slip casting on:

[Wikipedia]

[Google]

[Amazon]

Slip casting, or slipcasting, is a ceramic forming technique, and is widely used in industry and by craft potters to make ceramic forms. This technique is typically used to form complicated shapes like figurative ceramics that would be difficult to be reproduced by hand or other forming techniques. The technique involves a clay body slip, usually prepared in a blunger, being poured into

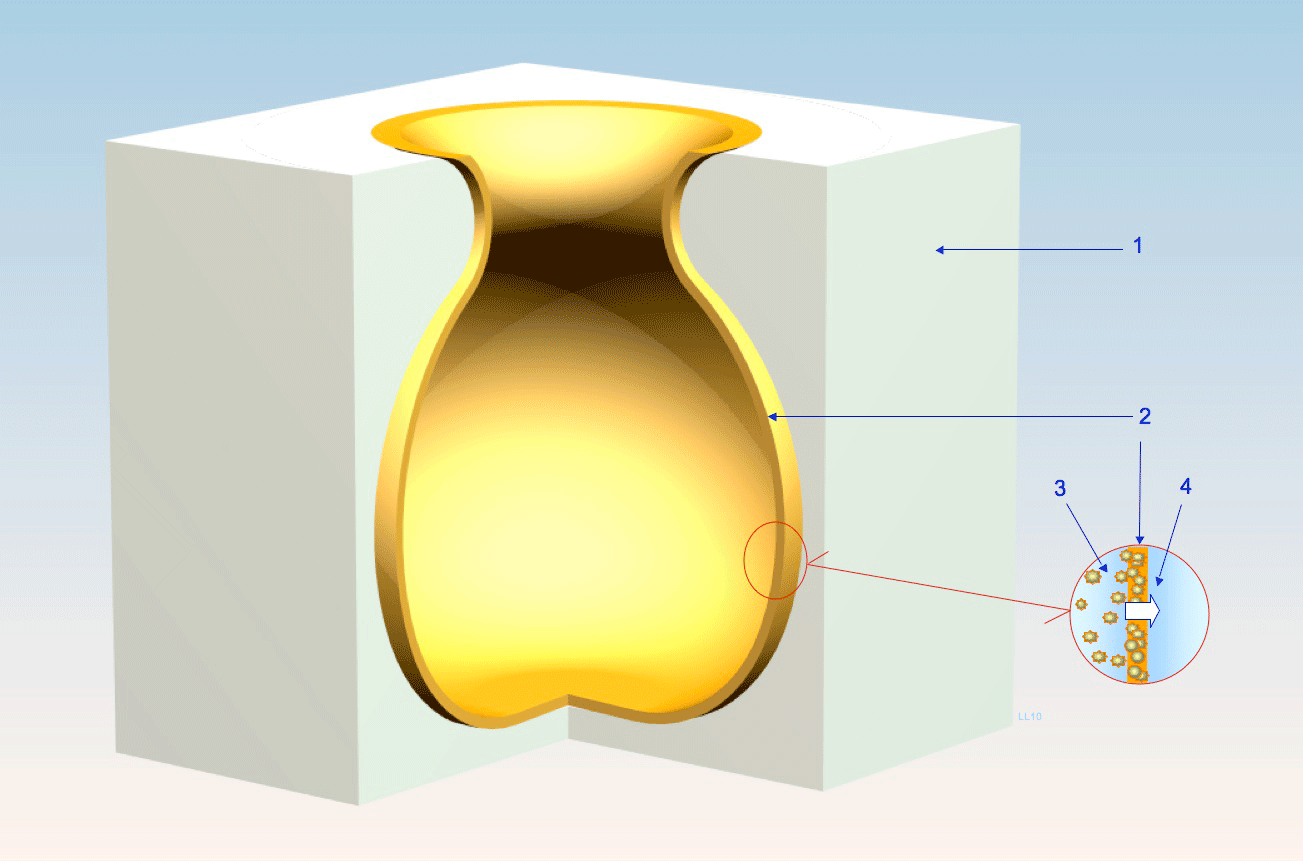

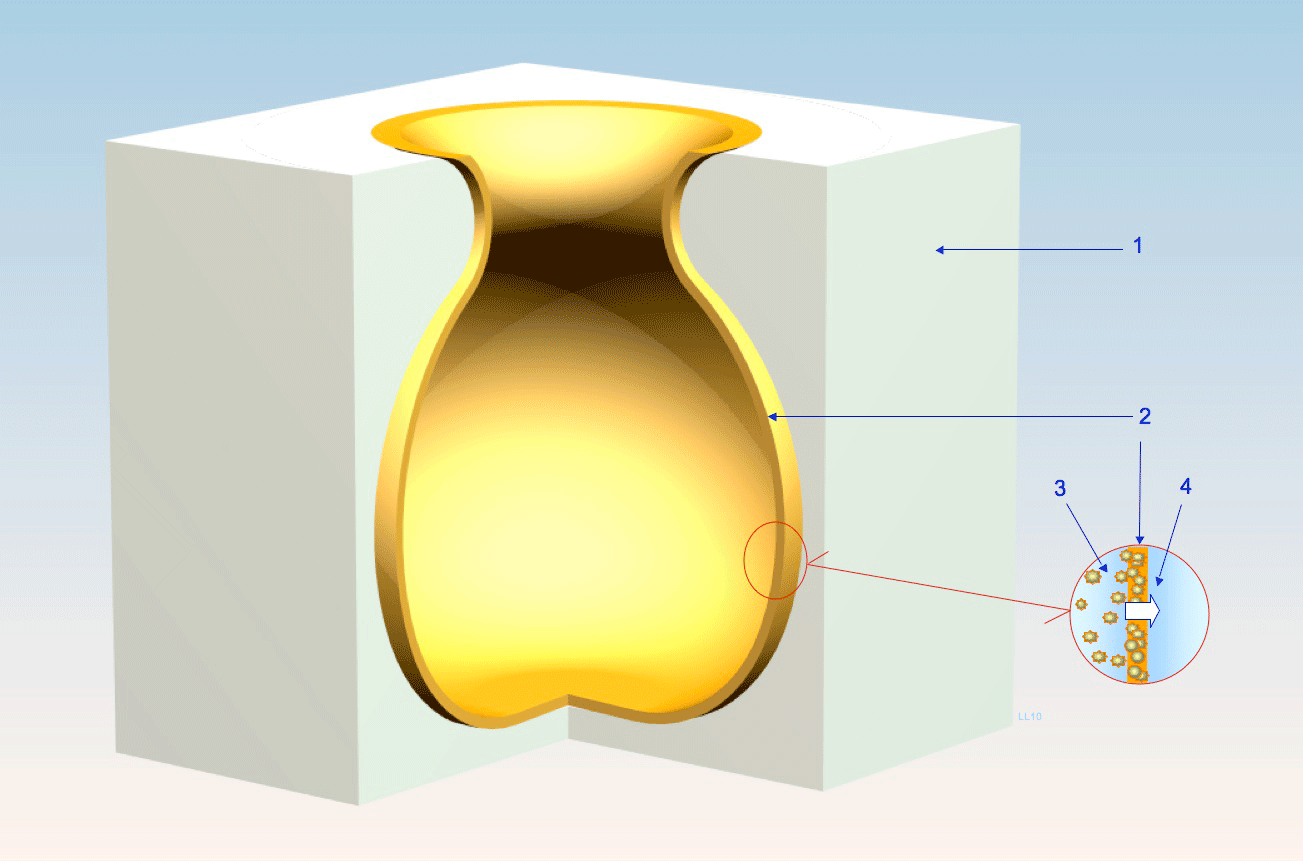

The casting slip is poured into a porous mould. Due to capillary pressure from the mold, a semi-solid particulate layer is formed on the mould through deposition of the solids in the slip. After a period of time, determined in advance by testing, the cast piece is removed from the mold; the cast needs to be sufficiently firm to handle without damage. The cast piece may then be ''fettled'' to remove the mold seam, before being dried to remove the remaining water. This typically results in a ''greenware'' piece which is then ready for subsequent processing, including glazing and firing.

The casting slip is poured into a porous mould. Due to capillary pressure from the mold, a semi-solid particulate layer is formed on the mould through deposition of the solids in the slip. After a period of time, determined in advance by testing, the cast piece is removed from the mold; the cast needs to be sufficiently firm to handle without damage. The cast piece may then be ''fettled'' to remove the mold seam, before being dried to remove the remaining water. This typically results in a ''greenware'' piece which is then ready for subsequent processing, including glazing and firing.

Conventional slip castingSlip casting for the beginnerSlip casting at the Emma Bridgewater factory in Stoke-On-Trent, EnglandPressure casting of sanitarywareTeacher's notes on slip casting by The American Ceramic Society

plaster

Plaster is a building material used for the protective or decorative coating of walls and ceilings and for moulding and casting decorative elements. In English, "plaster" usually means a material used for the interiors of buildings, while "re ...

moulds and allowed to form a layer, the ''cast'', on the internal walls of the mould.

It is suited for the consistent and precise shaping of complex shapes. It is the standard shaping technique for sanitaryware, such as toilets and basins, and is commonly used for smaller pieces like figurines and teapot

A teapot is a vessel used for steeping tea leaves or a herbal mix in boiling or near-boiling water and serving the resulting infusion called tea; usually put in a teacup. It is one of the core components of teaware.

Teapots usually have an ...

s.

History

The technique was first developed in China during theTang dynasty

The Tang dynasty (, ; zh, c=唐朝), or the Tang Empire, was an Dynasties of China, imperial dynasty of China that ruled from 618 to 907, with an Wu Zhou, interregnum between 690 and 705. It was preceded by the Sui dynasty and followed ...

(618–917), but was relatively little-used in China until recent times. It seems to have been reinvented independently in England around 1745 "reputedly by Ralph Daniels of Corbridge

Corbridge is a village in Northumberland, England, west of Newcastle upon Tyne, Newcastle and east of Hexham. Villages nearby include Halton, Northumberland, Halton, Acomb, Northumberland, Acomb, Aydon and Sandhoe.

Etymology

Corbridge was k ...

", and before long was widely used by European porcelain manufacturers, and then became the main forming technique for sanitaryware by the end of the century.

Technical considerations

''Solid casting'' is used to produce solid articles, such as cup handles; for this the mold frequently includes a reservoir of excess slip. ''Hollow casting'' is used to produce articles such as teapots. The properties of a casting slip depends on multiple factors, including:'Sanitaryware Technology'. Domenico Fortuna. Gruppo Editoriale Faenza Editrice S.p.A. 2000. *the properties of each raw material in the slip, *the solids content of the slip, *the clay:non-plastic ratio in the slip, *the chemicals in the slip, either deliberately added or introduced from the raw materials and water, *the type and amount ofdeflocculant

In colloidal chemistry, flocculation is a process by which colloidal particles come out of suspension to sediment in the form of floc or flake, either spontaneously or due to the addition of a clarifying agent. The action differs from precipit ...

,

*the ambient conditions, especially temperature and humidity, and

*the amount of energy involved in mixing the raw materials to prepare the slip.

Additionally, factors affecting the rate of formation of the cast piece include:

*the viscosity

Viscosity is a measure of a fluid's rate-dependent drag (physics), resistance to a change in shape or to movement of its neighboring portions relative to one another. For liquids, it corresponds to the informal concept of ''thickness''; for e ...

and thixotropy

Thixotropy is a time-dependent shear thinning property. Certain gels or fluids that are thick or viscous under static conditions will flow (become thinner, less viscous) over time when shaken, agitated, shear-stressed, or otherwise stressed ...

of the slip, which are invariably modified immediately before casting,

*properties of the mold material, such as permeability, and

*moisture content of the mould.

The casting slip is poured into a porous mould. Due to capillary pressure from the mold, a semi-solid particulate layer is formed on the mould through deposition of the solids in the slip. After a period of time, determined in advance by testing, the cast piece is removed from the mold; the cast needs to be sufficiently firm to handle without damage. The cast piece may then be ''fettled'' to remove the mold seam, before being dried to remove the remaining water. This typically results in a ''greenware'' piece which is then ready for subsequent processing, including glazing and firing.

The casting slip is poured into a porous mould. Due to capillary pressure from the mold, a semi-solid particulate layer is formed on the mould through deposition of the solids in the slip. After a period of time, determined in advance by testing, the cast piece is removed from the mold; the cast needs to be sufficiently firm to handle without damage. The cast piece may then be ''fettled'' to remove the mold seam, before being dried to remove the remaining water. This typically results in a ''greenware'' piece which is then ready for subsequent processing, including glazing and firing.

Casting times

A lavatory closet typically takes around 40 to 60 minutes to cast using the conventional technique, with a Swiss manufacturer noting that "preparing the mould and casting a single piece can take up to 40 minutes." Thinner sections will be quicker, with one source advising 5–10 mm taking 10–15 minutes. Casting times for ceramictableware

Tableware items are the dishware and utensils used for setting a table, serving food, and dining. The term includes cutlery, glassware, serving dishes, serving utensils, and other items used for practical as well as decorative purposes. The ...

have been reported as 35 to 60 minutes for earthenware

Earthenware is glazed or unglazed Vitrification#Ceramics, nonvitreous pottery that has normally been fired below . Basic earthenware, often called terracotta, absorbs liquids such as water. However, earthenware can be made impervious to liquids ...

and 8 to 20 minutes for bone china

Bone china is a type of vitreous, translucent pottery, the raw materials for which include bone ash, feldspathic material and kaolin. It has been defined as "ware with a translucent body" containing a minimum of 30% of phosphate derived from c ...

. Other reports include: 30–50 minutes at a US studio pottery; around 60 minutes at a small Portuguese manufacturer of decorative ceramics; "approximately 15 minutes" from a US distance learning

Distance education, also known as distance learning, is the education of students who may not always be physically present at school, or where the learner and the teacher are separated in both time and distance; today, it usually involves online ...

university; 15–20 minutes in an article for studio potters; and 15–45 minutes in a guide for beginners.

Casting times are notably shorter by pressure casting, with 2 minutes reported for tableware bowls and dishes, and 6–8 minutes for sanitaryware. The cycle time per piece of sanitaryware using high pressure at Duravit

Duravit AG, founded in 1817 and headquartered in Hornberg, Germany, is primarily a manufacturer of porcelain bathroom fittings. In recent years, the company has diversified its scope to include other products.

History

Founded as a small earthe ...

is reported to be 20 minutes.

Solids content of the slip

To achieve an acceptable rate of cast formation and minimize drying shrinkage, a slip with a high content of solids is needed. The generally accepted solids content of a Vitreous China sanitaryware casting slip ranges between 72 and 75% by weight, which corresponds to slip densities of 1.80–1.85 g/cm3. Certain chemicals, known as deflocculants, are used to disperse agglomerates in the slip, and so decrease the viscosity and also allow a higher solids content; the latter is important to minimize drying shrinkage. Examples of deflocculants includesodium carbonate

Sodium carbonate (also known as washing soda, soda ash, sal soda, and soda crystals) is the inorganic compound with the formula and its various hydrates. All forms are white, odourless, water-soluble salts that yield alkaline solutions in water ...

and sodium silicate

Sodium silicate is a generic name for chemical compounds with the formula or ·, such as sodium metasilicate (), sodium orthosilicate (), and sodium pyrosilicate (). The anions are often polymeric. These compounds are generally colorless tra ...

. Typical deflocculant additions used for a Vitreous China casting slip are 0.1-0.65%; the rheological properties of the clay components are the main influencing factors for the dosage.

A mathematical formula developed by Alexandre Brongniart

Alexandre Brongniart (5 February 17707 October 1847) was a French chemist, mineralogist, geologist, paleontologist, and zoologist, who collaborated with Georges Cuvier on a study of the geology of the region around Paris. Observing fossil conten ...

of Sèvres Porcelain

Sèvres (, ) is a French Communes of France, commune in the southwestern suburbs of Paris. It is located from the Kilometre zero, centre of Paris, in the Hauts-de-Seine department of the Île-de-France region. The commune, which had a populatio ...

is used to determine the dry material content of the slip. This has become to be known as Brongniart's formula.

Pressure casting

Pressure casting is a development of traditional slipcasting which was developed in the 1970s for the production of sanitaryware and more recently has been applied to tableware. Specially developed polymeric materials allow a mold to be subject to application of external pressures up to 4.0 MPa; much higher than slip casting in plaster molds where the capillary forces correspond to a pressure of around 0.1–0.2 MPa. The high pressure leads to much faster casting rates and, hence, faster production cycles: one study found that by increasing the pressure from 0.25 to 4.0 bar (3.6 to 58 psi) decreased the casting time for a 6-mm cast of aporcelain

Porcelain (), also called china, is a ceramic material made by heating Industrial mineral, raw materials, generally including kaolinite, in a kiln to temperatures between . The greater strength and translucence of porcelain, relative to oth ...

body from about 45 to 15 min. Using pressure casting, a Geberit factory in Finland

Finland, officially the Republic of Finland, is a Nordic country in Northern Europe. It borders Sweden to the northwest, Norway to the north, and Russia to the east, with the Gulf of Bothnia to the west and the Gulf of Finland to the south, ...

casts a toilet in 20 minutes.

Furthermore, the application of high-pressure air through the polymeric molds upon demolding the cast means that a new casting cycle can be started immediately in the same mold, unlike plaster moulds which require lengthy drying times. The polymeric materials have much greater durability than plaster and, therefore, it is possible to achieve products with better dimensional tolerances and much longer mold life.

Advantages of pressure casting over conventional casting have been summarized as higher productivity, higher yield, improved ware quality, lower distortion of the cast piece, reduced surface defects, reduced production space, reduced demand for molds, reduced energy costs, and readily fitting with the automation of demolding and handling.

Ceramic laminates

As a processing technique forceramic

A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcela ...

laminates, a ceramic powder is often placed in suspension to form a slip with a high solids content (>60 wt%) as well as a very low viscosity value (<40 mPa). A series of layers can be formed by changing the composition of the slips used in repeated castings. If the chemistry of the materials being used is well understood, the thickness of the layers can be controlled by varying the length of time involved in the casting.

Slipware

Slip-cast ware, objects that are formed using slip casting, should not be confused with slipware, pottery that is formed by any technique and then decorated using slip. The French for slip is ''barbotine

wikt: barbotine, Barbotine is the French for slip (ceramics), ceramic slip, or a mixture of clay and water used for moulding or decorating pottery. In English the term is used for three different techniques of decorating pottery, though in all cas ...

'' (''coulée en barbotine'' means slip casting). As far back as the Roman Empire

The Roman Empire ruled the Mediterranean and much of Europe, Western Asia and North Africa. The Roman people, Romans conquered most of this during the Roman Republic, Republic, and it was ruled by emperors following Octavian's assumption of ...

, potters created what is termed "Barbotine ware" by using clay slip to decorate the surface of pots. "Barbotine pottery" is sometimes used for 19th-century French and American pottery with added slip cast decoration, as well as (confusingly) 17th century English slipware that is decorated with thick blobs of slip.

External links

Conventional slip casting

References

{{Pottery Pottery