Gas Spring on:

[Wikipedia]

[Google]

[Amazon]

A gas spring, also known as a gas strut or gas damper, is a type of spring that, unlike a typical mechanical spring that relies on

A gas spring, also known as a gas strut or gas damper, is a type of spring that, unlike a typical mechanical spring that relies on

A gas spring, also known as a gas strut or gas damper, is a type of spring that, unlike a typical mechanical spring that relies on

A gas spring, also known as a gas strut or gas damper, is a type of spring that, unlike a typical mechanical spring that relies on elastic deformation

In engineering, deformation (the change in size or shape of an object) may be ''elastic'' or ''plastic''.

If the deformation is negligible, the object is said to be ''rigid''.

Main concepts

Occurrence of deformation in engineering application ...

, uses compressed gas

Bottled gas is a term used for substances which are gaseous at standard temperature and pressure (STP) and have been compressed and stored in carbon steel, stainless steel, aluminum, or composite containers known as gas cylinders.

Gas sta ...

contained within an enclosed cylinder

A cylinder () has traditionally been a three-dimensional solid, one of the most basic of curvilinear geometric shapes. In elementary geometry, it is considered a prism with a circle as its base.

A cylinder may also be defined as an infinite ...

. They rely on a sliding piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder (engine), cylinder a ...

to pneumatically

Pneumatics (from Greek 'wind, breath') is the use of gas or pressurized air in mechanical systems.

Pneumatic systems used in industry are commonly powered by compressed air or compressed inert gases. A centrally located and electrically- ...

store potential energy

In physics, potential energy is the energy of an object or system due to the body's position relative to other objects, or the configuration of its particles. The energy is equal to the work done against any restoring forces, such as gravity ...

and withstand external force

In physics, a force is an influence that can cause an Physical object, object to change its velocity unless counterbalanced by other forces. In mechanics, force makes ideas like 'pushing' or 'pulling' mathematically precise. Because the Magnitu ...

applied parallel to the direction of the piston shaft (loosely analogous similarly to a bicycle pump

A bicycle pump is a type of positive-displacement air pump specifically designed for inflating bicycle tires. It has a connection or adapter for use with one or both of the two most common types of valves used on bicycles, Schrader or ...

without a gas outlet).

Gas springs are used in automobiles to support hatches, hoods, and covers. They are also used in furniture and doors, as well as in medical beds. They are used industrially in machine tool presses. Fast-acting gas springs are used in aerospace design and weapons applications, and large, extended gas springs are used in passive heave compensators, which stabilize drilling operations against waves.

Gas springs are usually implemented in one of two ways. A ''pneumatic suspension'' gas spring directly compresses a chamber of air with the piston. A ''hydro-pneumatic suspension'' gas spring instead compresses a chamber of oil linked to an accumulator in which the pressure of the oil compresses the gas. Nitrogen

Nitrogen is a chemical element; it has Symbol (chemistry), symbol N and atomic number 7. Nitrogen is a Nonmetal (chemistry), nonmetal and the lightest member of pnictogen, group 15 of the periodic table, often called the Pnictogen, pnictogens. ...

is a common gas in gas springs because it is inert and nonflammable.

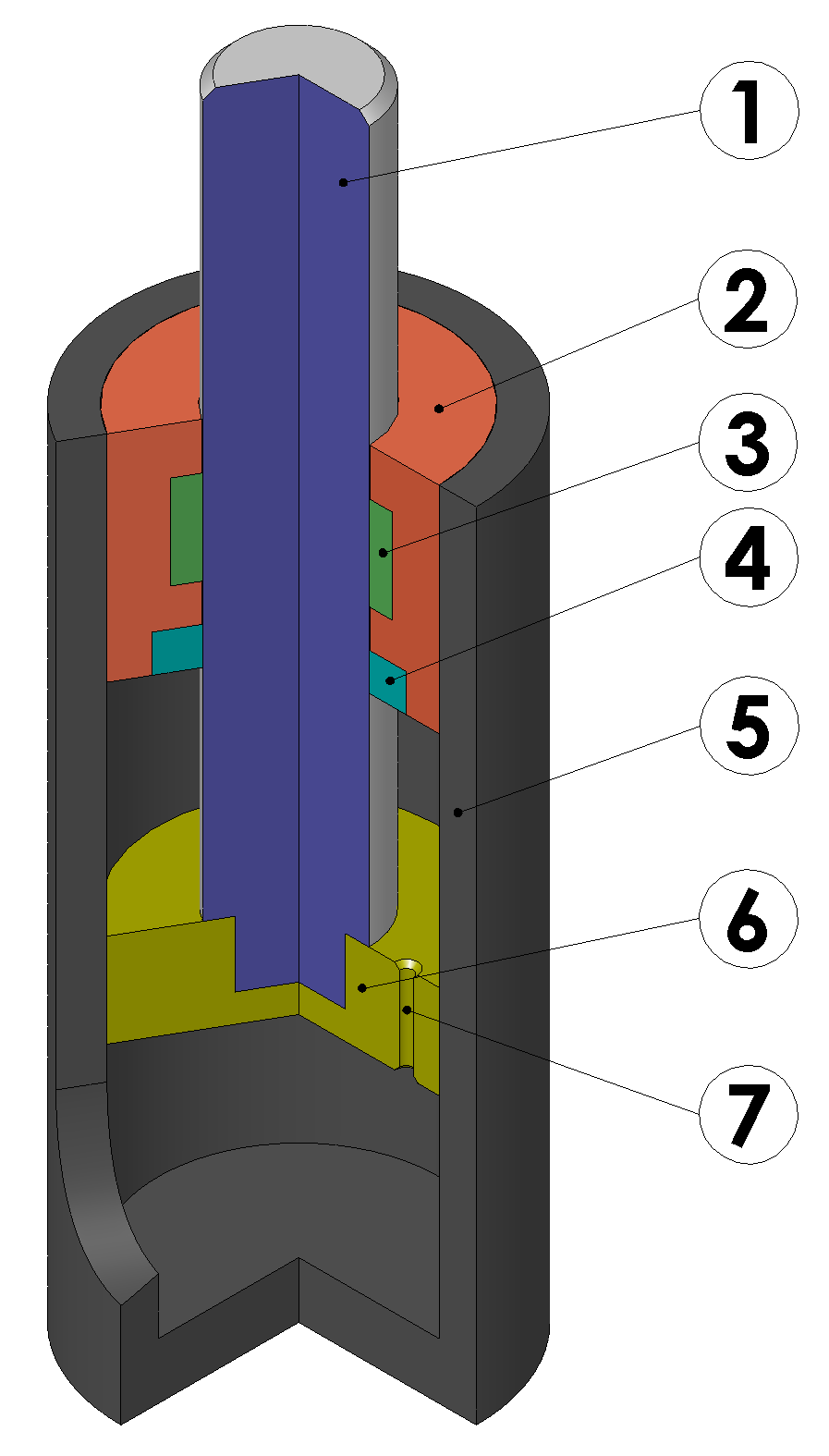

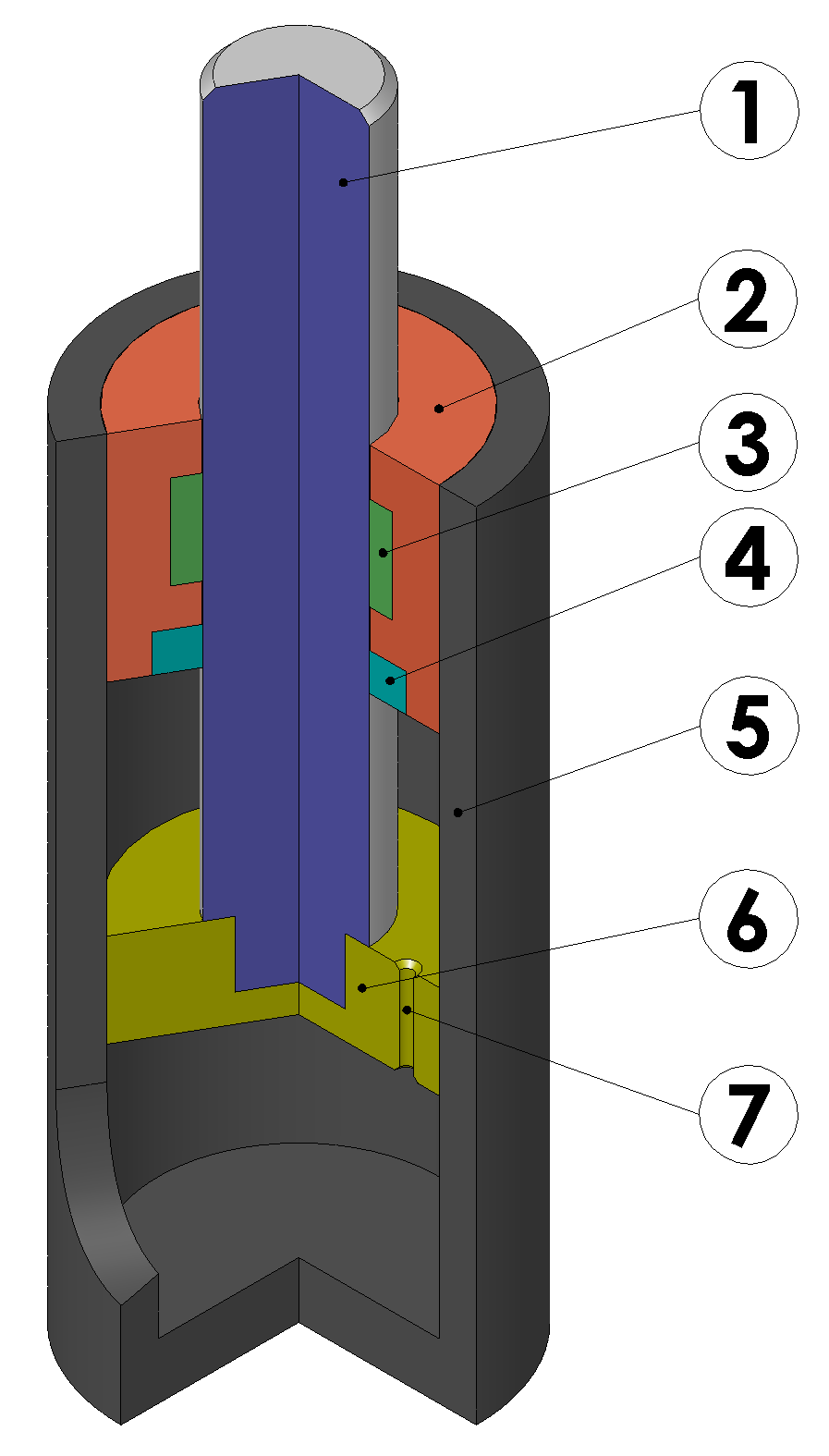

Principle of operation

A gas spring consists of a sealed cylinder filled with a charge of high-pressure gas, a piston rod attached to a piston with a sliding seal, and some oil. The piston (or the cylinder wall) contains a number of channels that allow the gas to transfer between the lower chamber (between the piston and the closed end of the cylinder) and the upper chamber (between the piston and the head cap). This causes the pressure in both chambers to equilibrate no matter how far the piston is pushed down the tube. In the ideal case of a piston moving with zero friction through a fully sealed cylinder, there are two key phenomena which can be thought of as acting simultaneously inside the spring as it is compressed. Firstly, as the spring is compressed and the piston rod is pushed into the cylinder, the effective volume of the cylinder decreases due to the extra space now being occupied by the solid piston rod. This would be the case even if there were no piston attached to the rod, as the only changing factor is the cylindrical volume of the rod itself. Second, the bottom of the piston always experiences a greater force opposite to the compressing action than the top. Even though the compressed gas exerts an equal amount of force on all the inner surfaces of the cylinder and piston rod, the force contribution in the direction of travel is practically zero for the sides of the rod, but nearly total for the bottom of the rod. The addition of a piston to the end of the rod thus does not alter the net forces involved, but instead partially separates the cylinder into two volumes with restricted flow of gas and oil between them, through flow-restriction channels in either the piston or the cylinder wall. Gas springs whose pistons have fine holes in them for damping are called slow-damper springs and are common on safety gates and doors.Other details

According toHooke's law

In physics, Hooke's law is an empirical law which states that the force () needed to extend or compress a spring by some distance () scales linearly with respect to that distance—that is, where is a constant factor characteristic of ...

, If the internal plunger features a diaphragm that extends to the side of the gas tube, it will stop moving once the applied force becomes constant and will support a weight, like a normal spring. Some gas springs have fine holes in the plunger for additional damping: these are called "slow-damper springs" and are common on safety gates and doors. A gas spring designed for fast operation(s) is termed a "quick gas spring" and is used in the manufacture of air gun

An air gun or airgun is a gun that uses energy from compressed air or other gases that are mechanically pressurized and then released to propel and accelerate projectiles, similar to the principle of the primitive blowgun. This is in contr ...

s and recoil buffer A recoil buffer is a factory-installed or aftermarket component of firearms which serves to reduce the velocity and/or cushion the impact of recoiling parts of a firearm.

Design

The simplest form of recoil buffer is made from a resilient and defor ...

s.

It is possible to reduce the gas volume and increase its internal pressure by means of a movable end stop, or by allowing one tube to slide over another, allowing the characteristics of a gas spring to be adjusted during operation. The rod may be hollow by use of clever seals, or it may consist of multiple small-diameter rods. A small amount of oil is normally present.

The gas may be introduced by a Schrader-type valve, using a lip seal around the rod and forcing it to allow gas in by external overpressure or a shuttling O-ring

An O-ring, also known as a packing or a toric joint, is a mechanical gasket in the shape of a torus; it is a loop of elastomer with a round cross section (geometry), cross-section, designed to be seated in a groove and compressed during assembl ...

system. Gas springs with high caliber contain a very large amount of energy, and can be used as a power pack. In emergency use, the gas may be introduced via a gas generator cell, similar to those used in airbag

An airbag is a vehicle occupant-restraint system using a bag designed to inflate in milliseconds during a collision and then deflate afterwards. It consists of an airbag cushion, a flexible fabric bag, an inflation module, and an impact sensor. ...

s.

Variations

A gas spring can be given adjustable push-in force via a local knob or remote via a Bowden wire. Extended stroke is usually acquired through telescoping mechanisms, composed of one rod and multiple cylinders, where the smaller of the two cylinders actually acts as a second rod extending in and out of the larger cylinder. There are also techniques to make variable-lift gas springs. These are intended for short production runs and prototypes, and in applications where the exact force is important but hard to estimate in advance, such as lifting a lid slowly in a known time. In this case, the cylinder is supplied filled to maximum design pressure but equipped with a bleed port to allow gas to be released once installed. The intention is that the design can be over-sprung, and then the pressure is reduced in stages to optimize behavior. If too much gas is released, a new spring must be installed. It is also possible to make degressive gas springs, where the spring becomes more, not less, powerful as the main cylinder expands.Consequences

Poor manufacturing

Gas springs are often used in office chairs, truck tailgates, and wheelchairs, just to name a few. A rare concern with gas springs is that if it is made cheaply, using oxygen as its internal gas, the oxygen will combust given enough force. This is because oxygen is a combustible gas and nitrogen is not. Oxygen is not flammable itself however, it does oxidize the internal parts in high heat. The internal parts of the gas spring, in great tension and heat, then explodes with the oil and grease within the gas spring. A reported incident in 2008 involved an elderly man who suffered severe injuries due to a 150mm rod forcefully ejected from the explosion. There are a few common signs of failure for gas springs. To list a few: Leakage of gasses, failure to support its weight compacity, unusual noises, excessive bouncing, and sagging.See also

*Shock absorber

A shock absorber or damper is a mechanical or hydraulics, hydraulic device designed to absorb and Damping ratio, damp shock (mechanics), shock impulses. It does this by converting the kinetic energy of the shock into another form of energy (typic ...

References

{{DEFAULTSORT:Gas Spring Springs (mechanical)