is the fabrication, assembly or integration of tangible

In February 1994 and September 1995, the Wake Shield Facility was carried into orbit by the

In February 1994 and September 1995, the Wake Shield Facility was carried into orbit by the

. Madeinspace.us (May 31, 2013). Retrieved on 2015-11-24. The Additive Manufacturing Facility will be used by

. Madeinspace.us. Retrieved on November 24, 2015. Made In Space lists the advantages of 3D printing as easy customization, minimal raw material waste, optimized parts, faster production time, integrated electronics, limited human interaction, and option to modify the printing process. The Refabricator experiment, under development by Firmamentum, a division of Tethers Unlimited, Inc. under a NASA Phase III Small Business Innovation Research contract, combines a recycling system and a 3D printer to perform demonstration of closed-cycle in-space manufacturing on the International Space Station (ISS). The Refabricator experiment, which was delivered to the ISS aboard Cygnus NG-10 on November 19, 2018, processes plastic feedstock through multiple printing and recycling cycles to evaluate how many times the plastic materials can be re-used in the microgravity environment before their polymers degrade to unacceptable levels. Additionally, 3D printing in space can also account for the printing of meals.

Resources of Near-Earth Space

', University of Arizona Press, 1993. . *

Space Studies Institute

Spacehab

* v:Lunar Boom Town A role playing study group at Wikiversity where participants plan and study future space ventures. {{DEFAULTSORT:Space Manufacturing

Space manufacturing or In-space manufacturing (ISM in short) is the fabrication, assembly or integration of tangible

Space manufacturing or In-space manufacturing (ISM in short) is the fabrication, assembly or integration of tangible goods

In economics, goods are anything that is good, usually in the sense that it provides welfare or utility to someone. Alan V. Deardorff, 2006. ''Terms Of Trade: Glossary of International Economics'', World Scientific. Online version: Deardorffs ...

beyond Earth's atmosphere (or more generally, outside a planetary atmosphere), involving the transformation of raw or recycled materials into components, products, or infrastructure in space, where the manufacturing process is executed either by humans or automated systems by taking advantage of the unique characteristics of space. Synonyms of Space/In-space manufacturing are ''In-orbit manufacturing'' (since most production capabilities are limited to low Earth orbit

A low Earth orbit (LEO) is an geocentric orbit, orbit around Earth with a orbital period, period of 128 minutes or less (making at least 11.25 orbits per day) and an orbital eccentricity, eccentricity less than 0.25. Most of the artificial object ...

), ''Off-Earth manufacturing'', ''Space-based manufacturing'', ''Orbital manufacturing'', ''In-situ manufacturing'', ''In-space fabrication'', ''In-space production'', etc. In-space manufacturing is a part of the broader activity of in-space servicing, assembly and manufacturing (ISAM) and is related to in situ resource utilization (ISRU).

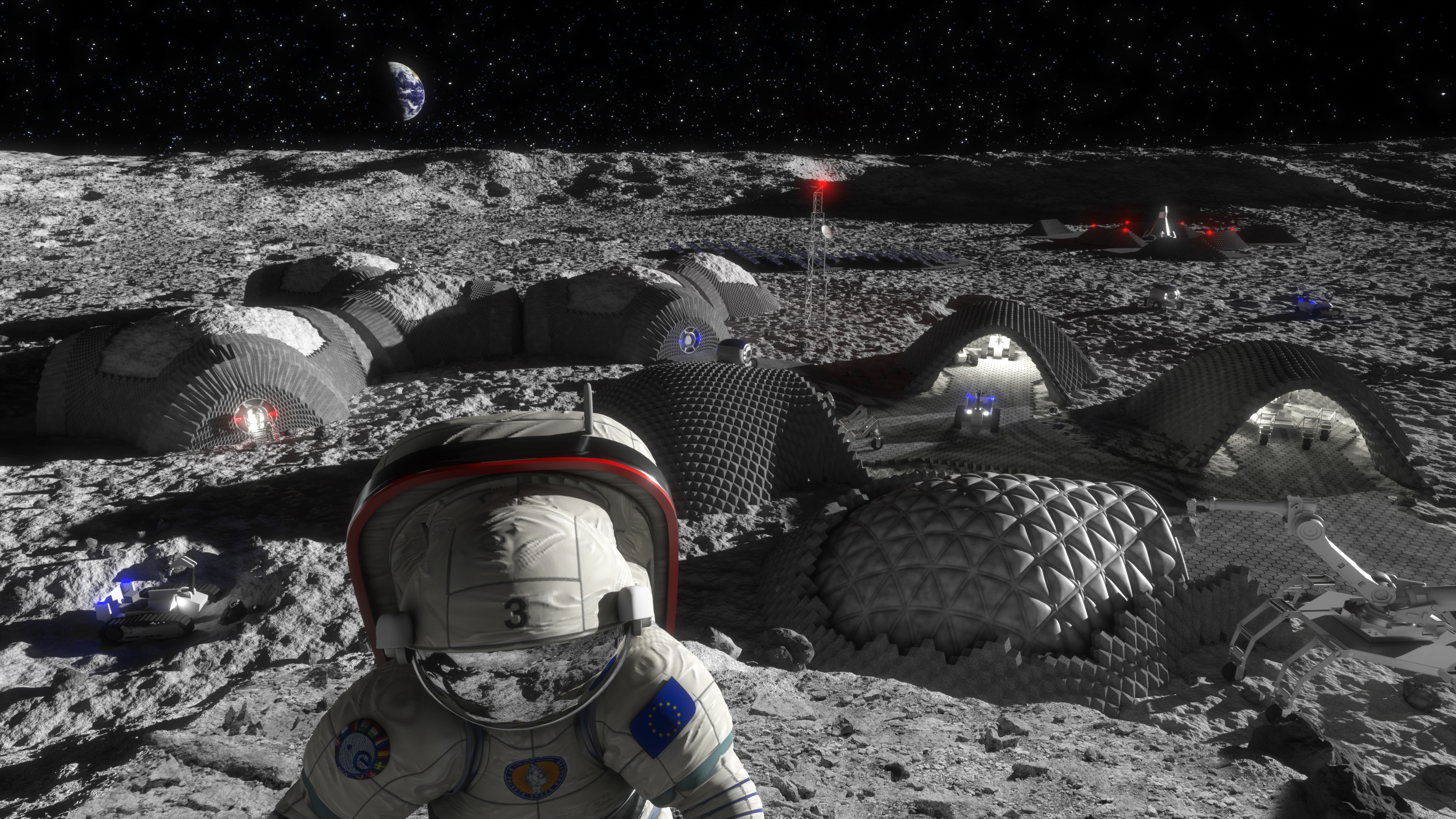

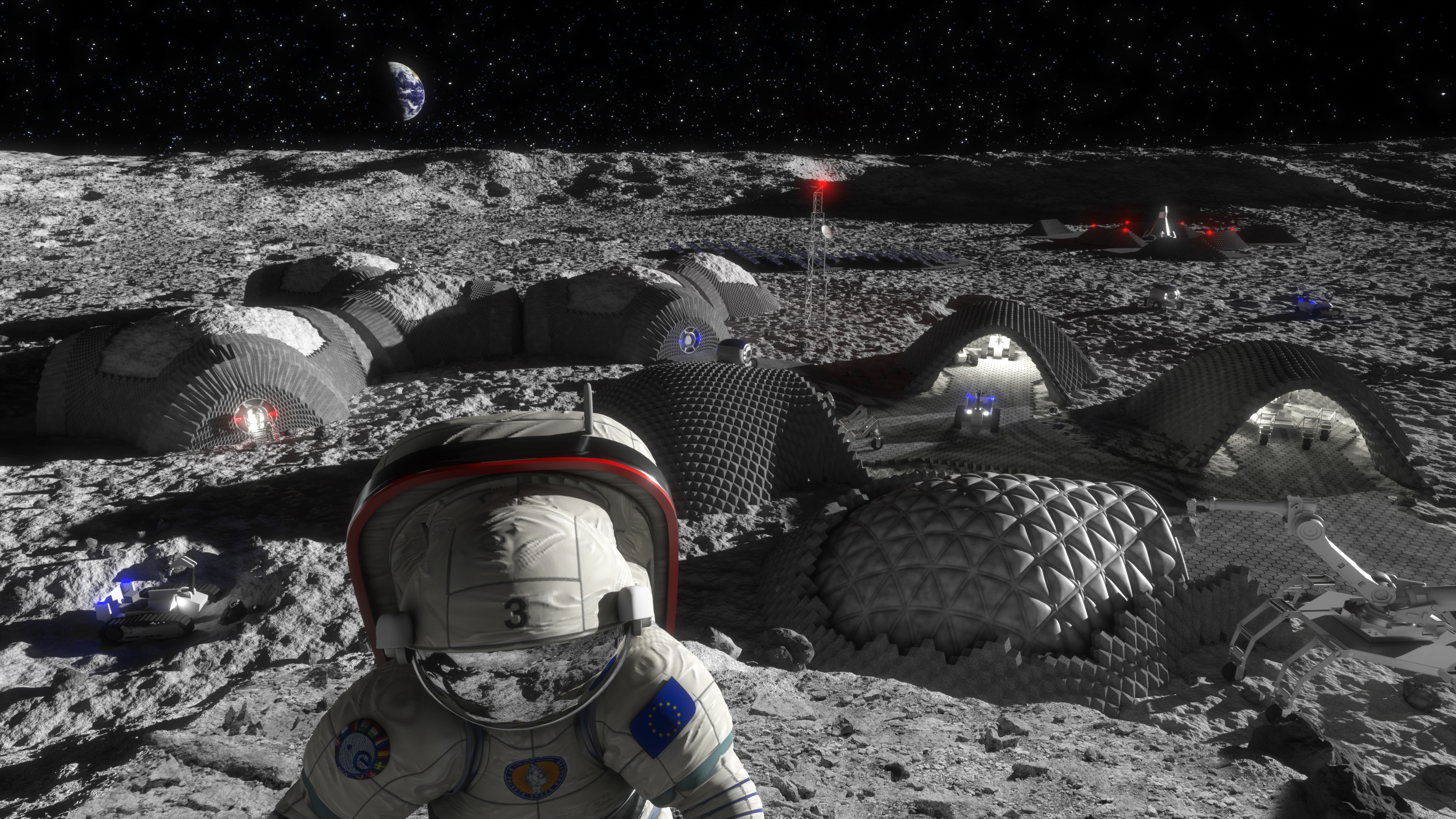

Three major domains of In-space manufacturing are ISM for space (space-for-space) where products remain in space, ISM for Earth (space-for-Earth) where goods with improved properties produced in outer-space microgravity are transported back to Earth, and ISM for surface where goods are produced on or sent to surfaces of celestial bodies like the Moon, Mars, and asteroids.

In-space manufacturing uses processes such as additive manufacturing (printing a 3D object in successive layers), subtractive manufacturing

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which util ...

(making 3D objects by successively removing material from a solid), hybrid manufacturing (usually combining additive

manufacturing and subtractive manufacturing) and welding (joining pieces of material by melting or plasticizing along a joint line).

In-space manufacturing removes spacecraft design limitations due to launch parameters (mass, vibration, structural load, etc.) and volume limitations imposed by payload size. It allows for recycling of launched materials, utilization space-mined resources and on-demand spare parts production, which enables on-site repair of critical parts (increasing reliability and redundancy) and infrastructure development. It takes advantage of unique space features such as microgravity, ultra-vacuum and containerless processing, which are difficult to do on Earth.

Areas

In-space manufacturing (ISM) can be categorized into three different areas according to the end use of manufactured products. In-space manufacturing for space (space-for-space) involves activities focused on in-orbit construction intended for use in space. ISM for Earth (space-for-Earth) is the production of new materials and products that exhibit enhanced properties when manufactured in microgravity, subsequently transported back to Earth. Lastly, ISM for surface extends to surface operations on celestial bodies such as the Moon, Mars, and asteroids.Rationale

There are several motivating factors behind in-space manufacturing. The space environment, in particular the effects ofmicrogravity

Weightlessness is the complete or near-complete absence of the sensation of weight, i.e., zero apparent weight. It is also termed zero g-force, or zero-g (named after the g-force) or, incorrectly, zero gravity.

Weight is a measurement of the fo ...

and vacuum

A vacuum (: vacuums or vacua) is space devoid of matter. The word is derived from the Latin adjective (neuter ) meaning "vacant" or "void". An approximation to such vacuum is a region with a gaseous pressure much less than atmospheric pressur ...

, enable the research of and production of goods that could otherwise not be manufactured on Earth. Secondly, the extraction and processing of raw materials from other astronomical bodies, also called In-Situ Resource Utilisation (ISRU), could enable more sustainable space exploration missions at reduced cost compared to launching all required resources from Earth. Furthermore, raw materials could be transported to low Earth orbit where they could be processed into goods that are shipped to Earth. By replacing terrestrial production on Earth, this seeks to preserve the Earth. Moreover, raw materials of very high value, for example gold, silver, or platinum, could be transported to low Earth orbit for processing or transfer to Earth which is thought to have the potential to become economically viable. In-space manufacturing supports long-duration space missions and colonization by enabling on-site repair and infrastructure development beyond Earth. Additionally, in the area of spaceflight technology, space manufacturing enhances mission safety by decentralizing manufacturing activities and establishing redundancy in critical systems, allows for customized production tailored to specific mission requirements, fostering rapid iteration and adaptation of designs, drives technological innovation in materials science, robotics, and additive manufacturing, with applications extending beyond space exploration, and lays the foundation for space-based infrastructure development, supporting a wide range of commercial activities and scientific research.

History

During the Soyuz 6 mission of 1969,Russia

Russia, or the Russian Federation, is a country spanning Eastern Europe and North Asia. It is the list of countries and dependencies by area, largest country in the world, and extends across Time in Russia, eleven time zones, sharing Borders ...

n cosmonauts performed the first welding experiments in space. Three different welding processes were tested using a hardware unit called Vulkan. The tests included welding aluminum

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

, titanium

Titanium is a chemical element; it has symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in ...

, and stainless steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES), or rustless steel, is an iron-based alloy that contains chromium, making it resistant to rust and corrosion. Stainless steel's resistance to corrosion comes from its chromi ...

.

The Skylab

Skylab was the United States' first space station, launched by NASA, occupied for about 24 weeks between May 1973 and February 1974. It was operated by three trios of astronaut crews: Skylab 2, Skylab 3, and Skylab 4. Skylab was constructe ...

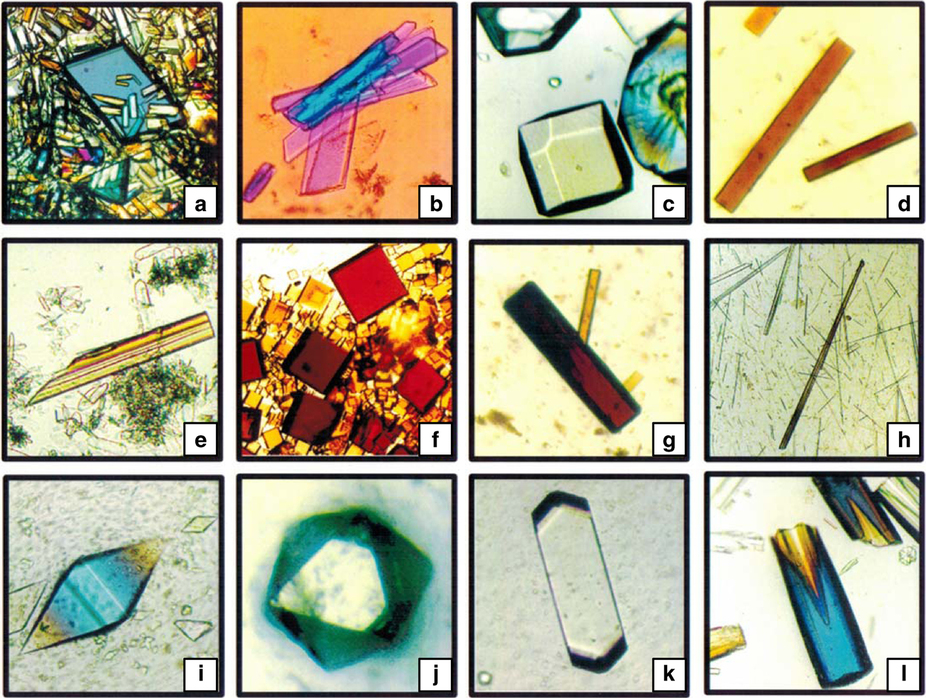

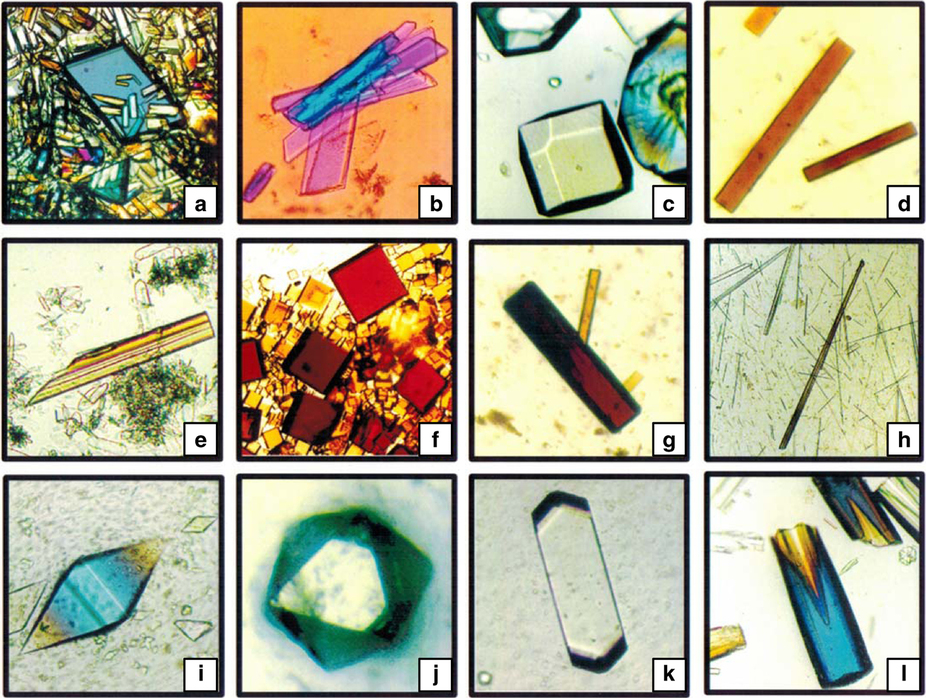

mission, launched in May 1973, served as a laboratory to perform various space manufacturing experiments. The station was equipped with a materials processing facility that included a multi-purpose electric furnace, a crystal

A crystal or crystalline solid is a solid material whose constituents (such as atoms, molecules, or ions) are arranged in a highly ordered microscopic structure, forming a crystal lattice that extends in all directions. In addition, macros ...

growth chamber, and an electron

The electron (, or in nuclear reactions) is a subatomic particle with a negative one elementary charge, elementary electric charge. It is a fundamental particle that comprises the ordinary matter that makes up the universe, along with up qua ...

beam gun. Among the experiments to be performed was research on molten metal processing; photographing the behavior of ignited materials in zero-gravity; crystal growth; processing of immiscible alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metal, metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have prop ...

s; brazing of stainless steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES), or rustless steel, is an iron-based alloy that contains chromium, making it resistant to rust and corrosion. Stainless steel's resistance to corrosion comes from its chromi ...

tubes, electron beam welding

Electron-beam welding (EBW) is a fusion welding process in which a charged-particle beam, beam of high-velocity electrons is applied to two materials to be joined. The workpieces melt and flow together as the kinetic energy of the electrons is ...

, and the formation of spheres from molten metal. The crew spent a total of 32 man-hours on materials science and space manufacturing investigation during the mission.

The Space Studies Institute began hosting a bi-annual ''Space Manufacturing Conference'' in 1977 .

Microgravity research in materials processing continued in 1983 using the Spacelab

Spacelab was a reusable laboratory developed by European Space Agency (ESA) and used on certain spaceflights flown by the Space Shuttle. The laboratory comprised multiple components, including a pressurized module, an unpressurized carrier, ...

facility. This module has been carried into orbit 26 times aboard the Space Shuttle

The Space Shuttle is a retired, partially reusable launch system, reusable low Earth orbital spacecraft system operated from 1981 to 2011 by the U.S. National Aeronautics and Space Administration (NASA) as part of the Space Shuttle program. ...

, . In this role the shuttle served as an interim, short-duration research platform before the completion of the International Space Station

The International Space Station (ISS) is a large space station that was Assembly of the International Space Station, assembled and is maintained in low Earth orbit by a collaboration of five space agencies and their contractors: NASA (United ...

.

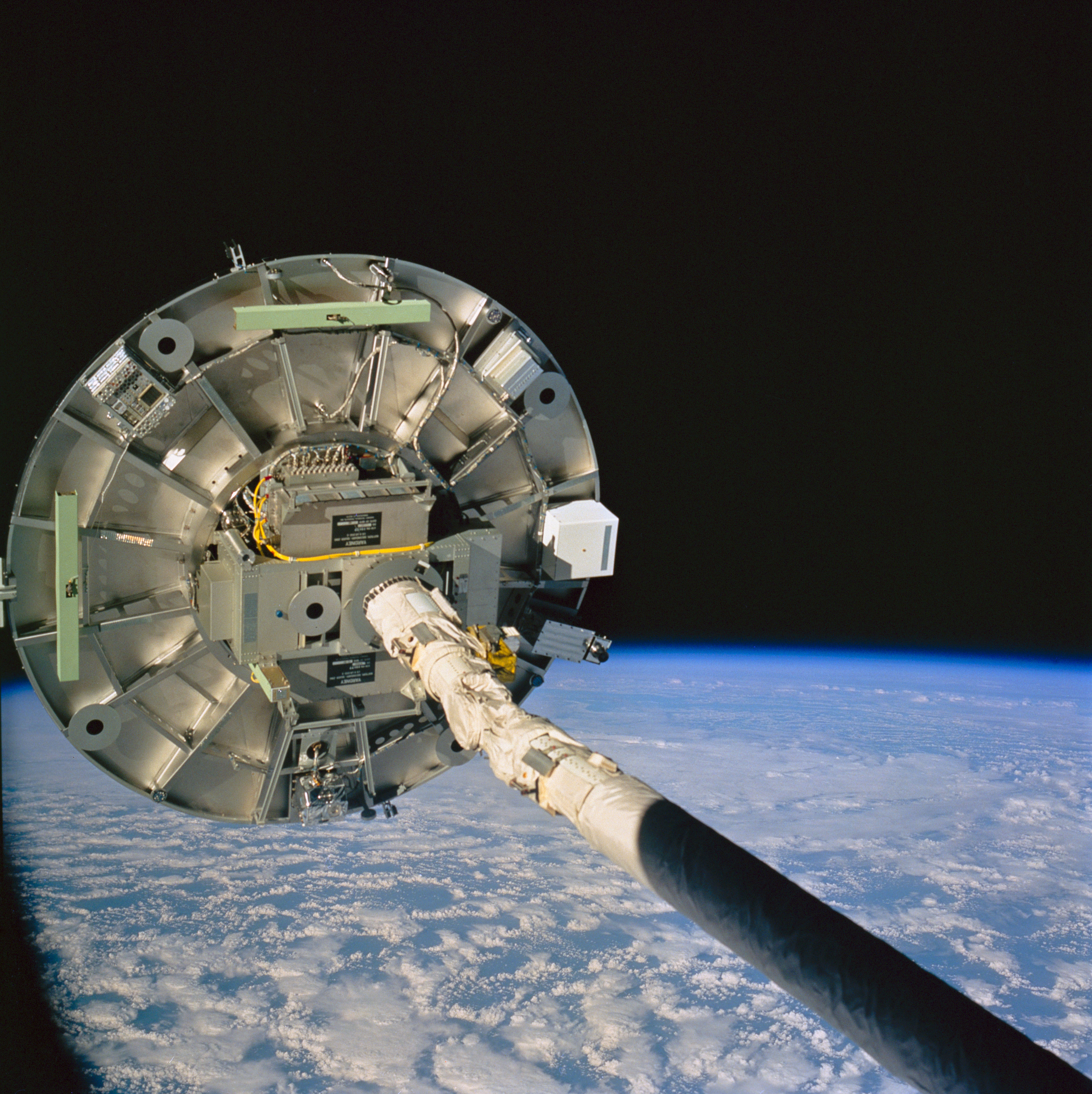

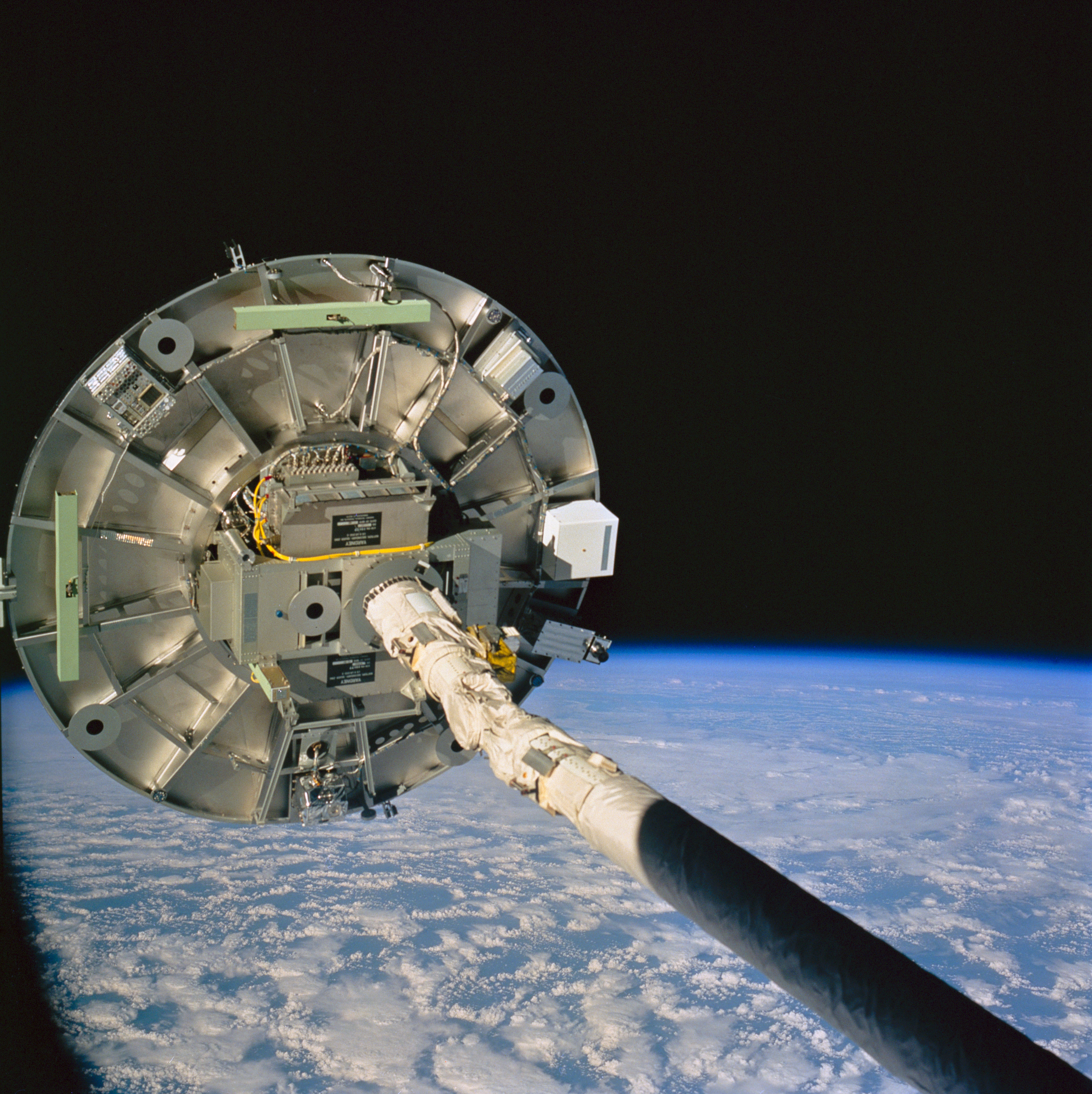

In February 1994 and September 1995, the Wake Shield Facility was carried into orbit by the

In February 1994 and September 1995, the Wake Shield Facility was carried into orbit by the Space Shuttle

The Space Shuttle is a retired, partially reusable launch system, reusable low Earth orbital spacecraft system operated from 1981 to 2011 by the U.S. National Aeronautics and Space Administration (NASA) as part of the Space Shuttle program. ...

. This demonstration platform used the vacuum created in the orbital wake to manufacture thin films of gallium arsenide

Gallium arsenide (GaAs) is a III-V direct band gap semiconductor with a Zincblende (crystal structure), zinc blende crystal structure.

Gallium arsenide is used in the manufacture of devices such as microwave frequency integrated circuits, monoli ...

and aluminum

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

gallium arsenide.

On May 31, 2005, the recoverable, uncrewed Foton-M2 laboratory was launched into orbit. Among the experiments were crystal growth and the behavior of molten-metal in weightlessness.

The completion of the International Space Station

The International Space Station (ISS) is a large space station that was Assembly of the International Space Station, assembled and is maintained in low Earth orbit by a collaboration of five space agencies and their contractors: NASA (United ...

has provided expanded and improved facilities for performing industrial research. These have and will continue to lead to improvements in our knowledge of materials sciences, new manufacturing techniques on Earth, and potentially some important discoveries in space manufacturing methods. NASA

The National Aeronautics and Space Administration (NASA ) is an independent agencies of the United States government, independent agency of the federal government of the United States, US federal government responsible for the United States ...

and Tethers Unlimited will test the Refabricator aboard the ISS, which is intended to recycle plastic for use in space additive manufacturing.

The Material Science Laboratory Electromagnetic Levitator (MSL-EML) on board the Columbus Laboratory is a science facility that can be used to study the melting and solidification properties of various materials. The Fluid Science Laboratory (FSL) is used to study the behavior of liquids in microgravity.

Material properties in the space environment

There are several unique differences between the properties of materials in space compared to the same materials on the Earth. These differences can be exploited to produce unique or improved manufacturing techniques. * The microgravity environment allows control of convection in liquids or gasses, and the elimination of sedimentation. Diffusion becomes the primary means of material mixing, allowing otherwise immiscible materials to be intermixed. * The environment allows enhanced growth of larger, higher-quality crystals in solution. * The ultraclean vacuum of space allows the creation of very pure materials and objects. The use of vapor deposition can be used to build up materials layer by layer, free from defects. *Surface tension

Surface tension is the tendency of liquid surfaces at rest to shrink into the minimum surface area possible. Surface tension (physics), tension is what allows objects with a higher density than water such as razor blades and insects (e.g. Ge ...

causes liquids in microgravity to form perfectly round spheres. This can cause problems when trying to pump liquids through a conduit, but it is very useful when perfect spheres of consistent size are needed for an application.

* Space can provide readily available extremes of heat and cold. Sunlight can be focused to concentrate enough heat to melt the materials, while objects kept in perpetual shade are exposed to temperatures close to absolute zero. The temperature gradient can be exploited to produce strong, glassy materials.

Material processing

For most manufacturing applications, specific material requirements must be satisfied.Mineral

In geology and mineralogy, a mineral or mineral species is, broadly speaking, a solid substance with a fairly well-defined chemical composition and a specific crystal structure that occurs naturally in pure form.John P. Rafferty, ed. (2011): Mi ...

ore

Ore is natural rock or sediment that contains one or more valuable minerals, typically including metals, concentrated above background levels, and that is economically viable to mine and process. The grade of ore refers to the concentration ...

s need to be refined to extract specific metal

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electrical resistivity and conductivity, electricity and thermal conductivity, heat relatively well. These properties are all associated wit ...

s, and volatile organic compound

Volatile organic compounds (VOCs) are organic compounds that have a high vapor pressure at room temperature. They are common and exist in a variety of settings and products, not limited to Indoor mold, house mold, Upholstery, upholstered furnitur ...

s will need to be purified. Ideally these raw materials are delivered to the processing site in an economical manner, where time to arrival, propulsion

Propulsion is the generation of force by any combination of pushing or pulling to modify the translational motion of an object, which is typically a rigid body (or an articulated rigid body) but may also concern a fluid. The term is derived from ...

energy

Energy () is the physical quantity, quantitative physical property, property that is transferred to a physical body, body or to a physical system, recognizable in the performance of Work (thermodynamics), work and in the form of heat and l ...

expenditure, and extraction costs are factored into the planning

Planning is the process of thinking regarding the activities required to achieve a desired goal. Planning is based on foresight, the fundamental capacity for mental time travel. Some researchers regard the evolution of forethought - the cap ...

process. Minerals can be obtained from asteroid

An asteroid is a minor planet—an object larger than a meteoroid that is neither a planet nor an identified comet—that orbits within the Solar System#Inner Solar System, inner Solar System or is co-orbital with Jupiter (Trojan asteroids). As ...

s, the lunar surface, or a planetary body. Volatiles could potentially be obtained from a comet

A comet is an icy, small Solar System body that warms and begins to release gases when passing close to the Sun, a process called outgassing. This produces an extended, gravitationally unbound atmosphere or Coma (cometary), coma surrounding ...

, carbonaceous chondrite or "C-Type" asteroids, or the moon

The Moon is Earth's only natural satellite. It Orbit of the Moon, orbits around Earth at Lunar distance, an average distance of (; about 30 times Earth diameter, Earth's diameter). The Moon rotation, rotates, with a rotation period (lunar ...

s of Mars

Mars is the fourth planet from the Sun. It is also known as the "Red Planet", because of its orange-red appearance. Mars is a desert-like rocky planet with a tenuous carbon dioxide () atmosphere. At the average surface level the atmosph ...

or other planets. It may also prove possible to extract hydrogen

Hydrogen is a chemical element; it has chemical symbol, symbol H and atomic number 1. It is the lightest and abundance of the chemical elements, most abundant chemical element in the universe, constituting about 75% of all baryon, normal matter ...

in the form of water ice or hydrated minerals from cold traps on the poles of the Moon

The Moon is Earth's only natural satellite. It Orbit of the Moon, orbits around Earth at Lunar distance, an average distance of (; about 30 times Earth diameter, Earth's diameter). The Moon rotation, rotates, with a rotation period (lunar ...

.

Unless the materials processing and the manufacturing sites are co-located with the resource extraction facilities, the raw materials would need to be moved about the Solar System

The Solar SystemCapitalization of the name varies. The International Astronomical Union, the authoritative body regarding astronomical nomenclature, specifies capitalizing the names of all individual astronomical objects but uses mixed "Sola ...

. There are several proposed means of providing propulsion for this material, including solar sail

Solar sails (also known as lightsails, light sails, and photon sails) are a method of spacecraft propulsion using radiation pressure exerted by sunlight on large surfaces. A number of spaceflight missions to test solar propulsion and navigati ...

s, electric sails, magnetic sails, electric ion thruster

An ion thruster, ion drive, or ion engine is a form of electric propulsion used for spacecraft propulsion. An ion thruster creates a cloud of positive ions from a neutral gas by ionizing it to extract some electrons from its atoms. The i ...

s, microwave electrothermal thrusters, or mass driver

A mass driver or electromagnetic catapult is a proposed method of non-rocket spacelaunch which would use a linear motor to Acceleration, accelerate and catapult Payload (air and space craft), payloads up to high speeds. Existing and proposed mass ...

s (this last method uses a sequence of electromagnets mounted in a line to accelerate a conducting material).

At the materials processing facility, the incoming materials will need to be captured by some means. Maneuvering rockets attached to the load can park the content in a matching orbit. Alternatively, if the load is moving at a low delta-v

Delta-''v'' (also known as "change in velocity"), symbolized as and pronounced , as used in spacecraft flight dynamics, is a measure of the impulse per unit of spacecraft mass that is needed to perform a maneuver such as launching from or l ...

relative to the destination, then it can be captured by means of a mass catcher. This could consist of a large, flexible net or inflatable structure that would transfer the momentum

In Newtonian mechanics, momentum (: momenta or momentums; more specifically linear momentum or translational momentum) is the product of the mass and velocity of an object. It is a vector quantity, possessing a magnitude and a direction. ...

of the mass to the larger facility. Once in place, the materials can be moved into place by mechanical means or by means of small thrusters.

Materials can be used for manufacturing either in their raw form, or by processing them to extract the constituent elements. Processing techniques include various chemical

A chemical substance is a unique form of matter with constant chemical composition and characteristic properties. Chemical substances may take the form of a single element or chemical compounds. If two or more chemical substances can be combin ...

, thermal, electrolytic, and magnet

A magnet is a material or object that produces a magnetic field. This magnetic field is invisible but is responsible for the most notable property of a magnet: a force that pulls on other ferromagnetic materials, such as iron, steel, nickel, ...

ic methods for separation. In the near term, relatively straightforward methods can be used to extract aluminum

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

, iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's o ...

, oxygen

Oxygen is a chemical element; it has chemical symbol, symbol O and atomic number 8. It is a member of the chalcogen group (periodic table), group in the periodic table, a highly reactivity (chemistry), reactive nonmetal (chemistry), non ...

, and silicon

Silicon is a chemical element; it has symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic lustre, and is a tetravalent metalloid (sometimes considered a non-metal) and semiconductor. It is a membe ...

from lunar and asteroidal sources. Less concentrated elements will likely require more advanced processing facilities, which may have to wait until a space manufacturing infrastructure is fully developed.

Some of the chemical processes will require a source of hydrogen

Hydrogen is a chemical element; it has chemical symbol, symbol H and atomic number 1. It is the lightest and abundance of the chemical elements, most abundant chemical element in the universe, constituting about 75% of all baryon, normal matter ...

for the production of water and acid

An acid is a molecule or ion capable of either donating a proton (i.e. Hydron, hydrogen cation, H+), known as a Brønsted–Lowry acid–base theory, Brønsted–Lowry acid, or forming a covalent bond with an electron pair, known as a Lewis ...

mixtures. Hydrogen gas can also be used to extract oxygen from the lunar regolith, although the process is not very efficient. So a readily available source of useful volatiles is a positive factor in the development of space manufacturing. Alternatively, oxygen can be liberated from the lunar regolith without reusing any imported materials by heating the regolith to in a vacuum. This was tested on Earth with lunar simulant in a vacuum chamber. As much as 20% of the sample was released as free oxygen. Eric Cardiff calls the remainder slag. This process is highly efficient in terms of imported materials used up per batch, but is not the most efficient process in energy per kilogram of oxygen.

One proposed method of purifying asteroid materials is through the use of carbon monoxide

Carbon monoxide (chemical formula CO) is a poisonous, flammable gas that is colorless, odorless, tasteless, and slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the si ...

(CO). Heating the material to and exposing it to CO causes the metals to form gaseous carbonyl

In organic chemistry, a carbonyl group is a functional group with the formula , composed of a carbon atom double bond, double-bonded to an oxygen atom, and it is divalent at the C atom. It is common to several classes of organic compounds (such a ...

s. This vapor can then be distilled to separate out the metal

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electrical resistivity and conductivity, electricity and thermal conductivity, heat relatively well. These properties are all associated wit ...

components, and the CO can then be recovered by another heating cycle. Thus an automated ship can scrape up loose surface materials

from, say, the relatively nearby 4660 Nereus (in delta-v terms), process the ore using solar heating and CO, and eventually return with a load of almost pure metal. The economics of this process can potentially allow the material to be extracted at one-twentieth the cost of launching from Earth, but it would require a two-year round trip to return any mined ore.

Manufacturing

Due tospeed of light

The speed of light in vacuum, commonly denoted , is a universal physical constant exactly equal to ). It is exact because, by international agreement, a metre is defined as the length of the path travelled by light in vacuum during a time i ...

constraints on communication, manufacturing in space at a distant point of resource acquisition will either require completely autonomous robotics to perform the labor, or a human crew with all the accompanying habitat and safety requirements. If the plant is built in orbit around the Earth

Earth is the third planet from the Sun and the only astronomical object known to Planetary habitability, harbor life. This is enabled by Earth being an ocean world, the only one in the Solar System sustaining liquid surface water. Almost all ...

, or near a crewed space habitat

A space settlement (also called a space habitat, spacestead, space city or space colony) is a Human settlement, settlement in outer space, sustaining more extensively Space habitat (facility), habitation facilities in space than a general space ...

, however, telerobotic devices can be used for certain tasks that require human intelligence and flexibility.

Solar power

Solar power, also known as solar electricity, is the conversion of energy from sunlight into electricity, either directly using photovoltaics (PV) or indirectly using concentrated solar power. Solar panels use the photovoltaic effect to c ...

provides a readily available power source for thermal processing. Even with heat alone, simple thermally-fused materials can be used for basic construction of stable structures. Bulk soil from the Moon or asteroids has a very low water content, and when melted to form glassy materials is very durable. These simple, glass

Glass is an amorphous (non-crystalline solid, non-crystalline) solid. Because it is often transparency and translucency, transparent and chemically inert, glass has found widespread practical, technological, and decorative use in window pane ...

y solids can be used for the assembly of habitats on the surface of the Moon or elsewhere. The solar energy can be concentrated in the manufacturing area using an array of steerable mirror

A mirror, also known as a looking glass, is an object that Reflection (physics), reflects an image. Light that bounces off a mirror forms an image of whatever is in front of it, which is then focused through the lens of the eye or a camera ...

s.

The availability and favorable physical properties of metals will make them a major component of space manufacturing. Most of the metal handling techniques used on Earth can also be adopted for space manufacturing. A few of these techniques will need significant modifications due to the microgravity

Weightlessness is the complete or near-complete absence of the sensation of weight, i.e., zero apparent weight. It is also termed zero g-force, or zero-g (named after the g-force) or, incorrectly, zero gravity.

Weight is a measurement of the fo ...

environment.

The production of hardened steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength a ...

in space will introduce some new factors. Carbon

Carbon () is a chemical element; it has chemical symbol, symbol C and atomic number 6. It is nonmetallic and tetravalence, tetravalent—meaning that its atoms are able to form up to four covalent bonds due to its valence shell exhibiting 4 ...

only appears in small proportions in lunar surface materials and will need to be delivered from elsewhere. Waste materials carried by humans from the Earth is one possible source, as are comets. The water normally used to quench steel will also be in short supply, and require strong agitation.

Casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or ...

steel can be a difficult process in microgravity, requiring special heating and injection processes, or spin forming. Heating can be performed using sunlight combined with electrical heaters. The casting process would also need to be managed to avoid the formation of voids as the steel cools and shrinks.

Various metal-working techniques can be used to shape the metal into the desired form. The standard methods are casting, drawing

Drawing is a Visual arts, visual art that uses an instrument to mark paper or another two-dimensional surface, or a digital representation of such. Traditionally, the instruments used to make a drawing include pencils, crayons, and ink pens, some ...

, forging

Forging is a manufacturing process involving the shaping of metal using localized compression (physics), compressive forces. The blows are delivered with a hammer (often a power hammer) or a die (manufacturing), die. Forging is often classif ...

, machining

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which util ...

, rolling

Rolling is a Motion (physics)#Types of motion, type of motion that combines rotation (commonly, of an Axial symmetry, axially symmetric object) and Translation (geometry), translation of that object with respect to a surface (either one or the ot ...

, and welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melting, melt the parts together and allow them to cool, causing Fusion welding, fusion. Co ...

. Both rolling and drawing metals require heating and subsequent cooling. Forging and extrusion can require powered presses, as gravity is not available. Electron beam welding has already been demonstrated on board the Skylab

Skylab was the United States' first space station, launched by NASA, occupied for about 24 weeks between May 1973 and February 1974. It was operated by three trios of astronaut crews: Skylab 2, Skylab 3, and Skylab 4. Skylab was constructe ...

, and will probably be the method of choice in space. Machining operations can require precision tools which will need to be imported from the Earth for some duration.

New space manufacturing technologies are being studied at places such as Marshall's ''National Center for Advanced Manufacturing''. The methods being investigated include coatings that can be sprayed on surfaces in space using a combination of heat and kinetic energy, and electron beam free form fabrication of parts. Approaches such as these, as well as examination of material properties that can be investigated in an orbiting laboratory, will be studied on the International Space Station

The International Space Station (ISS) is a large space station that was Assembly of the International Space Station, assembled and is maintained in low Earth orbit by a collaboration of five space agencies and their contractors: NASA (United ...

by NASA and Made In Space, Inc.

3D-printing in space

The option of3D printing

3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer ...

items in space holds many advantages over manufacturing situated on Earth. With 3D printing technologies, rather than exporting tools and equipment from Earth into space, astronauts have the option to manufacture needed items directly. On-demand patterns of manufacturing make long-distance space travel more feasible and self-sufficient as space excursions require less cargo. Mission safety is also improved.

The Made In Space, Inc. 3D printers, which launched in 2014 to the International Space Station

The International Space Station (ISS) is a large space station that was Assembly of the International Space Station, assembled and is maintained in low Earth orbit by a collaboration of five space agencies and their contractors: NASA (United ...

, are designed specifically for a zero-gravity or micro-gravity environment. The effort was awarded the Phase III Small Business Innovation and Research Contract."NASA to send first 3D printer into space". Madeinspace.us (May 31, 2013). Retrieved on 2015-11-24. The Additive Manufacturing Facility will be used by

NASA

The National Aeronautics and Space Administration (NASA ) is an independent agencies of the United States government, independent agency of the federal government of the United States, US federal government responsible for the United States ...

to carry out repairs (including during emergency situations), upgrades, and installation."Additive Manufacturing Facility for ISS: NASA SBIR Phase 2". Madeinspace.us. Retrieved on November 24, 2015. Made In Space lists the advantages of 3D printing as easy customization, minimal raw material waste, optimized parts, faster production time, integrated electronics, limited human interaction, and option to modify the printing process. The Refabricator experiment, under development by Firmamentum, a division of Tethers Unlimited, Inc. under a NASA Phase III Small Business Innovation Research contract, combines a recycling system and a 3D printer to perform demonstration of closed-cycle in-space manufacturing on the International Space Station (ISS). The Refabricator experiment, which was delivered to the ISS aboard Cygnus NG-10 on November 19, 2018, processes plastic feedstock through multiple printing and recycling cycles to evaluate how many times the plastic materials can be re-used in the microgravity environment before their polymers degrade to unacceptable levels. Additionally, 3D printing in space can also account for the printing of meals.

NASA

The National Aeronautics and Space Administration (NASA ) is an independent agencies of the United States government, independent agency of the federal government of the United States, US federal government responsible for the United States ...

's Advanced Food Technology program is currently investigating the possibility of printing food items in order to improve food quality, nutrient content, and variety.

Airbus

Airbus SE ( ; ; ; ) is a Pan-European aerospace corporation. The company's primary business is the design and manufacturing of commercial aircraft but it also has separate Airbus Defence and Space, defence and space and Airbus Helicopters, he ...

is developing and planning with the European Space Agency

The European Space Agency (ESA) is a 23-member International organization, international organization devoted to space exploration. With its headquarters in Paris and a staff of around 2,547 people globally as of 2023, ESA was founded in 1975 ...

to send and test the first 3D-printer printing metals in space at the ISS in a year from 2022, and establishing space manufacturing in three to four years from 2022.

Products

There are thought to be a number of useful products that can potentially be manufactured in space and result in an economic benefit. Research and development is required to determine the best commodities to be produced, and to find efficient production methods. The following products are considered prospective early candidates: * Growth of protein crystals * Improvedsemiconductor

A semiconductor is a material with electrical conductivity between that of a conductor and an insulator. Its conductivity can be modified by adding impurities (" doping") to its crystal structure. When two regions with different doping level ...

wafers

*Micro-encapsulation

Microencapsulation is a process in which tiny particles or droplets are surrounded by a coating to give small capsules, with useful properties. In general, it is used to incorporate food ingredients, enzymes, cells or other materials on a micr ...

As the infrastructure is developed and the cost of assembly drops, some of the manufacturing capacity can be directed toward the development of expanded facilities in space, including larger scale manufacturing plants. These will likely require the use of lunar and asteroid materials, and so follow the development of mining bases.

Rock is the simplest product, and at minimum is useful for radiation shielding. It can also be subsequently processed to extract elements for various uses.

Water from lunar sources, Near Earth Asteroids or Martian moons

The two moons of Mars are Phobos and Deimos. They are irregular in shape. Both were discovered by American astronomer Asaph Hall in August 1877 and are named after the Greek mythological twin characters Phobos (fear and panic) and Deimos (t ...

is thought to be relatively cheap and simple to extract, and gives adequate performance for many manufacturing and material shipping purposes. Separation of water into hydrogen and oxygen can be easily performed in small scale, but some scientists believe that this will not be performed on any large scale initially due to the large quantity of equipment and electrical energy needed to split water and liquify the resultant gases. Water used in steam rockets gives a specific impulse

Specific impulse (usually abbreviated ) is a measure of how efficiently a reaction mass engine, such as a rocket engine, rocket using propellant or a jet engine using fuel, generates thrust. In general, this is a ratio of the ''Impulse (physics), ...

of about 190 seconds; less than half that of hydrogen/oxygen, but this is adequate for delta-v's that are found between Mars and Earth. Water is useful as a radiation shield and in many chemical processes.

Ceramic

A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcela ...

s made from lunar or asteroid soil can be employed for a variety of manufacturing purposes. These uses include various thermal and electrical insulators, such as heat shields for payloads being delivered to the Earth's surface.

Metals can be used to assemble a variety of useful products, including sealed containers (such as tanks and pipes), mirrors for focusing sunlight, and thermal radiators. The use of metals for electrical devices would require insulators for the wires, so a flexible insulating material such as plastic or fiberglass will be needed.

A notable output of space manufacturing is expected to be solar panels. Expansive solar energy arrays can be constructed and assembled in space. As the structure does not need to support the loads that would be experienced on Earth, huge arrays can be assembled out of proportionately smaller amounts of material. The generated energy can then be used to power manufacturing facilities, habitats, spacecraft, lunar bases, and even beamed down to collectors on the Earth with microwave

Microwave is a form of electromagnetic radiation with wavelengths shorter than other radio waves but longer than infrared waves. Its wavelength ranges from about one meter to one millimeter, corresponding to frequency, frequencies between 300&n ...

s.

Other possibilities for space manufacturing include propellants for spacecraft, some repair parts for spacecraft and space habitats, and, of course, larger factories. Ultimately, space manufacturing facilities can hypothetically become nearly self-sustaining, requiring only minimal imports from the Earth. The microgravity environment allows for new possibilities in construction on a massive scale, including megascale engineering. These future projects might potentially assemble space elevators, massive solar array farms, very high capacity spacecraft, and rotating habitats capable of sustaining populations of tens of thousands of people in Earth-like conditions.

Challenges

The space environment is expected to be beneficial for production of a variety of products assuming the obstacles to it can be overcome. The most significant cost is overcoming the energy hurdle for boosting materials into orbit. Once this barrier is significantly reduced in cost perkilogram

The kilogram (also spelled kilogramme) is the base unit of mass in the International System of Units (SI), equal to one thousand grams. It has the unit symbol kg. The word "kilogram" is formed from the combination of the metric prefix kilo- (m ...

, the entry price for space manufacturing can make it much more attractive to entrepreneurs. After the heavy capitalization costs of assembling the mining

Mining is the Resource extraction, extraction of valuable geological materials and minerals from the surface of the Earth. Mining is required to obtain most materials that cannot be grown through agriculture, agricultural processes, or feasib ...

and manufacturing facilities are paid, the production will need to be economically profitable in order to become self-sustaining and beneficial to society.

The economic requirements of space manufacturing imply a need to collect the requisite raw materials at a minimum energy cost. The cost of space transport is directly related to the delta-v

Delta-''v'' (also known as "change in velocity"), symbolized as and pronounced , as used in spacecraft flight dynamics, is a measure of the impulse per unit of spacecraft mass that is needed to perform a maneuver such as launching from or l ...

, or change in velocity required to move from the mining sites to the manufacturing plants. Bringing material to Earth orbit from bodies such as Near-Earth asteroids, Phobos, Deimos or the lunar surface requires far less delta-v than launching from Earth itself, despite the greater distances involved. This makes these places economically attractive as sources of raw materials.

See also

* Acid leaching *Asteroid mining

Asteroid mining is the hypothetical extractivism, extraction of materials from asteroids and other minor planets, including near-Earth objects.

Notable asteroid mining challenges include the high cost of spaceflight, unreliable identification ...

* In situ resource utilization

* ISS manufacturing

* Self-replication

Self-replication is any behavior of a dynamical system that yields construction of an identical or similar copy of itself. Biological cells, given suitable environments, reproduce by cell division. During cell division, DNA is replicated and c ...

* Space-based economy

* Space colonization

Space colonization (or extraterrestrial colonization) is the human settlement, settlement or colonization of outer space and astronomical bodies. The concept in its broad sense has been applied to any permanent human presence in space, such ...

* Space elevator

* Spacelab

Spacelab was a reusable laboratory developed by European Space Agency (ESA) and used on certain spaceflights flown by the Space Shuttle. The laboratory comprised multiple components, including a pressurized module, an unpressurized carrier, ...

* Varda Space Industries

References

Further reading

* Andrew H. Cutler, ''Metallurgical Properties of Lunar and Asteroidal Steels'', 7th Princeton/AIAA/SSI Conference, 1985. * David Gump, ''Space Enterprise: Beyond NASA'', Praeger Publishers, 1990, . * T. A. Heppenheimer, ''Colonies in Space'', 1977, Stackpole Books, . * Lewis, J., Matthews, M.S., and Guerrieri, M.L., Editors, 1993,Resources of Near-Earth Space

', University of Arizona Press, 1993. . *

External links

Space Studies Institute

Spacehab

* v:Lunar Boom Town A role playing study group at Wikiversity where participants plan and study future space ventures. {{DEFAULTSORT:Space Manufacturing