Metallic Fiber on:

[Wikipedia]

[Google]

[Amazon]

Metallic fibers are manufactured

Metallic fibers are manufactured

Metal fibers exists in different forms and diameters. Generally, the sector offers metal fiber diameters from 100 μm down to 1 μm.

Metallic fibers exists in both long, continuous fibers as well as short fibers (with a length to diameter ratio of less than 100).

Compared to other fiber types, like

Metal fibers exists in different forms and diameters. Generally, the sector offers metal fiber diameters from 100 μm down to 1 μm.

Metallic fibers exists in both long, continuous fibers as well as short fibers (with a length to diameter ratio of less than 100).

Compared to other fiber types, like

A specially designed process allows the production of individual powder-like metal fibers known as short fibers with a length over diameter (L/D) range of 100. These short fibers can be used as such or in combination with metal powders to produce sintered filtration structures with ultra-high levels of filtration and high permeability.

A specially designed process allows the production of individual powder-like metal fibers known as short fibers with a length over diameter (L/D) range of 100. These short fibers can be used as such or in combination with metal powders to produce sintered filtration structures with ultra-high levels of filtration and high permeability.

To make cables, two or more filaments are twisted together a number of times. During the process, a cable's torsion and straightness are monitored. The cable can be fine-tuned for a certain application by combining different filament strengths, diameters or the number of twists, or by preforming.

To make cables, two or more filaments are twisted together a number of times. During the process, a cable's torsion and straightness are monitored. The cable can be fine-tuned for a certain application by combining different filament strengths, diameters or the number of twists, or by preforming.

Metal fiber can be used as reinforcement fiber for composite materials, improving breaking behavior upon impact and electrical conductivity. Traditional carbon or glass fiber reinforcement fibers have very limited elongation possibilities, which results in a brittle and explosive breaking behavior, whereas metal fibers can absorb much more energy before breaking. Processing is no different from any other reinforcement fiber for composite material. It is also possible to combine metal fibers with other fibers into a hybrid composite structure, which combines properties of its components (carbon, glass, or steel).

Metal fiber can be used as reinforcement fiber for composite materials, improving breaking behavior upon impact and electrical conductivity. Traditional carbon or glass fiber reinforcement fibers have very limited elongation possibilities, which results in a brittle and explosive breaking behavior, whereas metal fibers can absorb much more energy before breaking. Processing is no different from any other reinforcement fiber for composite material. It is also possible to combine metal fibers with other fibers into a hybrid composite structure, which combines properties of its components (carbon, glass, or steel).

Bekaert manufactures metal fibers and many derived products such as continuous fiber, sintered media, nonwoven structures, polymer pellets, braids, woven fabrics, cables, yarns and short fibers. Well established brand names are Bekipor, Beki-shield and Bekinox.

The

Bekaert manufactures metal fibers and many derived products such as continuous fiber, sintered media, nonwoven structures, polymer pellets, braids, woven fabrics, cables, yarns and short fibers. Well established brand names are Bekipor, Beki-shield and Bekinox.

The

Metallic fibers are manufactured

Metallic fibers are manufactured fibers

Fiber (spelled fibre in British English; from ) is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often inco ...

composed of metal

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electrical resistivity and conductivity, electricity and thermal conductivity, heat relatively well. These properties are all associated wit ...

, metallic alloys

An alloy is a mixture of chemical elements of which in most cases at least one is a metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have properties ...

, plastic

Plastics are a wide range of synthetic polymers, synthetic or Semisynthesis, semisynthetic materials composed primarily of Polymer, polymers. Their defining characteristic, Plasticity (physics), plasticity, allows them to be Injection moulding ...

-coated metal, metal-coated plastic, or a core completely covered by metal.

Having their origin in textile and clothing applications, gold

Gold is a chemical element; it has chemical symbol Au (from Latin ) and atomic number 79. In its pure form, it is a brightness, bright, slightly orange-yellow, dense, soft, malleable, and ductile metal. Chemically, gold is a transition metal ...

and silver

Silver is a chemical element; it has Symbol (chemistry), symbol Ag () and atomic number 47. A soft, whitish-gray, lustrous transition metal, it exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. ...

fibers have been used since ancient times as yarn

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. '' Thread'' is a type of yarn intended for sewing by hand or machine. Modern ...

s for fabric decoration. More recently, aluminium

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

yarns, aluminized plastic yarns, and aluminized nylon

Nylon is a family of synthetic polymers characterised by amide linkages, typically connecting aliphatic or Polyamide#Classification, semi-aromatic groups.

Nylons are generally brownish in color and can possess a soft texture, with some varieti ...

yarns have replaced gold and silver.

Today's metal fiber industry mainly offers fibers in stainless steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES), or rustless steel, is an iron-based alloy that contains chromium, making it resistant to rust and corrosion. Stainless steel's resistance to corrosion comes from its chromi ...

, nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

, titanium

Titanium is a chemical element; it has symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in ...

, copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

and aluminium for various applications. Metallic filaments can be coated with transparent films to minimize tarnishing.

Many methods exist to manufacture metallic fibers, and each comes with its own benefits and limitations. The most common methods include shaving from a larger stock,An introduction to Metal Fiber Technology - White Paper - https://www.bekaert.com/en/product-catalog/content/Metal-fibers/replacement-of-glass-fiber-media-by-metal-fiber-media casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or ...

directly from molten metal, and growing around a seed. Multiple fibers can also be woven or intertwined to form larger strands.

History

Gold and silver have been used since ancient times as decoration in the clothing andtextiles

Textile is an Hyponymy and hypernymy, umbrella term that includes various Fiber, fiber-based materials, including fibers, yarns, Staple (textiles)#Filament fiber, filaments, Thread (yarn), threads, and different types of #Fabric, fabric. ...

of kings, leaders, nobility

Nobility is a social class found in many societies that have an aristocracy. It is normally appointed by and ranked immediately below royalty. Nobility has often been an estate of the realm with many exclusive functions and characteristics. T ...

and other high status people. Many of these elegant textiles can be found in museums around the world. Historically, the metallic thread was constructed by wrapping a metal strip around a fiber core (cotton or silk), often in such a way as to reveal the color of the fiber core to enhance visual quality of the decoration. Ancient textiles and clothing woven from wholly or partly gold threads is sometimes referred to as ''cloth of gold

Cloth of gold or gold cloth (Latin: ''Tela aurea'') is a textile, fabric woven with a gold-wrapped or spinning (textiles), spun weft—referred to as "a spirally spun gold strip". In most cases, the core yarn is silk, wrapped (''filé'') with a ...

''. They have been woven on Byzantine

The Byzantine Empire, also known as the Eastern Roman Empire, was the continuation of the Roman Empire centred on Constantinople during late antiquity and the Middle Ages. Having survived the events that caused the fall of the Western Roman E ...

looms from the 7th to the 9th century, and after that in Sicily

Sicily (Italian language, Italian and ), officially the Sicilian Region (), is an island in the central Mediterranean Sea, south of the Italian Peninsula in continental Europe and is one of the 20 regions of Italy, regions of Italy. With 4. ...

, Cyprus

Cyprus (), officially the Republic of Cyprus, is an island country in the eastern Mediterranean Sea. Situated in West Asia, its cultural identity and geopolitical orientation are overwhelmingly Southeast European. Cyprus is the List of isl ...

, Lucca

Città di Lucca ( ; ) is a city and ''comune'' in Tuscany, Central Italy, on the Serchio River, in a fertile plain near the Ligurian Sea. The city has a population of about 89,000, while its Province of Lucca, province has a population of 383,9 ...

, and Venice

Venice ( ; ; , formerly ) is a city in northeastern Italy and the capital of the Veneto Regions of Italy, region. It is built on a group of 118 islands that are separated by expanses of open water and by canals; portions of the city are li ...

. Weaving also flourished in the 12th century during the legacy of Genghis Khan

Genghis Khan (born Temüjin; August 1227), also known as Chinggis Khan, was the founder and first khan (title), khan of the Mongol Empire. After spending most of his life uniting the Mongols, Mongol tribes, he launched Mongol invasions and ...

when art and trade flourished under Mongol rule in China and some Middle Eastern areas. The Dobeckmum Company produced the first modern metallic fiber in 1946.

During the early 1960s, Brunswick Corp. conducted a research program to develop an economically viable process for forming metallic filaments. They started producing metallic filaments in a laboratory-scale pilot plant. By 1964 Brunswick was producing fine metal fibers as small as 1 μm from 304 stainless steel. Their first large scale production facility, located in the US, started in 1966. Metal fibers are now widely produced and used in all kinds of technology. With a wide range of applications, it is a mature sector.

In the past, aluminium was often the base in a metallic fiber. More recently stainless steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES), or rustless steel, is an iron-based alloy that contains chromium, making it resistant to rust and corrosion. Stainless steel's resistance to corrosion comes from its chromi ...

has become the dominant metal for metallic fibers. Depending on the alloy, the metallic fibers provide properties to the yarn which allow the use in more high tech"An Overview of Metal Fiber Applications" - White paper - J.De Baerdemaeker, J.Vleurinck - https://www.bekaert.com/en/product-catalog/content/Metal-fibers/replacement-of-glass-fiber-media-by-metal-fiber-media applications.

Fiber properties

Metal fibers exists in different forms and diameters. Generally, the sector offers metal fiber diameters from 100 μm down to 1 μm.

Metallic fibers exists in both long, continuous fibers as well as short fibers (with a length to diameter ratio of less than 100).

Compared to other fiber types, like

Metal fibers exists in different forms and diameters. Generally, the sector offers metal fiber diameters from 100 μm down to 1 μm.

Metallic fibers exists in both long, continuous fibers as well as short fibers (with a length to diameter ratio of less than 100).

Compared to other fiber types, like carbon

Carbon () is a chemical element; it has chemical symbol, symbol C and atomic number 6. It is nonmetallic and tetravalence, tetravalent—meaning that its atoms are able to form up to four covalent bonds due to its valence shell exhibiting 4 ...

, glass

Glass is an amorphous (non-crystalline solid, non-crystalline) solid. Because it is often transparency and translucency, transparent and chemically inert, glass has found widespread practical, technological, and decorative use in window pane ...

, aramid

Aramid fibers, short for aromatic polyamide, are a class of heat-resistant and strong synthetic fibers. They are used in aerospace and military applications, for ballistic-rated bulletproof vest, body armor cloth, fabric and ballistic composites ...

fiber, or natural fibers, metal fibers have a low electrical resistance

The electrical resistance of an object is a measure of its opposition to the flow of electric current. Its reciprocal quantity is , measuring the ease with which an electric current passes. Electrical resistance shares some conceptual paral ...

. This makes them suitable for any application that requires electrical conductivity. They resist extreme temperatures well. Corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engine ...

resistance is achieved through the use of high-quality alloys in stainless steels or other metals. Other advantageous mechanical properties

A material property is an intensive property of a material, i.e., a physical property or chemical property that does not depend on the amount of the material. These quantitative properties may be used as a metric by which the benefits of one mate ...

of metal fibers include high failure strain, ductility

Ductility refers to the ability of a material to sustain significant plastic Deformation (engineering), deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic def ...

, shock resistance, fire resistance, and sound insulation.

Sintered

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, pla ...

metal fiber structures and products display high porosity

Porosity or void fraction is a measure of the void (i.e. "empty") spaces in a material, and is a fraction of the volume of voids over the total volume, between 0 and 1, or as a percentage between 0% and 100%. Strictly speaking, some tests measure ...

properties, while remaining structurally strong and durable. This benefits the function and structure of specific applications like filtration

Filtration is a physical separation process that separates solid matter and fluid from a mixture using a ''filter medium'' that has a complex structure through which only the fluid can pass. Solid particles that cannot pass through the filte ...

or electrodes

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit (e.g. a semiconductor, an electrolyte, a vacuum or a gas). In electrochemical cells, electrodes are essential parts that can consist of a variety ...

.

Coating

A coating is a covering that is applied to the surface of an object, or substrate. The purpose of applying the coating may be decorative, functional, or both. Coatings may be applied as liquids, gases or solids e.g. powder coatings.

Paints ...

metallic filaments helps to minimize tarnishing. When suitable adhesives

Adhesive, also known as glue, cement, mucilage, or paste, is any non-metallic substance applied to one or both surfaces of two separate items that binds them together and resists their separation.

The use of adhesives offers certain advantage ...

and films are used, they are not affected by salt water, chlorinated water (such as that found in swimming pools), or climatic conditions.

Production method

There are several processes which can be used for manufacturing metallic fibers. The most common technology is known as ''bundle drawing.'' Several thousand filaments are bundled together in a ''composite wire'', a tube which is drawn through a die to further reduce its diameter. The covering tube is later dissolved inacid

An acid is a molecule or ion capable of either donating a proton (i.e. Hydron, hydrogen cation, H+), known as a Brønsted–Lowry acid–base theory, Brønsted–Lowry acid, or forming a covalent bond with an electron pair, known as a Lewis ...

, resulting in individual continuous metal fibers. This composite wire is drawn further until the desired diameter of the individual filaments within the bundle is obtained. Bundle drawing technology allows for the production of continuous metal fiber bundles with lengths of up to several kilometers. Due to the nature of the process, the cross-section of the fibers is octagonal. In order to achieve high-quality fibers, this technology can be fine-tuned, resulting in uniform, very thin fibers with a very narrow equivalent diameter spread. Special developments within the last couple of years have allowed this technology to be used for the production of fibers with diameters as small as 200 nm and below.

In the '' laminating process'', a layer of aluminium is sealed between two layers of acetate

An acetate is a salt formed by the combination of acetic acid with a base (e.g. alkaline, earthy, metallic, nonmetallic, or radical base). "Acetate" also describes the conjugate base or ion (specifically, the negatively charged ion called ...

or polyester

Polyester is a category of polymers that contain one or two ester linkages in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include some natura ...

film. These fibers are then cut into lengthwise strips for yarns and wound onto bobbins. To achieve color, the metal can be colored and sealed in a clear film, the adhesive can be colored, or the film can be colored before laminating. There are many different variations of color and effect that can be made in metallic fibers, producing a wide range of looks.

With ''foil-shaving'' technology, fibers with diameters down to 14 μm and a more rectangular cross-section are feasible. This produces semicontinuous bundles of fibers or staple fibers.

''Machining

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which util ...

'' of staple fibers can produce semicontinuous bundles of fibers down to 10 μm. Improving staple fiber manufacturing allows a narrow diameter spread on these kinds of fibers as well as tuning of the geometry of the fiber. This technology is unique compared to foil shaving or fibers from melt spinning, due to the small diameters that can be reached and the relatively small diameter spread.

Metallic fibers can also be made by using the ''metallizing

Metallizing is the general name for the technique of coating metal on the surface of objects. Metallic coatings may be decorative, protective or functional.

Techniques for metallization started as early as mirror making. In 1835, Justus von Lie ...

process''. This process involves heating the metal until it vaporizes then depositing it at a high pressure onto the polyester film. This process produces thinner, more flexible, more durable, and more comfortable fibers.Kadolph, Sara J. and Langford, Anna L. "Textiles Ninth Edition" pg. 129-130.

Metal fiber may also be shaved from wire (steel wool

Steel wool, also known as iron wool or wire sponge, is a bundle of very fine and flexible sharp-edged steel filaments. It is the most common type of wire wool and is often the type meant when wire wool is mentioned. It was described as a new pro ...

), shaved from foil, or bundle drawn to form larger diameter wire.

Types of metallic fiber products

Sintered metal fibers

Metal fibers are converted into fiber media either as non-woven fleece orsintered

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, pla ...

structures composed of fibers ranging from 1.5 to 80 μm in diameter. Applications are based on both high permeable material (porosities up to 90% for sintered and up to 99% for non-woven structures) and high corrosion and temperature resistance. The sintered porous structure has no binder as the individual fibers are strongly bonded together by inter-metallic diffusion bonding. 3D sintered structures have also become a standard product. Recent developments include filter media using combinations of both metallic and non-metallic fibers.

Short fibers

A specially designed process allows the production of individual powder-like metal fibers known as short fibers with a length over diameter (L/D) range of 100. These short fibers can be used as such or in combination with metal powders to produce sintered filtration structures with ultra-high levels of filtration and high permeability.

A specially designed process allows the production of individual powder-like metal fibers known as short fibers with a length over diameter (L/D) range of 100. These short fibers can be used as such or in combination with metal powders to produce sintered filtration structures with ultra-high levels of filtration and high permeability.

Polymer pellets

Other metal fiber products are polymer pellets or grains composed out of metal fibers. Several bundles of fibers are glued together with a variety of sizings and an adequate compatible extrusion coating is applied. After chopping these coated bundles into pellets they can be used as additives in the production of engineered conductive and shielding plastic pieces byinjection molding

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for ...

and extrusion

Extrusion is a process used to create objects of a fixed cross section (geometry), cross-sectional profile by pushing material through a Die (manufacturing), die of the desired cross-section. Its two main advantages over other manufacturing pro ...

. The unique benefit of metal fibers is the conductive network formation with a relatively limited volume of conductive additives.

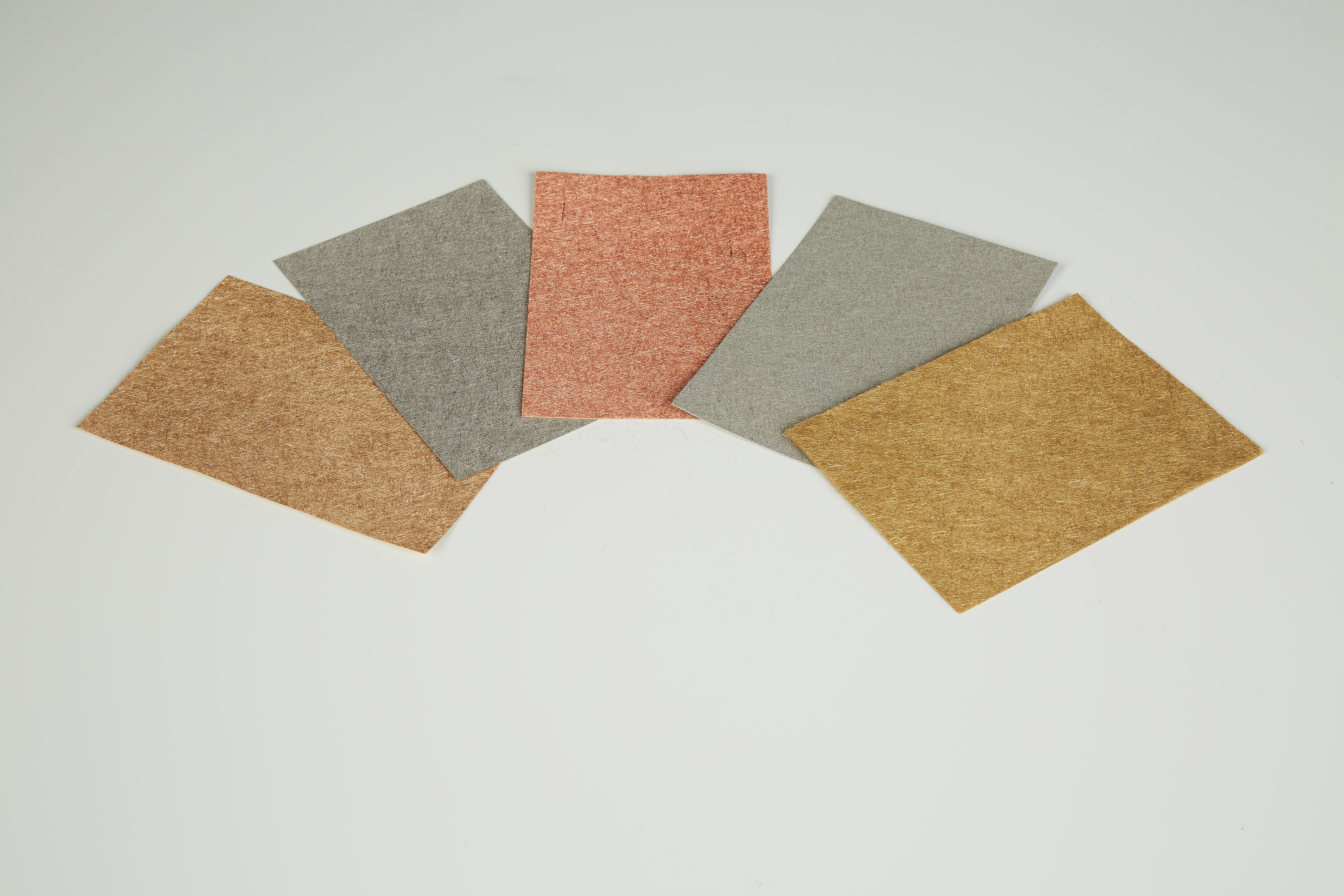

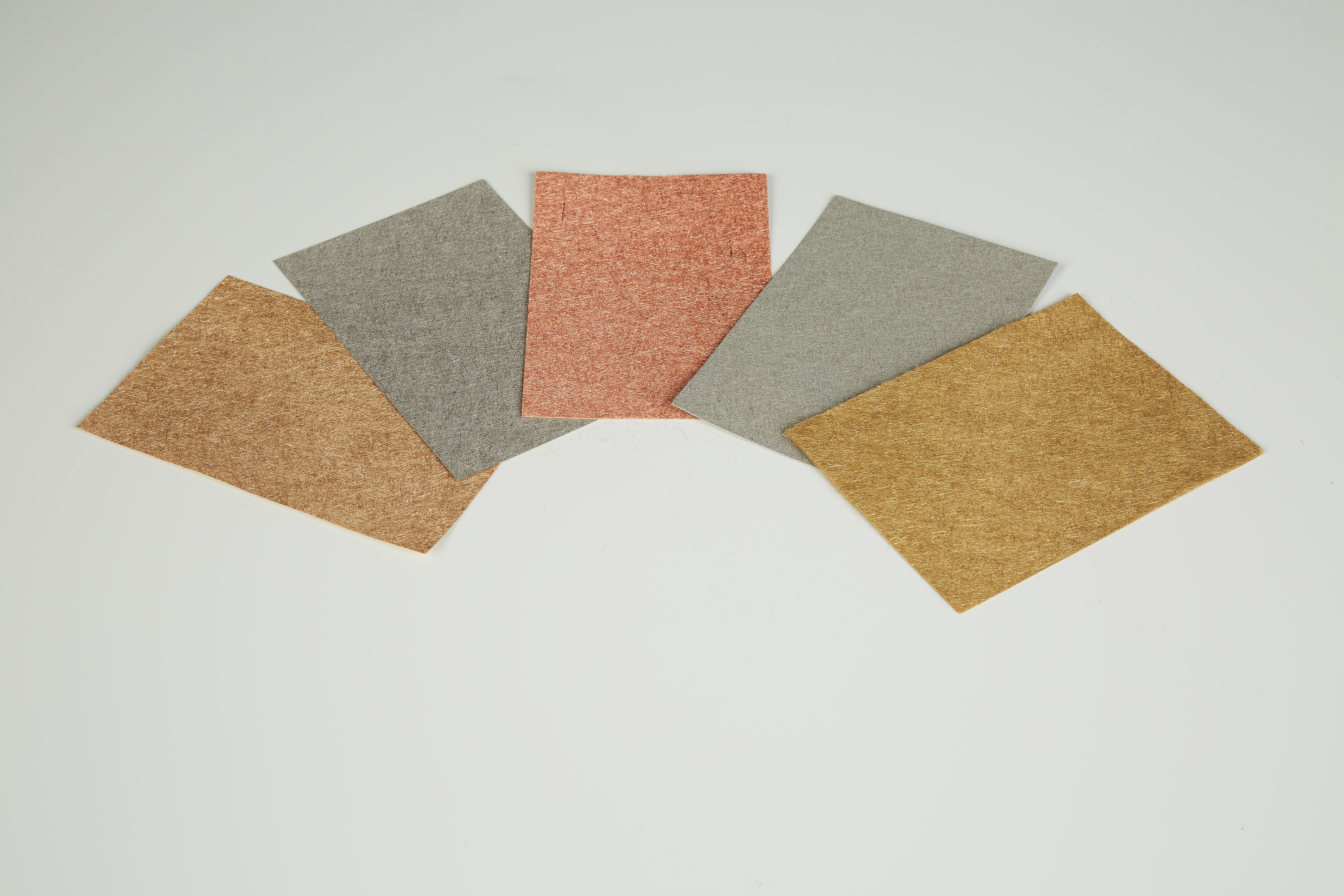

Nonwoven fibers

Non-wovens or felts can be produced with metal fibers, just like with traditional textile fibers. In a very limited number of cases, needle punching can be applied to entangle the fibers and obtain needle-punched felt.

Metal yarns

Bundles of stainless steel fibers can be converted into yarns by textile spinning processes. There are two forms of yarn: one with a low amount of fibers and one with a high amount of fibers. The former, with a number of filaments of around 275, can be converted into a filament yarn by adding twist to the bundle. Bundles with several thousands of fibers are typically used to convert fibers into spun yarn. That can be done by stretch breaking and subsequent traditional yarn spinning technologies. This results in 100% metal yarns. During the spinning process, tows can be blended and blended yarns can also be produced. Blends withcotton

Cotton (), first recorded in ancient India, is a soft, fluffy staple fiber that grows in a boll, or protective case, around the seeds of the cotton plants of the genus '' Gossypium'' in the mallow family Malvaceae. The fiber is almost pure ...

, polyester and wool

Wool is the textile fiber obtained from sheep and other mammals, especially goats, rabbits, and camelids. The term may also refer to inorganic materials, such as mineral wool and glass wool, that have some properties similar to animal w ...

are possible.

Subsequently, metal yarns can be further converted into various textile products using textile processes. Knitting

Knitting is a method for production of textile Knitted fabric, fabrics by interlacing yarn loops with loops of the same or other yarns. It is used to create many types of garments. Knitting may be done Hand knitting, by hand or Knitting machi ...

( circular, flat, warp) and weaving

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal ...

are possible, as well as braiding. Blended textile products can be obtained by combining metal yarns with other yarns, or by using yarns that have two kinds of fibers inside and hence are already blends by themselves.

Electrical cables

To make cables, two or more filaments are twisted together a number of times. During the process, a cable's torsion and straightness are monitored. The cable can be fine-tuned for a certain application by combining different filament strengths, diameters or the number of twists, or by preforming.

To make cables, two or more filaments are twisted together a number of times. During the process, a cable's torsion and straightness are monitored. The cable can be fine-tuned for a certain application by combining different filament strengths, diameters or the number of twists, or by preforming.Fiber Reinforced Composites

Metal fiber can be used as reinforcement fiber for composite materials, improving breaking behavior upon impact and electrical conductivity. Traditional carbon or glass fiber reinforcement fibers have very limited elongation possibilities, which results in a brittle and explosive breaking behavior, whereas metal fibers can absorb much more energy before breaking. Processing is no different from any other reinforcement fiber for composite material. It is also possible to combine metal fibers with other fibers into a hybrid composite structure, which combines properties of its components (carbon, glass, or steel).

Metal fiber can be used as reinforcement fiber for composite materials, improving breaking behavior upon impact and electrical conductivity. Traditional carbon or glass fiber reinforcement fibers have very limited elongation possibilities, which results in a brittle and explosive breaking behavior, whereas metal fibers can absorb much more energy before breaking. Processing is no different from any other reinforcement fiber for composite material. It is also possible to combine metal fibers with other fibers into a hybrid composite structure, which combines properties of its components (carbon, glass, or steel).

Producers

Metallic fibers are manufactured primarily in Europe. The largest and most integrated metal fiber producer worldwide is the multinational company Bekaert, headquartered inBelgium

Belgium, officially the Kingdom of Belgium, is a country in Northwestern Europe. Situated in a coastal lowland region known as the Low Countries, it is bordered by the Netherlands to the north, Germany to the east, Luxembourg to the southeas ...

, but with manufacturing footprint in Europe, Asia, and the Americas. Three manufacturers are still producing metallic yarn in the United States. Metlon Corporation is one of the remaining manufacturers in the U.S. that stocks a wide variety of laminated and non-laminated metallic yarns. Brightex Corporation, Reiko. Co of Japan and South Korea, such as Hwa Young, is also manufacturing metallic fibers. China also produces metallic yarns; the city of Dongyang contains more than 100 factories, though some of these are home-based production sites rather than conventional factories. Two of the more popular factories are Salu Metallic Yarn and Aoqi Textile.

In 2020, Fibrecoat, a German startup from Aachen

Aachen is the List of cities in North Rhine-Westphalia by population, 13th-largest city in North Rhine-Westphalia and the List of cities in Germany by population, 27th-largest city of Germany, with around 261,000 inhabitants.

Aachen is locat ...

, started producing aluminium-coated basalt fibres in Germany.

Trademarks

Bekaert manufactures metal fibers and many derived products such as continuous fiber, sintered media, nonwoven structures, polymer pellets, braids, woven fabrics, cables, yarns and short fibers. Well established brand names are Bekipor, Beki-shield and Bekinox.

The

Bekaert manufactures metal fibers and many derived products such as continuous fiber, sintered media, nonwoven structures, polymer pellets, braids, woven fabrics, cables, yarns and short fibers. Well established brand names are Bekipor, Beki-shield and Bekinox.

The Lurex

Lurex is the registered brand name of the Lurex Company, Ltd. for a type of yarn with a metallic appearance. The yarn is made from synthetic film, onto which a metallic aluminium, silver, or gold layer has been vaporized. "Lurex" may also refer ...

Company has manufactured metallic fibers in Europe for over fifty years. They produce a wide variety of metallic fiber products including fibers used in apparel

Clothing (also known as clothes, garments, dress, apparel, or attire) is any item worn on a human human body, body. Typically, clothing is made of fabrics or textiles, but over time it has included garments made from animal skin and other thin s ...

fabric, embroidery

Embroidery is the art of decorating Textile, fabric or other materials using a Sewing needle, needle to stitch Yarn, thread or yarn. It is one of the oldest forms of Textile arts, textile art, with origins dating back thousands of years across ...

, braid

A braid (also referred to as a plait; ) is a complex structure or pattern formed by interlacing three or more strands of flexible material such as textile yarns, wire, or hair.

The simplest and most common version is a flat, solid, three-strand ...

s, knitting, military regalia, trimmings, ropes, cords, and lace surface decoration. The majority of Lurex fibers have a polyamide film covering the metal strand but polyester and viscose are also used. The fibers are also treated with a lubricant called P.W., a mineral-based oil, which helps provide ease of use.

Metlon Corporation is a trademark of Metallic Yarns in the United States and has been producing metallic yarns for over sixty years. Metlon produces their metallic yarn by wrapping single slit yarns with two ends of nylon. One end of nylon is wrapped clockwise and the other end is wrapped counterclockwise around the metallic yarn. The most commonly used nylon is either 15 denier or 20 denier, but heavier deniers are used for special purposes.

Uses

Source: Metallic fibers are used in a wide range of sectors and segments. Automotive Metal fiber sintered sheets are used for diesel and gasoline particulate filtration and crankcase ventilation filters. Heat-resistant textile materials are made from metal fibers for automotive glass bending processes. These metal fiber cloths protect the glass during the bending process with highly elevated temperatures and high pressures. Metal fibers are used for heating cables for car seat heating and selective catalytic reduction tubes, and adblue tanks. Metal fiber heating cables show an extremely high flexibility and durability when compared to copper wire. Aerospace Metal fiber filters are used forhydraulic fluid

A hydraulic fluid or hydraulic liquid is the medium by which power is transferred in hydraulic machinery. Common hydraulic fluids are based on mineral oil or water. Examples of equipment that might use hydraulic fluids are excavators and backho ...

filtration in aircraft hydraulic systems. When compared to glass fiber filtration media, metal fibers show excellent durability, as the fibers are metallically bonded together by sintering, instead of kept together by a binder material.

Metal fiber sintered porous sheets are used as a sound attenuation medium in aircraft cabins, reducing HVAC

Heating, ventilation, and air conditioning (HVAC ) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. ...

sounds, and auxiliary power unit

An auxiliary power unit (APU) is a device on a vehicle that provides energy for functions other than propulsion. They are commonly found on large aircraft and naval ships as well as some large land vehicles. Aircraft APUs generally produce 115&n ...

noise.

Technical textiles

Metal fibers can serve as antistatic fibers for textiles, which can be used in electrical protective clothing or antistatic bags.

Metal fibers can also be used for shielding from electromagnetic interference (EMI).

Stainless steel fiber textiles can be heated by passing electrical current through them and can also be used for cut resistant clothing (gloves).

Filtration

Metal fiber filters can reach very high porosity, at very low pore sizes, which makes them suitable for HEPA and ULPA filtration. These filters are used in nuclear power plants as a safety measure to prevent eventual release of radioactive steam.

Marine

Metal fiber filters are used for the purification of marine fuel and lube oil.

Other

Another common use for metallic fibers is upholstery

Upholstery is the work of providing furniture, especially seats, with padding, springs, webbing, and fabric or leather covers. The word also refers to the materials used to upholster something.

''Upholstery'' comes from the Middle English wor ...

fabric and textiles such as lamé and brocade

Brocade () is a class of richly decorative shuttle (weaving), shuttle-woven fabrics, often made in coloured silks and sometimes with gold and silver threads. The name, related to the same root as the word "broccoli", comes from Italian langua ...

. Many people also use metallic fibers in weaving

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal ...

and needlepoint

Needlepoint is a type of canvas work, a form of embroidery in which yarn is stitched through a stiff open weave canvas. Traditionally needlepoint designs completely cover the canvas. Although needlepoint may be worked in a variety of stitches, ...

. Metal fibers are used in clothing. Metallic yarns are twisted with other fibers such as wool, nylon, cotton, and synthetic blends to produce yarns.

Stainless steel and other metal fibers are used in communication

Communication is commonly defined as the transmission of information. Its precise definition is disputed and there are disagreements about whether Intention, unintentional or failed transmissions are included and whether communication not onl ...

lines such as phone lines and cable television lines.

Stainless steel fibers are also used in carpet

A carpet is a textile floor covering typically consisting of an upper layer of Pile (textile), pile attached to a backing. The pile was traditionally made from wool, but since the 20th century synthetic fiber, synthetic fibres such as polyprop ...

s. They are dispersed throughout the carpet with other fibers so they are not detected. The presence of the fibers helps to conduct electricity so that the static shock is reduced. These types of carpets are often used in computer-use areas or other areas where static build-up could damage equipment. Other uses include tire cord, missile nose cones, work clothing such as protective suits, space suits, and cut resistant gloves for butchers and other people working near bladed or dangerous machinery.

Metal fibers can be used as a reinforcement or electrical conductivity fiber for fiber reinforced composites.

References

{{fibers Synthetic fibers Technical fabricsfiber

Fiber (spelled fibre in British English; from ) is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often inco ...