plasma torch on:

[Wikipedia]

[Google]

[Amazon]

A plasma torch (also known as a plasma arc, plasma gun, plasma cutter, or plasmatron) is a device for generating a directed flow of plasma.

The plasma jet can be used for applications including

A plasma torch (also known as a plasma arc, plasma gun, plasma cutter, or plasmatron) is a device for generating a directed flow of plasma.

The plasma jet can be used for applications including

In a DC torch, the

In a DC torch, the

File:TorchCuttingCloseup.jpg, Close up of a Hypertherm HyPerformance plasma torch cutting metal

File:STEP-NC plasma cutting.jpg, Prototype STEP-NC system driving plasma torch with ESAB CNC to cut and bevel half-inch steel plate. Laser marking of the front and back of the plate was also done in earlier operations.

File:ICP-SFMS Torch 1.JPG, Sector field ICP-MS torch

File:ICP-SFMS Torch 2.JPG, Sector field ICP-MS torch

A plasma torch (also known as a plasma arc, plasma gun, plasma cutter, or plasmatron) is a device for generating a directed flow of plasma.

The plasma jet can be used for applications including

A plasma torch (also known as a plasma arc, plasma gun, plasma cutter, or plasmatron) is a device for generating a directed flow of plasma.

The plasma jet can be used for applications including plasma cutting

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, although other ...

, plasma arc welding, plasma spraying, and plasma gasification for waste disposal.

Types

Thermal plasmas are generated in plasma torches bydirect current

Direct current (DC) is one-directional electric current, flow of electric charge. An electrochemical cell is a prime example of DC power. Direct current may flow through a conductor (material), conductor such as a wire, but can also flow throug ...

(DC), alternating current

Alternating current (AC) is an electric current that periodically reverses direction and changes its magnitude continuously with time, in contrast to direct current (DC), which flows only in one direction. Alternating current is the form in w ...

(AC), radio-frequency

Radio frequency (RF) is the oscillation rate of an alternating electric current or voltage or of a magnetic, electric or electromagnetic field or mechanical system in the frequency range from around to around . This is roughly between the ...

(RF) and other discharges. DC torches are the most commonly used and researched, because when compared to AC: "there is less flicker generation and noise, a more stable operation, better control, a minimum of two electrodes, lower electrode consumption, slightly lower refractory eatwear and lower power consumption".

Transferred vs. non-transferred

There are two types of DC torches: non-transferred and transferred. In non-transferred DC torches, the electrodes are inside the body/housing of the torch itself (creating the arc there). Whereas in a transferred torch one electrode is outside (and is usually the conductive material to be treated), allowing the arc to form outside of the torch over a larger distance. A benefit of transferred DC torches is that the plasma arc is formed outside the water-cooled body, preventing heat loss—as is the case with non-transferred torches, where their electrical-to-thermal efficiency

In thermodynamics, the thermal efficiency (\eta_) is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, steam turbine, steam engine, boiler, furnace, refrigerator, ACs etc.

For ...

can be as low as 50%, but the hot water can itself be utilized. Furthermore, transferred DC torches can be used in a twin-torch setup, where one torch is cathodic and the other anodic, which has the earlier benefit of a regular transferred single-torch system, but allows their use with non-conductive materials, as there is no need for it to form the other electrode. However, these types of setups are rare as most common non-conductive materials do not require the precise cutting ability of a plasma torch. In addition, the discharge generated by this particular plasma source configuration is characterized by a complex shape and fluid dynamics that requires a 3D description in order to be predicted, making performance unsteady. The electrodes of non-transferred torches are larger, because they suffer more wear by the plasma arc.

The quality of plasma produced is a function of density (pressure), temperature and torch power (the greater the better). With regards to the efficiency of the torch itself—this can vary among manufacturers and torch technology; though for example, Leal-Quirós reports that for Westinghouse Plasma Corp. torches “a thermal efficiency of 90% is easily possible; the efficiency represents the percentage of arc power that exits the torch and enters the process”.

Thermal plasma DC torches, non-transferred arc, hot cathode

In a DC torch, the

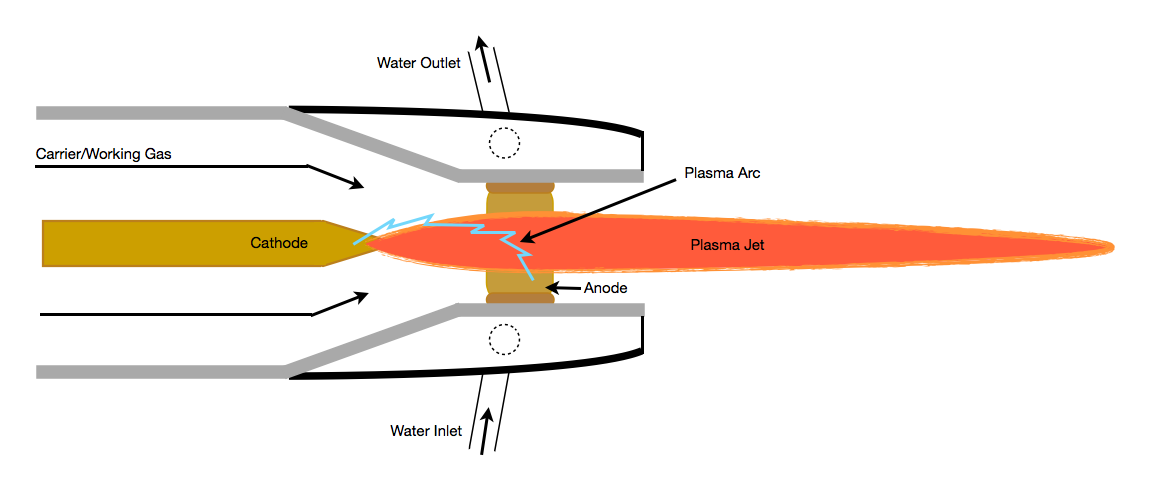

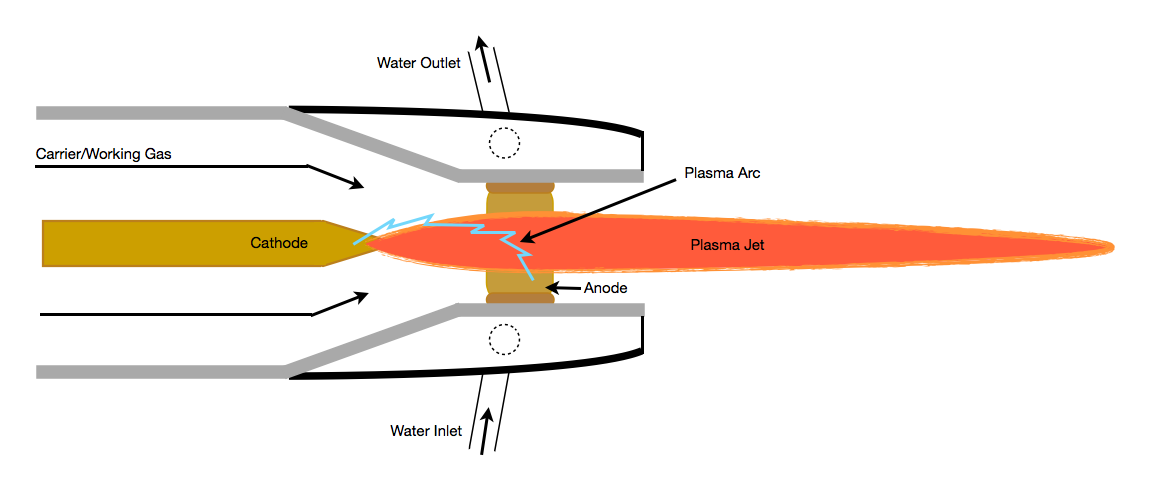

In a DC torch, the electric arc

An electric arc (or arc discharge) is an electrical breakdown of a gas that produces a prolonged electrical discharge. The electric current, current through a normally Electrical conductance, nonconductive medium such as air produces a plasma ( ...

is formed between the electrodes (which can be made of copper, tungsten

Tungsten (also called wolfram) is a chemical element; it has symbol W and atomic number 74. It is a metal found naturally on Earth almost exclusively in compounds with other elements. It was identified as a distinct element in 1781 and first ...

, graphite

Graphite () is a Crystallinity, crystalline allotrope (form) of the element carbon. It consists of many stacked Layered materials, layers of graphene, typically in excess of hundreds of layers. Graphite occurs naturally and is the most stable ...

, silver etc.), and the thermal plasma is formed from the continual input of carrier/working gas, projecting outward as a plasma jet/flame (as can be seen in the adjacent image). In DC torches, the carrier gas can be, for example, either oxygen, nitrogen, argon, helium, air, or hydrogen; and although termed such, it does not have to be a gas (thus, better termed a carrier fluid).

For example, a research plasma torch at the Institute of Plasma Physics (IPP) in Prague, Czech Republic, functions with an H2O vortex (as well as a small addition of argon to ignite the arc), and produces a high temperature/velocity plasma flame. In fact, early studies of arc stabilization employed a water-vortex. Overall, the electrode materials and carrier fluids have to be specifically matched to avoid excessive electrode corrosion or oxidation (and contamination of materials to be treated), while maintaining ample power and function.

Furthermore, the flow-rate of the carrier gas can be raised to promote a larger, more projecting plasma jet, provided that the arc current is sufficiently increased; and vice versa.

The plasma flame of a real plasma torch is a few inches long at most; it is to be distinguished from fictional long-range plasma weapons.

Gallery

See also

* Plasma sourceReferences

{{Reflist Plasma technology and applications Sustainable technologies