List Of Construction Methods on:

[Wikipedia]

[Google]

[Amazon]

The list of construction methods covers the processes and techniques used in the

* Beam sides: 9–12 hours.

* Beam soffits: 8–14 days.

* Beam props: 15–21 days.

This consists of a vertical mold of the desired shape and size matching the column to be poured. To keep the material thickness to a minimum, horizontal steel or timber clamps (or yokes) are used for batch filling and at varying centers for filling that is completed in one pour.

The head of the column can provide support for the beam formwork. Even though this gives good top lateral restraint, it can make the formwork complex. The column can be cast to the underside of the beams. A collar of formwork can be held around the cast column to complete the casting and support the incoming beam.

* Beam sides: 9–12 hours.

* Beam soffits: 8–14 days.

* Beam props: 15–21 days.

This consists of a vertical mold of the desired shape and size matching the column to be poured. To keep the material thickness to a minimum, horizontal steel or timber clamps (or yokes) are used for batch filling and at varying centers for filling that is completed in one pour.

The head of the column can provide support for the beam formwork. Even though this gives good top lateral restraint, it can make the formwork complex. The column can be cast to the underside of the beams. A collar of formwork can be held around the cast column to complete the casting and support the incoming beam.

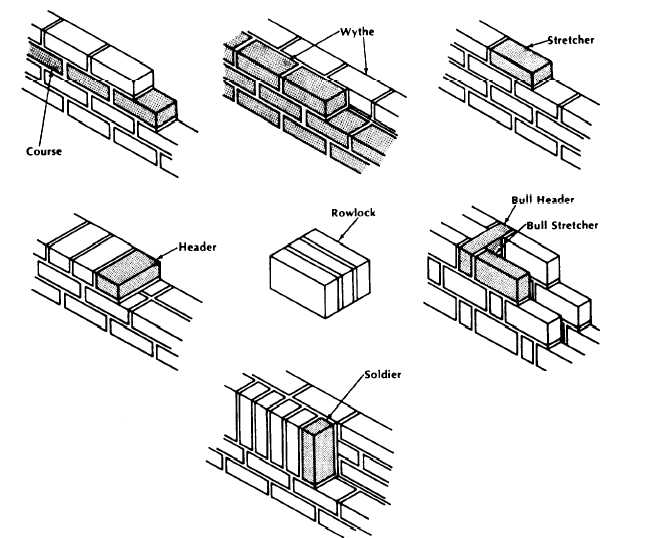

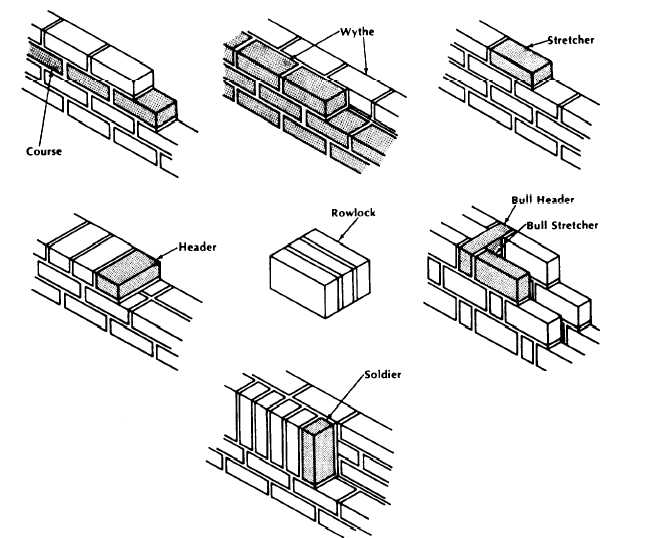

Bricks are laid with a mortar joint bonding them. The profile of the mortar can be varied depending on exposure or to create a specific visual effect. The most common profiles are flush (rag joint), bucket handle, weather struck, weather struck and cut and recessed.

The bonding pattern describes the alignment of the bricks. Many standard bond patterns have been defined, including

Bricks are laid with a mortar joint bonding them. The profile of the mortar can be varied depending on exposure or to create a specific visual effect. The most common profiles are flush (rag joint), bucket handle, weather struck, weather struck and cut and recessed.

The bonding pattern describes the alignment of the bricks. Many standard bond patterns have been defined, including

construction

Construction are processes involved in delivering buildings, infrastructure, industrial facilities, and associated activities through to the end of their life. It typically starts with planning, financing, and design that continues until the a ...

process. The construction method is essential for civil engineers; utilizing it appropriately can help to achieve the desired results. The term ''building'' refers to the creation of physical structures such as buildings, bridges or railways. One of the four types of buildings is residential and building methods are easiest to study in these structures.

Background

Construction

Construction are processes involved in delivering buildings, infrastructure, industrial facilities, and associated activities through to the end of their life. It typically starts with planning, financing, and design that continues until the a ...

involves the creation of physical structures such as buildings, bridges or railways.

Bricks are small rectangular blocks that can be used to form parts of buildings, typically walls. Before 7,000 BC, bricks were formed from hand-molded mud and dried by the sun. During the Industrial Revolution

The Industrial Revolution, sometimes divided into the First Industrial Revolution and Second Industrial Revolution, was a transitional period of the global economy toward more widespread, efficient and stable manufacturing processes, succee ...

, mass-produced bricks became a common alternative to stone. Stone was typically more expensive, less predictable and more difficult to handle. Bricks remain in common use. They are small and easy to handle, strong in compression, durable and low maintenance. They can be formed into complex shapes, providing ample opportunity for the construction of aesthetic designs.

The four basic types of structure are residential, institutional and commercial, industrial, and infrastructure/heavy.

Residential

Residential buildings go through five main stages, including foundations, formwork, scaffolding, concrete work and reinforcement.Foundation

Foundations provide support for structures, transferring their load to layers of soil or rock that have sufficient bearing capacity and suitable settlement characteristics to support them. There are four types of foundation depending on the bearing capacity. Civil engineers will often determine what type of foundation is suitable for the respective bearing capacity. The foundation construction method depends on considerations such as: * The nature of the load requiring support * Ground conditions * The presence of water * Space availability * Accessibility * Sensitivity to noise and vibrationShallow foundation

Shallow foundation

A shallow foundation is a type of building foundation that transfers structural load to the earth very near to the surface, rather than to a subsurface layer or a range of depths, as does a deep foundation. Customarily, a shallow foundation is con ...

s are used where the loads forced by a structure are low relative to the bearing capacity of the surface soils. Deep foundation

A pile or piling is a vertical structural element of a deep foundation, driven or drilled deep into the ground at the building site. A deep foundation is a type of foundation (architecture), foundation that transfers building loads to the e ...

s are needed where the bearing capacity of the surface soils is insufficient. Those loads need to be transferred to deeper layers with higher bearing capacity.

Raft or mat foundation

Raft foundations are slabs that cover a wide area, often the entire building footprint. They are suitable where ground conditions are too poor to create individual strip or pad foundations for a large number of individual loads. Raft foundations may combine beams to add support for specific loads.Pile foundation

Pile foundations are rectangular or circular pads used to support loads such as columns.Strip foundation

Strip foundations provide a continuous line of support to a linear structure such as a wall. Trench fill foundations are a variation of strip foundations. The trench excavation is almost completely filled with concrete. Rubble trench foundations are a further variation of trench fill foundations and are a traditional construction method that uses loose stone or rubble to minimise the use of concrete and improve drainage.Formwork

Formwork

Formwork is Molding (process), molds into which concrete or similar materials are either precast concrete, precast or cast-in-place concrete, cast-in-place. In the context of concrete construction, the falsework supports the shuttering mold ...

is used for the process of creating a mold into which concrete is poured and solidified. Traditional formwork is fabricated using wood, but it can employ steel, glass fibre, reinforced plastics and other materials.

Formwork for beams takes the form of a box that is supported and propped in the correct position and level. The removal time for the formwork will vary with air temperature, humidity and consequent curing rate. Typical striking times are as follows (using air temperature of 7-16 °C):

Falsework

Falsework

Falsework consists of temporary structures used in construction to support a permanent structure until its construction is sufficiently advanced to support itself. For arches, this is specifically called centering. Falsework includes temporary ...

consists of temporary structures used to support a permanent structure. Falsework need to have accurate calculation.

Bar bending

Rebar

Rebar (short for reinforcement bar or reinforcing bar), known when massed as reinforcing steel or steel reinforcement, is a tension device added to concrete to form ''reinforced concrete'' and reinforced masonry structures to strengthen and aid ...

is a steel bar or mesh of steel wires used in reinforced concrete and masonry structures to strengthen and hold the concrete in tension. The surface of rebar is often patterned to improve the quality of the bond with the concrete. Rebar is necessary to add tensile strength

Ultimate tensile strength (also called UTS, tensile strength, TS, ultimate strength or F_\text in notation) is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials, the ultimate ...

, while concrete is strong in compression

Compression may refer to:

Physical science

*Compression (physics), size reduction due to forces

*Compression member, a structural element such as a column

*Compressibility, susceptibility to compression

* Gas compression

*Compression ratio, of a ...

. It can support tensile loads and increase overall strength by casting rebar into concrete.

Concrete

Concrete is typically used in commercial buildings and civil engineering projects, for its strength and durability. Concrete is a mix of cement and water plus an aggregate such as sand or stone. Its compression strength means it can support heavy weights.Insulating concrete form

Insulating concrete forms or insulated concrete forms (ICF) are a building system to create reinforced concrete walls or floors with integral insulation. They are dry-stacked (without mortar) and filled with concrete. The units interlock somewha ...

s (ICFs) cam be used for home construction. They are made by pouring concrete between rigid panels, often made out of polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It i ...

foam. Rebar can provide additional strength internally, and the exterior panels can remain in place once the concrete sets. It is essential to check the levels of foundation before pouring.

Brick

Bricks are laid with a mortar joint bonding them. The profile of the mortar can be varied depending on exposure or to create a specific visual effect. The most common profiles are flush (rag joint), bucket handle, weather struck, weather struck and cut and recessed.

The bonding pattern describes the alignment of the bricks. Many standard bond patterns have been defined, including

Bricks are laid with a mortar joint bonding them. The profile of the mortar can be varied depending on exposure or to create a specific visual effect. The most common profiles are flush (rag joint), bucket handle, weather struck, weather struck and cut and recessed.

The bonding pattern describes the alignment of the bricks. Many standard bond patterns have been defined, including stretcher bond

Brickwork is masonry produced by a bricklayer, using bricks and Mortar (masonry), mortar. Typically, rows of bricks called ''Course (architecture), courses'' are laid on top of one another to build up a structure such as a brick wall.

Bricks ...

. Each stretcher (brick laid lengthwise) is offset by half a brick relative to the courses above and below of English bond. Stretchers and headers are laid with alternating courses aligned to one another. American common bond is similar to the English bond but with one course of headers for every six stretcher courses. English cross bond has courses of stretchers and headers, but with the alternating stretcher courses offset by half a brick.

Flemish bond

Flemish bond is a pattern of brickwork that is a common feature in Georgian architecture. The pattern features bricks laid lengthwise (''stretchers'') alternating with bricks laid with their shorter ends exposed (''headers'') within the same cou ...

consists of alternating stretchers and headers in each course. Header bond has courses of headers offset by half a brick. Stack bond consists of bricks laid directly on top of one another with joints aligned. This is a weak bond and is likely to require reinforcement. Garden wall bond has three courses of stretchers then one course of headers. Sussex bond has three stretchers and one header in each course.

References

{{Construction overview Construction