Plunger (hydraulics) on:

[Wikipedia]

[Google]

[Amazon]

A plunger is a

A plunger is a

A plunger is a

A plunger is a cylindrical

A cylinder () has traditionally been a Solid geometry, three-dimensional solid, one of the most basic of curvilinear geometric shapes. In elementary geometry, it is considered a Prism (geometry), prism with a circle as its base.

A cylinder may ...

rod used to transmit hydraulic

Hydraulics () is a technology and applied science using engineering, chemistry, and other sciences involving the mechanical properties and use of liquids. At a very basic level, hydraulics is the liquid counterpart of pneumatics, which concer ...

compression force. It is characterized by its length being much greater than its diameter

In geometry, a diameter of a circle is any straight line segment that passes through the centre of the circle and whose endpoints lie on the circle. It can also be defined as the longest Chord (geometry), chord of the circle. Both definitions a ...

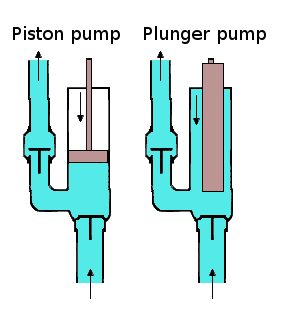

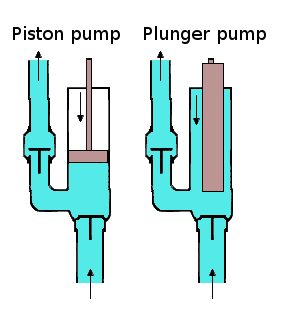

, and it is thus distinguished from a regular piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder (engine), cylinder a ...

(where the working surface is larger than the thickness of the rod, i.e. more like a disk).

They are mainly used as part of certain types of pumps and hydraulic machines. Plungers are used for fluid-mechanical power transmission in pumps ( plunger pumps), hydraulic gearboxes, high-pressure diesel injection pumps, hydraulic workshop presses and jacks, and other equipment, and are distinguished in fluid mechanics by being a piston without moving seals. The seals are instead located in the wall through which the plunger slides (as opposed to piston rings on a piston).

Plungers are often supplied with a suitable stationary plunger bushing that fits tightly against the plunger (together they are called a plunger pair), and together these form a seal that can withstand high pressures. Compared to a piston that has to act against a cylinder wall, it is easier to manufacture a plunger to close tolerances against a plunger bushing (since the plunger has a cylindrical shape). Some define a plunger as a type of piston that is also its own piston rod. Plunger pumps are often used to pump slurries

A slurry is a mixture of denser solids suspended in liquid, usually water. The most common use of slurry is as a means of transporting solids or separating minerals, the liquid being a carrier that is pumped on a device such as a centrifugal p ...

such as sludge

Sludge (possibly , or some dialect related to slush) is a semi-solid slurry that can be produced from a range of industrial processes, from water treatment, wastewater treatment or on-site sanitation systems. It can be produced as a settled sus ...

or liquid cement

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel ( aggregate) together. Cement mi ...

.

An advantage compared to classic pistons is the simplicity of manufacture (since the plunger is a simple rod) and the relatively easy use of a plunger bushing for sealing. Another advantage is resistance to dirt. Thanks to the simple shape, dirt has no place to stick, unlike a classic piston.

Unlike a piston (where the seal is on the piston rings), the seal of a plunger is located in the cylinder wall, and when the plunger performs a reciprocating motion, the plunger surface thus moves along the seal. Plungers are mainly used in hydraulic axial piston pumps, radial piston pumps and piston pumps. They have also become widespread in fuel supply systems for diesel engines

The diesel engine, named after the German engineer Rudolf Diesel, is an internal combustion engine in which ignition of diesel fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the die ...

( injection pumps) in pairs of plungers.

Plunger pump

Plunger pumps are capable of operating at higher pressures than piston pumps. The reason for this is that plungers require high precision on its outer cylindrical surface, while piston pumps require more precise machining of the inner surface of the cylinder, which is technically more difficult to achieve. The volume of the displaced medium depends directly on the stroke length of the plunger. By changing the pump stroke length, the flow rate will be adjusted. The precision achieved on modern plunger and rotary hydraulic plunger machines is so high that the distance between the inner and outer cylindrical surfaces of plunger pairs reaches 2-3micrometres

The micrometre (English in the Commonwealth of Nations, Commonwealth English as used by the International Bureau of Weights and Measures; SI symbol: μm) or micrometer (American English), also commonly known by the non-SI term micron, is a uni ...

(0.002-0.003 mm).

The pressure that plunger pairs can withstand is very high. During fuel injection in diesel engines, the pressure in the plunger pair can reach 200 megapascals (MPa).

Plunger lift

{{main, Plunger lift The term "plunger" is also used in pipelines. Here, the plunger is a movable control element in a control valve whose movement changes thevolume flow

Volume is a measure of regions in three-dimensional space. It is often quantified numerically using SI derived units (such as the cubic metre and litre) or by various imperial or US customary units (such as the gallon, quart, cubic inch). The ...

.ГОСТ Р 52720-2007. Арматура трубопроводная. Термины и определения.

References