Ford Flathead V8 Engine on:

[Wikipedia]

[Google]

[Amazon]

The Ford flathead V8 (often called simply the Ford flathead or flathead Ford) is a

as this video on the Ford flathead V8 shows

. The short crankshaft proved quite durable in comparison to six-cylinder engines when roughly handled. For these reasons, the flathead Ford became a favorite among hot-rodders, and this in turn led to a rich supply of aftermarket performance parts. With the use of specialized pistons or connecting rods the stroke of the crankshaft could be increased by welding and regrinding as a method of increasing engine displacement, usually in combination with overboring.

One of the most important innovations in the Ford flathead V8 was the

One of the most important innovations in the Ford flathead V8 was the

Types are classified by their

Types are classified by their

Simca Unic Marmon Bocquet

(SUMB) light trucks of the French military. During the 1990s, the Ford V8 that was used in these trucks was decommissioned and removed for more economical

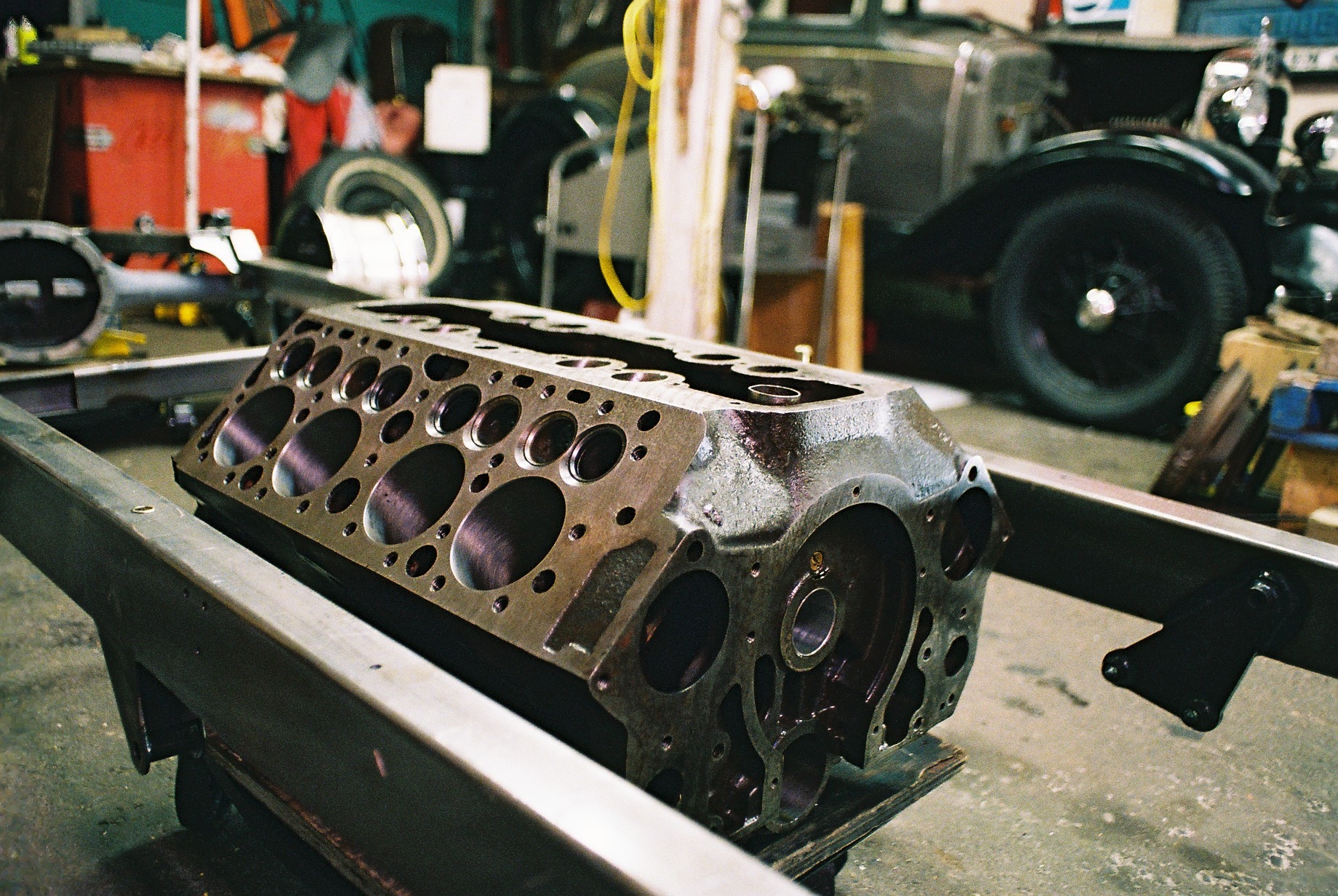

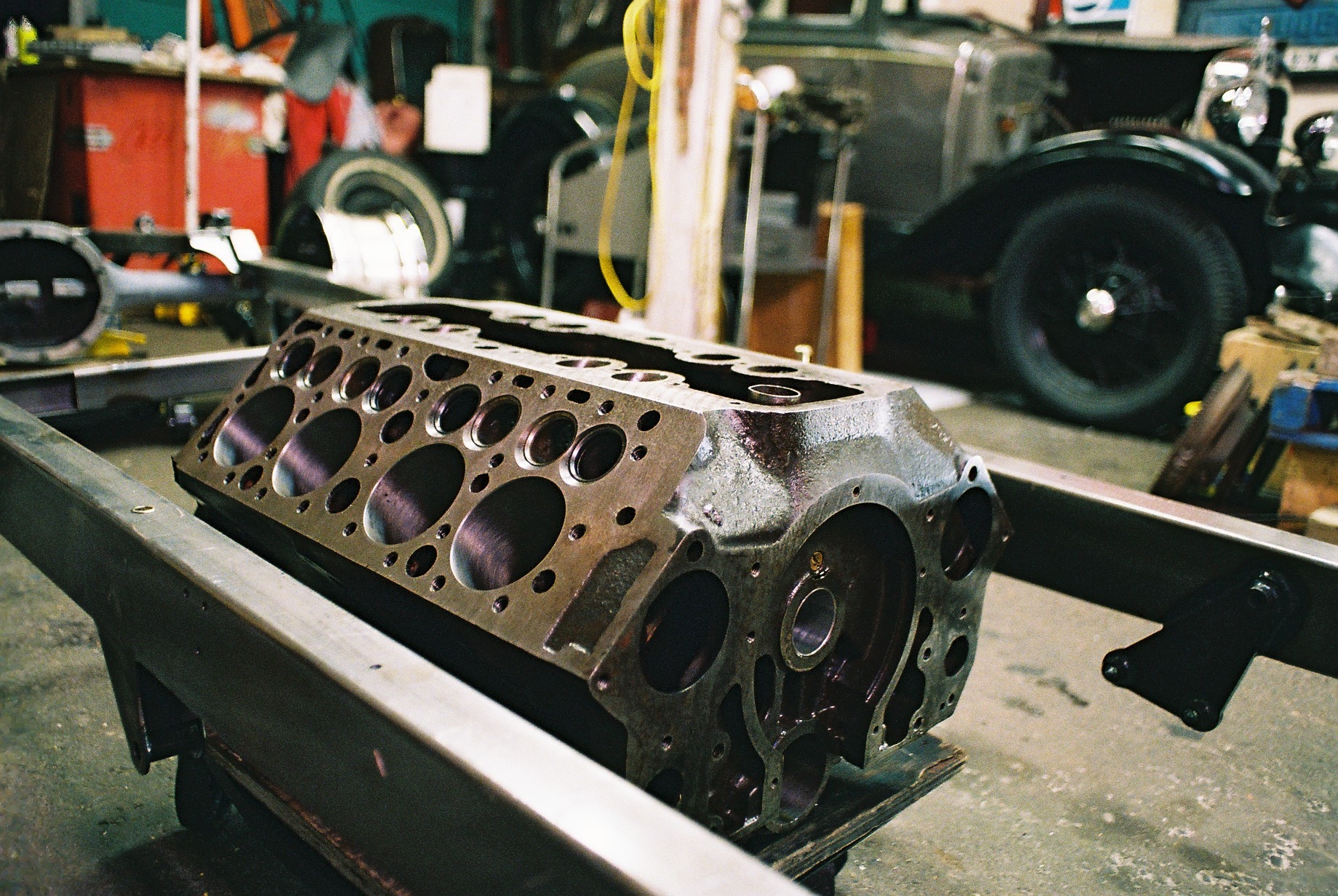

Newly Engineered Flathead BlockFord Flathead V8 Engine Guide

{{DEFAULTSORT:Ford flathead V8 engine Flathead V8 engines Gasoline engines by model

V8 engine

A V8 engine is an eight- cylinder piston engine in which two banks of four cylinders share a common crankshaft and are arranged in a V configuration.

Origins

The first known V8 was the Antoinette, designed by Léon Levavasseur, a ...

with a flat cylinder head introduced by the Ford Motor Company

Ford Motor Company (commonly known as Ford) is an American multinational corporation, multinational automobile manufacturer headquartered in Dearborn, Michigan, United States. It was founded by Henry Ford and incorporated on June 16, 1903. T ...

in 1932 and built by Ford through 1953. During the engine's first decade of production, when overhead-valve engines were used by only a small minority of makes, it was usually known simply as the Ford V‑8, and the first car model in which it was installed, the Model 18, was (and still is) often called simply the "Ford V-8" after its new engine.

An automotive milestone as the first affordable V8, it ranks as one of the company's most important developments.. The engine was intended to be used for big passenger cars and trucks;. p 214 it was installed in such (with minor, incremental changes). until 1953, making the engine's 21-year production run for the U.S. consumer market longer than the 19-year run of the Ford Model T engine. It was also built independently by Ford licensees..

The Ford flathead V8 was named on Ward's list of the 10 best engines of the 20th century. It was a staple of hot rodders in the 1950s, and it remains famous in the classic car

A classic car is typically described as an automobile 25 years or older, although a car's age is not the only requirement it must meet before being considered a "classic." However, a standard criteria for recognizing cars as classics does not ex ...

hobbies even today, despite the huge variety of other popular V8s that followed.

Development and production

Ford had helped pioneer the concept of an affordable mass-produced car. Historically, these used inline-four andinline-six

A straight-six engine (also referred to as an inline-six engine; abbreviated I6 or L6) is a piston engine with six cylinders arranged in a straight line along the crankshaft. A straight-six engine has perfect primary and secondary engine balanc ...

cylinder engines. Following French engineer Léon Levavasseur's invention of the V8 in 1902, V8s, V12s, and even V16s, were produced for use in luxury models.. The Cadillac V8 engine

The term Cadillac V8 may refer to any of a number of V8 engines produced by the Cadillac, Cadillac division of General Motors since it pioneered the first such mass-produced engine in 1914.

Most commonly, such a reference is to one of the manufa ...

is credited as the first mass-produced V8, and when Ford Motor Company acquired rival luxury marque Lincoln in 1922, the maker was already producing a flathead V8 with fork and blade connecting rods, which remained in production after Ford took over until 1932.

Even though Ford had an engineering team assigned to develop its own V8, many of the ideas and innovations were Henry Ford

Henry Ford (July 30, 1863 – April 7, 1947) was an American Technological and industrial history of the United States, industrialist and business magnate. As the founder of the Ford Motor Company, he is credited as a pioneer in making automob ...

's. The Model A, its variants (B and 18), and this V8 engine were developed between 1926 and 1932, and this period was the elder Ford's last central contribution to the company's engineering.

Mercury's version of the engine was introduced in 1939.

An economizing design feature of this engine was the use of three main bearings to support the crankshaft, rather than the customary five used with most V-8s. The flathead mounted the camshaft

A camshaft is a shaft that contains a row of pointed cams in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition syst ...

above the crankshaft

A crankshaft is a mechanical component used in a reciprocating engine, piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating Shaft (mechanical engineering), shaft containing one or more crankpins, ...

, like later pushrod-operated overhead-valve engines. Valves for each bank were mounted inside the triangular area formed by the "vee" of cylinders. The intake manifold fed both banks from inside the vee, but the exhaust ports had to pass between the cylinders to reach the outboard exhaust manifolds, since it did not use a t-head configuration. Such an arrangement transferred exhaust heat to the block, imposing a large cooling load; it required far more coolant and radiator capacity than equivalent overhead-valve V8 engines. Ford flathead V8s were notorious for cracking blocks if their barely adequate cooling systems were overtaxed (such as in trucking or racing). The simple design left much room for improvement, and the power available after even low cost modifications was usually substantially more than could be obtained from an overhead-valve inline six-cylinder engine of similar displacement

Displacement may refer to:

Physical sciences

Mathematics and physics

*Displacement (geometry), is the difference between the final and initial position of a point trajectory (for instance, the center of mass of a moving object). The actual path ...

.

The Ford flathead V8 was licensed to other producers. It was used by Simca in France

France, officially the French Republic, is a country located primarily in Western Europe. Overseas France, Its overseas regions and territories include French Guiana in South America, Saint Pierre and Miquelon in the Atlantic Ocean#North Atlan ...

until 1961 and in Brazil

Brazil, officially the Federative Republic of Brazil, is the largest country in South America. It is the world's List of countries and dependencies by area, fifth-largest country by area and the List of countries and dependencies by population ...

until 1964 for cars and until 1990 in the Simca Unic Marmon Bocquet military truck. In the United States, the flathead V8 was replaced by the more modern overhead-valve Ford Y-block engine in 1954. During World War II

World War II or the Second World War (1 September 1939 – 2 September 1945) was a World war, global conflict between two coalitions: the Allies of World War II, Allies and the Axis powers. World War II by country, Nearly all of the wo ...

, the engine was used on the first prototype of the Romanian Mareșal tank destroyer, but was considered too weak and thus replaced by more powerful engines for later versions of the vehicle.

Components

Crankshaft

The crankshaft development for the Ford flathead V8 was pioneering. The engine's production development program began with a forged steel crank, per conventional practice, but Ford then developed the improvedfoundry

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. The most common metals pr ...

practice, heat-treating, and materials handling logistics to make the cranks from cast steel

Steel casting is a specialized form of casting involving various types of steel cast to either final/net or near-net shape. Steel castings are used when iron castings cannot deliver enough strength or shock resistance.Oberg, p. 1332

Examples ...

instead, yielding a crank just as strong, but less expensive to produce.. These new methods were patented. The simple three-main-bearing crankshaft attached two connecting rods to a single crankpin, one rod from each cylinder bank. As with other crankshafts, static and dynamic balancing was performedas this video on the Ford flathead V8 shows

. The short crankshaft proved quite durable in comparison to six-cylinder engines when roughly handled. For these reasons, the flathead Ford became a favorite among hot-rodders, and this in turn led to a rich supply of aftermarket performance parts. With the use of specialized pistons or connecting rods the stroke of the crankshaft could be increased by welding and regrinding as a method of increasing engine displacement, usually in combination with overboring.

Block

One of the most important innovations in the Ford flathead V8 was the

One of the most important innovations in the Ford flathead V8 was the casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or ...

of the crankcase

A crankcase is the housing in a reciprocating engine, piston engine that surrounds the crankshaft. In most modern engines, the crankcase is integrated into the engine block.

Two-stroke engines typically use a crankcase-compression design, res ...

and all 8 cylinders

A cylinder () has traditionally been a three-dimensional solid, one of the most basic of curvilinear geometric shapes. In elementary geometry, it is considered a prism with a circle as its base.

A cylinder may also be defined as an infinite ...

in one engine block

In an internal combustion engine, the engine block is the structure that contains the cylinders and other components. The engine block in an early automotive engine consisted of just the cylinder block, to which a separate crankcase was attach ...

. This level of monobloc design for V-8 blocks had been accomplished before, but it had never seen mass production. Making it practical for the latter was an example of the production development needed to bring a V8 engine to the widely affordable segment of the market. Most V engines of the time had multiple cylinder blocks bolted to a common crankcase (itself a separate casting). At most, each bank of the V was an integral block, but many V engines had four- or even six-cylinder blocks, with cylinders cast in pairs or triples. Like most other engine blocks of the 20th century, it was cast iron

Cast iron is a class of iron–carbon alloys with a carbon content of more than 2% and silicon content around 1–3%. Its usefulness derives from its relatively low melting temperature. The alloying elements determine the form in which its car ...

; but the foundry practice (e.g., workflows, materials handling) was a revolutionary advancement in the mass production of castings.. Charles E. Sorensen lived up to his longtime nickname at Ford, "Cast-Iron Charlie", by leading this revolution to bring Ford's first V8 to market.

As with any V8, the block was relatively light for the displacement supported. The cooling jacket reaches down to the bottom dead center, which is unusually low. American engineers at the time believed this would improve the piston cooling.. p 215 The bottom of the block formed the parting line for the main bearing caps. The most complex part of the block was the exhaust passage routing. The exhaust valves were on the inside of the V and exhaust flow was initially downward and passed around the cylinders through the water jacket to exit on the outside of the cylinder block. The routing of the exhaust through the water jacket put an extremely heavy load on the cooling system and led to frequent overheating, especially on early models, if the cooling system was not maintained. Somewhat primitive water pumps used until the advent of the 1948 8RT and 1949 8BA models also contributed to the overheating problem. The space for the exhaust flow was also somewhat restricted, so the exhaust passages were tall and narrow in some locations. The gas flow past the rough sand castings could be greatly improved by polishing the passages. In early blocks, some cylinder walls were extremely thin due to cores shifting during casting.

Bearings

The engines built from 1932 to 1935 had poured main bearings which required skill and machine shop equipment to overhaul. Part of the 1936 production and all production from 1937 to the end of flathead V8 production had both replaceable shell main bearings and connecting rod inserts, enabling straightforward and low cost rebuilding, another reason why the Ford was a favorite of amateur mechanics. These shell main bearings are made of a cadmium silver alloy.Camshaft and timing

The Ford flathead V8 has a single camshaft located inside the engine block above the crankshaft. It is spur gear driven; the camshaft's spur gear is made of plastic. The camshaft has three camshaft bearings. A lid made of cast iron covers the camshaft spur gears; the ignition distributor is placed on top of this lid and is driven by the camshaft spur gears. For powering the fuel pump, the camshaft is fitted with an extra cam located in the bearing on the flywheel side.Lubrication

Ford products used high oil pressure for lubrication for the main and rod bearings, as do all modern vehicle combustion engines. This offered a significant performance advantage, as full pressure lubrication allowed for continuous use above 3500 rpm and would not starve the rod bearings for oil, which was necessary for high performance applications, such as racing. For this reason, bank robber Clyde Barrow preferred to steal Fords as getaway vehicles. It also eliminated a complex oil jet system to feed the rod bearings in the oil pan. As a side benefit to a prospective purchaser of a used vehicle, this also enabled the condition of the connecting rod and main bearings to be determined indirectly by observation of the oil pressure gauge after the vehicle was warmed up, provided that oil of normal viscosity was in use.Exhaust

The exhaust outlets in the 1932–48 cars and the 1932–47 trucks were near the front of the manifolds aiming down and sometimes out. A Y-pipe took the exhaust gases to the right side of the vehicle to a single muffler, then to a single pipe out the back on the right side. The left side exhaust manifold exhausted to the front in the 1949–53 Ford cars, where a crossover pipe took the exhaust to the forward end of the right side manifold on the car engines and between the 1st and second cylinder on some trucks, in turn exhausting to a single pipe at the rear. A common conversion for the 1949–53 Ford cars and 1952–53 Mercurys was to block off the right forward manifold entrance and route the left side exhaust to a new pipe to form a dual exhaust system with better flow characteristics. These typically involved installation of free-flowing mufflers, which if at a legal noise level still allowed low frequency sounds to pass, giving a characteristic rumbling dual exhaust sound to these systems. In the 1950s shortcut exhaust outlets with manually removed covers were added to street machines in emulation of vehicles intended for high speed straight line racing on dry lake beds, typically located just behind the front wheel, although chromed external runners sometimes extended to just forward of the rear wheel. These covers were referred to as ''lake plugs'', the pipes as ''lake pipes''. This style exhaust was also used legally in sanctioned drag racing and illegally in unsanctioned performance demonstrations.Internal Air flow

More extreme modifications were to improve the airflow by removing material from the top of the block between the valves and the cylinders (called ''relieving''), increasing the size of the inlet and exhaust passages (called ''porting''), and by ''polishing'' the sand-cast surfaces to improve air flow. Increased compression ratios could be cheaply obtained by milling material from the head or by obtaining aluminum heads as aftermarket parts. Higher capacity intake manifolds were similarly available. Changing the camshaft to a higher performance version required head removal so that the valves could be held up out of the way, so this was usually done only as part of a substantial rework of the basic engine.Overhead-valve kits

A popular modification for the flathead was conversion to an overhead-valve configuration, and many such modification kits were available, including the ''Ardun'' heads fromZora Arkus-Duntov

Zachary "Zora" Arkus-Duntov (born Zachar Arkus; December 25, 1909 – April 21, 1996) was a Russian"U.S., World War II Draft Cards Young Men, 1940-1947," digital images, ''Ancestry.com'' (http://www.ancestry.com : accessed May 21, 2024), Zachar A ...

who was to go on to fame as the "father of the Corvette". These conversions were not initially demanded by hot rod

Hot rods are typically American cars that might be old, classic, or modern and that have been rebuilt or modified with large engines optimized for speed and acceleration. One definition is: "a car that's been stripped down, souped up and ma ...

ders looking for extra power, as they had not yet exhausted the capabilities of the flathead configuration, but were demanded by users of the engine in trucks and other such high load applications, where the constant flow of hot exhaust through the block to the exhaust manifolds caused the entire engine to overheat; the overhead-valve heads routed the exhaust out more directly, and away from the block.

Hot-rodding applications

In the early 1950s, many hot-rodders could not afford to purchase and modify even a "cheap" flathead V-8, and a large investment in machine work and aftermarket parts was necessary to bring a Ford flathead V-8 to even the performance levels of most stock OHV V-8s available at the time. Even many inline six-cylinder engines from that period could be modified to produce more reliable and practical power than Ford V-8s, as the Ford flathead V-8 is saddled with many design features that make modifying it for true high-performance use difficult and expensive compared with other V-8s. As modern OHV V-8s became available and affordable in salvage yards, the Ford flathead V-8 rapidly disappeared from the hot-rodding scene. Hot-rodding in general moved away from the salvage-yard car builds as parts and labor became more expensive and many hot-rod shops priced themselves out of business. The modern OHV V-8 powered vehicles available also contributed to the demise of hot-rodding's original culture (affordable modifications by working-class car owners), as new factory cars became capable of much higher performance than most hot-rods. Today the flat-head Ford is mainly used in "retro" hot-rod builds by builders more interested in an historic feel and recreating history than performance. Even four-cylinder Ford engines are used to make a retro hot-rod "correct".Modern performance flatheads

Ford flatheads are stillhot rod

Hot rods are typically American cars that might be old, classic, or modern and that have been rebuilt or modified with large engines optimized for speed and acceleration. One definition is: "a car that's been stripped down, souped up and ma ...

ded today, with a special land speed record

The land speed record (LSR) or absolute land speed record is the highest speed achieved by a person using a vehicle on land. By a 1964 agreement between the Fédération Internationale de l'Automobile (FIA) and Fédération Internationale de M ...

class for flathead engines. The current record holder achieves and . The current land speed record for a Ford flathead V8 stands at 302.462mph.

Tractor conversions

During the 1930s to 1950s, the farm market in North America and parts of Europe demanded ever-increasing power output from farmtractor

A tractor is an engineering vehicle specifically designed to deliver a high tractive effort (or torque) at slow speeds, for the purposes of hauling a Trailer (vehicle), trailer or machinery such as that used in agriculture, mining or constructio ...

s. It was in this climate that Ford experimented with V-8 tractor designs, some individual farmers converted their 4-cylinder tractors to Ford inline-6 or V-8 engines, and a few aftermarket companies offered such conversions for sale. Among the latter, the best-known were Funk conversions by brothers Joe and Howard Funk. In the 1930s, the Funk brothers built aircraft—including the Funk B, which used an engine design based on Ford engines. In the late 1940s, their aircraft line became unprofitable, but they found renewed profitability in aftermarket parts for tractors—transmissions, engines, and accessories. They sold many converted Ford N-Series tractors and conversion kits using Ford industrial inline-6 engines and Ford flathead V-8 engines.

Version types

displacement

Displacement may refer to:

Physical sciences

Mathematics and physics

*Displacement (geometry), is the difference between the final and initial position of a point trajectory (for instance, the center of mass of a moving object). The actual path ...

.

221

The original flathead engine displaced , with bore and stroke.''Street Rodder'', 1/85, p. 73 Theblock

Block or blocked may refer to:

Arts, entertainment and media Broadcasting

* Block programming, the result of a programming strategy in broadcasting

* W242BX, a radio station licensed to Greenville, South Carolina, United States known as ''96.3 ...

was cast as a single piece ('' monobloc'') for durability, and a single-barrel carburetor

A carburetor (also spelled carburettor or carburetter)

is a device used by a gasoline internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the Ventu ...

fed the engine. The 1932 V8-18 with 5.5:1 compression produced . The 1933–34 V8-40 raised compression to 6.33:1 and power to . In 1934 a two barrel down draft carburetor was introduced. 1935's V8-48 saw compression drop to 6.3:1, but power climb to , and torque was rated at . It became the V8-68 in 1936, with compression, horsepower, and torque unchanged.

Production of the original 221 lasted from 1932 through to 1936. These engines can be identified by the fact that the water pumps are at the front of the heads. A similar 221 flathead was used in Fords for 1937 and 1938 but the block was revised to have the water pumps mounted on the block. This design also relocated the water outlet from the front of the heads to the top center of the heads. These, designated V8-78, were offered with standard 6.2:1 compression aluminum or 7.5:1 compression iron cylinder head

In a piston engine, the cylinder head sits above the cylinders, forming the roof of the combustion chamber. In sidevalve engines the head is a simple plate of metal containing the spark plugs and possibly heat dissipation fins. In more modern ...

s, rated at and (aluminum) or (iron). The 1932 through 1938 motors used twenty-one studs to hold down each head and are known as "21 stud" motors. This motor continued to be made into the 1950s in Europe.

In late 1938 Ford introduced V8-81A, commonly called the "24 stud" engine because it uses twenty-four studs to hold down each head. This engine debuted at the same time as the 239 motor. With 6.12:1 compression, horsepower remained the same, but torque increased by . In 1939, as the V8-91A, compression increased to 6.15:1, power rose to , and torque reached ; the ratings remained the same for the 1940 V8-01A, 1941 V8-11A, and the last civilian model, the V8-21A, which saw compression rise to 6.2:1. This engine was used through 1942 for civilian use and saw some use in military vehicles during World War Two. Collectively all of the 221 motors are commonly referred to as "85 horse" motors.

239

Ford introduced the V8-99A engine with bore and stroke and 6.15:1 compression in 1939. It produced and . This was done to provide a more powerful engine for the Mercury cars, which Ford Motor Company started making in 1939. It was used in Mercurys in 1939 and in Fords in 1946. This engine is very similar to later versions of the 221 engine. As the V8-09A in 1940, compression, power, and torque were unchanged; in 1941, the V8-19A compression and power were static, but torque rose by , while the 1942 V8-29A increased compression to 6.4:1 and power to , while torque stayed the same. Postwar, it became the V8-69 (suffixed "A" in Fords, "M" in Mercurys), with compression 6.75:1, , and . For 1947 and 1948, only the designation changed, to V8-79 and -89. The 239 was redesigned in 1948 as the 8RT for Ford trucks and in 1949 as the 8BA for the cars. It had higher 6.8:1 compression, but performance was unchanged. The 1950 V8-0BA boosted torque by , the 1951 -1BA by more, while in 1952, as the V8-B2, compression climbed to 7.2:1, power to , and torque to , then to in the -B3 of 1953, its final year. The 1948 to 1953 engines have a revised cooling and ignition system. Collectively all 239 engines are referred to as "100 horse" engines, although the horsepower was increased in 1952 to 110 horsepower in cars and 106 horsepower in trucks. This engine was used in Ford's transit buses during the most productive years of the company's short stint in the transit bus business from the mid-1930s to the early 1950s, most notably in the 1939–1947 version of the Ford Transit Bus. The latest iteration of this engine was used from 1948 to 1953 in the U.S and till 1954 in Canada. It was initially designated the 8BA (see above) in automobiles and the 8RT in trucks. 8RT remained the truck engine designation throughout the entire run from 1948 through 1953 in the U.S (1954 in Canada). The engines were essentially identical. Earlier Ford V8s had the unique Ford designed distributor driven directly from the forward end of the camshaft, which was an inconvenient location for maintenance. This final flathead used a more conventional distributor driven at a right angle to the crankshaft and located at the right front of the engine where it was readily accessible. The water inlets and thermostat housings were moved to the front end of the heads, and the 21 studs and nuts that attached the heads on the old engine were replaced by 24 bolts.136

A V8-74 version was introduced in the United States in 1937. With bore and stroke and 6.6:1 compression, the engine was rated and . The designation changed again in 1939, to V8-922A, but the specifications remained the same. It was produced in Europe in 1935 and 1936, and was used in the many standard Ford vehicles based on the car platform of the era. It was not very popular with U.S. buyers who were used to the cars. Redesignated V8-82A in 1938, V8-922A in 1939, and V8-022A in 1940, compression, power, and torque remained unchanged. The engine was very popular as a powerplant for midget race cars afterWorld War II

World War II or the Second World War (1 September 1939 – 2 September 1945) was a World war, global conflict between two coalitions: the Allies of World War II, Allies and the Axis powers. World War II by country, Nearly all of the wo ...

. This engine is most commonly referred to as the "60 horse" flathead, or the V8-60. It was replaced by the 226 straight-6 in the 1941 Fords, though it would continue to be used after the war in the French Ford Vedette and the British Ford Pilot.

In 1952 Ford France (who called this engine the ''Aquilon'') created a somewhat bored out version displacing . Production was taken over by Simca in 1954 who began installing it in their Simca Vedette in 1955. Simca then transferred the Aquilon production line to Simca do Brasil, where it was kept in production until 1969 (the company was known as Chrysler Brazil from July 1967). Simca do Brasil introduced a version in May 1962 but the real surprise was the "Emi-Sul" of April 1966. This engine has overhead valves and hemispherical combustion chamber

A hemispherical combustion chamber is a combustion chamber in the cylinder head of an internal combustion engine with a domed "sphere, hemispheric" shape. An engine featuring this type of hemispherical chamber is known as a hemi engine. In pra ...

s; it produced in its most powerful version.

255

The 1948–1953 , referred to as the model BG, was achieved by use of a stroke crankshaft in the 8BA/8RT engine. It was only used in Mercury cars, and heavy service trucks. Known as the V8-9CM in 1949, it featured 6.8:1 compression, , and torque, which stayed the same for the 1950 V8-0CM. The 1951 V8-1CM raised this by , and torque, The 1952 V8-MA boosted compression to 7.2:1, power to , and torque to , while only the name changed, dropping the -MA, for the last year of production, 1953. Because of interchangeability, the Mercury crank made a popular upgrade in the 239 amonghot rod

Hot rods are typically American cars that might be old, classic, or modern and that have been rebuilt or modified with large engines optimized for speed and acceleration. One definition is: "a car that's been stripped down, souped up and ma ...

ders. In fact, in the 1950s, the flathead block was often fitted with crankshafts of up to stroke.''Street Rodder'', 1/85, p. 72. In addition, rodders in the 1950s routinely bored them out by (to ).

French-built 255 engines were fitted to thSimca Unic Marmon Bocquet

(SUMB) light trucks of the French military. During the 1990s, the Ford V8 that was used in these trucks was decommissioned and removed for more economical

Renault

Renault S.A., commonly referred to as Groupe Renault ( , , , also known as the Renault Group in English), is a French Multinational corporation, multinational Automotive industry, automobile manufacturer established in 1899. The company curr ...

engines to be retrofitted. Thus the Ford V8 engines were sold off and thus provided a new source of little-worn engines for the hotrodding community. The block metallurgy, being much later, was also stronger than the originals.

337

The flathead V8 was the largest production version of the Ford V8, designed for large truck service. When Lincoln could not produce theV12 engine

A V12 engine is a twelve-Cylinder (engine), cylinder Internal combustion engine#Reciprocating engines, piston engine where two banks of six cylinders are arranged in a V engine, V configuration around a common crankshaft. V12 engines are more c ...

for the 1949 model year, the 337 engine was adapted for passenger car use. The 337 features a bore and a stroke.

It was introduced in the 1948 two and a half ton and three ton Ford trucks and the 1949 Lincoln passenger cars. It was produced through the 1951 model year, and replaced in 1952 in Lincoln passenger cars and Ford three ton trucks with the overhead-valve Lincoln Y-block V8. The two and a half ton Ford trucks got a version of the 317 engine.

In the song " Hot Rod Lincoln", the engine referred to in the original lyrics was a Lincoln V12, not mentioned in the Commander Cody version.

*Vehicles used

** Lincoln (EL-series)

** Lincoln Cosmopolitan

** Ford F-Series (medium duty truck)

See also

* List of Ford engines *Universal Carrier

The Universal Carrier, a development of the earlier Bren Gun Carrier from its light machine gun armament, was one of a family of light armoured tracked vehicles built by Vickers-Armstrongs and other companies.

The first carriers – the Br ...

, the most-produced of all WWII tracked military vehicles, powered with Ford flathead V8 engines.

References

Sources

*Shelton, Chris. "Then, Now, and Forever" in ''Hot Rod'', March 2017, pp. 16–29.Bibliography

* * * * *External links

Newly Engineered Flathead Block

{{DEFAULTSORT:Ford flathead V8 engine Flathead V8 engines Gasoline engines by model