Kraton (polymer) on:

[Wikipedia]

[Google]

[Amazon]

Kraton is the trade name given to a number of high-performance

Kraton employees accept an ASC Innovation Award

Kraton polymers are styrenic

Kraton polymers are styrenic

Kraton polymers are always used in blends with various other ingredients like paraffinic oils, polyolefins, polystyrene, bitumen, tackifying resins, and fillers to provide a very large range of end-use products ranging from hot melt adhesives to impact-modified transparent polypropylene bins, from medical TPE compounds to modified bitumen roofing felts or from oil gel toys (including sex toys) to elastic attachments in diapers.

It can make

Kraton polymers are always used in blends with various other ingredients like paraffinic oils, polyolefins, polystyrene, bitumen, tackifying resins, and fillers to provide a very large range of end-use products ranging from hot melt adhesives to impact-modified transparent polypropylene bins, from medical TPE compounds to modified bitumen roofing felts or from oil gel toys (including sex toys) to elastic attachments in diapers.

It can make

elastomer

An elastomer is a polymer with viscoelasticity (i.e. both viscosity and elasticity) and with weak intermolecular forces, generally low Young's modulus (E) and high failure strain compared with other materials. The term, a portmanteau of ''ela ...

s manufactured by Kraton Polymers, and used as synthetic

Synthetic may refer to:

Science

* Synthetic biology

* Synthetic chemical or compound, produced by the process of chemical synthesis

* Synthetic elements, chemical elements that are not naturally found on Earth and therefore have to be created in ...

replacements for rubber

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds.

Types of polyisoprene ...

. Kraton polymers offer many of the properties of natural rubber, such as flexibility, high traction, and sealing abilities, but with increased resistance to heat, weathering, and chemicals.

Company

The origin of Kraton polymers goes back to the synthetic rubber (GR-S) program funded by the U.S. government during World War II to develop and establish a domestic supply capability for synthetic styrene butadiene rubber (SBR) as an alternative to natural rubber.Shell Oil Company

Shell USA, Inc. (formerly Shell Oil Company, Inc.) is the United States–based wholly owned subsidiary of Shell plc, a UK-based transnational corporation " oil major" which is among the largest oil companies in the world. Approximately 18,000 ...

purchased the Torrance, California facility from the U.S. government that was built to make synthetic styrene butadiene rubber. The company formed Elastomers Division that eventually became Kraton Corporation. Shell Oil Company broaden the product portfolio of elastomers in the 1950s, under the technical leadership of Murray Luftglass and Norman R. Legge.

As part of the divestment program that was announced by Shell in December 1998, the Kraton elastomers business was sold to a private equity firm Ripplewood Holdings

Ripplewood is an American private equity firm based in New York City that focuses on leveraged buyouts, venture capital, late stage venture, growth capital, management buyouts, leveraged recapitalizations and other illiquid investments.

Ripplewo ...

in 2000. Kraton completed IPO on December 17, 2009, to became a separate publicly traded company. In 2021 Kraton employees won an ASC Innovation Award for "Next Generation of Biobased Tackifiers REvolutionTM"Kraton employees accept an ASC Innovation Award

Properties

Kraton polymers are styrenic

Kraton polymers are styrenic block copolymer

In polymer chemistry, a copolymer is a polymer derived from more than one species of monomer. The polymerization of monomers into copolymers is called copolymerization. Copolymers obtained from the copolymerization of two monomer species are som ...

(SBC) consisting of polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It i ...

blocks and rubber blocks. The rubber blocks consist of polybutadiene

Polybutadiene utadiene rubber, BRis a synthetic rubber. It offers high elasticity, high resistance to wear, good strength even without fillers, and excellent abrasion resistance when filled and vulcanized. "Polybutadiene" is a collective name fo ...

, polyisoprene

Polyisoprene is, strictly speaking, a collective name for polymers that are produced by polymerization of isoprene. In practice polyisoprene is commonly used to refer to synthetic ''cis''-1,4-polyisoprene, made by the industrial polymerisation of ...

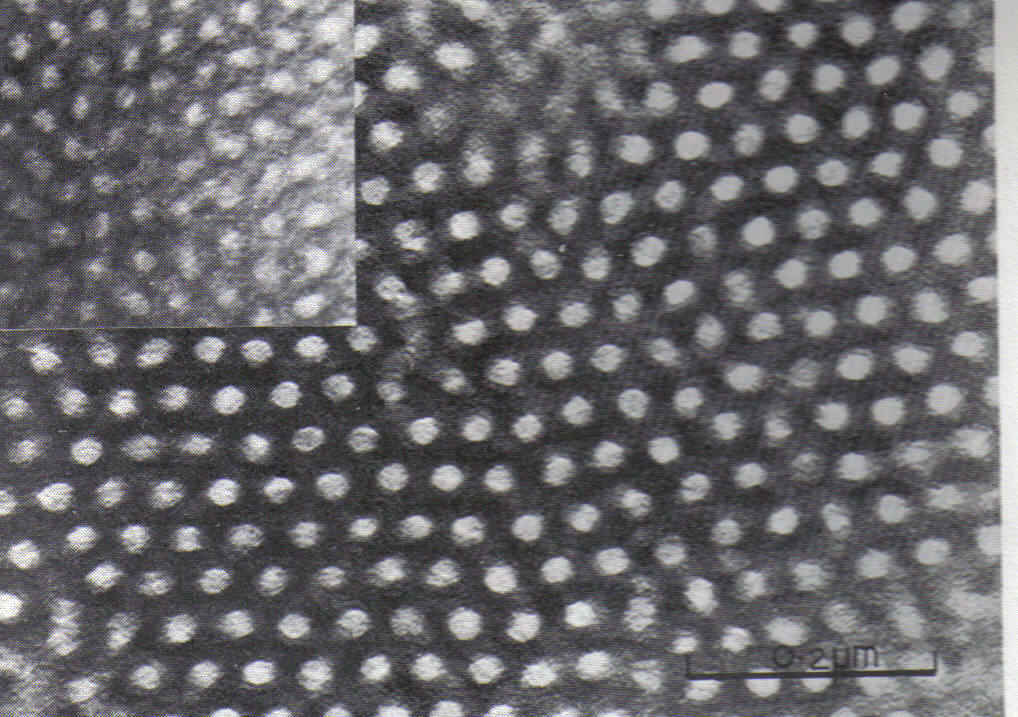

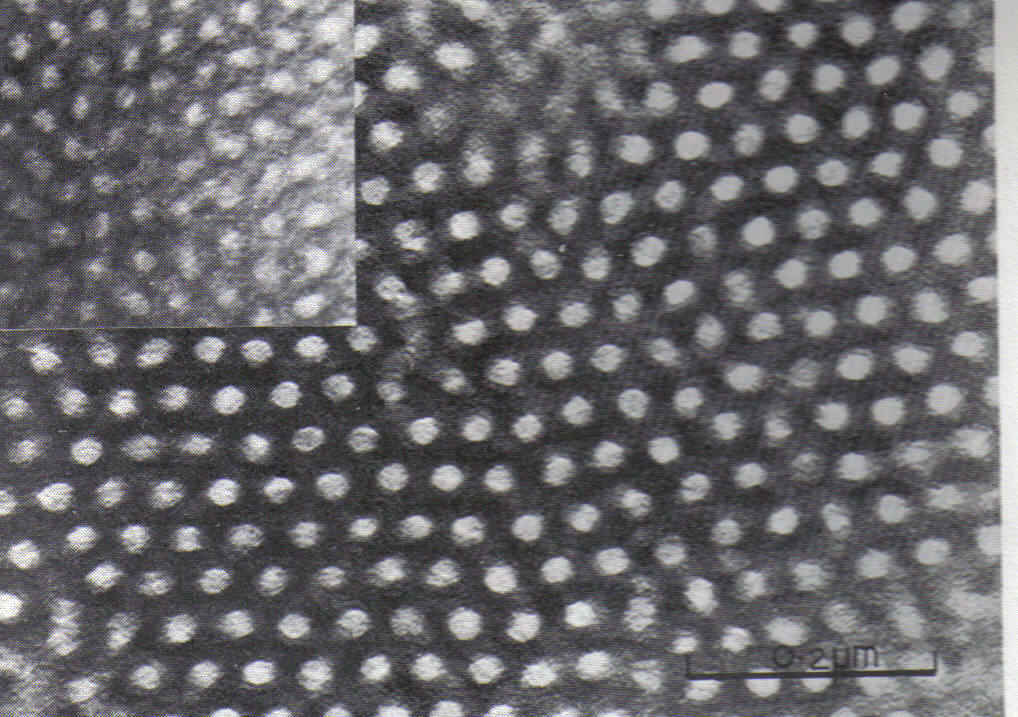

, or their hydrogenated equivalents. The tri-block with polystyrene blocks at both extremities linked together by a rubber block is the most important polymer structure observed in SBC. If the rubber block consists of polybutadiene, the corresponding triblock structure is: poly(styrene-block-butadiene-block-styrene) usually abbreviated as SBS. Kraton D (SBS and SIS) and their selectively hydrogenated versions Kraton G (SEBS and SEPS) are the major Kraton polymer structures. The microstructure of SBS consists of domains of polystyrene arranged regularly in a matrix of polybutadiene, as shown in the TEM micrograph. The picture was obtained on a thin film of polymer cast onto mercury from solution, and then stained with osmium tetroxide

Osmium tetroxide (also osmium(VIII) oxide) is the chemical compound with the formula OsO4. The compound is noteworthy for its many uses, despite its toxicity and the rarity of osmium. It also has a number of unusual properties, one being that the ...

.

The glass transition temperature

The glass–liquid transition, or glass transition, is the gradual and reversible transition in amorphous materials (or in amorphous regions within semicrystalline materials) from a hard and relatively brittle "glassy" state into a viscous or rub ...

(Tg) of the polybutadiene blocks is typically −90 °C and Tg of the polystyrene blocks is +100 °C. So, at any temperature between about −90 °C and +100 °C Kraton SBS will act as a physically crosslinked elastomer

An elastomer is a polymer with viscoelasticity (i.e. both viscosity and elasticity) and with weak intermolecular forces, generally low Young's modulus (E) and high failure strain compared with other materials. The term, a portmanteau of ''ela ...

. If Kraton polymers are heated substantially above the Tg of the styrene-derived blocks, that is, above about 100 °C, like 170 °C the physical cross-links change from rigid glass

Glass is an amorphous (non-crystalline solid, non-crystalline) solid. Because it is often transparency and translucency, transparent and chemically inert, glass has found widespread practical, technological, and decorative use in window pane ...

y regions to flowable melt regions and the entire material flows and therefore can be cast, molded, or extruded into any desired form. On cooling, this new form resumes its elastomeric character. This is the reason such a material is called a thermoplastic elastomer

Thermoplastic elastomers (TPE), sometimes referred to as thermoplastic rubbers (TPR), are a class of copolymers or a physical mix of polymers (usually a plastic and a rubber) that consist of materials with both thermoplastic and elastomeric prop ...

(TPE). The polystyrene blocks form domains of nanometre

330px, Different lengths as in respect to the Molecule">molecular scale.

The nanometre (international spelling as used by the International Bureau of Weights and Measures; SI symbol: nm), or nanometer (American spelling), is a unit of length ...

size in the microstructure, and they stabilize the form of the molded material. Depending on the rubber-to-polystyrene ratio in the material, the polystyrene domains can be spherical or form cylinders or lamellae. The hydrogenated Kraton polymers named Kraton G exhibit improved resistance to temperature (processing at 200–230 °C is common), to oxidation, and to UV. SEBS and SEPS due to their polyolefinic rubber nature present excellent compatibility with polyolefins and paraffinic oils.

Applications

Kraton polymers are always used in blends with various other ingredients like paraffinic oils, polyolefins, polystyrene, bitumen, tackifying resins, and fillers to provide a very large range of end-use products ranging from hot melt adhesives to impact-modified transparent polypropylene bins, from medical TPE compounds to modified bitumen roofing felts or from oil gel toys (including sex toys) to elastic attachments in diapers.

It can make

Kraton polymers are always used in blends with various other ingredients like paraffinic oils, polyolefins, polystyrene, bitumen, tackifying resins, and fillers to provide a very large range of end-use products ranging from hot melt adhesives to impact-modified transparent polypropylene bins, from medical TPE compounds to modified bitumen roofing felts or from oil gel toys (including sex toys) to elastic attachments in diapers.

It can make asphalt

Asphalt most often refers to:

* Bitumen, also known as "liquid asphalt cement" or simply "asphalt", a viscous form of petroleum mainly used as a binder in asphalt concrete

* Asphalt concrete, a mixture of bitumen with coarse and fine aggregates, u ...

flexible, which is necessary if the asphalt is to be used to coat a surface that is below grade or for highly demanding paving applications like F1 racing tracks.

Kraton-based compounds are also used in non-slip knife handles.

The earliest commercial components using Kraton G (thermoplastic rubber) in the automobile industry were in 1970s. The implementation of U.S. requirements for automobile bumpers to absorb impacts with no damage to the car's safety equipment lead to the first successful commercial automotive application of specialized flexible polymers as fascia for the 1974 AMC Matador

The AMC Matador is a series of mid- and full-size automobiles produced by American Motors Corporation (AMC) from 1971 through 1978 model years. Initially positioned as a mid-size family car, the Matador spanned two distinct generations: the fir ...

.

American Motors Corporation

American Motors Corporation (AMC; commonly referred to as American Motors) was an American automobile manufacturing company formed by the mergers and acquisitions, merger of Nash-Kelvinator Corporation and Hudson Motor Car Company on May 1, 19 ...

(AMC) also used this polymer plastic on the AMC Eagle

The AMC Eagle is a compact four-wheel drive passenger vehicle manufactured and marketed in a single generation by American Motors Corporation (AMC) for model years 1980 through 1987 and continued by Chrysler, Chrysler Corporation following it ...

for the color matched flexible wheel arch flares that flowed into rocker panel extensions. This was needed because of the Eagle's 2-inch wider track compared to the AMC Concord

The AMC Concord is a compact car manufactured and marketed by the American Motors Corporation for model years 1978 through 1983. The Concord was essentially a revision of the AMC Hornet that was discontinued after 1977, but better equipped, qu ...

platform on which the AWD cars were based on. The Eagle's Kraton bodywork was lightweight, flexible, and did not crack in cold weather as is typical of fiberglass automobile body components.

Some grades of Kraton can also be dissolved into hydrocarbon oils to create "shear thinning" grease-type products that are used in the manufacture of telecommunications cables containing optical fibers.

References

* * {{Authority control Polymers Copolymers Brand name materials