resin dispensing on:

[Wikipedia]

[Google]

[Amazon]

{{Unreferenced, date=May 2009

A resin dispensing system is a technical installation to process casting resin for the purpose of filling, sealing, covering or soaking technical parts, especially in the field of electricity and electronics like

In a dispensing system the following processes have to be performed:

*Conditioning of the resin mix

*Material transportation

*Metering

*Mixing

*Casting

A good resin dispensing system provides high quality casting of the same high standard even during long series in mass production.

In a dispensing system the following processes have to be performed:

*Conditioning of the resin mix

*Material transportation

*Metering

*Mixing

*Casting

A good resin dispensing system provides high quality casting of the same high standard even during long series in mass production.

Which kind of feeding pump has to be used depends mainly on the viscosity of the material and the abrasiveness of the fillers.

For low to medium viscous material:

*

Which kind of feeding pump has to be used depends mainly on the viscosity of the material and the abrasiveness of the fillers.

For low to medium viscous material:

*

Getting constant volume is, technically, relatively simple and metering systems relying on constant volume dispensing therefore are especially simple and reliable.

A very good way is the use of piston metering heads. The ratio of resin to hardener can be determined exactly by the ratio of the width of two separate pistons, one for resin, one for hardener, where both pistons are pushed simultaneously. The amount is determined by a common stopper, limiting the stroke of both pistons equally.

State of the art (2009) are metering volumes from 0,01 mL to about 250 mL, may be even more.

Getting constant volume is, technically, relatively simple and metering systems relying on constant volume dispensing therefore are especially simple and reliable.

A very good way is the use of piston metering heads. The ratio of resin to hardener can be determined exactly by the ratio of the width of two separate pistons, one for resin, one for hardener, where both pistons are pushed simultaneously. The amount is determined by a common stopper, limiting the stroke of both pistons equally.

State of the art (2009) are metering volumes from 0,01 mL to about 250 mL, may be even more.

By using adequate controls, many variations of casting are available. For instance, dams can be cast in different forms. Cast from highly viscous,

By using adequate controls, many variations of casting are available. For instance, dams can be cast in different forms. Cast from highly viscous,

transformer

A transformer is a passive component that transfers electrical energy from one electrical circuit to another circuit, or multiple circuits. A varying current in any coil of the transformer produces a varying magnetic flux in the transformer' ...

s, LCDs and other devices of various size.

Due to progressing miniaturization and introduction of electronics into new areas, quality requirements for the parts are rising, and thus the quality of dispensing must be increased as well. To obtain the required quality, on one hand, the resin system has to be developed and optimized accordingly. On the other hand, the resin dispensing system has to work more and more precisely to obtain best dispensing. Because of continuously increasing cost pressure, casting devices must be capable of increased quality, while also becoming faster and more reliable.

Requirements for good dispensing

First of all, by dispensing, electrical and electronic parts have to be insulated reliably and penetration of moisture has to be excluded totally. Very often heat has to be conducted out from the part properly, an attribute that can be improved by the choice of an appropriate resin e.g. epoxy, polyurethane or silicone.Process steps in a dispensing system

In a dispensing system the following processes have to be performed:

*Conditioning of the resin mix

*Material transportation

*Metering

*Mixing

*Casting

A good resin dispensing system provides high quality casting of the same high standard even during long series in mass production.

In a dispensing system the following processes have to be performed:

*Conditioning of the resin mix

*Material transportation

*Metering

*Mixing

*Casting

A good resin dispensing system provides high quality casting of the same high standard even during long series in mass production.

Conditioning

Several properties of the resin mix, with or without filler material, one component or two components (resin + hardener), are crucial for the quality of the product: *Even distribution of the fillers (no settling) *Elimination of air and moisture *Constant, often elevated temperature to maintain low viscosity Even distribution of the fillers without setting is maintained by ongoing stirring. Air and moisture are eliminated by evacuating the material tanks. Elevated temperature is reached and maintained by thoroughly controlled heating of the tanks, the material feeding lines, the pumps and metering heads. In filled, complex resin mixes conditioning is especially crucial for the quality of the product.Material transportation

Which kind of feeding pump has to be used depends mainly on the viscosity of the material and the abrasiveness of the fillers.

For low to medium viscous material:

*

Which kind of feeding pump has to be used depends mainly on the viscosity of the material and the abrasiveness of the fillers.

For low to medium viscous material:

*Piston pump

A piston pump is a type of positive displacement pump where the high-pressure seal reciprocates with the piston. Piston pumps can be used to move liquids or compress gases. They can operate over a wide range of pressures. High pressure operatio ...

s

*Eccentric screw pump

A screw pump is a positive-displacement pump that use one or several screws to move fluid solids or liquids along the screw(s) axis.

Three principal forms exist; In its simplest form (the Archimedes' screw pump or 'water screw'), a single scr ...

s

*Progressive cavity pump

Progressive may refer to:

Politics

* Progressivism, a political philosophy in support of social reform

** Progressivism in the United States, the political philosophy in the American context

* Progressive realism, an American foreign policy pa ...

s

*Gear pump

A gear pump uses the meshing of gears to pump fluid by displacement. They are one of the most common types of pumps for hydraulic fluid power applications. The gear pump was invented around 1600 by Johannes Kepler.

Gear pumps are also wid ...

s

Gear pumps are not fit for abrasive material

For highly viscous material follower plate pump {{Unreferenced, date=June 2019, bot=noref (GreenC bot)

image:Schoepfkolbenpumpe mit Vakuumplatte.png, 250px, A scooping piston pump used with follower plate.

The red arrows show the flow of the material, the blue ones the movement of the piston and ...

s are connected with an eccentric screw pump or a scooping piston pump. Metering is controlled for mass, time, and volume to determine the amount of resin dispensed.

Metering by mass

Weighing provides very exact determination of amount, but it lengthens the cycle time. Also, a scale within a production line can be quite sensitive to malfunction and hard to use on boards populated with many parts. Because of these issues, this method is rarely used.Metering by using Volume

Getting constant volume is, technically, relatively simple and metering systems relying on constant volume dispensing therefore are especially simple and reliable.

A very good way is the use of piston metering heads. The ratio of resin to hardener can be determined exactly by the ratio of the width of two separate pistons, one for resin, one for hardener, where both pistons are pushed simultaneously. The amount is determined by a common stopper, limiting the stroke of both pistons equally.

State of the art (2009) are metering volumes from 0,01 mL to about 250 mL, may be even more.

Getting constant volume is, technically, relatively simple and metering systems relying on constant volume dispensing therefore are especially simple and reliable.

A very good way is the use of piston metering heads. The ratio of resin to hardener can be determined exactly by the ratio of the width of two separate pistons, one for resin, one for hardener, where both pistons are pushed simultaneously. The amount is determined by a common stopper, limiting the stroke of both pistons equally.

State of the art (2009) are metering volumes from 0,01 mL to about 250 mL, may be even more.

Metering by using time

This method demands that the appropriate pumps provide precisely constant flow of the material. Flow of material is started by a controlled valve and stopped after a certain time. This method is especially susceptible to metering flaws, because the slightest change in flow speed causes different amounts of dispensed resin and/or hardener. Providing for an absolutely constant flow calls for relatively high electronic complexity, but provides much greater flexibility in adjusting the proportions of hardener to resin.Mixing

In two component resins, thorough mixing is crucial to obtain equal reaction between resin and hardener throughout all the material. There are three possible ways to mix: *static mixing tube *dynamic blender *dynamic static mixing tubeStatic mixing tube

The components meet in a mixing tube made of plastic. The tube contains immobile walls to divide and bring together the material several times, mixing resin and hardener by this process. The mixing tube is not cleaned after use, but discarded. :advantages: nomoving parts

Machines include both fixed and moving parts. The moving parts have controlled and constrained motions.

Moving parts are machine components excluding any moving fluids, such as fuel, coolant or hydraulic fluid. Moving parts also do not include ...

, no post-process cleaning, no residue of cleaning liquid

:disadvantages: mixing tubes as litter, intensity of mixing can hardly be varied

Dynamic mixing

The components meet in a mixing chamber, usually made of stainless steel and there they are mixed homogeneously by a rotating blender. To optimize mixing, the rotational speed can be controlled electronically. Mixing chamber and blender have to be cleaned with a special cleaning fluid to be used again. Usually this happens automatically. :advantage: the mixing intensity can be controlled exactly. :disadvantages: more due to failure because of moving parts, cleaning required, possibly residue of cleaning fluid, used cleaning fluid is waste or even hazardous waste, expensive replacement or cleaning of the chamber in case of encrustation because of hardened resin within the mixing chamber.Static-dynamic mixing

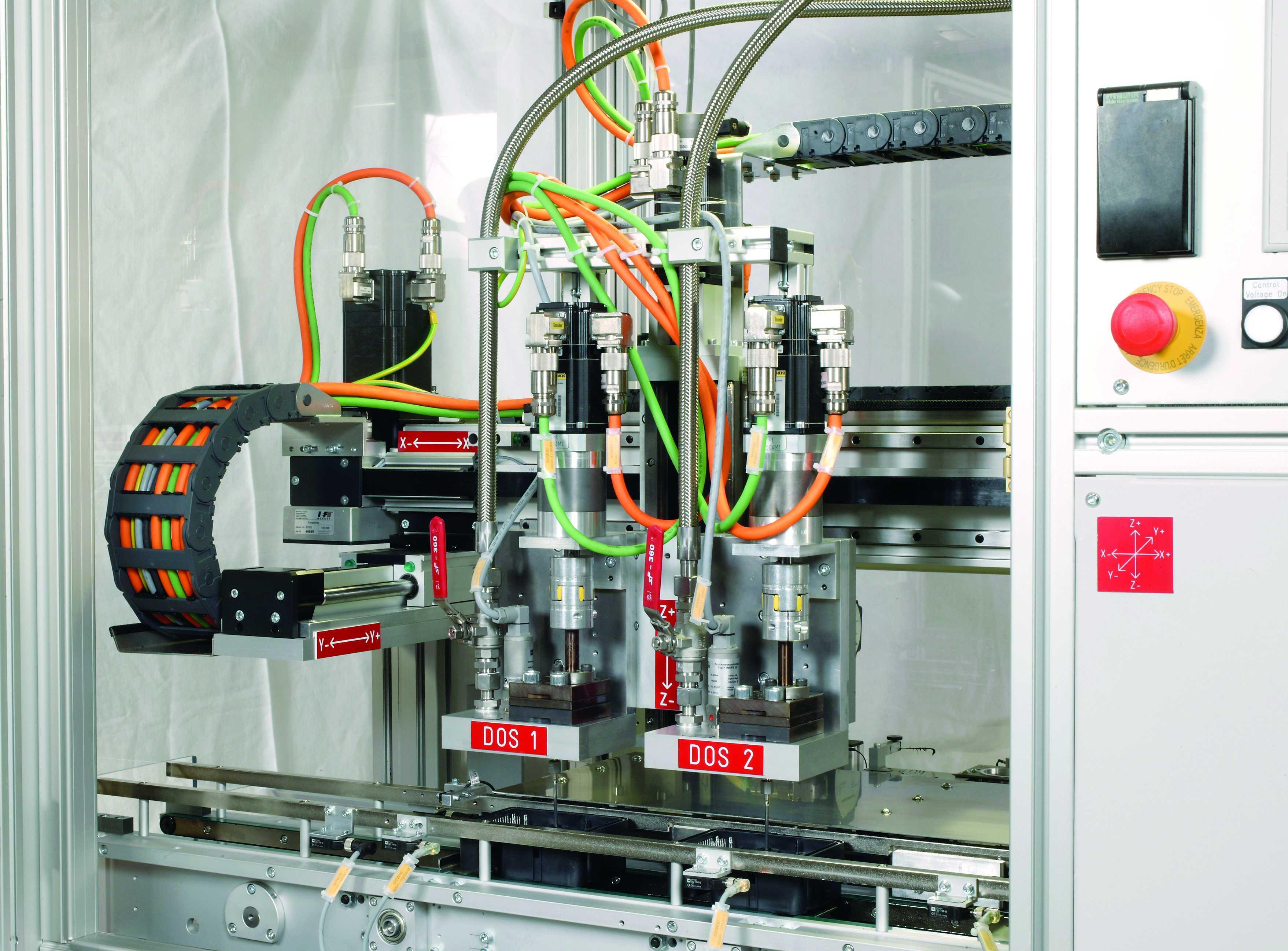

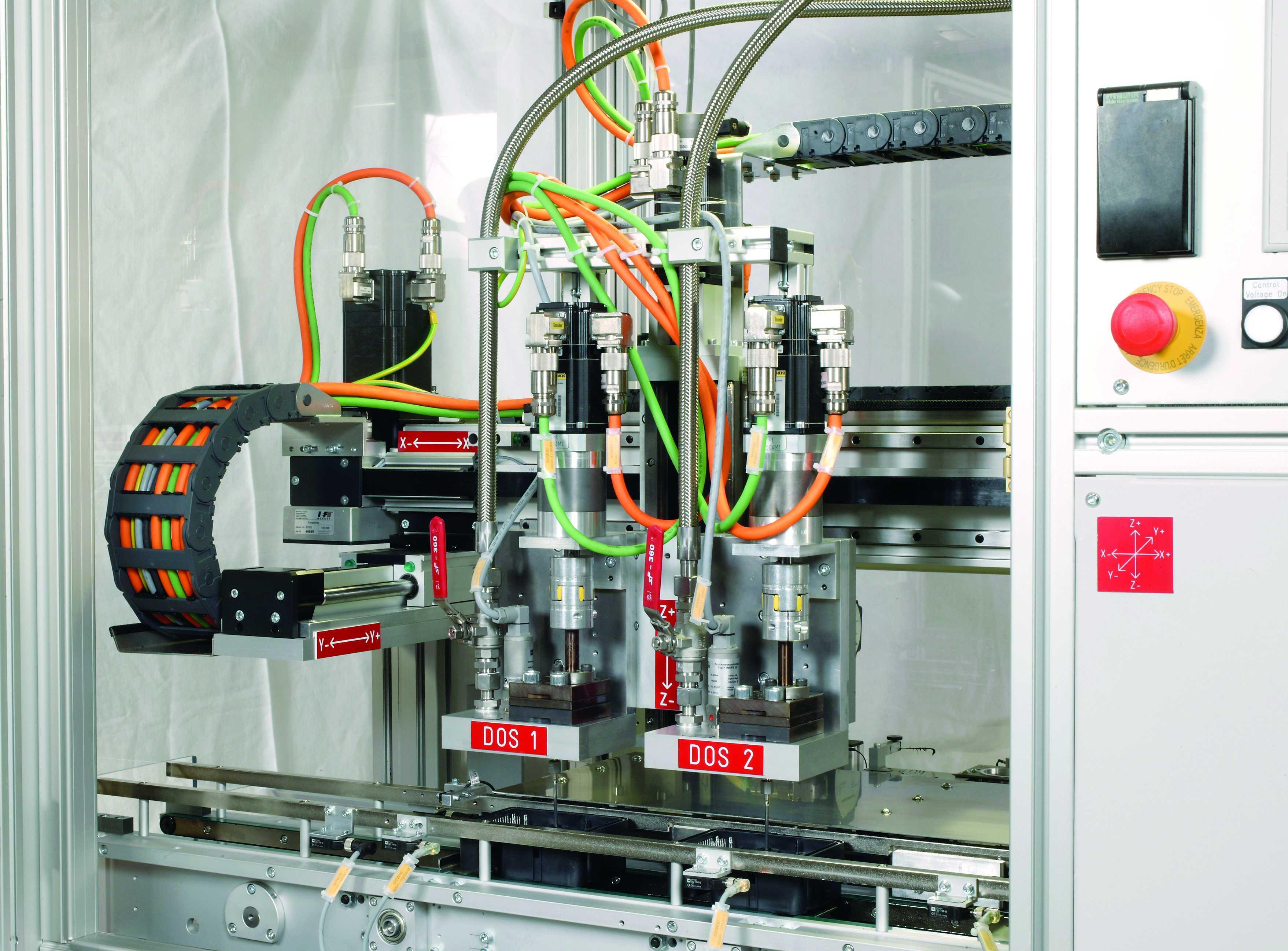

A mixing tube made from plastic contains a helix driven by an external motor. This method is rarely used.Dispensing

To provide for best casting, the part and the dispensing unit have to be moved relatively to each other. In principle there are two ways: *Movement of the dispensing unit *Movement of the part For many applications, dispensing can only be done successfully in vacuum. This is true especially for parts with a largeundercut

Undercut may refer to:

* Price slashing, a pricing technique designed to eliminate competition

*Undercut procedure, a procedure for fair allocation of indivisible objects.

*Undercut (boxing), a type of boxing punch

* ''Undercut'' (film), a stunt p ...

, i.e. soaking of transformation coils. In such cases bubble free dispensing can only be obtained in vacuum. For this purpose dispensing systems are equipped with vacuum chambers. To shorten cycle times there can be an airlock at the entrance and one at the exit. In vacuum dispensing only systems where the parts are moving and the dispenser remains in place can be built reasonably.

For the production of series, dispensing systems with multifold metering heads can be used. At this time (2006) there are systems running capable to do up to thirty dispensing acts simultaneously.

Variability of dispensing

The most simple way of dispensing is, to cast a certain amount of resin into one spot of a not moving part. Such simple systems sometimes are called metering systems. Centrifugal casting tables are available. The mold is fixed on this rotary table and while the resin mix is dispensed into the mold, centrifugal force ensures a solid, clean bubble free fill. The part is also stronger due to stress hardening. In some cases, the parts are equal to pressure injection dispensing. By using adequate controls, many variations of casting are available. For instance, dams can be cast in different forms. Cast from highly viscous,

By using adequate controls, many variations of casting are available. For instance, dams can be cast in different forms. Cast from highly viscous, thixotropic

Thixotropy is a time-dependent shear thinning property. Certain gels or fluids that are thick or viscous under static conditions will flow (become thinner, less viscous) over time when shaken, agitated, shear-stressed, or otherwise stressed ( ...

material, dams can be filled with resin of low viscosity (dam & fill). The deposition speed of the resin can be varied during casting or casting can be done in several portions. At the same time the part can execute complex movements. Using additional options of that kind make it possible to solve difficult casting problems.

Implementation of Dispensing into a Production Line

A casting system can be combined with many different production steps within a production line. So casting becomes an integrated part of the whole manufacturing of a part. To account for the delicate requirements of dispensing in all production steps in the best way, the most significant manufacturers are active in automation as well. The newest development in this area is the design of a production line from prefabricated, ideally adapted modules. This speeds up the development of individual solutions and decreases their costs.Examples for Application of Dispensing

More and more parts are sealed by casting, because this accelerates the production and increases the lifetime and functionality of the parts. On the other side, sealed parts cannot be repaired.Sealing of electronic parts

Electronic units, plugged into a board, usually are sealed by resin to protect them from environmental influences and from mechanical damage. In those cases dispensing usually means just to fill up a form, a relatively simple process.Production of LEDs

Light-emitting diode

A light-emitting diode (LED) is a semiconductor device that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons. The color of the light ( ...

s are produced in fully automated lines. Part of it is the dispensing in transparent plastics. Here short working cycles are of great significance to lower the price of the little lights. This an example for the use of multiple metering heads.

Soaking of electrical windings

Inelectric motor

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate forc ...

s and in transformers, multiple layers of windings of fine copper wire are essential. Today they usually are soaked in resin to protect them from environmental influences and to improve insulation from each other. Because of the fine structure of the space between the windings and because of much undercut, soaking of such windings puts highest demands to the used dispensing device.

See also

*Microdispensing

Microdispensing is the technique of producing liquid media dosages in volumes of less than one microlitre. The continuing miniaturization in almost all technical areas creates constant challenges for industry, development and research facilities. ...

* Resin casting

Resin casting is a method of plastic casting where a mold is filled with a liquid synthetic resin, which then hardens. It is primarily used for small-scale production like industrial prototypes and dentistry. It can be done by amateur hobbyists wit ...

Industrial processes