IRNDT Fig 04 En on:

[Wikipedia]

[Google]

[Amazon]

Active

Active thermography uses an external source for measured object excitation, that means introducing an energy into the object. The excitation sources can be classified by the principles:

* optical radiation or microwaves absorption,

*

Active thermography uses an external source for measured object excitation, that means introducing an energy into the object. The excitation sources can be classified by the principles:

* optical radiation or microwaves absorption,

*

IRNDT (infra-red nondestructive testing) method is suitable for detection and inspection of cracks, defects, cavities, voids and inhomogeneities in material, it is also possible to use the method for inspection of welded joints of metal and plastic parts, inspection of

IRNDT (infra-red nondestructive testing) method is suitable for detection and inspection of cracks, defects, cavities, voids and inhomogeneities in material, it is also possible to use the method for inspection of welded joints of metal and plastic parts, inspection of

thermography

Infrared thermography (IRT), thermal video or thermal imaging, is a process where a thermal camera captures and creates an image of an object by using infrared radiation emitted from the object in a process, which are examples of infrared im ...

is an advanced nondestructive testing

Nondestructive testing (NDT) is any of a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage.

The terms nondestructive examination (NDE), n ...

procedure, which uses a thermographic measurement of a tested material thermal response after its external excitation. This principle can be used also for non-contact infrared non-destructive testing (IRNDT) of materials.

The IRNDT method is based on an excitation of a tested material by an external source, which brings some energy to the material. Halogen lamp

A halogen lamp (also called tungsten halogen, quartz-halogen, and quartz iodine lamp) is an incandescent lamp consisting of a tungsten filament sealed in a compact transparent envelope that is filled with a mixture of an inert gas and a small ...

s, flash-lamps, ultrasonic horn

An ultrasonic horn (also known as acoustic horn, sonotrode, acoustic waveguide, ultrasonic probe) is a tapering metal bar commonly used for augmenting the oscillation displacement amplitude provided by an ultrasonic transducer operating at the l ...

or other sources can be used as the excitation source for the IRNDT. The excitation causes a tested material thermal response, which is measured by an infrared camera

Infrared thermography (IRT), thermal video or thermal imaging, is a process where a thermal camera captures and creates an image of an object by using infrared radiation emitted from the object in a process, which are examples of infrared im ...

. It is possible to obtain information about the tested material surface and sub-surface defects or material inhomogeneities by using a suitable combination of excitation source, excitation procedure, infrared camera and evaluation method.

Modern thermographic systems with high-speed and high-sensitivity IR cameras extend the possibilities of the inspection method. Modularity

Modularity is the degree to which a system's components may be separated and recombined, often with the benefit of flexibility and variety in use. The concept of modularity is used primarily to reduce complexity by breaking a system into varying ...

of the systems allows their usage for research and development applications as well as in modern industrial production line

A production line is a set of sequential operations established in a factory where components are assembled to make a finished article or where materials are put through a refining process to produce an end-product that is suitable for onward ...

s.

Thermovision nondestructive testing of components can be carried out on a wide range of various materials. Thermographic inspection of material can be regarded as a method of infrared defectoscopy, that is capable of revealing material imperfections such as cracks, defects, voids, cavities and other inhomogeneities. The thermographic testing can be provided on individual components in a laboratory or directly on technology facilities that are in duty.

Theory

Active thermography uses an external source for measured object excitation, that means introducing an energy into the object. The excitation sources can be classified by the principles:

* optical radiation or microwaves absorption,

*

Active thermography uses an external source for measured object excitation, that means introducing an energy into the object. The excitation sources can be classified by the principles:

* optical radiation or microwaves absorption,

* electromagnetic induction

Electromagnetic or magnetic induction is the production of an electromotive force, electromotive force (emf) across an electrical conductor in a changing magnetic field.

Michael Faraday is generally credited with the discovery of induction in 1 ...

,

* elastic waves transformation (e.g. ultrasound),

* convection

Convection is single or Multiphase flow, multiphase fluid flow that occurs Spontaneous process, spontaneously through the combined effects of material property heterogeneity and body forces on a fluid, most commonly density and gravity (see buoy ...

(e.g. hot air),

* plastic deformation

In engineering, deformation (the change in size or shape of an object) may be ''elastic'' or ''plastic''.

If the deformation is negligible, the object is said to be ''rigid''.

Main concepts

Occurrence of deformation in engineering application ...

transformation (thermoplastic effect during mechanical loading).

Various excitation sources can be used for the active thermography and nondestructive testing, for example laser heating, flash lamps, halogen lamps, electrical heating, ultrasonic horn

An ultrasonic horn (also known as acoustic horn, sonotrode, acoustic waveguide, ultrasonic probe) is a tapering metal bar commonly used for augmenting the oscillation displacement amplitude provided by an ultrasonic transducer operating at the l ...

, eddy currents, microwave

Microwave is a form of electromagnetic radiation with wavelengths shorter than other radio waves but longer than infrared waves. Its wavelength ranges from about one meter to one millimeter, corresponding to frequency, frequencies between 300&n ...

s, and others. The measured object can be heated by an external source directly, e.g. by halogen lamps or hot air. The material inhomogeneities or defects cause then a distortion of temperature field. This distortion is detected as temperature differences on the material surface. Another possibility is to use thermophysical processes in the material, when mechanical or electrical energy is transformed into thermal energy

The term "thermal energy" is often used ambiguously in physics and engineering. It can denote several different physical concepts, including:

* Internal energy: The energy contained within a body of matter or radiation, excluding the potential en ...

due to defects and inhomogeneities. It creates local temperature sources, which cause temperature differences detected on the object surface by infrared techniques, such as in the case of ultrasound

Ultrasound is sound with frequency, frequencies greater than 20 Hertz, kilohertz. This frequency is the approximate upper audible hearing range, limit of human hearing in healthy young adults. The physical principles of acoustic waves apply ...

excitation.

Methods

A lot of methods were developed for active thermography for the nondestructive testing measurement evaluation. The evaluation methods selection depends on application, used excitation source and excitation type (pulse, periodic, continuous). In the simplest case, the response is evident from a thermogram directly. However, it is necessary to use advanced analysis techniques in most cases. The most common methods include Lock-In, Pulse or Transient (Step thermography) evaluation techniques, with continuous excitation used in some cases: * Lock-In thermography (periodic excitation method). Amodulated

Signal modulation is the process of varying one or more properties of a periodic waveform in electronics and telecommunication for the purpose of transmitting information.

The process encodes information in form of the modulation or message ...

periodic source is used for the excitation. The phase and amplitude shift of the measured signal are evaluated and the analysis can be done by various techniques. Halogen lamps, LED lamp

An LED lamp or LED light is an electric light that produces light using light-emitting diodes (LEDs). LED lamps are significantly more energy-efficient than equivalent incandescent lamps and fluorescent lamps. The most efficient commercial ...

s, ultrasound, laser

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word ''laser'' originated as an acronym for light amplification by stimulated emission of radi ...

or an electric current are suitable excitation sources. It has the advantage that it can be used on large surfaces, and it puts a low thermal energy on the part being inspected. The disadvantage is a longer measurement time and dependence of detection capabilities on a geometrical

Geometry (; ) is a branch of mathematics concerned with properties of space such as the distance, shape, size, and relative position of figures. Geometry is, along with arithmetic, one of the oldest branches of mathematics. A mathematician w ...

orientation of defects (except of an indirect excitation such as ultrasound). The Lock-In method is suitable for testing components with a low thermal diffusivity

Diffusivity is a rate of diffusion, a measure of the rate at which particles or heat or fluids can spread.

It is measured differently for different mediums.

Diffusivity may refer to:

*Thermal diffusivity, diffusivity of heat

*Diffusivity of mass: ...

and it has many modifications for various specific applications (such as Lock-In Ref, Lock-In Online, etc.).

* Pulse thermography (pulse method). A very short pulse – usually in the units of millisecond

A millisecond (from '' milli-'' and second; symbol: ms) is a unit of time in the International System of Units equal to one thousandth (0.001 or 10−3 or 1/1000) of a second or 1000 microseconds.

A millisecond is to one second, as one second i ...

s – is used to excite the object. The cooling process is then analyzed. A flash lamp is typically used as an excitation source. The advantage of this method is the speed of the analysis and a possibility to estimate the defects depth. The disadvantage is a limited depth of the analysis, a limited area that can be inspected (with regard to a usable power of excitation sources) and a dependence of detection capabilities on geometrical orientation of defects.

* Transient thermography (step thermography, thermal wave method). In principle, the excitation and evaluation are similar to the pulse thermography, however, the pulse length is much bigger. Less powerful excitation sources are required compared to the pulse thermography. It is therefore possible to analyze larger areas and the measurement time is shorter than in the case of Lock-In thermography. As in the pulse thermography, the sensitivity of the method is limited by the geometrical orientation of defects. Halogen lamps are the suitable excitation source for this type of evaluation.

* Continual excitation. The simplest method usable only in special applications.

A high-speed cooled infrared camera with a high sensitivity is commonly used for IRNDT applications. However, an uncooled bolometric infrared camera can be used for specific applications. It can significantly reduce acquisition costs of the measurement system.

The IR nondestructive testing system are usually modular. It means that various excitation sources can be combined with various infrared cameras and various evaluation methods depending on application, tested material, measuring time demands, size of a tested area, etc. The modularity allows universal usage of the system for various industrial, scientific and research applications.

Applications

IRNDT (infra-red nondestructive testing) method is suitable for detection and inspection of cracks, defects, cavities, voids and inhomogeneities in material, it is also possible to use the method for inspection of welded joints of metal and plastic parts, inspection of

IRNDT (infra-red nondestructive testing) method is suitable for detection and inspection of cracks, defects, cavities, voids and inhomogeneities in material, it is also possible to use the method for inspection of welded joints of metal and plastic parts, inspection of solar cell

A solar cell, also known as a photovoltaic cell (PV cell), is an electronic device that converts the energy of light directly into electricity by means of the photovoltaic effect.

s and solar panel

A solar panel is a device that converts sunlight into electricity by using photovoltaic (PV) cells. PV cells are made of materials that produce excited electrons when exposed to light. These electrons flow through a circuit and produce direct ...

s, determination of internal structure of material etc.

The main advantage of IRNDT method is availability for inspection of various materials in wide range of industrial and research applications. IRNDT measurement is fast, nondestructive and noncontact. Restrictive condition for IRNDT method is inspection depth combined with dimension and orientation of defect/crack/inhomogeneity in material.

Inspection of laser welded plastic parts

Laser welding

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word ''laser'' originated as an acronym for light amplification by stimulated emission of rad ...

of plastics is a progressive technology of connecting materials with different optical properties. Classical methods for testing of welding performance and weld joints quality – such as the metallographic cut microscopic analysis or X-ray

An X-ray (also known in many languages as Röntgen radiation) is a form of high-energy electromagnetic radiation with a wavelength shorter than those of ultraviolet rays and longer than those of gamma rays. Roughly, X-rays have a wavelength ran ...

tomography

Tomography is imaging by sections or sectioning that uses any kind of penetrating wave. The method is used in radiology, archaeology, biology, atmospheric science, geophysics, oceanography, plasma physics, materials science, cosmochemistry, ast ...

– are not suitable for routine measurements. Pulse IRNDT analysis can be successfully used for weld inspection in many cases.

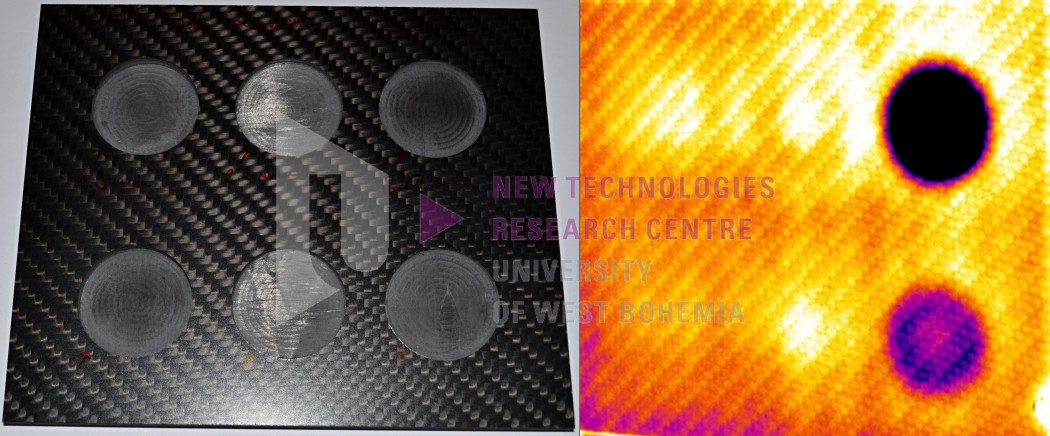

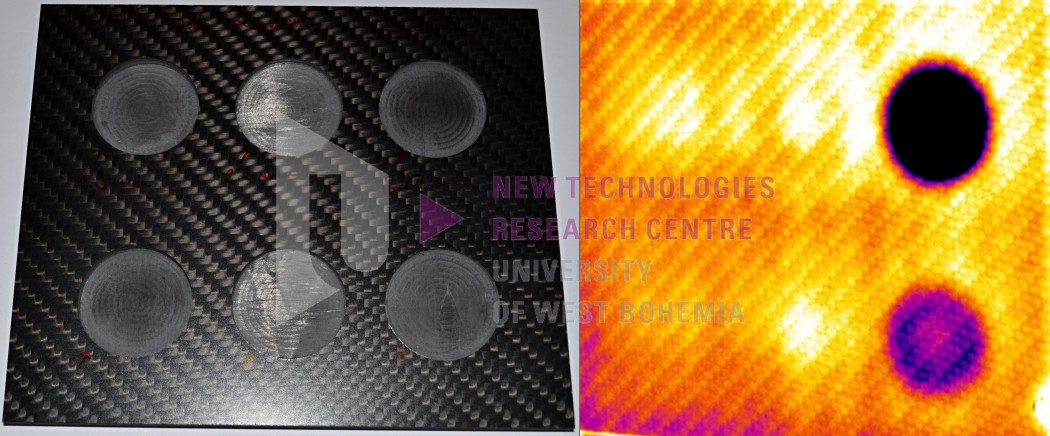

The images show an example of plastic parts inspection with a defective weld and with a correct weld. The gaps in the defective weld and the correct uninterrupted weld line are both well visible in the results of the IRNDT flash-pulse analysis.

Inspection of laser welded joints

Laser beam welding

Laser beam welding (LBW) is a welding technique used to join pieces of metal or thermoplastics through the use of a laser. The beam provides a concentrated heat source, allowing for narrow, deep welds and high welding rates. The process is freque ...

is a modern technology of fusion welding

Fusion welding is a generic term for welding processes that rely on melting to join materials of similar compositions and melting points. Due to the high-temperature phase transitions inherent to these processes, a heat-affected zone is created ...

. Currently finds its wide usage not only in the field of scientific research but also establishes itself in a variety of industries. Among the most frequent users belong the automotive industry

The automotive industry comprises a wide range of company, companies and organizations involved in the design, Business development, development, manufacturing, marketing, selling, Maintenance, repairing, and Custom car, modification of motor ve ...

, which due to its stable continuous innovation enables fast implementation of advanced technologies in their production. It is clear that laser welding significantly enhances engineering designs and thus brings a number of new products which previously could not be made by conventional methods.

The laser welding

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word ''laser'' originated as an acronym for light amplification by stimulated emission of rad ...

can produce quality welds of different types, both extremely thin and thick blanks. Weldable are common carbon steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states:

* no minimum content is specified or required for chromium, cobalt ...

s, stainless steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES), or rustless steel, is an iron-based alloy that contains chromium, making it resistant to rust and corrosion. Stainless steel's resistance to corrosion comes from its chromi ...

s, aluminum

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

and its alloys, copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

, titanium

Titanium is a chemical element; it has symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in ...

and last but not least, special materials and its combinations.

An integral part of the weldment production is a quality control

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "a part of quality management focused on fulfilling quality requirements".

This approach plac ...

. Unlike conventional non-destructive test methods, IRNDT is used not only after the laser welding process, but also during it. This makes possible to decide whether or not to the weldment comply with established quality criteria during manufacture process.

Solar cells testing

Active thermography, particularly lock-in thermography, is widely employed for inspecting solar cells. While effective, lock-in thermography often requires physical contact with the solar cell for excitation. However, techniques that involve periodic excitation using light sources allow for non-contact testing of electrode-free cells. Common methods such as Illuminated Lock-In Thermography (ILIT) and Open Circuit Voltage Illuminated Lock-In Thermography (VOC-ILIT) are used to investigate defects or issues like ohmic shunts, cracks, open or short circuits, and degradation in photovoltaic materials. Pulsed thermography, another method under investigation, provides a non-contact alternative with significantly reduced inspection times; however, it usually offers lower detectability than the ILIT method.References

{{Reflist Materials science