Ironmaster on:

[Wikipedia]

[Google]

[Amazon]

An ironmaster is the manager, and usually owner, of a

W Van Leer's children all joined the iron business as well.

W Van Leer's children all joined the iron business as well.

Lowthian Bell (1816–1904) was, like Abraham Darby, the forceful patriarch of an ironmaking dynasty. Both his son Hugh Bell and his grandson Maurice Bell were directors of the Bell iron and steel company. His father, Thomas Bell, was a founder of Losh, Wilson and Bell, an iron and alkali company. The firm had works at Walker, near

Lowthian Bell (1816–1904) was, like Abraham Darby, the forceful patriarch of an ironmaking dynasty. Both his son Hugh Bell and his grandson Maurice Bell were directors of the Bell iron and steel company. His father, Thomas Bell, was a founder of Losh, Wilson and Bell, an iron and alkali company. The firm had works at Walker, near

forge

A forge is a type of hearth used for heating metals, or the workplace (smithy) where such a hearth is located. The forge is used by the smith to heat a piece of metal to a temperature at which it becomes easier to shape by forging, or to the ...

or blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure.

In a ...

for the processing of iron. It is a term mainly associated with the period of the Industrial Revolution

The Industrial Revolution, sometimes divided into the First Industrial Revolution and Second Industrial Revolution, was a transitional period of the global economy toward more widespread, efficient and stable manufacturing processes, succee ...

, especially in Great Britain.

The ironmaster was usually a large-scale entrepreneur and thus an important member of a community. He would have a large country house or mansion as his residence. The organization of operations surrounding the smelting

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron-making, iron, copper extraction, copper ...

, refining

Refining is the process of purification of a (1) substance or a (2) form. The term is usually used of a natural resource that is almost in a usable form, but which is more useful in its pure form. For instance, most types of natural petroleum w ...

, and casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or ...

of iron was labour-intensive, and so there would be numerous workers reliant on the furnace works.

There were ironmasters (possibly not called such) from the 17th century onward, but they became more prominent with the great expansion in the British iron industry during the Industrial Revolution.

17th-century ironmasters (examples)

An early ironmaster was John Winter (about 1600–1676) who owned substantial holdings in theForest of Dean

The Forest of Dean is a geographical, historical and cultural region in the western part of the Counties of England, county of Gloucestershire, England. It forms a roughly triangle, triangular plateau bounded by the River Wye to the west and no ...

. During the English Civil War

The English Civil War or Great Rebellion was a series of civil wars and political machinations between Cavaliers, Royalists and Roundhead, Parliamentarians in the Kingdom of England from 1642 to 1651. Part of the wider 1639 to 1653 Wars of th ...

he cast cannons for Charles I. Following the Restoration, Winter developed his interest in the iron industry, and experimented with a new type of coking oven. This was a precursor to the later work of Abraham Darby I

Abraham Darby, in his later life called Abraham Darby the Elder, now sometimes known for convenience as Abraham Darby I (14 April 1677 – 5 May 1717, the first and best known of Abraham Darby (disambiguation), several men of that name), was ...

who successfully used coke to smelt iron.

18th-century ironmasters (examples)

Abraham Darby

Three successive generations of the same family all bearing the name Abraham Darby are renowned for their contributions to the development of the English iron industry. Their works atCoalbrookdale

Coalbrookdale is a town in the Ironbridge Gorge and the Telford and Wrekin borough of Shropshire, England, containing a settlement of great significance in the history of iron ore smelting. It lies within the civil parish called The Gorge, Shro ...

in Shropshire nurtured the start of improvements in metallurgy

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys.

Metallurgy encompasses both the ...

that allowed large-scale production of the iron that made the development of steam engine

A steam engine is a heat engine that performs Work (physics), mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a Cylinder (locomotive), cyl ...

s and railways possible, although their most notable innovation was The Iron Bridge

The Iron Bridge is a cast iron arch bridge that crosses the River Severn in Shropshire, England. Opened in 1781, it was the first major bridge in the world to be made of cast iron. Its success inspired the widespread use of cast iron as a str ...

.

John Wilkinson

One of the best-known ironmasters of the early part of the industrial revolution was John Wilkinson (1728–1808), who was considered to have "iron madness", extending even to makingcast iron

Cast iron is a class of iron–carbon alloys with a carbon content of more than 2% and silicon content around 1–3%. Its usefulness derives from its relatively low melting temperature. The alloying elements determine the form in which its car ...

coffins. Wilkinson's patented method for boring iron cylinders was first used to create cannons, but later provided the precision needed to create James Watt

James Watt (; 30 January 1736 (19 January 1736 OS) – 25 August 1819) was a Scottish inventor, mechanical engineer, and chemist who improved on Thomas Newcomen's 1712 Newcomen steam engine with his Watt steam engine in 1776, which was f ...

's first steam engines.

Samuel Van Leer

Samuel Van Leer

Captain Samuel Van Leer (January 7, 1747 – October 15, 1825) was a military officer from Pennsylvania who served as a captain in the Continental Army during the American Revolutionary War and as a lieutenant in the Chester County Light Horse Vo ...

was a well-known ironmaster and a United States Army officer during the American Revolutionary War

The American Revolutionary War (April 19, 1775 – September 3, 1783), also known as the Revolutionary War or American War of Independence, was the armed conflict that comprised the final eight years of the broader American Revolution, in which Am ...

. He started a military career with enthusiasm with his neighbor General Anthony Wayne

Anthony Wayne (January 1, 1745 – December 15, 1796) was an American soldier, officer, statesman, and a Founding Father of the United States. He adopted a military career at the outset of the American Revolutionary War, where his military expl ...

in 1775. His furnace, Reading Furnace in Pennsylvania, supplied cannon and cannonballs for the Continental Army

The Continental Army was the army of the United Colonies representing the Thirteen Colonies and later the United States during the American Revolutionary War. It was formed on June 14, 1775, by a resolution passed by the Second Continental Co ...

. Van Leer's furnace was a center of colonial ironmaking and is associated with the introduction of the Franklin Stove

The Franklin stove is a metal-lined fireplace named after Benjamin Franklin, who invented it in 1742. It had a hollow baffle near the rear (to transfer more heat from the fire to a room's air) and relied on an "inverted siphon" to draw the fir ...

, and the retreat of George Washington

George Washington (, 1799) was a Founding Fathers of the United States, Founding Father and the first president of the United States, serving from 1789 to 1797. As commander of the Continental Army, Washington led Patriot (American Revoluti ...

's army following its defeat at the Battle of Brandywine

The Battle of Brandywine, also known as the Battle of Brandywine Creek, was fought between the American Continental Army of General George Washington and the British Army of General Sir William Howe on September 11, 1777, as part of the Am ...

, where they came for musket repairs. The location is listed as a temporary George Washington Headquarter.19th-century ironmasters (examples)

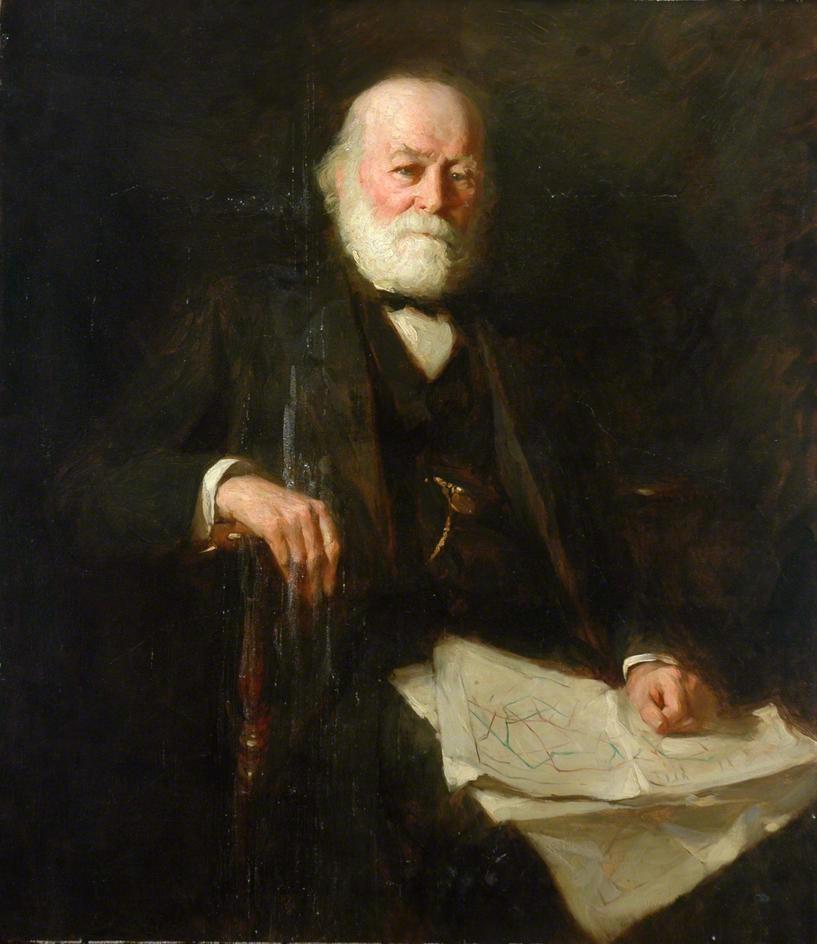

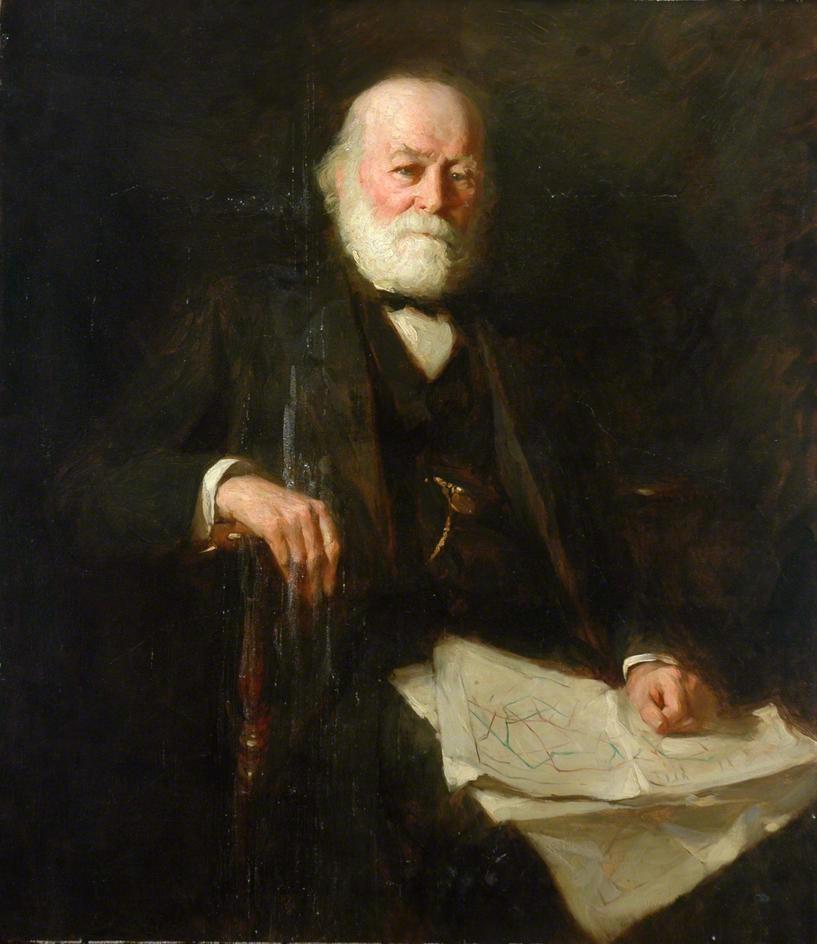

Lowthian Bell

Lowthian Bell (1816–1904) was, like Abraham Darby, the forceful patriarch of an ironmaking dynasty. Both his son Hugh Bell and his grandson Maurice Bell were directors of the Bell iron and steel company. His father, Thomas Bell, was a founder of Losh, Wilson and Bell, an iron and alkali company. The firm had works at Walker, near

Lowthian Bell (1816–1904) was, like Abraham Darby, the forceful patriarch of an ironmaking dynasty. Both his son Hugh Bell and his grandson Maurice Bell were directors of the Bell iron and steel company. His father, Thomas Bell, was a founder of Losh, Wilson and Bell, an iron and alkali company. The firm had works at Walker, near Newcastle upon Tyne

Newcastle upon Tyne, or simply Newcastle ( , Received Pronunciation, RP: ), is a City status in the United Kingdom, cathedral city and metropolitan borough in Tyne and Wear, England. It is England's northernmost metropolitan borough, located o ...

, and at Port Clarence, Middlesbrough

Middlesbrough ( ), colloquially known as Boro, is a port town in the Borough of Middlesbrough, North Yorkshire, England. Lying to the south of the River Tees, Middlesbrough forms part of the Teesside Built up area, built-up area and the Tees Va ...

, contributing largely to the growth of those towns and of the economy of the northeast of England. Bell accumulated a large fortune, with mansions including Washington New Hall, Rounton Grange near Northallerton

Northallerton ( ) is a market town and civil parish in North Yorkshire, England. It is near the River Wiske in the Vale of Mowbray and had a population of 16,832 in 2011. Northallerton is an administrative centre for York and North Yorkshire ...

, and the mediaeval Mount Grace Priory near Osmotherley.

Henry Bolckow and John Vaughan

Henry Bolckow

Henry William Ferdinand Bolckow, originally Heinrich Wilhelm Ferdinand Bölckow, (8 December 1806 – 18 June 1878) was a Victorian industrialist and Member of Parliament, acknowledged as being one of the founders of modern Middlesbrough.

In a ...

(1806–1878) and John Vaughan (1799–1868) were lifelong business partners, friends, and brothers-in-law. They established what became the largest of all Victorian era

In the history of the United Kingdom and the British Empire, the Victorian era was the reign of Queen Victoria, from 20 June 1837 until her death on 22 January 1901. Slightly different definitions are sometimes used. The era followed the ...

iron and steel companies, Bolckow Vaughan

Bolckow, Vaughan & Co., Ltd was an English steelmaking, ironmaking and mining company founded in 1864, based on the partnership since 1840 of its two founders, Henry Bolckow and John Vaughan (ironmaster), John Vaughan. The firm drove the dramat ...

, in Middlesbrough. Bolckow brought financial acumen, and Vaughan brought ironmaking and engineering expertise. The two men trusted each other implicitly and "never interfered in the slightest degree with each other's work. Mr. Bolckow had the entire management of the financial department, while Mr. Vaughan as worthily controlled the practical work of the establishment." At its peak the firm was the largest steel producer in Britain, possibly in the world.

Andrew Handyside

Andrew Handyside (1805–1887) was born in Edinburgh and set up works in Derby where he made ornamental items, bridges and pillar boxes, many of which survive today.Samuel Richards

Samuel Richards (1769–1842) was born in Philadelphia to William Richards, the manager of the Batsto Iron Works beginning in 1784. Samuel Richards was heavily involved with the early 19th century iron industry in southernNew Jersey

New Jersey is a U.S. state, state located in both the Mid-Atlantic States, Mid-Atlantic and Northeastern United States, Northeastern regions of the United States. Located at the geographic hub of the urban area, heavily urbanized Northeas ...

. His most notable enterprise was the management of the iron works at Atsion, New Jersey from 1824 until his death in 1842. He was also involved with Martha Furnace, and Weymouth Furnace.

See also

*Pig iron

Pig iron, also known as crude iron, is an intermediate good used by the iron industry in the production of steel. It is developed by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with si ...

* Wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.05%) in contrast to that of cast iron (2.1% to 4.5%), or 0.25 for low carbon "mild" steel. Wrought iron is manufactured by heating and melting high carbon cast iron in an ...

References

{{Use dmy dates, date=October 2019 Industrial Revolution History of metallurgy Metalworking occupations