Roberts Loom on:

[Wikipedia]

[Google]

[Amazon]

The Roberts loom was a cast-iron

The Roberts loom was a cast-iron

Roberts was born at

Roberts was born at

Selected Cotton Chats- Draper Corporation 1901- 1923

(Last checked 3 October 2012) {{Lancashire Cotton Textile machinery Weaving equipment History of the textile industry Industrial Revolution in England 1830 introductions Textile mills in Lancashire 19th-century inventions Welsh inventions 19th century in Lancashire

The Roberts loom was a cast-iron

The Roberts loom was a cast-iron power loom

A power loom is a mechanized loom.

Shuttle looms

The main components of the loom are the warp beam, heddles, harnesses, shuttle, reed, and takeup roll. In the loom, yarn processing includes shedding, picking, battening and taking-up operations ...

introduced by Richard Roberts in 1830. It was the first loom that was more viable than a hand loom and was easily adjustable and reliable, which led to its widespread use in the Lancashire cotton industry.

Richard Roberts

Roberts was born at

Roberts was born at Llanymynech

Llanymynech is a village and former civil parish straddling the Wales-England border, border between Powys, Wales, and Shropshire, England, about north of the Welsh town of Welshpool. The name is Welsh language, Welsh for "Llan (placename), L ...

, on the border between England

England is a Countries of the United Kingdom, country that is part of the United Kingdom. It is located on the island of Great Britain, of which it covers about 62%, and List of islands of England, more than 100 smaller adjacent islands. It ...

and Wales

Wales ( ) is a Countries of the United Kingdom, country that is part of the United Kingdom. It is bordered by the Irish Sea to the north and west, England to the England–Wales border, east, the Bristol Channel to the south, and the Celtic ...

. He was the son of William Roberts, a shoemaker, who also kept the New Bridge tollgate. Roberts was educated by the parish priest, and early found employment with a boatman on the Ellesmere Canal

The Ellesmere Canal was a waterway in England and Wales that was planned to carry boat traffic between the rivers Mersey and Severn. The proposal would create a link between the Port of Liverpool and the mineral industries in north east Wales an ...

and later at the local limestone quarries. He received some instruction in drawing from Robert Bough, a road surveyor, who was working under Thomas Telford

Thomas Telford (9 August 1757 – 2 September 1834) was a Scottish civil engineer. After establishing himself as an engineer of road and canal projects in Shropshire, he designed numerous infrastructure projects in his native Scotland, as well ...

.

He was responsible for developing ever more precise machine tools

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All ...

, working eventually from 15 Deansgate, Manchester

Manchester () is a city and the metropolitan borough of Greater Manchester, England. It had an estimated population of in . Greater Manchester is the third-most populous metropolitan area in the United Kingdom, with a population of 2.92&nbs ...

. Here he worked on improving textile machinery. He patented the cast-iron loom in 1822 and in 1830 patented the self-acting mule thus revolutionising the production of both the spinning

Spin or spinning most often refers to:

* Spin (physics) or particle spin, a fundamental property of elementary particles

* Spin quantum number, a number which defines the value of a particle's spin

* Spinning (textiles), the creation of yarn or thr ...

and weaving

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal ...

industries.

The weaving process

The major components of the loom are the warp beam, heddles, harnesses, shuttle, reed and takeup roll. In the loom, yarn processing includes shedding, picking, battening and taking-up operations.The loom

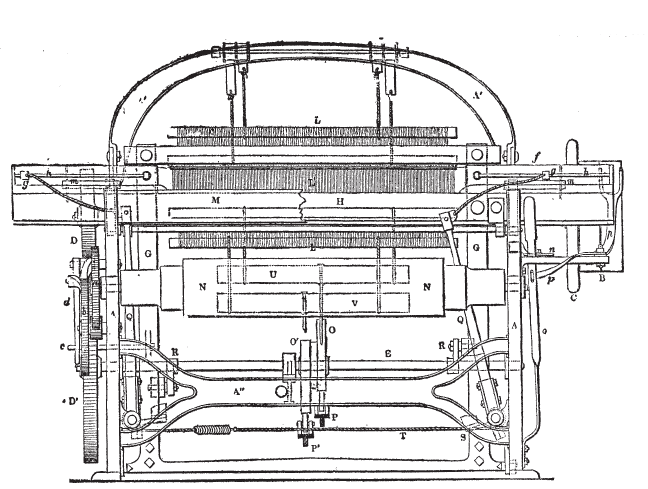

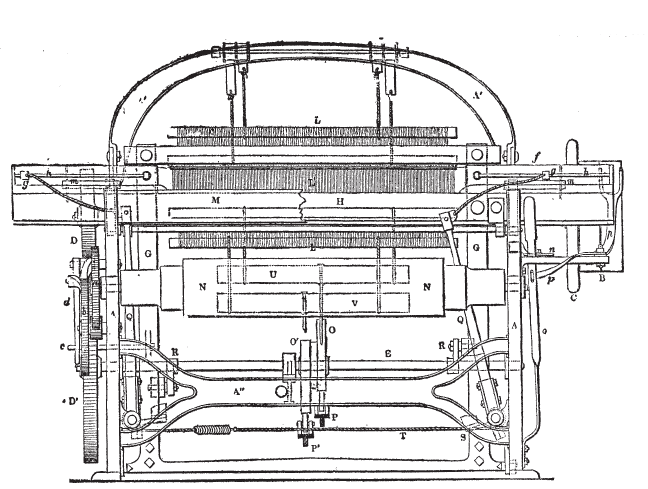

The Roberts loom of 1830 incorporated ideas embodied in an 1822 patent. The frame of the loom was cast iron. There were two side frames cast as single pieces. The three cross tails were machined for an accurate assembly. The great arched rail at the top supports the healds. The front and back cross rails bifurcate at each side to give a larger binding surface. The warp passes from the warp beam, passes over a friction guide roller, where it horizontally passes through the loom to a breastbeam. Here it turns vertically to the cloth beam. Even tension is essential as any variation will lead to broken threads. As the warp beam empties its effective diameter changes making the warp slacker- tension is maintained by adding a wooden pulley to the beam, around which are two turns of rope that are attached to mill weights- thus retarding the beam through friction. The cloth beam bears a toothed wheel which works a pinion. A ratchet wheel is attached with a click level to take up the slack in the cloth. This was Roberts invention. The heddles are of standard construction. They are arranged in groups of four, obviously even threads and odd must go up and down alternatively but twoheddle

A heddle or heald is an integral part of a loom. Each thread in the warp passes through a heddle,"Weaving." ''The Encyclopædia Britannica''. 11th ed. 1911. which is used to separate the warp threads for the passage of the weft."Heddle." '' ...

s are used for the evens and two for the odds so adjacent threads do not rub. The lower end of the heddle leaves is attached to treadles or marches. These are depressed by cam referred to as eccentrics..

The loom is powered by a leather steam-belt which drives the driving shaft. Here there is a flywheel to smooth the motion and a crank mechanism to drive the battens (swords) and a toothed wheel. This engages a second shaft known as the tappet shaft or wiper shaft whose job is to lower the treadles and throw the shuttle. This turns half the speed of the driving shaft, so its toothed wheel is twice the size.

The shuttle is thrown by two levers attached to the side frame, but activated by a friction roller on the tappet shaft. As the shuttle enters the shuttle-box at the end of its travel, it depresses a lever which acts as a brake. If this lever is not depressed then the loom is stopped.

Economics

The Roberts was made at a time when the power loom industry was set to expand. Until this moment, hand looms were more common than power looms. The reliable Roberts loom was quickly adopted and again it was the spinning side that was short of capacity. Roberts then addressed this, with the construction of a self-acting (automatic) spinning mule. Essentially, textile production was no longer a skilled craft but an industrial process that could be manned by semi-skilled labour. Mule spinning became the man's occupation, and weaving a girl's occupation.References

Bibliography

* * *External links

Selected Cotton Chats- Draper Corporation 1901- 1923

(Last checked 3 October 2012) {{Lancashire Cotton Textile machinery Weaving equipment History of the textile industry Industrial Revolution in England 1830 introductions Textile mills in Lancashire 19th-century inventions Welsh inventions 19th century in Lancashire