Infrared Non-destructive Testing Of Materials on:

[Wikipedia]

[Google]

[Amazon]

Infrared (IR; sometimes called infrared light) is

Infrared (IR; sometimes called infrared light) is

A third scheme divides up the band based on the response of various detectors:Miller, ''Principles of Infrared Technology'' (Van Nostrand Reinhold, 1992), and Miller and Friedman, ''Photonic Rules of Thumb'', 2004.

* Near-infrared: from 0.7 to 1.0 μm (from the approximate end of the response of the human eye to that of silicon).

* Short-wave infrared: 1.0 to 3 μm (from the cut-off of silicon to that of the MWIR atmospheric window).

A third scheme divides up the band based on the response of various detectors:Miller, ''Principles of Infrared Technology'' (Van Nostrand Reinhold, 1992), and Miller and Friedman, ''Photonic Rules of Thumb'', 2004.

* Near-infrared: from 0.7 to 1.0 μm (from the approximate end of the response of the human eye to that of silicon).

* Short-wave infrared: 1.0 to 3 μm (from the cut-off of silicon to that of the MWIR atmospheric window).

Infrared radiation is popularly known as "heat radiation", but light and electromagnetic waves of any frequency will heat surfaces that absorb them. Infrared light from the Sun accounts for 49% of the heating of Earth, with the rest being caused by visible light that is absorbed then re-radiated at longer wavelengths. Visible light or ultraviolet-emitting lasers can char paper and incandescently hot objects emit visible radiation. Objects at room

Infrared radiation is popularly known as "heat radiation", but light and electromagnetic waves of any frequency will heat surfaces that absorb them. Infrared light from the Sun accounts for 49% of the heating of Earth, with the rest being caused by visible light that is absorbed then re-radiated at longer wavelengths. Visible light or ultraviolet-emitting lasers can char paper and incandescently hot objects emit visible radiation. Objects at room

Infrared is used in night vision equipment when there is insufficient visible light to see.

Infrared is used in night vision equipment when there is insufficient visible light to see.

Infrared radiation can be used to remotely determine the temperature of objects (if the emissivity is known). This is termed thermography, or in the case of very hot objects in the NIR or visible it is termed

Infrared radiation can be used to remotely determine the temperature of objects (if the emissivity is known). This is termed thermography, or in the case of very hot objects in the NIR or visible it is termed

World First Thermal Hyperspectral Camera for Unmanned Aerial Vehicles

.

In

In

Infrared tracking, also known as infrared homing, refers to a passive missile guidance system, which uses the

Infrared tracking, also known as infrared homing, refers to a passive missile guidance system, which uses the

Infrared radiation can be used as a deliberate heating source. For example, it is used in

Infrared radiation can be used as a deliberate heating source. For example, it is used in

In the field of climatology, atmospheric infrared radiation is monitored to detect trends in the energy exchange between the Earth and the atmosphere. These trends provide information on long-term changes in Earth's climate. It is one of the primary parameters studied in research into

In the field of climatology, atmospheric infrared radiation is monitored to detect trends in the energy exchange between the Earth and the atmosphere. These trends provide information on long-term changes in Earth's climate. It is one of the primary parameters studied in research into

Infrared reflectography can be applied to paintings to reveal underlying layers in a non-destructive manner, in particular the artist's underdrawing or outline drawn as a guide. Art conservators use the technique to examine how the visible layers of paint differ from the underdrawing or layers in between (such alterations are called pentimenti when made by the original artist). This is very useful information in deciding whether a painting is the prime version by the original artist or a copy, and whether it has been altered by over-enthusiastic restoration work. In general, the more pentimenti, the more likely a painting is to be the prime version. It also gives useful insights into working practices. Reflectography often reveals the artist's use of carbon black, which shows up well in reflectograms, as long as it has not also been used in the ground underlying the whole painting. Infrared reflectography can be realized by modified commercial digital cameras in the NIR spectral region or by dedicated instruments in the SWIR spectral region. The recent extension of reflectography into the MWIR spectral region has proved capable of detecting subtle differences in surface materials.

Finally, NIR reflectography can be performed with good results using smartphone cameras .

Recent progress in the design of infrared-sensitive cameras makes it possible to discover and depict not only underpaintings and pentimenti, but entire paintings that were later overpainted by the artist. Notable examples are Picasso's ''Woman Ironing'' and ''Blue Room (Picasso), Blue Room'', where in both cases a portrait of a man has been made visible under the painting as it is known today.

Similar uses of infrared are made by conservators and scientists on various types of objects, especially very old written documents such as the Dead Sea Scrolls, the Roman works in the Villa of the Papyri, and the Silk Road texts found in the Dunhuang Caves. Carbon black used in ink can show up extremely well.

Infrared reflectography can be applied to paintings to reveal underlying layers in a non-destructive manner, in particular the artist's underdrawing or outline drawn as a guide. Art conservators use the technique to examine how the visible layers of paint differ from the underdrawing or layers in between (such alterations are called pentimenti when made by the original artist). This is very useful information in deciding whether a painting is the prime version by the original artist or a copy, and whether it has been altered by over-enthusiastic restoration work. In general, the more pentimenti, the more likely a painting is to be the prime version. It also gives useful insights into working practices. Reflectography often reveals the artist's use of carbon black, which shows up well in reflectograms, as long as it has not also been used in the ground underlying the whole painting. Infrared reflectography can be realized by modified commercial digital cameras in the NIR spectral region or by dedicated instruments in the SWIR spectral region. The recent extension of reflectography into the MWIR spectral region has proved capable of detecting subtle differences in surface materials.

Finally, NIR reflectography can be performed with good results using smartphone cameras .

Recent progress in the design of infrared-sensitive cameras makes it possible to discover and depict not only underpaintings and pentimenti, but entire paintings that were later overpainted by the artist. Notable examples are Picasso's ''Woman Ironing'' and ''Blue Room (Picasso), Blue Room'', where in both cases a portrait of a man has been made visible under the painting as it is known today.

Similar uses of infrared are made by conservators and scientists on various types of objects, especially very old written documents such as the Dead Sea Scrolls, the Roman works in the Villa of the Papyri, and the Silk Road texts found in the Dunhuang Caves. Carbon black used in ink can show up extremely well.

* 1830: Leopoldo Nobili made the first thermopile IR detector.

* 1840: John Herschel produces the first thermal image, called a thermogram.

* 1860: Gustav Kirchhoff formulated the Kirchhoff's law of thermal radiation, blackbody theorem .

* 1873: Willoughby Smith discovered the photoconductivity of selenium.

* 1878: Samuel Pierpont Langley invents the first bolometer, a device which is able to measure small temperature fluctuations, and thus the power of far infrared sources.

* 1879: Stefan–Boltzmann law formulated empirically that the power radiated by a blackbody is proportional to ''T''4.

* 1880s and 1890s: Lord Rayleigh and Wilhelm Wien solved part of the blackbody equation, but both solutions diverged in parts of the electromagnetic spectrum. This problem was called the "ultraviolet catastrophe and infrared catastrophe".

* 1892: Willem Henri Julius published infrared spectra of 20 organic compounds measured with a bolometer in units of angular displacement.

* 1901: Max Planck published the Planck's law, blackbody equation and theorem. He solved the problem by quantizing the allowable energy transitions.

* 1905: Albert Einstein developed the theory of the photoelectric effect.

* 1905–1908: William Coblentz published infrared spectra in units of wavelength (micrometers) for several chemical compounds in ''Investigations of Infra-Red Spectra''.

* 1917: Theodore Case developed the thallous sulfide detector, which helped produce the first infrared search and track device able to detect aircraft at a range of one mile (1.6 km).

* 1935: Lead salts – early missile guidance in World War II.

* 1938: Yeou Ta predicted that the pyroelectric effect could be used to detect infrared radiation.

* 1945: The Zielgerät 1229 "Vampir" infrared weapon system was introduced as the first portable infrared device for military applications.

* 1952: Heinrich Welker grew synthetic InSb crystals.

* 1950s and 1960s: Nomenclature and radiometric units defined by Fred Nicodemenus, G. J. Zissis and R. Clark; Robert Clark Jones defined ''D''*.

* 1958: W. D. Lawson (Royal Radar Establishment in Malvern) discovered IR detection properties of Mercury cadmium telluride (HgCdTe).

* 1958: AIM-4 Falcon, Falcon and AIM-9 Sidewinder, Sidewinder missiles were developed using infrared technology.

* 1960s: Paul Kruse (engineer), Paul Kruse and his colleagues at Honeywell Research Center demonstrate the use of HgCdTe as an effective chemical compound, compound for infrared detection.

* 1962: J. Cooper demonstrated pyroelectric detection.

* 1964: W. G. Evans discovered infrared thermoreceptors in a pyrophile beetle.

* 1965: First IR handbook; first commercial imagers (Barnes, Agema (now part of FLIR Systems Inc.)); Richard Hudson (physicist), Richard Hudson's landmark text; F4 TRAM FLIR by Hughes Aircraft Company, Hughes; phenomenology pioneered by Fred Simmons (scientist), Fred Simmons and A. T. Stair; U.S. Army's night vision lab formed (now Night Vision and Electronic Sensors Directorate (NVESD)), and Rachets develops detection, recognition and identification modeling there.

* 1970: Willard Boyle and George E. Smith proposed CCD at Bell Labs for picture phone.

* 1973: Common module program started by NVESD.

* 1978: Infrared imaging astronomy came of age, observatories planned, NASA Infrared Telescope Facility, IRTF on Mauna Kea opened; 32 × 32 and 64 × 64 arrays produced using InSb, HgCdTe and other materials.

* 2013: On 14 February, researchers developed a neural implant that gives rats the ability to sense infrared light, which for the first time provides living creatures with new abilities, instead of simply replacing or augmenting existing abilities.

* 1830: Leopoldo Nobili made the first thermopile IR detector.

* 1840: John Herschel produces the first thermal image, called a thermogram.

* 1860: Gustav Kirchhoff formulated the Kirchhoff's law of thermal radiation, blackbody theorem .

* 1873: Willoughby Smith discovered the photoconductivity of selenium.

* 1878: Samuel Pierpont Langley invents the first bolometer, a device which is able to measure small temperature fluctuations, and thus the power of far infrared sources.

* 1879: Stefan–Boltzmann law formulated empirically that the power radiated by a blackbody is proportional to ''T''4.

* 1880s and 1890s: Lord Rayleigh and Wilhelm Wien solved part of the blackbody equation, but both solutions diverged in parts of the electromagnetic spectrum. This problem was called the "ultraviolet catastrophe and infrared catastrophe".

* 1892: Willem Henri Julius published infrared spectra of 20 organic compounds measured with a bolometer in units of angular displacement.

* 1901: Max Planck published the Planck's law, blackbody equation and theorem. He solved the problem by quantizing the allowable energy transitions.

* 1905: Albert Einstein developed the theory of the photoelectric effect.

* 1905–1908: William Coblentz published infrared spectra in units of wavelength (micrometers) for several chemical compounds in ''Investigations of Infra-Red Spectra''.

* 1917: Theodore Case developed the thallous sulfide detector, which helped produce the first infrared search and track device able to detect aircraft at a range of one mile (1.6 km).

* 1935: Lead salts – early missile guidance in World War II.

* 1938: Yeou Ta predicted that the pyroelectric effect could be used to detect infrared radiation.

* 1945: The Zielgerät 1229 "Vampir" infrared weapon system was introduced as the first portable infrared device for military applications.

* 1952: Heinrich Welker grew synthetic InSb crystals.

* 1950s and 1960s: Nomenclature and radiometric units defined by Fred Nicodemenus, G. J. Zissis and R. Clark; Robert Clark Jones defined ''D''*.

* 1958: W. D. Lawson (Royal Radar Establishment in Malvern) discovered IR detection properties of Mercury cadmium telluride (HgCdTe).

* 1958: AIM-4 Falcon, Falcon and AIM-9 Sidewinder, Sidewinder missiles were developed using infrared technology.

* 1960s: Paul Kruse (engineer), Paul Kruse and his colleagues at Honeywell Research Center demonstrate the use of HgCdTe as an effective chemical compound, compound for infrared detection.

* 1962: J. Cooper demonstrated pyroelectric detection.

* 1964: W. G. Evans discovered infrared thermoreceptors in a pyrophile beetle.

* 1965: First IR handbook; first commercial imagers (Barnes, Agema (now part of FLIR Systems Inc.)); Richard Hudson (physicist), Richard Hudson's landmark text; F4 TRAM FLIR by Hughes Aircraft Company, Hughes; phenomenology pioneered by Fred Simmons (scientist), Fred Simmons and A. T. Stair; U.S. Army's night vision lab formed (now Night Vision and Electronic Sensors Directorate (NVESD)), and Rachets develops detection, recognition and identification modeling there.

* 1970: Willard Boyle and George E. Smith proposed CCD at Bell Labs for picture phone.

* 1973: Common module program started by NVESD.

* 1978: Infrared imaging astronomy came of age, observatories planned, NASA Infrared Telescope Facility, IRTF on Mauna Kea opened; 32 × 32 and 64 × 64 arrays produced using InSb, HgCdTe and other materials.

* 2013: On 14 February, researchers developed a neural implant that gives rats the ability to sense infrared light, which for the first time provides living creatures with new abilities, instead of simply replacing or augmenting existing abilities.

Infrared: A Historical Perspective

(Omega Engineering)

Infrared Data Association

, a standards organization for infrared data interconnection

detailed explanation of infrared light. (NASA)

Herschel's original paper from 1800 announcing the discovery of infrared light

The thermographic's library

, collection of thermogram

Infrared reflectography in analysis of paintings

at ColourLex * Molly Faries

Techniques and Applications – Analytical Capabilities of Infrared Reflectography: An Art Historian s Perspective

, in Scientific Examination of Art: Modern Techniques in Conservation and Analysis, Sackler NAS Colloquium, 2005 {{Authority control Infrared, Electromagnetic spectrum

Infrared (IR; sometimes called infrared light) is

Infrared (IR; sometimes called infrared light) is electromagnetic radiation

In physics, electromagnetic radiation (EMR) is a self-propagating wave of the electromagnetic field that carries momentum and radiant energy through space. It encompasses a broad spectrum, classified by frequency or its inverse, wavelength ...

(EMR) with wavelength

In physics and mathematics, wavelength or spatial period of a wave or periodic function is the distance over which the wave's shape repeats.

In other words, it is the distance between consecutive corresponding points of the same ''phase (waves ...

s longer than that of visible light

Light, visible light, or visible radiation is electromagnetic radiation that can be perceived by the human eye. Visible light spans the visible spectrum and is usually defined as having wavelengths in the range of 400–700 nanometres (nm ...

but shorter than microwaves

Microwave is a form of electromagnetic radiation with wavelengths shorter than other radio waves but longer than infrared waves. Its wavelength ranges from about one meter to one millimeter, corresponding to frequencies between 300 MHz an ...

. The infrared spectral band

Spectral bands are regions of a given spectrum, having a specific range of wavelengths or frequencies. Most often, it refers to electromagnetic bands, regions of the electromagnetic spectrum.

More generally, spectral bands may also be means in ...

begins with the waves that are just longer than those of red

Red is the color at the long wavelength end of the visible spectrum of light, next to orange and opposite violet. It has a dominant wavelength of approximately 625–750 nanometres. It is a primary color in the RGB color model and a seconda ...

light (the longest waves in the visible spectrum

The visible spectrum is the spectral band, band of the electromagnetic spectrum that is visual perception, visible to the human eye. Electromagnetic radiation in this range of wavelengths is called ''visible light'' (or simply light).

The optica ...

), so IR is invisible to the human eye. IR is generally (according to ISO, CIE) understood to include wavelengths from around to . IR is commonly divided between longer-wavelength thermal IR, emitted from terrestrial sources, and shorter-wavelength IR or near-IR, part of the solar spectrum

Sunlight is the portion of the electromagnetic radiation which is emitted by the Sun (i.e. solar radiation) and received by the Earth, in particular the visible light perceptible to the human eye as well as invisible infrared (typically perc ...

. Longer IR wavelengths (30–100 μm) are sometimes included as part of the terahertz radiation

Terahertz radiation – also known as submillimeter radiation, terahertz waves, tremendously high frequency

(THF), T-rays, T-waves, T-light, T-lux or THz – consists of electromagnetic waves within the International Telecommunicat ...

band. Almost all black-body radiation

Black-body radiation is the thermal radiation, thermal electromagnetic radiation within, or surrounding, a body in thermodynamic equilibrium with its environment, emitted by a black body (an idealized opaque, non-reflective body). It has a specific ...

from objects near room temperature

Room temperature, colloquially, denotes the range of air temperatures most people find comfortable indoors while dressed in typical clothing. Comfortable temperatures can be extended beyond this range depending on humidity, air circulation, and ...

is in the IR band. As a form of EMR, IR carries energy

Energy () is the physical quantity, quantitative physical property, property that is transferred to a physical body, body or to a physical system, recognizable in the performance of Work (thermodynamics), work and in the form of heat and l ...

and momentum

In Newtonian mechanics, momentum (: momenta or momentums; more specifically linear momentum or translational momentum) is the product of the mass and velocity of an object. It is a vector quantity, possessing a magnitude and a direction. ...

, exerts radiation pressure

Radiation pressure (also known as light pressure) is mechanical pressure exerted upon a surface due to the exchange of momentum between the object and the electromagnetic field. This includes the momentum of light or electromagnetic radiation of ...

, and has properties corresponding to both those of a wave

In physics, mathematics, engineering, and related fields, a wave is a propagating dynamic disturbance (change from List of types of equilibrium, equilibrium) of one or more quantities. ''Periodic waves'' oscillate repeatedly about an equilibrium ...

and of a particle

In the physical sciences, a particle (or corpuscle in older texts) is a small localized object which can be described by several physical or chemical properties, such as volume, density, or mass.

They vary greatly in size or quantity, from s ...

, the photon

A photon () is an elementary particle that is a quantum of the electromagnetic field, including electromagnetic radiation such as light and radio waves, and the force carrier for the electromagnetic force. Photons are massless particles that can ...

.

It was long known that fires emit invisible heat

In thermodynamics, heat is energy in transfer between a thermodynamic system and its surroundings by such mechanisms as thermal conduction, electromagnetic radiation, and friction, which are microscopic in nature, involving sub-atomic, ato ...

; in 1681 the pioneering experimenter Edme Mariotte

Edme Mariotte (; ; c. 162012 May 1684) was a French physicist and priest (abbé). He is particularly well known for formulating Boyle's law independently of Robert Boyle. Mariotte is also credited with designing the first Newton's cradle.

Biog ...

showed that glass, though transparent to sunlight, obstructed radiant heat. In 1800 the astronomer Sir William Herschel

Frederick William Herschel ( ; ; 15 November 1738 – 25 August 1822) was a German-British astronomer and composer. He frequently collaborated with his younger sister and fellow astronomer Caroline Herschel. Born in the Electorate of Hanover ...

discovered that infrared radiation is a type of invisible radiation in the spectrum lower in energy than red light, by means of its effect on a thermometer

A thermometer is a device that measures temperature (the hotness or coldness of an object) or temperature gradient (the rates of change of temperature in space). A thermometer has two important elements: (1) a temperature sensor (e.g. the bulb ...

.Michael Rowan-Robinson (2013). ''Night Vision: Exploring the Infrared Universe''. Cambridge University Press. p. 23. . Slightly more than half of the energy from the Sun

The Sun is the star at the centre of the Solar System. It is a massive, nearly perfect sphere of hot plasma, heated to incandescence by nuclear fusion reactions in its core, radiating the energy from its surface mainly as visible light a ...

was eventually found, through Herschel's studies, to arrive on Earth

Earth is the third planet from the Sun and the only astronomical object known to Planetary habitability, harbor life. This is enabled by Earth being an ocean world, the only one in the Solar System sustaining liquid surface water. Almost all ...

in the form of infrared. The balance between absorbed and emitted infrared radiation has an important effect on Earth's climate

Climate is the long-term weather pattern in a region, typically averaged over 30 years. More rigorously, it is the mean and variability of meteorological variables over a time spanning from months to millions of years. Some of the meteoro ...

.

Infrared radiation is emitted or absorbed by molecule

A molecule is a group of two or more atoms that are held together by Force, attractive forces known as chemical bonds; depending on context, the term may or may not include ions that satisfy this criterion. In quantum physics, organic chemi ...

s when changing rotational-vibrational movements. It excites vibration

Vibration () is a mechanical phenomenon whereby oscillations occur about an equilibrium point. Vibration may be deterministic if the oscillations can be characterised precisely (e.g. the periodic motion of a pendulum), or random if the os ...

al modes in a molecule through a change in the dipole moment, making it a useful frequency range for study of these energy states for molecules of the proper symmetry. Infrared spectroscopy

Infrared spectroscopy (IR spectroscopy or vibrational spectroscopy) is the measurement of the interaction of infrared radiation with matter by absorption, emission, or reflection. It is used to study and identify chemical substances or functio ...

examines absorption and transmission of photon

A photon () is an elementary particle that is a quantum of the electromagnetic field, including electromagnetic radiation such as light and radio waves, and the force carrier for the electromagnetic force. Photons are massless particles that can ...

s in the infrared range.

Infrared radiation is used in industrial, scientific, military, commercial, and medical applications. Night-vision devices using active near-infrared illumination allow people or animals to be observed without the observer being detected. Infrared astronomy

Infrared astronomy is a sub-discipline of astronomy which specializes in the astronomical observation, observation and analysis of astronomical objects using infrared (IR) radiation. The wavelength of infrared light ranges from 0.75 to 300 microm ...

uses sensor-equipped telescope

A telescope is a device used to observe distant objects by their emission, Absorption (electromagnetic radiation), absorption, or Reflection (physics), reflection of electromagnetic radiation. Originally, it was an optical instrument using len ...

s to penetrate dusty regions of space such as molecular cloud

A molecular cloud—sometimes called a stellar nursery if star formation is occurring within—is a type of interstellar cloud of which the density and size permit absorption nebulae, the formation of molecules (most commonly molecular hydrogen, ...

s, to detect objects such as planet

A planet is a large, Hydrostatic equilibrium, rounded Astronomical object, astronomical body that is generally required to be in orbit around a star, stellar remnant, or brown dwarf, and is not one itself. The Solar System has eight planets b ...

s, and to view highly red-shift

In physics, a redshift is an increase in the wavelength, and corresponding decrease in the frequency and photon energy, of electromagnetic radiation (such as light). The opposite change, a decrease in wavelength and increase in frequency and e ...

ed objects from the early days of the universe

The universe is all of space and time and their contents. It comprises all of existence, any fundamental interaction, physical process and physical constant, and therefore all forms of matter and energy, and the structures they form, from s ...

. Infrared thermal-imaging cameras are used to detect heat loss in insulated systems, to observe changing blood flow in the skin, to assist firefighting, and to detect the overheating of electrical components. Military and civilian applications include target acquisition

Target acquisition is the detection and identification of the location of a target in sufficient detail to permit the effective employment of lethal and non-lethal means. The term is used for a broad area of applications.

A "target" here is an e ...

, surveillance

Surveillance is the monitoring of behavior, many activities, or information for the purpose of information gathering, influencing, managing, or directing. This can include observation from a distance by means of electronic equipment, such as ...

, night vision

Night vision is the ability to see in low-light conditions, either naturally with scotopic vision or through a night-vision device. Night vision requires both sufficient spectral range and sufficient intensity range. Humans have poor night v ...

, homing, and tracking. Humans at normal body temperature radiate chiefly at wavelengths around 10 μm. Non-military uses include thermal efficiency

In thermodynamics, the thermal efficiency (\eta_) is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, steam turbine, steam engine, boiler, furnace, refrigerator, ACs etc.

For ...

analysis, environmental monitoring, industrial facility inspections, detection of grow-ops

Cultivation of cannabis is the production of cannabis infructescences ("buds" or "leaves"). Cultivation techniques for other purposes (such as hemp production) differ.

In the United States, all cannabis products in a regulated market must be ...

, remote temperature sensing, short-range wireless communication

Wireless communication (or just wireless, when the context allows) is the transfer of information (''telecommunication'') between two or more points without the use of an electrical conductor, optical fiber or other continuous guided med ...

, spectroscopy

Spectroscopy is the field of study that measures and interprets electromagnetic spectra. In narrower contexts, spectroscopy is the precise study of color as generalized from visible light to all bands of the electromagnetic spectrum.

Spectro ...

, and weather forecasting

Weather forecasting or weather prediction is the application of science and technology forecasting, to predict the conditions of the Earth's atmosphere, atmosphere for a given location and time. People have attempted to predict the weather info ...

.

Definition and relationship to the electromagnetic spectrum

There is no universally accepted definition of the range of infrared radiation. Typically, it is taken to extend from the nominal red edge of the visible spectrum at 780 nm to 1 mm. This range of wavelengths corresponds to afrequency

Frequency is the number of occurrences of a repeating event per unit of time. Frequency is an important parameter used in science and engineering to specify the rate of oscillatory and vibratory phenomena, such as mechanical vibrations, audio ...

range of approximately 430 THz down to 300 GHz. Beyond infrared is the microwave portion of the electromagnetic spectrum

The electromagnetic spectrum is the full range of electromagnetic radiation, organized by frequency or wavelength. The spectrum is divided into separate bands, with different names for the electromagnetic waves within each band. From low to high ...

. Increasingly, terahertz radiation is counted as part of the microwave band, not infrared, moving the band edge of infrared to 0.1 mm (3 THz).

Nature

Sunlight

Sunlight is the portion of the electromagnetic radiation which is emitted by the Sun (i.e. solar radiation) and received by the Earth, in particular the visible spectrum, visible light perceptible to the human eye as well as invisible infrare ...

, at an effective temperature of 5,780 K (5,510 °C, 9,940 °F), is composed of near-thermal-spectrum radiation that is slightly more than half infrared. At zenith

The zenith (, ) is the imaginary point on the celestial sphere directly "above" a particular location. "Above" means in the vertical direction (Vertical and horizontal, plumb line) opposite to the gravity direction at that location (nadir). The z ...

, sunlight provides an irradiance

In radiometry, irradiance is the radiant flux ''received'' by a ''surface'' per unit area. The SI unit of irradiance is the watt per square metre (symbol W⋅m−2 or W/m2). The CGS unit erg per square centimetre per second (erg⋅cm−2⋅s−1) ...

of just over 1 kW per square meter at sea level. Of this energy, 527 W is infrared radiation, 445 W is visible light, and 32 W is ultraviolet

Ultraviolet radiation, also known as simply UV, is electromagnetic radiation of wavelengths of 10–400 nanometers, shorter than that of visible light, but longer than X-rays. UV radiation is present in sunlight and constitutes about 10% of ...

radiation. Nearly all the infrared radiation in sunlight is near infrared, shorter than 4 μm.

On the surface of Earth, at far lower temperatures than the surface of the Sun, some thermal radiation consists of infrared in the mid-infrared region, much longer than in sunlight. Black-body, or thermal, radiation is continuous: it radiates at all wavelengths. Of these natural thermal radiation processes, only lightning and natural fires are hot enough to produce much visible energy, and fires produce far more infrared than visible-light energy.

Regions

In general, objects emit infrared radiation across a spectrum of wavelengths, but sometimes only a limited region of the spectrum is of interest because sensors usually collect radiation only within a specific bandwidth. Thermal infrared radiation also has a maximum emission wavelength, which is inversely proportional to the absolute temperature of object, in accordance withWien's displacement law

In physics, Wien's displacement law states that the black-body radiation curve for different temperatures will peak at different wavelengths that are inversely proportional to the temperature. The shift of that peak is a direct consequence of ...

. The infrared band is often subdivided into smaller sections, although how the IR spectrum is thereby divided varies between different areas in which IR is employed.

Visible limit

Infrared radiation is generally considered to begin with wavelengths longer than visible by the human eye. There is no hard wavelength limit to what is visible, as the eye's sensitivity decreases rapidly but smoothly, for wavelengths exceeding about 700 nm. Therefore wavelengths just longer than that can be seen if they are sufficiently bright, though they may still be classified as infrared according to usual definitions. Light from a near-IR laser may thus appear dim red and can present a hazard since it may actually carry a large amount of energy. Even IR at wavelengths up to 1,050 nm from pulsed lasers can be seen by humans under certain conditions.Commonly used subdivision scheme

A commonly used subdivision scheme is: NIR and SWIR together is sometimes called "reflected infrared", whereas MWIR and LWIR is sometimes referred to as "thermal infrared".CIE division scheme

TheInternational Commission on Illumination

The International Commission on Illumination (usually abbreviated CIE for its French name Commission internationale de l'éclairage) is the international authority on light, illumination, colour, and colour spaces. It was established in 1913 a ...

(CIE) recommended the division of infrared radiation into the following three bands:

ISO 20473 scheme

ISO

The International Organization for Standardization (ISO ; ; ) is an independent, non-governmental, international standard development organization composed of representatives from the national standards organizations of member countries.

Me ...

20473 specifies the following scheme:

Astronomy division scheme

Astronomers typically divide the infrared spectrum as follows: These divisions are not precise and can vary depending on the publication. The three regions are used for observation of different temperature ranges, and hence different environments in space. The most common photometric system used in astronomy allocates capital letters to different spectral regions according to filters used; I, J, H, and K cover the near-infrared wavelengths; L, M, N, and Q refer to the mid-infrared region. These letters are commonly understood in reference to atmospheric windows and appear, for instance, in the titles of many papers.Sensor response division scheme

InGaAs

Indium gallium arsenide (InGaAs) (alternatively gallium indium arsenide, GaInAs) is a ternary alloy (chemical compound) of indium arsenide (InAs) and gallium arsenide (GaAs). Indium and gallium are group III elements of the periodic table while ...

covers to about 1.8 μm; the less sensitive lead salts cover this region. Cryogenically cooled MCT detectors can cover the region of 1.0–2.5μm.

* Mid-wave infrared: 3 to 5 μm (defined by the atmospheric window and covered by indium antimonide

Indium antimonide (InSb) is a crystalline compound made from the elements indium (In) and antimony (Sb). It is a narrow- gap semiconductor material from the III- V group used in infrared detectors, including thermal imaging cameras, FLIR sy ...

, InSb and mercury cadmium telluride

Hg1−''x''Cd''x''Te or mercury cadmium telluride (also cadmium mercury telluride, MCT, MerCad Telluride, MerCadTel, MerCaT or CMT) is a chemical compound of cadmium telluride (CdTe) and mercury telluride (HgTe) with a tunable bandgap spanning th ...

, HgCdTe, and partially by lead selenide

Lead selenide (PbSe), or lead(II) selenide, a selenide of lead, is a semiconductor material. It forms cubic crystals of the NaCl structure; it has a direct bandgap of 0.27 eV at room temperature. (Note that incorrectly identifies PbSe and ...

, PbSe).

* Long-wave infrared: 8 to 12, or 7 to 14 μm (this is the atmospheric window covered by HgCdTe and microbolometer

A microbolometer is a specific type of bolometer used as a detector in a thermal camera. Infrared radiation with wavelengths between 7.5–14 μm strikes the detector material, heating it, and thus changing its electrical resistance. This resista ...

s).

* Very-long wave infrared (VLWIR) (12 to about 30 μm, covered by doped silicon).

Near-infrared is the region closest in wavelength to the radiation detectable by the human eye. mid- and far-infrared are progressively further from the visible spectrum. Other definitions follow different physical mechanisms (emission peaks, vs. bands, water absorption) and the newest follow technical reasons (the common silicon

Silicon is a chemical element; it has symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic lustre, and is a tetravalent metalloid (sometimes considered a non-metal) and semiconductor. It is a membe ...

detectors are sensitive to about 1,050 nm, while InGaAs

Indium gallium arsenide (InGaAs) (alternatively gallium indium arsenide, GaInAs) is a ternary alloy (chemical compound) of indium arsenide (InAs) and gallium arsenide (GaAs). Indium and gallium are group III elements of the periodic table while ...

's sensitivity starts around 950 nm and ends between 1,700 and 2,600 nm, depending on the specific configuration). No international standards for these specifications are currently available.

The onset of infrared is defined (according to different standards) at various values typically between 700 nm and 800 nm, but the boundary between visible and infrared light is not precisely defined. The human eye is markedly less sensitive to light above 700 nm wavelength, so longer wavelengths make insignificant contributions to scenes illuminated by common light sources. Particularly intense near-IR light (e.g., from laser

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word ''laser'' originated as an acronym for light amplification by stimulated emission of radi ...

s, LEDs or bright daylight with the visible light filtered out) can be detected up to approximately 780 nm, and will be perceived as red light. Intense light sources providing wavelengths as long as 1,050 nm can be seen as a dull red glow, causing some difficulty in near-IR illumination of scenes in the dark (usually this practical problem is solved by indirect illumination). Leaves are particularly bright in the near IR, and if all visible light leaks from around an IR-filter are blocked, and the eye is given a moment to adjust to the extremely dim image coming through a visually opaque IR-passing photographic filter, it is possible to see the Wood effect that consists of IR-glowing foliage.

Telecommunication bands

Inoptical communications

Optical communication, also known as optical telecommunication, is communication at a distance using light to carry information. It can be performed visually or by using electronic devices. The earliest basic forms of optical communication date b ...

, the part of the infrared spectrum that is used is divided into seven bands based on availability of light sources, transmitting/absorbing materials (fibers), and detectors:

The C-band is the dominant band for long-distance telecommunications network

A telecommunications network is a group of Node (networking), nodes interconnected by telecommunications links that are used to exchange messages between the nodes. The links may use a variety of technologies based on the methodologies of circuit ...

s. The S and L bands are based on less well established technology, and are not as widely deployed.

Heat

Infrared radiation is popularly known as "heat radiation", but light and electromagnetic waves of any frequency will heat surfaces that absorb them. Infrared light from the Sun accounts for 49% of the heating of Earth, with the rest being caused by visible light that is absorbed then re-radiated at longer wavelengths. Visible light or ultraviolet-emitting lasers can char paper and incandescently hot objects emit visible radiation. Objects at room

Infrared radiation is popularly known as "heat radiation", but light and electromagnetic waves of any frequency will heat surfaces that absorb them. Infrared light from the Sun accounts for 49% of the heating of Earth, with the rest being caused by visible light that is absorbed then re-radiated at longer wavelengths. Visible light or ultraviolet-emitting lasers can char paper and incandescently hot objects emit visible radiation. Objects at room temperature

Temperature is a physical quantity that quantitatively expresses the attribute of hotness or coldness. Temperature is measurement, measured with a thermometer. It reflects the average kinetic energy of the vibrating and colliding atoms making ...

will emit radiation

In physics, radiation is the emission or transmission of energy in the form of waves or particles through space or a material medium. This includes:

* ''electromagnetic radiation'' consisting of photons, such as radio waves, microwaves, infr ...

concentrated mostly in the 8 to 25 μm band, but this is not distinct from the emission of visible light by incandescent objects and ultraviolet by even hotter objects (see black body

A black body or blackbody is an idealized physical body that absorbs all incident electromagnetic radiation, regardless of frequency or angle of incidence. The radiation emitted by a black body in thermal equilibrium with its environment is ...

and Wien's displacement law

In physics, Wien's displacement law states that the black-body radiation curve for different temperatures will peak at different wavelengths that are inversely proportional to the temperature. The shift of that peak is a direct consequence of ...

).

Heat

In thermodynamics, heat is energy in transfer between a thermodynamic system and its surroundings by such mechanisms as thermal conduction, electromagnetic radiation, and friction, which are microscopic in nature, involving sub-atomic, ato ...

is energy in transit that flows due to a temperature difference. Unlike heat transmitted by thermal conduction

Thermal conduction is the diffusion of thermal energy (heat) within one material or between materials in contact. The higher temperature object has molecules with more kinetic energy; collisions between molecules distributes this kinetic energy ...

or thermal convection, thermal radiation can propagate through a vacuum

A vacuum (: vacuums or vacua) is space devoid of matter. The word is derived from the Latin adjective (neuter ) meaning "vacant" or "void". An approximation to such vacuum is a region with a gaseous pressure much less than atmospheric pressur ...

. Thermal radiation is characterized by a particular spectrum of many wavelengths that are associated with emission from an object, due to the vibration of its molecules at a given temperature. Thermal radiation can be emitted from objects at any wavelength, and at very high temperatures such radiation is associated with spectra far above the infrared, extending into visible, ultraviolet, and even X-ray regions (e.g. the solar corona

In astronomy, a corona (: coronas or coronae) is the outermost layer of a star's Stellar atmosphere, atmosphere. It is a hot but relatively luminosity, dim region of Plasma (physics), plasma populated by intermittent coronal structures such as so ...

). Thus, the popular association of infrared radiation with thermal radiation is only a coincidence based on typical (comparatively low) temperatures often found near the surface of planet Earth.

The concept of emissivity

The emissivity of the surface of a material is its effectiveness in emitting energy as thermal radiation. Thermal radiation is electromagnetic radiation that most commonly includes both visible radiation (light) and infrared radiation, which is n ...

is important in understanding the infrared emissions of objects. This is a property of a surface that describes how its thermal emissions deviate from the ideal of a black body

A black body or blackbody is an idealized physical body that absorbs all incident electromagnetic radiation, regardless of frequency or angle of incidence. The radiation emitted by a black body in thermal equilibrium with its environment is ...

. To further explain, two objects at the same physical temperature may not show the same infrared image if they have differing emissivity. For example, for any pre-set emissivity value, objects with higher emissivity will appear hotter, and those with a lower emissivity will appear cooler (assuming, as is often the case, that the surrounding environment is cooler than the objects being viewed). When an object has less than perfect emissivity, it obtains properties of reflectivity and/or transparency, and so the temperature of the surrounding environment is partially reflected by and/or transmitted through the object. If the object were in a hotter environment, then a lower emissivity object at the same temperature would likely appear to be hotter than a more emissive one. For that reason, incorrect selection of emissivity and not accounting for environmental temperatures will give inaccurate results when using infrared cameras and pyrometers.

Applications

Night vision

Infrared is used in night vision equipment when there is insufficient visible light to see.

Infrared is used in night vision equipment when there is insufficient visible light to see. Night vision devices

A night-vision device (NVD), also known as a night optical/observation device (NOD) or night-vision goggle (NVG), is an optoelectronic device that allows visualization of images in low levels of light, improving the user's night vision.

The ...

operate through a process involving the conversion of ambient light photons into electrons that are then amplified by a chemical and electrical process and then converted back into visible light. Infrared light sources can be used to augment the available ambient light for conversion by night vision devices, increasing in-the-dark visibility without actually using a visible light source.

The use of infrared light and night vision devices should not be confused with thermal imaging

Infrared thermography (IRT), thermal video or thermal imaging, is a process where a thermal camera captures and creates an image of an object by using infrared radiation emitted from the object in a process, which are examples of infrared im ...

, which creates images based on differences in surface temperature by detecting infrared radiation (heat

In thermodynamics, heat is energy in transfer between a thermodynamic system and its surroundings by such mechanisms as thermal conduction, electromagnetic radiation, and friction, which are microscopic in nature, involving sub-atomic, ato ...

) that emanates from objects and their surrounding environment.

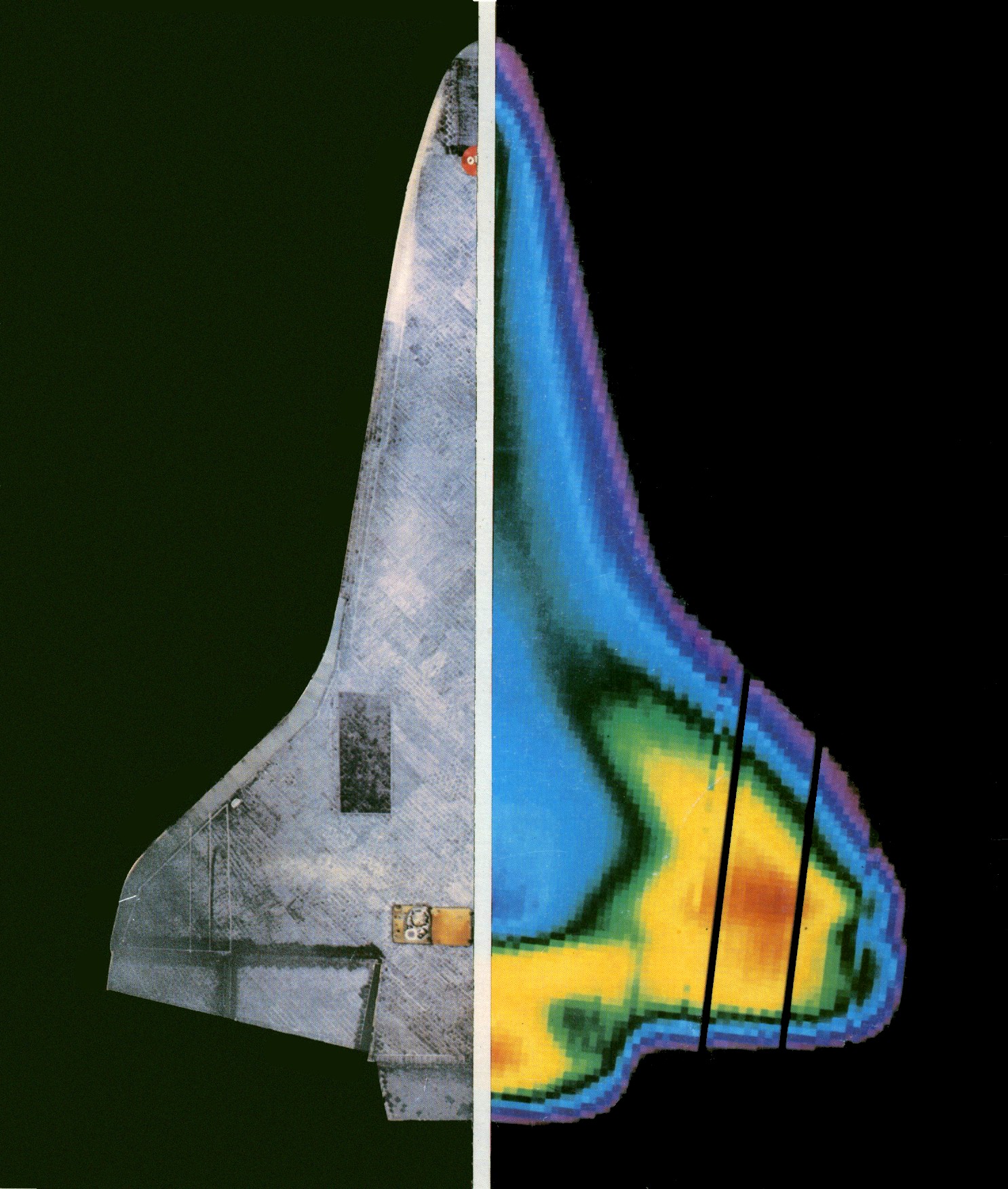

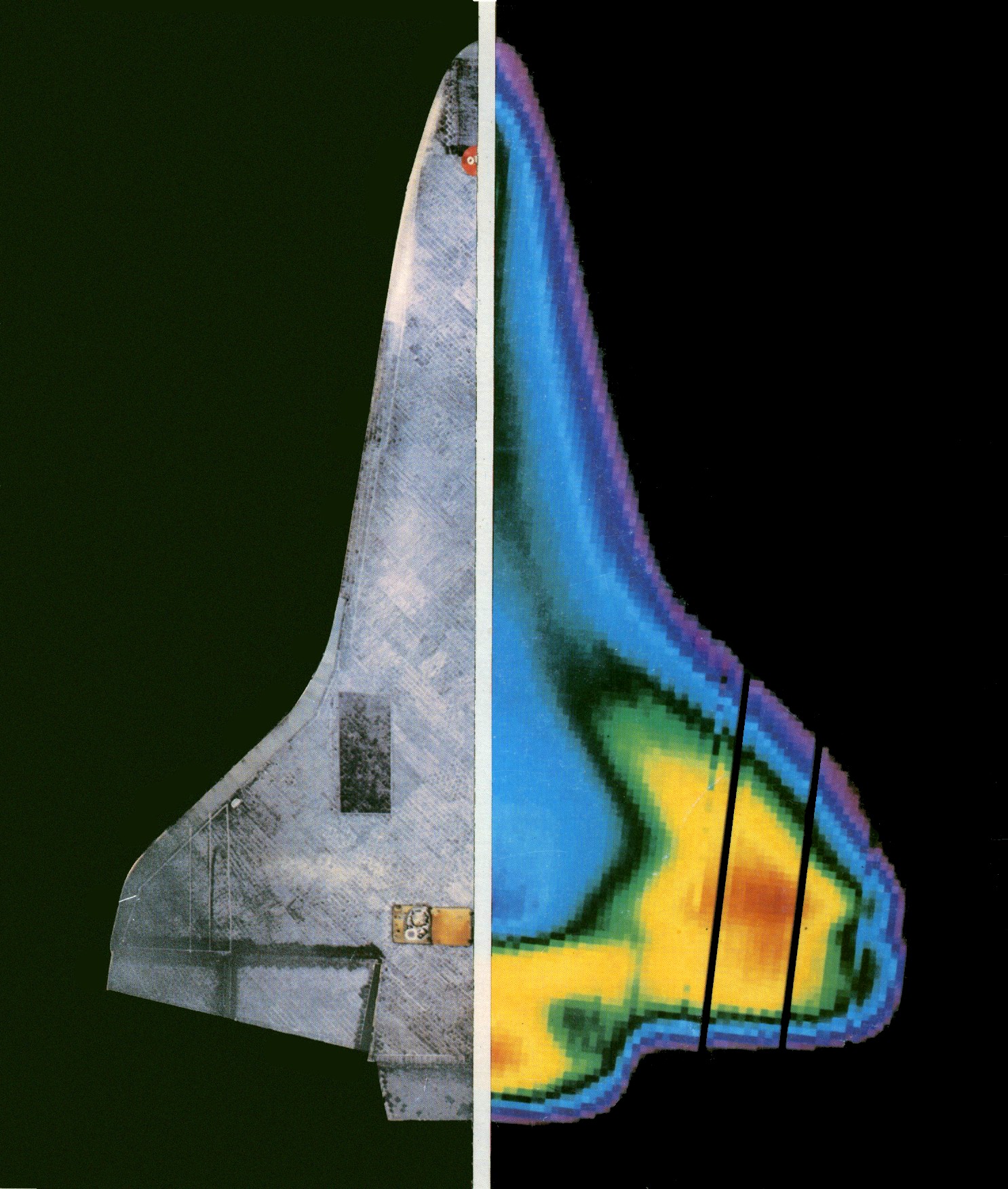

Thermography

Infrared radiation can be used to remotely determine the temperature of objects (if the emissivity is known). This is termed thermography, or in the case of very hot objects in the NIR or visible it is termed

Infrared radiation can be used to remotely determine the temperature of objects (if the emissivity is known). This is termed thermography, or in the case of very hot objects in the NIR or visible it is termed pyrometry

A pyrometer, or radiation thermometer, is a type of remote sensing thermometer used to measure the temperature of distant objects. Various forms of pyrometers have historically existed. In the modern usage, it is a device that from a distance de ...

. Thermography (thermal imaging) is mainly used in military and industrial applications but the technology is reaching the public market in the form of infrared cameras on cars due to greatly reduced production costs.

Thermographic cameras detect radiation in the infrared range of the electromagnetic spectrum (roughly 9,000–14,000 nm or 9–14 μm) and produce images of that radiation. Since infrared radiation is emitted by all objects based on their temperatures, according to the black-body radiation law, thermography makes it possible to "see" one's environment with or without visible illumination. The amount of radiation emitted by an object increases with temperature, therefore thermography allows one to see variations in temperature (hence the name).

Hyperspectral imaging

A hyperspectral image is a "picture" containing continuousspectrum

A spectrum (: spectra or spectrums) is a set of related ideas, objects, or properties whose features overlap such that they blend to form a continuum. The word ''spectrum'' was first used scientifically in optics to describe the rainbow of co ...

through a wide spectral range at each pixel. Hyperspectral imaging is gaining importance in the field of applied spectroscopy particularly with NIR, SWIR, MWIR, and LWIR spectral regions. Typical applications include biological, mineralogical, defence, and industrial measurements.

Thermal infrared hyperspectral imaging can be similarly performed using a thermographic camera

Infrared thermography (IRT), thermal video or thermal imaging, is a process where a Thermographic camera, thermal camera captures and creates an image of an object by using infrared radiation emitted from the object in a process, which are exa ...

, with the fundamental difference that each pixel contains a full LWIR spectrum. Consequently, chemical identification of the object can be performed without a need for an external light source such as the Sun or the Moon. Such cameras are typically applied for geological measurements, outdoor surveillance and UAV

An unmanned aerial vehicle (UAV) or unmanned aircraft system (UAS), commonly known as a drone, is an aircraft with no human pilot, crew, or passengers onboard, but rather is controlled remotely or is autonomous.De Gruyter Handbook of Drone ...

applications.Frost&Sullivan, Technical Insights, Aerospace&Defence (Feb 2011)World First Thermal Hyperspectral Camera for Unmanned Aerial Vehicles

.

Other imaging

In

In infrared photography

In infrared photography, the photographic film or image sensor used is sensitive to infrared light. The part of the spectrum used is referred to as near-infrared to distinguish it from far-infrared, which is the domain of thermal imaging. Wav ...

, infrared filter

Infrared cut-off filters, sometimes called IR filters or heat-absorbing filters, are designed to reflect or block near-infrared wavelengths while passing visible light. They are often used in devices with bright incandescent light bulbs (such as ...

s are used to capture the near-infrared spectrum. Digital camera

A digital camera, also called a digicam, is a camera that captures photographs in Digital data storage, digital memory. Most cameras produced today are digital, largely replacing those that capture images on photographic film or film stock. Dig ...

s often use infrared blockers. Cheaper digital cameras and camera phones

A camera phone is a mobile phone that is able to capture photographs and often record video using one or more built-in digital cameras. It can also send the resulting image wirelessly and conveniently. The first commercial phone with a color c ...

have less effective filters and can view intense near-infrared, appearing as a bright purple-white color. This is especially pronounced when taking pictures of subjects near IR-bright areas (such as near a lamp), where the resulting infrared interference can wash out the image. There is also a technique called 'T-ray

Terahertz radiation – also known as submillimeter radiation, terahertz waves, tremendously high frequency

(THF), T-rays, T-waves, T-light, T-lux or THz – consists of electromagnetic waves within the International Telecommunicat ...

' imaging, which is imaging using far-infrared

Far infrared (FIR) or long wave refers to a specific range within the infrared spectrum of electromagnetic radiation. It encompasses radiation with wavelengths ranging from 15 μm ( micrometers) to 1 mm, which corresponds to a freque ...

or terahertz radiation

Terahertz radiation – also known as submillimeter radiation, terahertz waves, tremendously high frequency

(THF), T-rays, T-waves, T-light, T-lux or THz – consists of electromagnetic waves within the International Telecommunicat ...

. Lack of bright sources can make terahertz photography more challenging than most other infrared imaging techniques. Recently T-ray imaging has been of considerable interest due to a number of new developments such as terahertz time-domain spectroscopy

In physics, terahertz time-domain spectroscopy (THz-TDS) is a spectroscopic technique in which the properties of matter are probed with short pulses of terahertz radiation. The generation and detection scheme is sensitive to the sample's effect ...

.

Tracking

emission

Emission may refer to:

Chemical products

* Emission of air pollutants, notably:

** Flue gas, gas exiting to the atmosphere via a flue

** Exhaust gas, flue gas generated by fuel combustion

** Emission of greenhouse gases, which absorb and emit rad ...

from a target of electromagnetic radiation in the infrared part of the spectrum to track it. Missiles that use infrared seeking are often referred to as "heat-seekers" since infrared (IR) is just below the visible spectrum of light in frequency and is radiated strongly by hot bodies. Many objects such as people, vehicle engines, and aircraft generate and retain heat, and as such, are especially visible in the infrared wavelengths of light compared to objects in the background.

Heating

Infrared radiation can be used as a deliberate heating source. For example, it is used in

Infrared radiation can be used as a deliberate heating source. For example, it is used in infrared sauna

An infrared sauna uses infrared heaters to emit infrared light experienced as radiant heat which is absorbed by the surface of the skin. Infrared saunas are popular in alternative therapies, where they are claimed to help with a number of medica ...

s to heat the occupants. It may also be used in other heating applications, such as to remove ice from the wings of aircraft (de-icing).

Infrared heating is also becoming more popular in industrial manufacturing processes, e.g. curing of coatings, forming of plastics, annealing, plastic welding, and print drying. In these applications, infrared heaters replace convection ovens and contact heating.

Cooling

A variety of technologies or proposed technologies take advantage of infrared emissions to cool buildings or other systems. The LWIR (8–15 μm) region is especially useful since some radiation at these wavelengths can escape into space through the atmosphere'sinfrared window

The infrared atmospheric window is an atmospheric window in the infrared spectrum where there is relatively little absorption of terrestrial thermal radiation by atmospheric gases. The window plays an important role in the atmospheric greenhouse ...

. This is how passive daytime radiative cooling

Passive daytime radiative cooling (PDRC) (also passive radiative cooling, daytime passive radiative cooling, radiative sky cooling, photonic radiative cooling, and terrestrial radiative cooling) is the use of unpowered, reflective/Emissivity, ther ...

(PDRC) surfaces are able to achieve sub-ambient cooling temperatures under direct solar intensity, enhancing terrestrial heat flow

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, ...

to outer space with zero energy consumption

Energy consumption is the amount of energy used.

Biology

In the body, energy consumption is part of energy homeostasis. It derived from food energy. Energy consumption in the body is a product of the basal metabolic rate and the physical acti ...

or pollution

Pollution is the introduction of contaminants into the natural environment that cause harm. Pollution can take the form of any substance (solid, liquid, or gas) or energy (such as radioactivity, heat, sound, or light). Pollutants, the component ...

. PDRC surfaces maximize shortwave solar reflectance

Albedo ( ; ) is the fraction of sunlight that is Diffuse reflection, diffusely reflected by a body. It is measured on a scale from 0 (corresponding to a black body that absorbs all incident radiation) to 1 (corresponding to a body that reflects ...

to lessen heat gain while maintaining strong longwave infrared (LWIR) thermal radiation

Thermal radiation is electromagnetic radiation emitted by the thermal motion of particles in matter. All matter with a temperature greater than absolute zero emits thermal radiation. The emission of energy arises from a combination of electro ...

heat transfer

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, ...

. When imagined on a worldwide scale, this cooling method has been proposed as a way to slow and even reverse global warming

Present-day climate change includes both global warming—the ongoing increase in global average temperature—and its wider effects on Earth's climate system. Climate change in a broader sense also includes previous long-term changes ...

, with some estimates proposing a global surface area coverage of 1-2% to balance global heat fluxes.

Communications

IR data transmission is also employed in short-range communication among computer peripherals andpersonal digital assistant

A personal digital assistant (PDA) is a multi-purpose mobile device which functions as a personal information manager. Following a boom in the 1990s and 2000s, PDAs were mostly displaced by the widespread adoption of more highly capable smar ...

s. These devices usually conform to standards published by IrDA

IrDA is a wireless standard designed for exchanging data using infrared (IR). Infrared ports for this purpose have been implemented in portable electronic devices such as mobile telephones, laptops, cameras, printers, and medical devices. The mai ...

, the Infrared Data Association. Remote controls and IrDA devices use infrared light-emitting diode

A light-emitting diode (LED) is a semiconductor device that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons. The color of the light (corre ...

s (LEDs) to emit infrared radiation that may be concentrated by a lens

A lens is a transmissive optical device that focuses or disperses a light beam by means of refraction. A simple lens consists of a single piece of transparent material, while a compound lens consists of several simple lenses (''elements'') ...

into a beam that the user aims at the detector. The beam is modulated

Signal modulation is the process of varying one or more properties of a periodic waveform in electronics and telecommunication for the purpose of transmitting information.

The process encodes information in form of the modulation or message ...

, i.e. switched on and off, according to a code which the receiver interprets. Usually very near-IR is used (below 800 nm) for practical reasons. This wavelength is efficiently detected by inexpensive silicon

Silicon is a chemical element; it has symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic lustre, and is a tetravalent metalloid (sometimes considered a non-metal) and semiconductor. It is a membe ...

photodiode

A photodiode is a semiconductor diode sensitive to photon radiation, such as visible light, infrared or ultraviolet radiation, X-rays and gamma rays. It produces an electrical current when it absorbs photons. This can be used for detection and me ...

s, which the receiver uses to convert the detected radiation to an electric current

An electric current is a flow of charged particles, such as electrons or ions, moving through an electrical conductor or space. It is defined as the net rate of flow of electric charge through a surface. The moving particles are called charge c ...

. That electrical signal is passed through a high-pass filter

A high-pass filter (HPF) is an electronic filter that passes signals with a frequency higher than a certain cutoff frequency and attenuates signals with frequencies lower than the cutoff frequency. The amount of attenuation for each frequency ...

which retains the rapid pulsations due to the IR transmitter but filters out slowly changing infrared radiation from ambient light. Infrared communications are useful for indoor use in areas of high population density. IR does not penetrate walls and so does not interfere with other devices in adjoining rooms. Infrared is the most common way for remote control

A remote control, also known colloquially as a remote or clicker, is an consumer electronics, electronic device used to operate another device from a distance, usually wirelessly. In consumer electronics, a remote control can be used to operat ...

s to command appliances.

Infrared remote control protocols like RC-5

The RC-5 protocol was developed by Philips in the early 1980s as a semi-proprietary consumer IR (infrared) remote control communication protocol for consumer electronics. It was subsequently adopted by most European manufacturers, as well as by m ...

, SIRC, are used to communicate with infrared.

Free-space optical communication

Free-space optical communication (FSO) is an optical communication technology that uses light propagating in free space to wirelessly transmit data for telecommunications or computer networking over long distances. "Free space" means air, oute ...

using infrared laser

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word ''laser'' originated as an acronym for light amplification by stimulated emission of radi ...

s can be a relatively inexpensive way to install a communications link in an urban area operating at up to 4 gigabit/s, compared to the cost of burying fiber optic cable, except for the radiation damage. "Since the eye cannot detect IR, blinking or closing the eyes to help prevent or reduce damage may not happen."

Infrared lasers are used to provide the light for optical fiber

An optical fiber, or optical fibre, is a flexible glass or plastic fiber that can transmit light from one end to the other. Such fibers find wide usage in fiber-optic communications, where they permit transmission over longer distances and at ...

communications systems. Wavelengths around 1,330 nm (least dispersion

Dispersion may refer to:

Economics and finance

*Dispersion (finance), a measure for the statistical distribution of portfolio returns

* Price dispersion, a variation in prices across sellers of the same item

*Wage dispersion, the amount of variat ...

) or 1,550 nm (best transmission) are the best choices for standard silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , commonly found in nature as quartz. In many parts of the world, silica is the major constituent of sand. Silica is one of the most complex and abundant f ...

fibers.

IR data transmission of audio versions of printed signs is being researched as an aid for visually impaired people through the Remote infrared audible signage Remote infrared audible signage (RIAS) was developed by Smith-Kettlewell Eye Research Institute (as Talking SignsR) so that print-disabled people, such as those that are blind or have low-vision, or are illiterate, foreign, or visually impaired, w ...

project.

Transmitting IR data from one device to another is sometimes referred to as beaming

In physics, relativistic beaming (also known as Doppler beaming, Doppler boosting, or the headlight effect) is the process by which relativistic effects modify the apparent luminosity of emitting matter that is moving at speeds close to th ...

.

IR is sometimes used for assistive audio as an alternative to an audio induction loop

An audio induction loop system (also called an audio-frequency induction loop or AFIL, or a hearing loop) is an assistive listening device for individuals with reduced ranges of hearing.

History

The first patented magnetic induction loop co ...

.

Spectroscopy

Infrared spectroscopy, Infrared vibrational spectroscopy (see also near-infrared spectroscopy) is a technique that can be used to identify molecules by analysis of their constituent bonds. Each chemical bond in a molecule vibrates at a frequency characteristic of that bond. A group of atoms in a molecule (e.g., CH2) may have multiple modes of oscillation caused by the stretching and bending motions of the group as a whole. If an oscillation leads to a change in dipole in the molecule then it will absorb aphoton

A photon () is an elementary particle that is a quantum of the electromagnetic field, including electromagnetic radiation such as light and radio waves, and the force carrier for the electromagnetic force. Photons are massless particles that can ...

that has the same frequency. The vibrational frequencies of most molecules correspond to the frequencies of infrared light. Typically, the technique is used to study organic compounds using light radiation from the mid-infrared, 4,000–400 cm−1. A spectrum of all the frequencies of absorption in a sample is recorded. This can be used to gain information about the sample composition in terms of chemical groups present and also its purity (for example, a wet sample will show a broad O-H absorption around 3200 cm−1). The unit for expressing radiation in this application, cm−1, is the spectroscopic wavenumber. It is the frequency divided by the speed of light in vacuum.

Thin film metrology

In the semiconductor industry, infrared light can be used to characterize materials such as thin films and periodic trench structures. By measuring the reflectance of light from the surface of a semiconductor wafer, the index of refraction (n) and the extinction Coefficient (k) can be determined via the Forouhi–Bloomer model, Forouhi–Bloomer dispersion equations. The reflectance from the infrared light can also be used to determine the critical dimension, depth, and sidewall angle of high aspect ratio trench structures.Meteorology

Weather satellites equipped with scanning radiometers produce thermal or infrared images, which can then enable a trained analyst to determine cloud heights and types, to calculate land and surface water temperatures, and to locate ocean surface features. The scanning is typically in the range 10.3–12.5 μm (IR4 and IR5 channels). Clouds with high and cold tops, such as cyclones or cumulonimbus clouds, are often displayed as red or black, lower warmer clouds such as Stratus cloud, stratus or stratocumulus are displayed as blue or grey, with intermediate clouds shaded accordingly. Hot land surfaces are shown as dark-grey or black. One disadvantage of infrared imagery is that low clouds such as stratus or fog can have a temperature similar to the surrounding land or sea surface and do not show up. However, using the difference in brightness of the IR4 channel (10.3–11.5 μm) and the near-infrared channel (1.58–1.64 μm), low clouds can be distinguished, producing a ''fog'' satellite picture. The main advantage of infrared is that images can be produced at night, allowing a continuous sequence of weather to be studied. These infrared pictures can depict ocean eddies or vortices and map currents such as the Gulf Stream, which are valuable to the shipping industry. Fishermen and farmers are interested in knowing land and water temperatures to protect their crops against frost or increase their catch from the sea. Even El Niño phenomena can be spotted. Using color-digitized techniques, the gray-shaded thermal images can be converted to color for easier identification of desired information. The main water vapour channel at 6.40 to 7.08 μm can be imaged by some weather satellites and shows the amount of moisture in the atmosphere.Climatology

global warming

Present-day climate change includes both global warming—the ongoing increase in global average temperature—and its wider effects on Earth's climate system. Climate change in a broader sense also includes previous long-term changes ...

, together with solar radiation.

A pyrgeometer is utilized in this field of research to perform continuous outdoor measurements. This is a broadband infrared radiometer with sensitivity for infrared radiation between approximately 4.5 μm and 50 μm.

Astronomy

Astronomers observe objects in the infrared portion of the electromagnetic spectrum using optical components, including mirrors, lenses and solid state digital detectors. For this reason it is classified as part of optical astronomy. To form an image, the components of an infrared telescope need to be carefully shielded from heat sources, and the detectors are chilled using liquid helium. The sensitivity of Earth-based infrared telescopes is significantly limited by water vapor in the atmosphere, which absorbs a portion of the infrared radiation arriving from space outside of selected atmospheric windows. This limitation can be partially alleviated by placing the telescope observatory at a high altitude, or by carrying the telescope aloft with a balloon or an aircraft. Space telescopes do not suffer from this handicap, and so outer space is considered the ideal location for infrared astronomy. The infrared portion of the spectrum has several useful benefits for astronomers. Cold, darkmolecular cloud

A molecular cloud—sometimes called a stellar nursery if star formation is occurring within—is a type of interstellar cloud of which the density and size permit absorption nebulae, the formation of molecules (most commonly molecular hydrogen, ...

s of gas and dust in our galaxy will glow with radiated heat as they are irradiated by imbedded stars. Infrared can also be used to detect protostars before they begin to emit visible light. Stars emit a smaller portion of their energy in the infrared spectrum, so nearby cool objects such as planet

A planet is a large, Hydrostatic equilibrium, rounded Astronomical object, astronomical body that is generally required to be in orbit around a star, stellar remnant, or brown dwarf, and is not one itself. The Solar System has eight planets b ...

s can be more readily detected. (In the visible light spectrum, the glare from the star will drown out the reflected light from a planet.)

Infrared light is also useful for observing the cores of active galaxies, which are often cloaked in gas and dust. Distant galaxies with a high redshift will have the peak portion of their spectrum shifted toward longer wavelengths, so they are more readily observed in the infrared.

Cleaning

Infrared cleaning is a technique used by some motion picture film scanners, film scanners and flatbed scanners to reduce or remove the effect of dust and scratches upon the finished image scanning, scan. It works by collecting an additional infrared channel from the scan at the same position and resolution as the three visible color channels (red, green, and blue). The infrared channel, in combination with the other channels, is used to detect the location of scratches and dust. Once located, those defects can be corrected by scaling or replaced by inpainting.Art conservation and analysis

Biological systems

The pit viper has a pair of infrared sensory pits on its head. There is uncertainty regarding the exact thermal sensitivity of this biological infrared detection system. Other organisms that have thermoreceptive organs are pythons (family Pythonidae), some boas (family Boidae), the Common Vampire Bat (''Desmodus rotundus''), a variety of jewel beetles (''Melanophila acuminata''), darkly pigmented butterflies (''Pachliopta aristolochiae'' and ''Troides rhadamantus plateni''), and possibly blood-sucking bugs (''Triatoma infestans''). By detecting the heat that their prey emits, crotaline and Booidea, boid snakes identify and capture their prey using their Infrared sensing in snakes, IR-sensitive pit organs. Comparably, IR-sensitive pits on the Common Vampire Bat (''Desmodus rotundus'') aid in the identification of blood-rich regions on its warm-blooded victim. The jewel beetle, ''Melanophila acuminata'', locates forest fires via infrared pit organs, where on recently burnt trees, they deposit their eggs. Thermoreceptors on the wings and antennae of butterflies with dark pigmentation, such ''Pachliopta aristolochiae'' and ''Troides rhadamantus plateni'', shield them from heat damage as they sunbathe in the sun. Additionally, it's hypothesised that thermoreceptors let bloodsucking bugs (''Triatoma infestans'') locate their warm-blooded victims by sensing their body heat. Some fungi like ''Venturia inaequalis'' require near-infrared light for ejection. Although near-infrared vision (780–1,000 nm) has long been deemed impossible due to noise in visual pigments, sensation of near-infrared light was reported in the common carp and in three cichlid species. Fish use NIR to capture prey and for phototactic swimming orientation. NIR sensation in fish may be relevant under poor lighting conditions during twilight and in turbid surface waters.Photobiomodulation

Near-infrared light, or photobiomodulation, is used for treatment of chemotherapy-induced oral ulceration as well as wound healing. There is some work relating to anti-herpes virus treatment. Research projects include work on central nervous system healing effects via cytochrome c oxidase upregulation and other possible mechanisms.Health hazards

Strong infrared radiation in certain industry high-heat settings may be hazardous to the eyes, resulting in damage or blindness to the user. Since the radiation is invisible, special IR-proof goggles must be worn in such places.Scientific history

The discovery of infrared radiation is ascribed toWilliam Herschel

Frederick William Herschel ( ; ; 15 November 1738 – 25 August 1822) was a German-British astronomer and composer. He frequently collaborated with his younger sister and fellow astronomer Caroline Herschel. Born in the Electorate of Hanover ...

, the astronomer, in the early 19th century. Herschel published his results in 1800 before the Royal Society of London. Herschel used a Triangular prism (optics), prism to refract light from the sun and detected the infrared, beyond the red

Red is the color at the long wavelength end of the visible spectrum of light, next to orange and opposite violet. It has a dominant wavelength of approximately 625–750 nanometres. It is a primary color in the RGB color model and a seconda ...

part of the spectrum, through an increase in the temperature recorded on a thermometer

A thermometer is a device that measures temperature (the hotness or coldness of an object) or temperature gradient (the rates of change of temperature in space). A thermometer has two important elements: (1) a temperature sensor (e.g. the bulb ...

. He was surprised at the result and called them "Calorific Rays". The term "infrared" did not appear until late 19th century. The Latin prefix ''infra-'' means below, as it is light below red on the spectrum. An Pictet's experiment, earlier experiment in 1790 by Marc-Auguste Pictet demonstrated the reflection and focusing of radiant heat via mirrors in the absence of visible light.

Other important dates include:

* 1830: Leopoldo Nobili made the first thermopile IR detector.

* 1840: John Herschel produces the first thermal image, called a thermogram.

* 1860: Gustav Kirchhoff formulated the Kirchhoff's law of thermal radiation, blackbody theorem .

* 1873: Willoughby Smith discovered the photoconductivity of selenium.

* 1878: Samuel Pierpont Langley invents the first bolometer, a device which is able to measure small temperature fluctuations, and thus the power of far infrared sources.

* 1879: Stefan–Boltzmann law formulated empirically that the power radiated by a blackbody is proportional to ''T''4.

* 1880s and 1890s: Lord Rayleigh and Wilhelm Wien solved part of the blackbody equation, but both solutions diverged in parts of the electromagnetic spectrum. This problem was called the "ultraviolet catastrophe and infrared catastrophe".

* 1892: Willem Henri Julius published infrared spectra of 20 organic compounds measured with a bolometer in units of angular displacement.