Industrial CT Scanning on:

[Wikipedia]

[Google]

[Amazon]

Industrial computed tomography (CT) scanning is any computer-aided tomographic process, usually

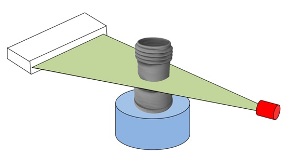

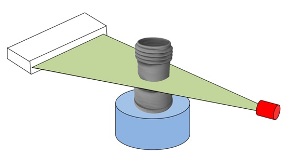

''Line beam scanning'' is the traditional process of industrial CT scanning.Hofmann, J., Flisch, A., Obrist, A., Adaptive CT scanning-mesh based optimisation methods for industrial X-ray computer tomography applications. NDT&E International (37), 2004, pp. 271–278. X-rays are produced and the beam is collimated to create a line. The X-ray line beam is then translated across the part and data is collected by the detector. The data is then reconstructed to create a 3-D volume rendering of the part.

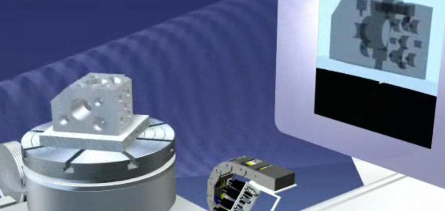

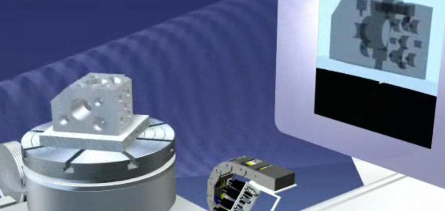

In ''cone beam scanning'', the part to be scanned is placed on a rotary table. As the part rotates, the cone of X-rays produce a large number of 2D images that are collected by the detector. The 2D images are then processed to create a 3D volume rendering of the external and internal geometries of the part.

''Line beam scanning'' is the traditional process of industrial CT scanning.Hofmann, J., Flisch, A., Obrist, A., Adaptive CT scanning-mesh based optimisation methods for industrial X-ray computer tomography applications. NDT&E International (37), 2004, pp. 271–278. X-rays are produced and the beam is collimated to create a line. The X-ray line beam is then translated across the part and data is collected by the detector. The data is then reconstructed to create a 3-D volume rendering of the part.

In ''cone beam scanning'', the part to be scanned is placed on a rotary table. As the part rotates, the cone of X-rays produce a large number of 2D images that are collected by the detector. The 2D images are then processed to create a 3D volume rendering of the external and internal geometries of the part.

X-ray computed tomography

An X-ray (also known in many languages as Röntgen radiation) is a form of high-energy electromagnetic radiation with a wavelength shorter than those of ultraviolet rays and longer than those of gamma rays. Roughly, X-rays have a wavelength ran ...

, that uses irradiation to produce three-dimensional internal and external representations of a scanned object. Industrial CT scanning has been used in many areas of industry for internal inspection of components. Some of the key uses for industrial CT scanning have been flaw detection, failure analysis, metrology, assembly analysis and reverse engineering

Reverse engineering (also known as backwards engineering or back engineering) is a process or method through which one attempts to understand through deductive reasoning how a previously made device, process, system, or piece of software accompl ...

applications. Just as in medical imaging

Medical imaging is the technique and process of imaging the interior of a body for clinical analysis and medical intervention, as well as visual representation of the function of some organs or tissues (physiology). Medical imaging seeks to revea ...

, industrial imaging includes both nontomographic radiography (industrial radiography

Industrial radiography is a modality of non-destructive testing that uses ionizing radiation to inspect materials and components with the objective of locating and quantifying defects and degradation in material properties that would lead to the ...

) and computed tomographic radiography (computed tomography).

Types of scanners

''Line beam scanning'' is the traditional process of industrial CT scanning.Hofmann, J., Flisch, A., Obrist, A., Adaptive CT scanning-mesh based optimisation methods for industrial X-ray computer tomography applications. NDT&E International (37), 2004, pp. 271–278. X-rays are produced and the beam is collimated to create a line. The X-ray line beam is then translated across the part and data is collected by the detector. The data is then reconstructed to create a 3-D volume rendering of the part.

In ''cone beam scanning'', the part to be scanned is placed on a rotary table. As the part rotates, the cone of X-rays produce a large number of 2D images that are collected by the detector. The 2D images are then processed to create a 3D volume rendering of the external and internal geometries of the part.

''Line beam scanning'' is the traditional process of industrial CT scanning.Hofmann, J., Flisch, A., Obrist, A., Adaptive CT scanning-mesh based optimisation methods for industrial X-ray computer tomography applications. NDT&E International (37), 2004, pp. 271–278. X-rays are produced and the beam is collimated to create a line. The X-ray line beam is then translated across the part and data is collected by the detector. The data is then reconstructed to create a 3-D volume rendering of the part.

In ''cone beam scanning'', the part to be scanned is placed on a rotary table. As the part rotates, the cone of X-rays produce a large number of 2D images that are collected by the detector. The 2D images are then processed to create a 3D volume rendering of the external and internal geometries of the part.

History

Industrial CT scanning technology was introduced in 1972 with the invention of theCT scan

A computed tomography scan (CT scan), formerly called computed axial tomography scan (CAT scan), is a medical imaging technique used to obtain detailed internal images of the body. The personnel that perform CT scans are called radiographers or ...

ner for medical imaging by Godfrey Hounsfield. The invention earned him a Nobel Prize in medicine, which he shared with Allan McLeod Cormack. Many advances in CT scanning have allowed for its use in the industrial field for metrology in addition to the visual inspection primarily used in the medical field (medical CT scan

A computed tomography scan (CT scan), formerly called computed axial tomography scan (CAT scan), is a medical imaging technique used to obtain detailed internal images of the body. The personnel that perform CT scans are called radiographers or ...

).

Analysis and inspection techniques

Various inspection uses and techniques include part-to-CAD comparisons, part-to-part comparisons, assembly and defect analysis, void analysis, wall thickness analysis, and generation of CAD data. The CAD data can be used forreverse engineering

Reverse engineering (also known as backwards engineering or back engineering) is a process or method through which one attempts to understand through deductive reasoning how a previously made device, process, system, or piece of software accompl ...

, geometric dimensioning and tolerance analysis, and production part approval.

Assembly

One of the most recognized forms of analysis using CT is for assembly, or visual analysis. CT scanning provides views inside components in their functioning position, without disassembly. Some software programs for industrial CT scanning allow for measurements to be taken from the CT dataset volume rendering. These measurements are useful for determining the clearances between assembled parts or the dimension of an individual feature.

Void, crack and defect detection

Traditionally, determining defects, voids and cracks within an object would require destructive testing. CT scanning can detect internal features and flaws displaying this information in 3D without destroying the part. Industrial CT scanning (3D X-ray) is used to detect flaws inside a part such as porosity, an inclusion, or a crack. It has been also used to detect the origin and propagation of damages in concrete. Metal casting and moulded plastic components are typically prone to porosity because of cooling processes, transitions between thick and thin walls, and material properties. Void analysis can be used to locate, measure, and analyze voids inside plastic or metal components.Geometric dimensioning and tolerancing analysis

Traditionally, without destructive testing, full metrology has only been performed on the exterior dimensions of components, such as with a coordinate-measuring machine (CMM) or with a vision system to map exterior surfaces. Internal inspection methods would require using a 2D X-ray of the component or the use of destructive testing. Industrial CT scanning allows for full non-destructive metrology. With unlimited geometrical complexity,3D printing

3D printing, or additive manufacturing, is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer ...

allows for complex internal features to be created with no impact on cost, such features are not accessible using traditional CMM. The first 3D printed artefact that is optimised for characterisation of form using computed tomography CT

Image-based finite element methods

Image-based finite element method converts the 3D image data from X-ray computed tomography directly into meshes forfinite element analysis

Finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical models, mathematical modeling. Typical problem areas of interest include the traditional fields of structural ...

. Benefits of this method include modelling complex geometries (e.g. composite materials) or accurately modelling "as manufactured" components at the micro-scale.

Trends and Developments

The industrial computed tomography market is forecast to reach a size of USD 773.45 million to USD 1,116.5 million between 2029 and 2030. Regional trends show that strong market growth is expected, particularly in the Asia-Pacific region, but also in North America and Europe, due to strict safety regulations and preventive maintenance of industrial equipment. Growth is being driven primarily by the ongoing development of CT devices and services that enable precise and non-destructive testing of components. Innovations such as the use of artificial intelligence for automated fault analyses and the development of mobile CT systems are expanding the possibilities.Developments for Forensic Science

Computed Tomography (CT) has become an increasingly valuable tool in forensic science, particularly in conducting virtual autopsies. Unlike traditional autopsies, which require invasive procedures, CT scans allow for non-invasive internal examinations of the body, producing detailed 3D images of bones, organs, and soft tissues. This technology is especially useful for detecting fractures, foreign objects (such as bullets or shrapnel), gas embolisms, and signs of trauma that may not be immediately visible externally. CT scans can preserve forensic evidence more effectively and are particularly beneficial in cases involving mass disasters, decomposition, or cultural and religious objections to dissection. Furthermore, digital imaging from CT can be stored and reviewed multiple times, aiding both legal investigations and educational purposes. Overall, CT has enhanced the accuracy, efficiency, and accessibility of post-mortem examinations in forensic contexts.List of uses of CT scanning in Forensic Science

Sources: # Virtual Autopsies (Virtopsies) #* Non-invasive internal examinations of deceased individuals. # Detection of Fractures #* Identification of skull, rib, and other skeletal fractures, especially those not visible externally. # Visualization of Foreign Objects #* Location and analysis of bullets, shrapnel, or other embedded materials. # Assessment of Trauma #* Differentiation between antemortem (before death) and postmortem (after death) injuries. # Analysis of Gas Embolisms #* Identification of air or gas in blood vessels, which may indicate drowning, decompression sickness, or medical malpractice. # Age Estimation #* Evaluation of skeletal maturity and dental development in unidentified remains. # Facial Reconstruction Support #* High-resolution skull imaging for reconstructing a face digitally. # Identification of Pathologies #* Detection of diseases, infections, or chronic conditions that may relate to cause of death. # Documentation and Archiving #* Permanent, revisitable digital records of body condition and evidence. # Comparison with Antemortem Data * Matching postmortem CT scans with medical imaging from a person’s lifetime for identification. # Explosion and Blast Injury Analysis * Assessment of internal damage patterns caused by high-pressure events. # Burn Victim Analysis * Examining internal structures in severely burned bodies when traditional autopsy is limited. # Decomposition Studies * Monitoring changes in tissues and gases during the decomposition process. # Cultural/Religious Sensitivity * Alternative to invasive autopsies when cutting open a body is not permitted. # Mass Disaster Victim Identification * Efficient imaging of multiple bodies for quick identification and trauma assessment.See also

*CT scan

A computed tomography scan (CT scan), formerly called computed axial tomography scan (CAT scan), is a medical imaging technique used to obtain detailed internal images of the body. The personnel that perform CT scans are called radiographers or ...

* Industrial radiography

Industrial radiography is a modality of non-destructive testing that uses ionizing radiation to inspect materials and components with the objective of locating and quantifying defects and degradation in material properties that would lead to the ...

* Cone beam computed tomography, applications in quality control and metrology

Metrology is the scientific study of measurement. It establishes a common understanding of Unit of measurement, units, crucial in linking human activities. Modern metrology has its roots in the French Revolution's political motivation to stan ...

.

* PCB reverse engineering, an application of industrial CT to image printed circuit boards non-destructively.

References

{{DEFAULTSORT:Industrial Ct Scanning Tomography Materials science Microtomography Microtechnology Nondestructive testing Reverse engineering Articles containing video clips