Pulse Tube Refrigerator on:

[Wikipedia]

[Google]

[Amazon]

The pulse tube refrigerator (PTR) or pulse tube cryocooler is a developing technology that emerged largely in the early 1980s with a series of other innovations in the broader field of

Figure 1 represents the Stirling-type single-orifice pulse-tube refrigerator (PTR), which is filled with a gas, typically

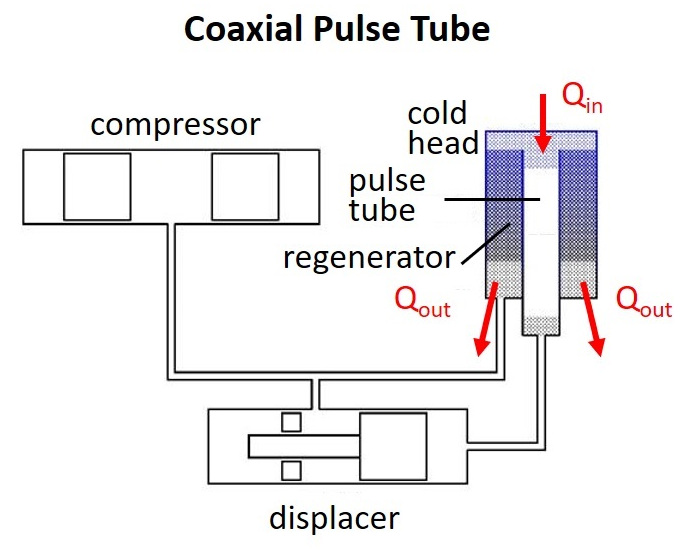

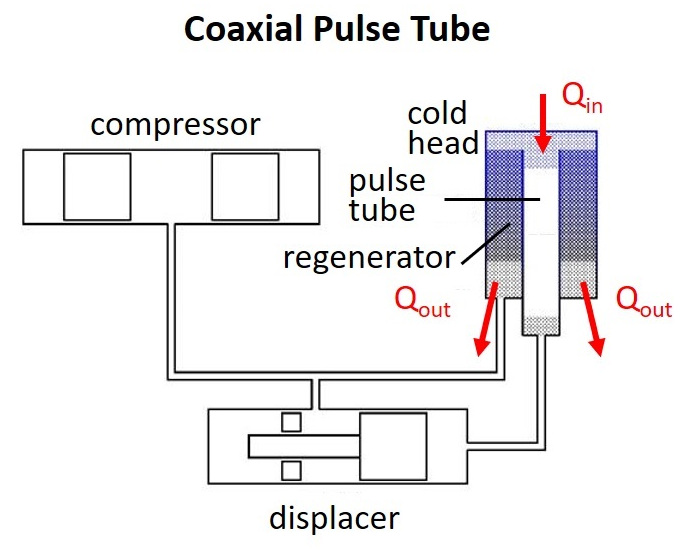

Figure 1 represents the Stirling-type single-orifice pulse-tube refrigerator (PTR), which is filled with a gas, typically  Figure 3 shows a coaxial pulse tube, which is a more useful configuration in which the regenerator surrounds the central pulse tube. This is compact and places the cold head at an end, so it is easy to integrate with whatever is to be cooled. The displacer can be passively driven, and this recovers work that would otherwise be dissipated in the orifice.

Figure 3 shows a coaxial pulse tube, which is a more useful configuration in which the regenerator surrounds the central pulse tube. This is compact and places the cold head at an end, so it is easy to integrate with whatever is to be cooled. The displacer can be passively driven, and this recovers work that would otherwise be dissipated in the orifice.

A Short History of Pulse Tube Refrigerators (NASA)SHI Cryogenics Group HomeCryomech HomePulse-tube animation (Thales Cryogenics)

{{Thermodynamic cycles, state=uncollapsed Cooling technology Cryogenics Thermodynamic cycles

thermoacoustics

Thermoacoustics is the interaction between temperature, density and pressure variations of Acoustic wave, acoustic waves. Thermoacoustic heat engines can readily be driven using solar energy or waste heat and they can be controlled using proportion ...

. In contrast with other cryocoolers (e.g. Stirling cryocooler

A Stirling engine is a heat engine that is operated by the cyclic expansion and contraction of air or other gas (the ''working fluid'') by exposing it to different temperatures, resulting in a net conversion of heat energy to mechanical work.

...

and GM-refrigerators), this cryocooler can be made without moving parts

Machines include both fixed and moving parts. The moving parts have controlled and constrained motions.

Moving parts are machine components excluding any moving fluids, such as fuel, coolant or hydraulic fluid. Moving parts also do not include ...

in the low temperature part of the device, making the cooler suitable for a wide variety of applications.

Uses

Pulse tube cryocoolers are used in niche industrial applications such assemiconductor

A semiconductor is a material with electrical conductivity between that of a conductor and an insulator. Its conductivity can be modified by adding impurities (" doping") to its crystal structure. When two regions with different doping level ...

fabrication and superconducting

Superconductivity is a set of physical properties observed in superconductors: materials where electrical resistance vanishes and magnetic fields are expelled from the material. Unlike an ordinary metallic conductor, whose resistance decreases g ...

radio-frequency

Radio frequency (RF) is the oscillation rate of an alternating electric current or voltage or of a magnetic, electric or electromagnetic field or mechanical system in the frequency range from around to around . This is roughly between the ...

circuits. They are also used in military

A military, also known collectively as armed forces, is a heavily armed, highly organized force primarily intended for warfare. Militaries are typically authorized and maintained by a sovereign state, with their members identifiable by a d ...

applications such as for the cooling of infrared sensors

Infrared thermography (IRT), thermal video or thermal imaging, is a process where a thermal camera captures and creates an image of an object by using infrared radiation emitted from the object in a process, which are examples of infrared im ...

.

In research, PTRs are often used as precoolers of dilution refrigerator

A 3He/4He dilution refrigerator is a cryogenics, cryogenic device that provides continuous cooling to temperatures as low as 2 Kelvin, mK, with no moving parts in the low-temperature region. The cooling power is provided by the heat o ...

s. They are also being developed for cooling of astronomical

Astronomy is a natural science that studies celestial objects and the phenomena that occur in the cosmos. It uses mathematics, physics, and chemistry in order to explain their origin and their overall evolution. Objects of interest include ...

detectors

A sensor is often defined as a device that receives and responds to a signal or stimulus. The stimulus is the quantity, property, or condition that is sensed and converted into electrical signal.

In the broadest definition, a sensor is a devi ...

where liquid cryogens are typically used, such as the Atacama Cosmology Telescope

The Atacama Cosmology Telescope (ACT) was a cosmological millimeter-wave telescope located on Cerro Toco in the Atacama Desert in the north of Chile. ACT made high-sensitivity, arcminute resolution, microwave-wavelength surveys of the sky in or ...

or the Qubic experiment (an interferometer for cosmology studies). Pulse tubes are particularly useful in space-based telescopes such as the James Webb Space Telescope

The James Webb Space Telescope (JWST) is a space telescope designed to conduct infrared astronomy. As the largest telescope in space, it is equipped with high-resolution and high-sensitivity instruments, allowing it to view objects too old, Lis ...

where it is not possible to replenish the cryogens as they are depleted. It has also been suggested that pulse tubes could be used to liquefy oxygen

Oxygen is a chemical element; it has chemical symbol, symbol O and atomic number 8. It is a member of the chalcogen group (periodic table), group in the periodic table, a highly reactivity (chemistry), reactive nonmetal (chemistry), non ...

on Mars

Mars is the fourth planet from the Sun. It is also known as the "Red Planet", because of its orange-red appearance. Mars is a desert-like rocky planet with a tenuous carbon dioxide () atmosphere. At the average surface level the atmosph ...

.

Principle of operation

Figure 1 represents the Stirling-type single-orifice pulse-tube refrigerator (PTR), which is filled with a gas, typically

Figure 1 represents the Stirling-type single-orifice pulse-tube refrigerator (PTR), which is filled with a gas, typically helium

Helium (from ) is a chemical element; it has chemical symbol, symbol He and atomic number 2. It is a colorless, odorless, non-toxic, inert gas, inert, monatomic gas and the first in the noble gas group in the periodic table. Its boiling point is ...

at a pressure varying from 10 to 30 bar. From left to right the components are:

* a compressor, with a piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder (engine), cylinder a ...

moving back and forth at room temperature ''T''H

* a heat exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contac ...

X1 where heat is released to the surroundings at room temperature

* a regenerator consisting of a porous

Porosity or void fraction is a measure of the void (i.e. "empty") spaces in a material, and is a fraction of the volume of voids over the total volume, between 0 and 1, or as a percentage between 0% and 100%. Strictly speaking, some tests measure ...

medium with a large specific heat (which can be stainless steel wire mesh, copper wire mesh, phosphor bronze wire mesh, lead balls, lead shot, or rare earth materials) in which the gas flows back and forth

* a heat exchanger X2, cooled by the gas, where the useful cooling power is delivered at the low temperature ''T''L, taken from the object to be cooled

* a tube in which the gas is pushed and pulled

* a heat exchanger X3 near room temperature where heat is released to the surroundings

* a flow resistance (often called orifice)

* a buffer volume (a large closed volume at practically constant pressure)

The part in between X1 and X3 is thermally insulated from the surroundings, usually by vacuum. The pressure varies gradually and the velocities of the gas are low. So the name "pulse" tube cooler is misleading, since there are no pulses in the system.

The piston moves periodically from left to right and back. As a result, the gas also moves from left to right and back while the pressure within the system increases and decreases. If the gas from the compressor space moves to the right, it enters the regenerator with temperature ''T''H and leaves the regenerator at the cold end with temperature ''T''L, hence heat is transferred into the regenerator material. On its return, the heat stored within the regenerator is transferred back into the gas.

In the tube, the gas is thermally isolated (adiabatic), so the temperature of the gas in the tube varies with the pressure.

At the cold end of the tube, the gas enters the tube via X2 when the pressure is high with temperature ''T''L and returns when the pressure is low with a temperature below ''T''L, hence taking up heat from X2: this gives the desired cooling effect at X2.

To understand why the low-pressure gas returns at a lower temperature, look at figure 1 and consider gas molecules close to X3 (at the hot end), which move in and out of the tube through the orifice. Molecules flow into the tube (to the left) when the pressure in the tube is low (it is sucked into the tube via X3, coming from the orifice and the buffer). Upon entering the tube, it has the temperature ''T''H. Later in the cycle, the same mass of gas is pushed out from the tube again when the pressure inside the tube is high. As a consequence, its temperature will be higher than ''T''H. In the heat exchanger X3, it releases heat and cools down to the ambient temperature ''T''H.

Figure 3 shows a coaxial pulse tube, which is a more useful configuration in which the regenerator surrounds the central pulse tube. This is compact and places the cold head at an end, so it is easy to integrate with whatever is to be cooled. The displacer can be passively driven, and this recovers work that would otherwise be dissipated in the orifice.

Figure 3 shows a coaxial pulse tube, which is a more useful configuration in which the regenerator surrounds the central pulse tube. This is compact and places the cold head at an end, so it is easy to integrate with whatever is to be cooled. The displacer can be passively driven, and this recovers work that would otherwise be dissipated in the orifice.

Performance

The performance of the cooler is determined mainly by the quality of the regenerator. It has to satisfy conflicting requirements: it must have a low flow resistance (so it must be short with wide channels), but the heat exchange should also be good (so it must be long with narrow channels). The material must have a large heat capacity. At temperatures above 50K practically all materials are suitable. Bronze or stainless steel is often used. For temperatures between 10 and 50K lead is most suitable. Below 10K one uses magnetic materials which are specially developed for this application. The so-calledcoefficient of performance

The coefficient of performance or COP (sometimes CP or CoP) of a heat pump, refrigerator or air conditioning system is a ratio of useful heating or cooling provided to work (energy) required. Higher COPs equate to higher efficiency, lower energy ( ...

(COP; denoted ) of coolers is defined as the ratio between the cooling power and the compressor power ''P''. In formula: . For a perfectly reversible cooler, is given by Carnot's theorem:

However, a pulse-tube refrigerator is not perfectly reversible due to the presence of the orifice, which has flow resistance. Instead, the COP of an ideal PTR is given by

which is lower than that of ideal coolers.

Comparison with other coolers

In most coolers gas is compressed and expanded periodically. Well-known coolers such as theStirling engine

A Stirling engine is a heat engine that is operated by the cyclic expansion and contraction of air or other gas (the ''working fluid'') by exposing it to different temperatures, resulting in a net conversion of heat energy to mechanical Work (ph ...

coolers and the popular Gifford-McMahon coolers have a displacer that ensures that the cooling (due to expansion) takes place in a different region of the machine than the heating (due to compression). Due to its clever design, the PTR does not have such a displacer, making the construction of a PTR simpler, cheaper, and more reliable. Furthermore, there are no mechanical vibrations and no electro-magnetic interferences. The basic operation of cryocoolers and related thermal machines is described by De Waele

History

W. E. Gifford and R. C. Longsworth, in the 1960s, invented the so-called Basic Pulse Tube Refrigerator. The modern PTR was invented in 1984 by Mikulin who introduced an orifice to the basic pulse tube. He reached a temperature of 105K. Soon after that, PTRs became better due to the invention of new variations. This is shown in figure 4, where the lowest temperature for PTRs is plotted as a function of time. At the moment, the lowest temperature is below the boiling point of helium (4.2K). Originally this was considered to be impossible. For some time it looked as if it would be impossible to cool below the lambda point of 4He (2.17K), but the ''low-temperature group'' of the Eindhoven University of Technology managed to cool to a temperature of 1.73K by replacing the usual 4He as refrigerant by its rare isotope 3He. Later this record was broken by the Giessen Group that managed to get even below 1.3K. In a collaboration between the groups from Giessen and Eindhoven a temperature of 1.2K was reached by combining a PTR with a superfluid vortex cooler.Types

For cooling, the source of the pressure variations is unimportant. PTRs for temperatures below 20K usually operate at frequencies of 1 to 2 Hz and with pressure variations from 10 to 25 bar. The swept volume of the compressor would be very high (up to one liter and more). Therefore, the compressor is uncoupled from the cooler. A system of valves (usually a rotating valve) alternately connects the high-pressure and the low-pressure side of the compressor to the hot end of the regenerator. As the high-temperature part of this type of PTR is the same as of GM-coolers, this type of PTR is called a GM-type PTR. The gas flows through the valves are accompanied by losses which are absent in the Stirling-type PTR. PTRs can be classified according to their shape. If the regenerator and the tube are in line (as in fig. 1) we talk about a linear PTR. The disadvantage of the linear PTR is that the cold spot is in the middle of the cooler. For many applications it is preferable that the cooling is produced at the end of the cooler. By bending the PTR we get a U-shaped cooler. Both hot ends can be mounted on the flange of the vacuum chamber at room temperature. This is the most common shape of PTRs. For some applications it is preferable to have a cylindrical geometry. In that case the PTR can be constructed in a coaxial way so that the regenerator becomes a ring-shaped space surrounding the tube. The lowest temperature reached with single-stage PTRs is just above 10K. However, one PTR can be used to precool the other. The hot end of the second tube is connected to room temperature and not to the cold end of the first stage. In this clever way it is avoided that the heat, released at the hot end of the second tube, is a load on the first stage. In applications the first stage also operates as a temperature-anchoring platform for e.g. shield cooling of superconducting-magnet cryostats. Matsubara and Gao were the first to cool below 4K with a three-stage PTR. With two-stage PTRs temperatures of 2.1K, so just above the λ-point of helium, have been obtained. With a three-stage PTR 1.73K has been reached using 3He as the working fluid.Prospects

The coefficient of performance of PTRs at room temperature is low, so it is not likely that they will play a role in domestic cooling. However, below about 80K the coefficient of performance is comparable with other coolers (compare equations () and ()) and in the low-temperature region the advantages get the upper hand. PTRs are commercially available for temperatures in the region of 70K and 4K. They are applied in infrared detection systems, for reduction of thermal noise in devices based on (high-''T''c) superconductivity such asSQUID

A squid (: squid) is a mollusc with an elongated soft body, large eyes, eight cephalopod limb, arms, and two tentacles in the orders Myopsida, Oegopsida, and Bathyteuthida (though many other molluscs within the broader Neocoleoidea are also ...

s, and filters for telecommunication. PTRs are also suitable for cooling MRI-systems and energy-related systems using superconducting magnets. In so-called dry magnets, coolers are used so that no cryoliquid is needed at all or for the recondensation of the evaporated helium. Also the combination of cryocoolers with 3He-4He dilution refrigerator

A 3He/4He dilution refrigerator is a cryogenics, cryogenic device that provides continuous cooling to temperatures as low as 2 Kelvin, mK, with no moving parts in the low-temperature region. The cooling power is provided by the heat o ...

s for the temperature region down to 2mK is attractive since in this way the whole temperature range from room temperature to 2mK is easier to access.

For many low temperature experiments, mechanical vibrations caused by PTRs can cause microphonics

Microphonics, microphony, or microphonism describes the phenomenon wherein certain components in electronic devices transform mechanical vibrations into an undesired electrical signal (noise). The term comes from analogy with a microphone, wh ...

on measurement lines, which is a big disadvantage of PTRs. Particularly for scanning probe microscopy uses, PTR-based scanning tunneling microscopes (STMs) have historically difficult due to the extreme vibration sensitivity of STM. Use of an exchange gas above the vibration sensitive scanning head enabled the first PTR based low temperature STMs. Now, there are commercially available PTR-based, cryogen free scanning probe systems.

See also

*Cryocooler

A cryocooler is a refrigerator designed to reach cryogenic temperatures (below 120 K, -153 °C, -243.4 °F). The term is most often used for smaller systems, typically table-top size, with input powers less than about 20 kW. Some can have inpu ...

* Regenerative cooling

Regenerative cooling is a method of cooling gases in which compressed gas is cooled by allowing it to expand and thereby take heat from the surroundings. The cooled expanded gas then passes through a heat exchanger where it cools the incoming com ...

* Timeline of low-temperature technology

The following is a timeline of low-temperature technology and cryogenic technology (refrigeration down to close to absolute zero, i.e. –273.15 °C, −459.67 °F or 0 K). It also lists important milestones in thermometry, thermodynamics ...

References

External links

A Short History of Pulse Tube Refrigerators (NASA)

{{Thermodynamic cycles, state=uncollapsed Cooling technology Cryogenics Thermodynamic cycles