Metal Assisted Chemical Etching on:

[Wikipedia]

[Google]

[Amazon]

Metal Assisted Chemical Etching (also known as MACE) is the process of wet chemical

Metal Assisted Chemical Etching (also known as MACE) is the process of wet chemical

Some elements of MACE are commonly accepted in the scientific community, while others are still under debate. There is agreement that the reduction of the oxidizing agent is catalyzed by the noble metal particle (see figure to the left). This means that the metal particle has a surplus of positive charge which is eventually transferred to the silicon substrate. Each of the positive charges in the substrate can be identified as a hole (h+) in the

Some elements of MACE are commonly accepted in the scientific community, while others are still under debate. There is agreement that the reduction of the oxidizing agent is catalyzed by the noble metal particle (see figure to the left). This means that the metal particle has a surplus of positive charge which is eventually transferred to the silicon substrate. Each of the positive charges in the substrate can be identified as a hole (h+) in the

As already stated above MACE requires metal particles or a thin metal thin film on top of a silicon substrate. This can be achieved with several methods such as

As already stated above MACE requires metal particles or a thin metal thin film on top of a silicon substrate. This can be achieved with several methods such as

The reason why MACE is heavily researched is that it allows completely anisotropic etching of silicon substrates which is not possible with other wet chemical etching methods (see figure to the right). Usually the silicon substrate is covered with a protective layer such as

The reason why MACE is heavily researched is that it allows completely anisotropic etching of silicon substrates which is not possible with other wet chemical etching methods (see figure to the right). Usually the silicon substrate is covered with a protective layer such as

Metal Assisted Chemical Etching (also known as MACE) is the process of wet chemical

Metal Assisted Chemical Etching (also known as MACE) is the process of wet chemical etching

Etching is traditionally the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglio (incised) in the metal. In modern manufacturing, other chemicals may be used on other type ...

of semiconductors

A semiconductor is a material with electrical conductivity between that of a conductor and an insulator. Its conductivity can be modified by adding impurities (" doping") to its crystal structure. When two regions with different doping levels ...

(mainly silicon

Silicon is a chemical element; it has symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic lustre, and is a tetravalent metalloid (sometimes considered a non-metal) and semiconductor. It is a membe ...

) with the use of a metal

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electrical resistivity and conductivity, electricity and thermal conductivity, heat relatively well. These properties are all associated wit ...

catalyst

Catalysis () is the increase in rate of a chemical reaction due to an added substance known as a catalyst (). Catalysts are not consumed by the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quick ...

, usually deposited on the surface of a semiconductor

A semiconductor is a material with electrical conductivity between that of a conductor and an insulator. Its conductivity can be modified by adding impurities (" doping") to its crystal structure. When two regions with different doping level ...

in the form of a thin film or nanoparticle

A nanoparticle or ultrafine particle is a particle of matter 1 to 100 nanometres (nm) in diameter. The term is sometimes used for larger particles, up to 500 nm, or fibers and tubes that are less than 100 nm in only two directions. At ...

s. The semiconductor, covered with the metal, is then immersed in an etching solution containing an oxidizing agent

An oxidizing agent (also known as an oxidant, oxidizer, electron recipient, or electron acceptor) is a substance in a redox chemical reaction that gains or " accepts"/"receives" an electron from a (called the , , or ''electron donor''). In ot ...

and hydrofluoric acid

Hydrofluoric acid is a solution of hydrogen fluoride (HF) in water. Solutions of HF are colorless, acidic and highly corrosive. A common concentration is 49% (48–52%) but there are also stronger solutions (e.g. 70%) and pure HF has a boiling p ...

. The metal on the surface catalyzes the reduction of the oxidizing agent and therefore in turn also the dissolution of silicon. In the majority of the conducted research this phenomenon of increased dissolution rate is also spatially confined, such that it is increased in close proximity to a metal particle at the surface. Eventually this leads to the formation of straight pores that are etched into the semiconductor (see figure to the right). This means that a pre-defined pattern of the metal on the surface can be directly transferred to a semiconductor substrate.

History of development

MACE is a relatively new technology in semiconductor engineering and therefore it has yet to be a process that is used in industry. The first attempts of MACE consisted of a silicon wafer that was partially covered with aluminum and then immersed in an etching solution. This material combination led to an increased etching rate compared to bare silicon. Often this very first attempt is also called galvanic etching instead of metal assisted chemical etching. Further research showed that a thin film of a noble metal deposited on a silicon wafer's surface can also locally increase the etching rate. In particular, it was observed that noble metal particles sink down into the material when the sample is immersed in an etching solution containing an oxidizing agent andhydrofluoric acid

Hydrofluoric acid is a solution of hydrogen fluoride (HF) in water. Solutions of HF are colorless, acidic and highly corrosive. A common concentration is 49% (48–52%) but there are also stronger solutions (e.g. 70%) and pure HF has a boiling p ...

(see image in the introduction). This method is now commonly called the metal assisted chemical etching of silicon.

Other semiconductors were also successfully etched with MACE, such as silicon carbide

Silicon carbide (SiC), also known as carborundum (), is a hard chemical compound containing silicon and carbon. A wide bandgap semiconductor, it occurs in nature as the extremely rare mineral moissanite, but has been mass-produced as a powder a ...

or gallium nitride

Gallium nitride () is a binary III/ V direct bandgap semiconductor commonly used in blue light-emitting diodes since the 1990s. The compound is a very hard material that has a Wurtzite crystal structure. Its wide band gap of 3.4 eV af ...

. However, the main portion of research is dedicated to MACE of silicon.

It has been shown that both noble metal

A noble metal is ordinarily regarded as a metallic chemical element, element that is generally resistant to corrosion and is usually found in nature in its native element, raw form. Gold, platinum, and the other platinum group metals (ruthenium ...

s such as gold

Gold is a chemical element; it has chemical symbol Au (from Latin ) and atomic number 79. In its pure form, it is a brightness, bright, slightly orange-yellow, dense, soft, malleable, and ductile metal. Chemically, gold is a transition metal ...

, platinum

Platinum is a chemical element; it has Symbol (chemistry), symbol Pt and atomic number 78. It is a density, dense, malleable, ductility, ductile, highly unreactive, precious metal, precious, silverish-white transition metal. Its name origina ...

, palladium

Palladium is a chemical element; it has symbol Pd and atomic number 46. It is a rare and lustrous silvery-white metal discovered in 1802 by the English chemist William Hyde Wollaston. He named it after the asteroid Pallas (formally 2 Pallas), ...

, and silver

Silver is a chemical element; it has Symbol (chemistry), symbol Ag () and atomic number 47. A soft, whitish-gray, lustrous transition metal, it exhibits the highest electrical conductivity, thermal conductivity, and reflectivity of any metal. ...

, and base metal

A base metal is a common and inexpensive metal, as opposed to a precious metal such as gold or silver. In numismatics, coins often derived their value from the precious metal content; however, base metals have also been used in coins in the past ...

s such as iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's o ...

, nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

, copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

, and aluminium

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

can act as a catalyst

Catalysis () is the increase in rate of a chemical reaction due to an added substance known as a catalyst (). Catalysts are not consumed by the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quick ...

in the process.

Theory

Some elements of MACE are commonly accepted in the scientific community, while others are still under debate. There is agreement that the reduction of the oxidizing agent is catalyzed by the noble metal particle (see figure to the left). This means that the metal particle has a surplus of positive charge which is eventually transferred to the silicon substrate. Each of the positive charges in the substrate can be identified as a hole (h+) in the

Some elements of MACE are commonly accepted in the scientific community, while others are still under debate. There is agreement that the reduction of the oxidizing agent is catalyzed by the noble metal particle (see figure to the left). This means that the metal particle has a surplus of positive charge which is eventually transferred to the silicon substrate. Each of the positive charges in the substrate can be identified as a hole (h+) in the valence band

In solid-state physics, the valence band and conduction band are the bands closest to the Fermi level, and thus determine the electrical conductivity of the solid. In nonmetals, the valence band is the highest range of electron energies in ...

of the substrate, or in more chemical terms it may be interpreted as a weakened Si-Si bond due to the removal of an electron.

The weakened bonds can be attacked by a nucleophilic species such as HF or H2O, which in turn leads to the dissolution of the silicon substrate in close proximity to the noble metal particle.

From a thermodynamic point of view, the MACE process is possible because the redox potential

Redox potential (also known as oxidation / reduction potential, ''ORP'', ''pe'', ''E_'', or E_) is a measure of the tendency of a chemical species to acquire electrons from or lose electrons to an electrode and thereby be reduced or oxidised respe ...

of the redox couple corresponding to the used oxidizing agents (hydrogen peroxide

Hydrogen peroxide is a chemical compound with the formula . In its pure form, it is a very pale blue liquid that is slightly more viscosity, viscous than Properties of water, water. It is used as an oxidizer, bleaching agent, and antiseptic, usua ...

or potassium permanganate

Potassium permanganate is an inorganic compound with the chemical formula KMnO4. It is a purplish-black crystalline salt, which dissolves in water as K+ and ions to give an intensely pink to purple solution.

Potassium permanganate is widely us ...

) are below the valence band edge at the electrochemical energy scale. Equivalently, one could say that the electrochemical potential

Electrochemistry is the branch of physical chemistry concerned with the relationship between electrical potential difference and identifiable chemical change. These reactions involve electrons moving via an electronically conducting phase (typi ...

of the electron

The electron (, or in nuclear reactions) is a subatomic particle with a negative one elementary charge, elementary electric charge. It is a fundamental particle that comprises the ordinary matter that makes up the universe, along with up qua ...

in the etching solution (due to the presence of oxidizing agent) is lower than the electrochemical potential of the electron in the substrate, hence electrons are removed from the silicon. In the end, this accumulation of positive charge leads to the dissolution of the substrate by hydrofluoric acid.

MACE consists of multiple individual reactions. At the metal particle, the oxidizing agent is reduced. In the case of hydrogen peroxide this can be written down as follows:

:

The created holes (h+) are then consumed during the dissolution of silicon. There are several possible reactions via which the dissolution can take place, but here just one example is given:

:

There are still some unclear aspects of the MACE process. The model proposed above requires contact of the metal particle with the silicon substrate which is somehow conflicting with the etching solution being underneath the particle. This can be explained with a dissolution and redeposition of metal during MACE. In particular it is proposed, that some metal ions from the particle are dissolved and eventually are re-deposited at the silicon surface with a redox reaction. In this case the metal particle (or even larger noble metal thin films) could partially maintain contact to the substrate while also etching could partially take place underneath the metal.

It is also observed that in the vicinity of straight pores as shown in the introduction also a micro-porous region between the pores is formed. Generally this is attributed to holes that diffuse away from the particle and hence contribute to etching at more distant locations.

This behavior is dependent on the doping type of substrate as well as on the type of noble metal particle. Therefore, it is proposed that the formation of such a porous region beneath the straight pores depends on the type of barrier that is formed at the metal/silicon interface. In the case of an upward band bending

In solid-state physics, band bending refers to the process in which the electronic band structure in a material curves up or down near a junction or interface. It does not involve any physical (spatial) bending. When the electrochemical potential ...

the electric field in the depletion layer would point towards the metal. Therefore, holes cannot diffuse further into the substrate and thus no formation of a micro-porous region is observed. In the case of downward band-bending holes could escape into the bulk of the silicon substrate and eventually lead to etching there.

Experimental procedure of MACE

As already stated above MACE requires metal particles or a thin metal thin film on top of a silicon substrate. This can be achieved with several methods such as

As already stated above MACE requires metal particles or a thin metal thin film on top of a silicon substrate. This can be achieved with several methods such as sputter deposition

Sputter deposition is a physical vapor deposition (PVD) method of thin film deposition by the phenomenon of sputtering. This involves ejecting material from a "target" that is a source onto a "substrate" such as a silicon wafer.

Resputtering is ...

or thermal evaporation

A thermal column (or thermal) is a rising mass of buoyant air, a convective current in the atmosphere, that transfers heat energy vertically. Thermals are created by the uneven heating of Earth's surface from solar radiation, and are an example ...

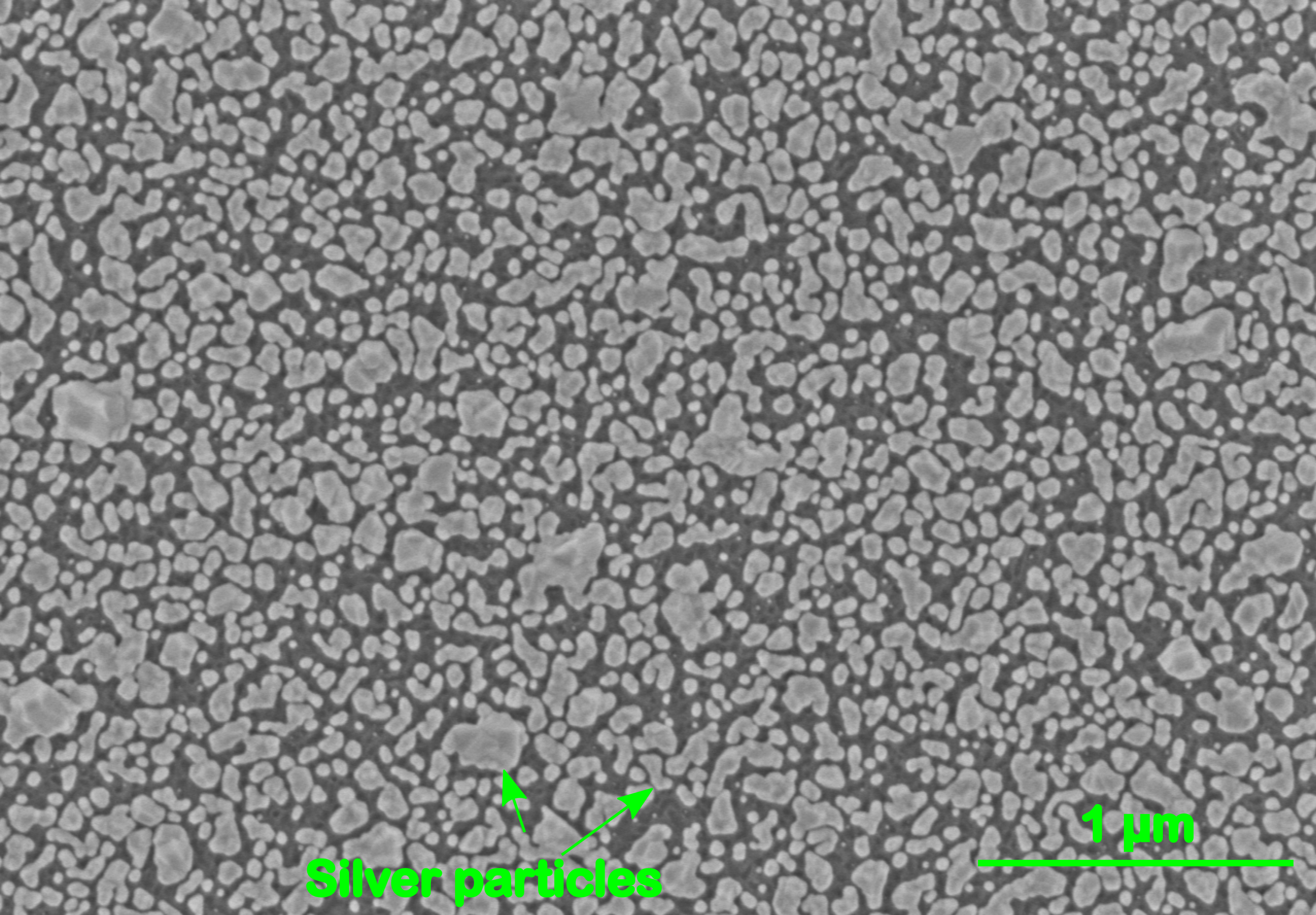

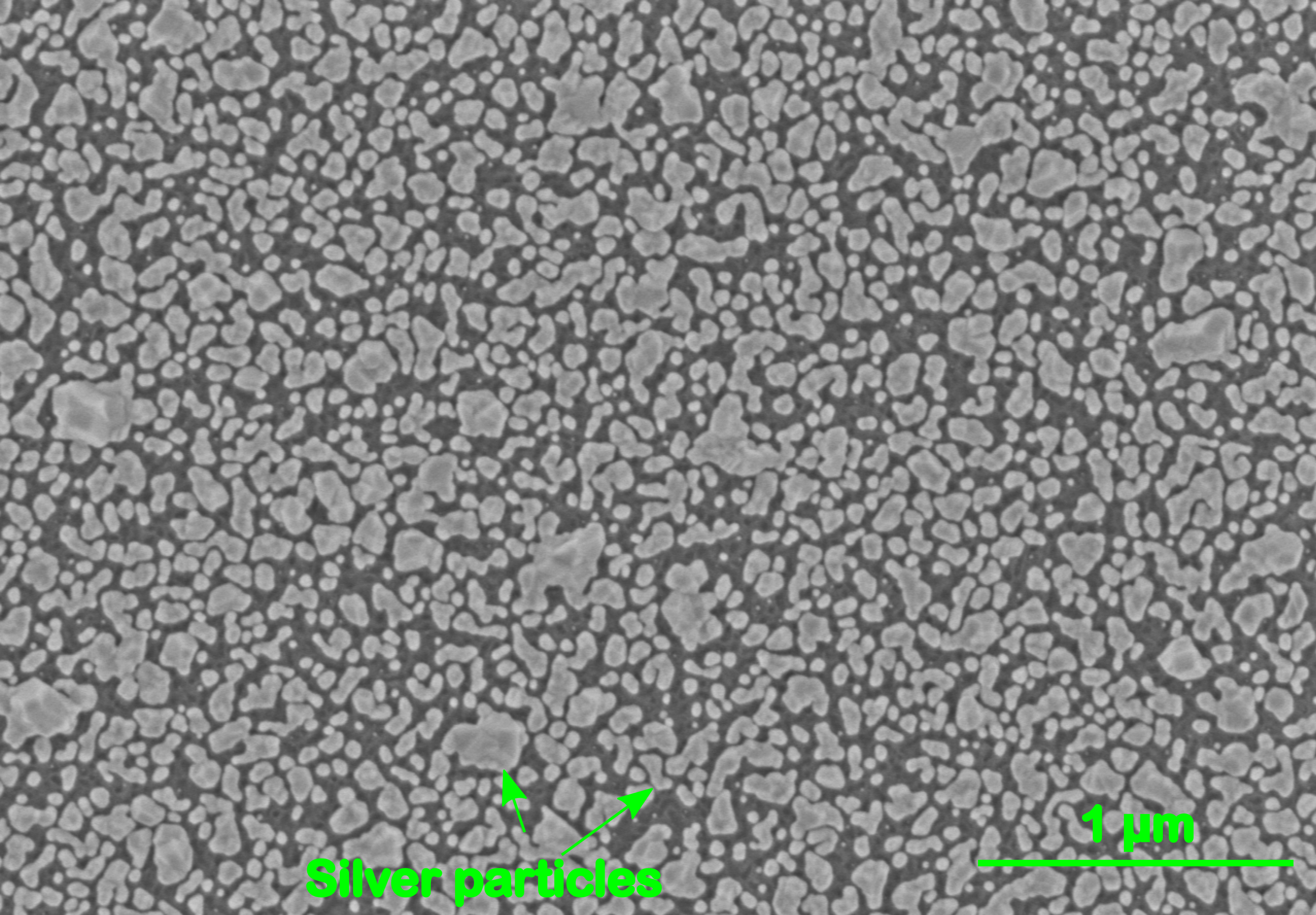

.Kabalan, Amal. "A Comparative Study on the Effects of Passivation Methods on the Carrier Lifetime of RIE and MACE Silicon Micropillars." Applied Sciences 9.9 (2019): 1804. A method to obtain particles from a continuous thin film is thermal dewetting.Backes, A., et al. "Influence of metallic catalyst and doping level on the metal assisted chemical etching of silicon." Scripta Materialia 114 (2016): 27-30.

These deposition methods can be combined with lithography

Lithography () is a planographic method of printing originally based on the miscibility, immiscibility of oil and water. The printing is from a stone (lithographic limestone) or a metal plate with a smooth surface. It was invented in 1796 by ...

Chang, Shih‐Wei, et al. "Densely packed arrays of ultra‐high‐aspect‐ratio silicon nanowires fabricated using block‐copolymer lithography and metal‐assisted etching." Advanced functional materials 19.15 (2009): 2495-2500. such that only desired regions are covered with metal. Since MACE is an anisotropic etching method (etching takes place not in all spatial directions) a pre-defined metal pattern can be directly transferred into the silicon substrate.

Another method of depositing metal particles or thin films is electroless plating of noble metals on the surface of silicon. Since the redox potentials of the redox couples of noble metals are below the valence band edge of silicon, noble metal ions can (like described in the theory section) inject holes (or extract electrons) from the substrate while they are reduced. In the end metallic particles or films are obtained at the surface.Smith, Zachary R., Rosemary L. Smith, and Scott D. Collins. "Mechanism of nanowire formation in metal assisted chemical etching." Electrochimica Acta 92 (2013): 139-147.

Finally, after the deposition of the metal on the surface of silicon, the sample is immersed in an etching solution containing hydrofluoric acid and oxidizing agent. Etching will take place as long as the oxidizing agent and the acid are consumed or until the sample is removed from the etching solution.

Applications of MACE

The reason why MACE is heavily researched is that it allows completely anisotropic etching of silicon substrates which is not possible with other wet chemical etching methods (see figure to the right). Usually the silicon substrate is covered with a protective layer such as

The reason why MACE is heavily researched is that it allows completely anisotropic etching of silicon substrates which is not possible with other wet chemical etching methods (see figure to the right). Usually the silicon substrate is covered with a protective layer such as photoresist

A photoresist (also known simply as a resist) is a light-sensitive material used in several processes, such as photolithography and photoengraving, to form a patterned coating on a surface. This process is crucial in the electronics industry.

T ...

before it is immersed in an etching solution. The etching solution usually has no preferred direction of attacking the substrate, therefore isotropic etching takes place. In semiconductor engineering, however it is often required that the sidewalls of the etched trenches are steep. This is usually realized with methods that operate in the gas-phase such as reactive ion etching

Reactive-ion etching (RIE) is an etching technology used in microfabrication. RIE is a type of dry etching which has different characteristics than wet etching. RIE uses chemically reactive plasma to remove material deposited on wafers. The ...

. These methods require expensive equipment compared to simple wet etching. MACE, in principle allows the fabrication of steep trenches but is still cheap compared to gas-phase etching methods.

Porous silicon

Metal assisted chemical etching allows for the production ofporous silicon

Porous silicon (abbreviated as "PS" or "pSi") is a form of the chemical element silicon that has introduced nanopores in its microstructure, rendering a large surface to volume ratio in the order of 500 m2/cm3.

History

Porous silicon was disco ...

with photoluminescence

Photoluminescence (abbreviated as PL) is light emission from any form of matter after the absorption of photons (electromagnetic radiation). It is one of many forms of luminescence (light emission) and is initiated by photoexcitation (i.e. phot ...

.

Black silicon

Black silicon

Black silicon is a semiconductor material, a surface modification of silicon with very low reflectivity and correspondingly high absorption of visible (and infrared) light.

The modification was discovered in the 1980s as an unwanted side effect ...

is silicon with a modified surface and is a type of porous silicon

Porous silicon (abbreviated as "PS" or "pSi") is a form of the chemical element silicon that has introduced nanopores in its microstructure, rendering a large surface to volume ratio in the order of 500 m2/cm3.

History

Porous silicon was disco ...

. There are several works on obtaining black silicon

Black silicon is a semiconductor material, a surface modification of silicon with very low reflectivity and correspondingly high absorption of visible (and infrared) light.

The modification was discovered in the 1980s as an unwanted side effect ...

using MACE technology. The main application of black silicon is solar energy

Solar energy is the radiant energy from the Sun's sunlight, light and heat, which can be harnessed using a range of technologies such as solar electricity, solar thermal energy (including solar water heating) and solar architecture. It is a ...

.

Black gallium arsenide

Black gallium arsenide with light trapping properties have been also produced by MACE.References

{{reflist Etching Chemistry Research lasers Semiconductors Engineering