Impact Mill on:

[Wikipedia]

[Google]

[Amazon]

Impact mills are one of two general classes of milling devices used to reduce the particle size of a material.

Impact mills are one of two general classes of milling devices used to reduce the particle size of a material.

Impact mills are one of two general classes of milling devices used to reduce the particle size of a material.

Impact mills are one of two general classes of milling devices used to reduce the particle size of a material.

Description

The other class ofmills

Mills is the plural form of mill, but may also refer to:

As a name

* Mills (surname), a common family name of English or Gaelic origin

* Mills (given name)

*Mills, a fictional British secret agent in a trilogy by writer Manning O'Brine

Places U ...

are "attrition" or grinding mills. Impact mills pulverize the material upon impact. The feasibility of impact mills was greatly enhanced by the mechanization and engineering of the Industrial Revolution

The Industrial Revolution, sometimes divided into the First Industrial Revolution and Second Industrial Revolution, was a transitional period of the global economy toward more widespread, efficient and stable manufacturing processes, succee ...

. Prior to the industrial revolution, milling was primarily done by attrition or grinding the material between two surfaces. Attrition milling continues to be the dominant milling class, particularly in the milling of agricultural products (i.e. grain into flour). Roller mill

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and others. Roller grain mills are an alternative to traditional ...

s and stone mills are two examples of attrition (grinding) mills.

Variations of impact mills

Impact mills either pulverize the material by simply employing gravity or they can mill dynamically upon impact with a high speed rotor,hammer

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nail (fastener), nails into wood, to sh ...

or pin

A pin is a device, typically pointed, used for fastening objects or fabrics together. Pins can have the following sorts of body:

*a shaft of a rigid inflexible material meant to be inserted in a slot, groove, or hole (as with pivots, hinges, an ...

.

Gravitational impact mills

Gravitational impact mills pulverize the material inside a rotating chamber. This is accomplished by a cascading motion of larger pieces repetitively impacting and compressively grinding the product into finer particles as it rotates in the chamber. These are generally referred to as " autogenous" impact mills. This action can be enhanced by placing steel balls in the chamber. The class of gravitational impact mills that incorporate steel balls in the chamber are appropriately referred to as "ball mill

A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attri ...

".

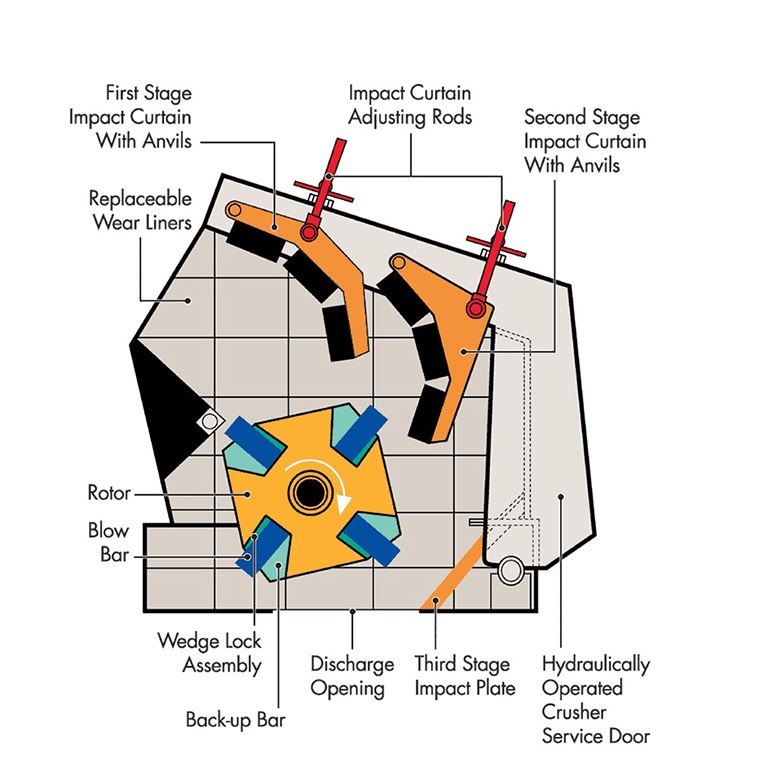

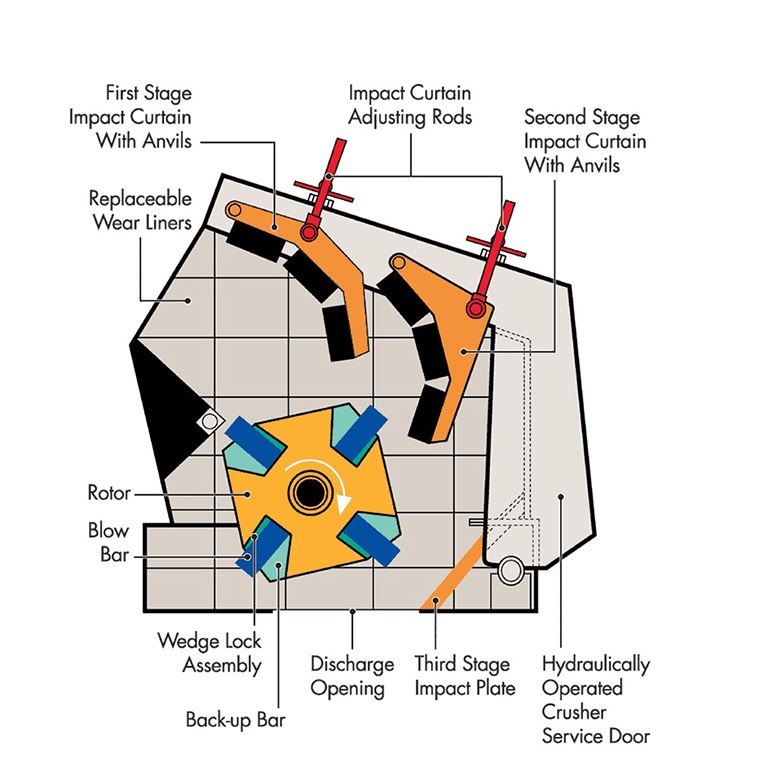

Dynamic impact mills

Dynamic impact would occur when material is dropped into a chamber where it receives a pulverizing blow from ahammer

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nail (fastener), nails into wood, to sh ...

, rotor or pin. Pulverizing can be enhanced by engineering the rotor or hammer to pass close to a serrated fixed stator. Pin, unifine; and VSI mills are examples of dynamic impact mills.

References

{{reflist Industrial equipment Grinding mills