Setpoint (control system) on:

[Wikipedia]

[Google]

[Amazon]

In

In

In

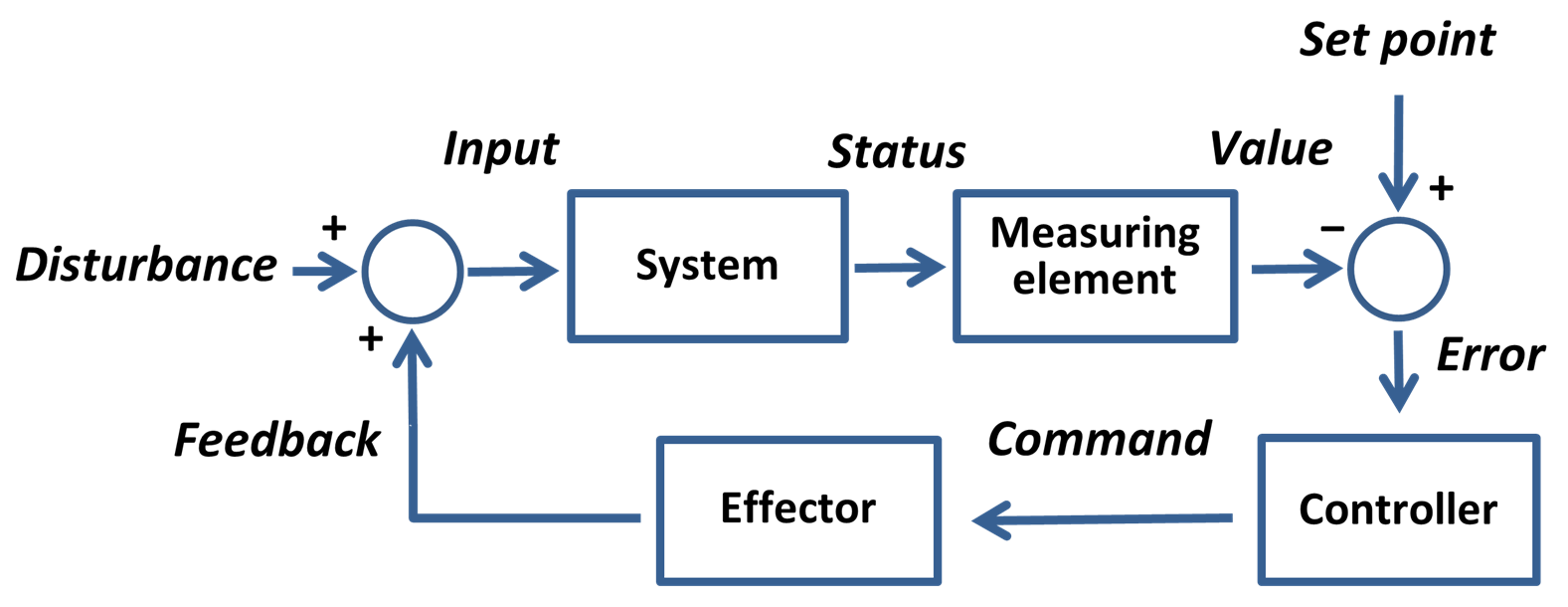

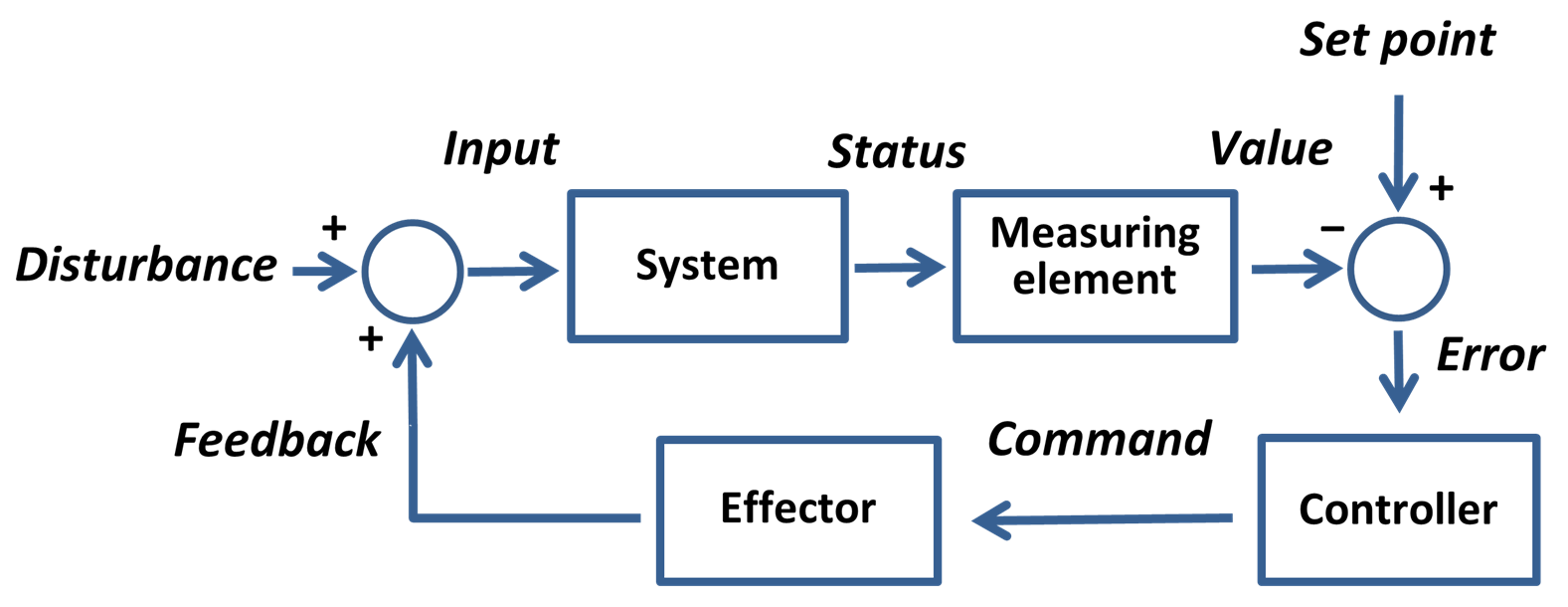

In cybernetics

Cybernetics is the transdisciplinary study of circular causal processes such as feedback and recursion, where the effects of a system's actions (its outputs) return as inputs to that system, influencing subsequent action. It is concerned with ...

and control theory

Control theory is a field of control engineering and applied mathematics that deals with the control system, control of dynamical systems in engineered processes and machines. The objective is to develop a model or algorithm governing the applic ...

, a setpoint (SP; also set point) is the desired or target value for an essential variable, or process value (PV) of a control system

A control system manages, commands, directs, or regulates the behavior of other devices or systems using control loops. It can range from a single home heating controller using a thermostat controlling a domestic boiler to large industrial ...

, which may differ from the actual measured value of the variable. Departure of such a variable from its setpoint is one basis for error-controlled regulation using negative feedback

Negative feedback (or balancing feedback) occurs when some function (Mathematics), function of the output of a system, process, or mechanism is feedback, fed back in a manner that tends to reduce the fluctuations in the output, whether caused ...

for automatic control. A setpoint can be any physical quantity or parameter that a control system seeks to regulate, such as temperature, pressure, flow rate, position, speed, or any other measurable attribute.

In the context of PID controller, the setpoint represents the reference or goal for the controlled process variable. It serves as the benchmark against which the actual process variable (PV) is continuously compared. The PID controller calculates an error signal by taking the difference between the setpoint and the current value of the process variable. Mathematically, this error is expressed as:

:

where is the error at a given time , is the setpoint, is the process variable at time .

The PID controller uses this error signal to determine how to adjust the control output to bring the process variable as close as possible to the setpoint while maintaining stability and minimizing overshoot.

Examples

Cruise control The error can be used to return a system to its norm. An everyday example is the cruise control on a road vehicle; where external influences such as gradients cause speed changes (PV), and the driver also alters the desired set speed (SP). The automatic control algorithm restores the actual speed to the desired speed in the optimum way, without delay or overshoot, by altering the power output of the vehicle's engine. In this way the error is used to control the PV so that it equals the SP. A widespread of error is classically used in the PID controller. Industrial applications Special consideration must be given for engineering applications. In industrial systems, physical or process restraints may limit the determined set point. For example, a reactor which operates more efficiently at higher temperatures may be rated to withstand 500°C. However, for safety reasons, the set point for the reactor temperature control loop would be well below this limit, even if this means the reactor is running less efficiently.See also

*Process control

Industrial process control (IPC) or simply process control is a system used in modern manufacturing which uses the principles of control theory and physical industrial control systems to monitor, control and optimize continuous Industrial processe ...

* Proportional–integral–derivative controllerReferences

Classical control theory Control devices Control engineering Control loop theory Cybernetics Process engineering {{Tech-stub