Die Cutting (web) on:

[Wikipedia]

[Google]

[Amazon]

Die cutting is the general process of using a die to shear webs of low-strength materials, such as

Die cutting is the general process of using a die to shear webs of low-strength materials, such as

rubber

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds.

Types of polyisoprene ...

, fibre

Fiber (spelled fibre in British English; from ) is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often incorp ...

, foil

Foil may refer to:

Materials

* Foil (metal), a quite thin sheet of metal, usually manufactured with a rolling mill machine

* Metal leaf, a very thin sheet of decorative metal

* Aluminium foil, a type of wrapping for food

* Tin foil, metal foil ma ...

, cloth

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, and different types of fabric. At first, the word "textiles" only referred to woven fabrics. However, weaving is n ...

, paper

Paper is a thin sheet material produced by mechanically or chemically processing cellulose fibres derived from wood, Textile, rags, poaceae, grasses, Feces#Other uses, herbivore dung, or other vegetable sources in water. Once the water is dra ...

, corrugated fibreboard, chipboard, paperboard

Paperboard is a thick paper-based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker (usually over 0.30 mm, 0.012 in, or 12 Inch#Equivalents, points) than paper and has certain superior ...

, plastic

Plastics are a wide range of synthetic polymers, synthetic or Semisynthesis, semisynthetic materials composed primarily of Polymer, polymers. Their defining characteristic, Plasticity (physics), plasticity, allows them to be Injection moulding ...

s, pressure-sensitive adhesive tapes, foam

Foams are two-phase materials science, material systems where a gas is dispersed in a second, non-gaseous material, specifically, in which gas cells are enclosed by a distinct liquid or solid material. Note, this source focuses only on liquid ...

, and sheet metal

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

Thicknesses can vary significantly; extremely thin sheets are considered foil (metal), foil or Metal leaf, leaf, and pieces thicker than 6 mm (0.25 ...

. In the metalworking

Metalworking is the process of shaping and reshaping metals in order to create useful objects, parts, assemblies, and large scale structures. As a term, it covers a wide and diverse range of processes, skills, and tools for producing objects on e ...

and leather

Leather is a strong, flexible and durable material obtained from the tanning (leather), tanning, or chemical treatment, of animal skins and hides to prevent decay. The most common leathers come from cattle, sheep, goats, equine animals, buffal ...

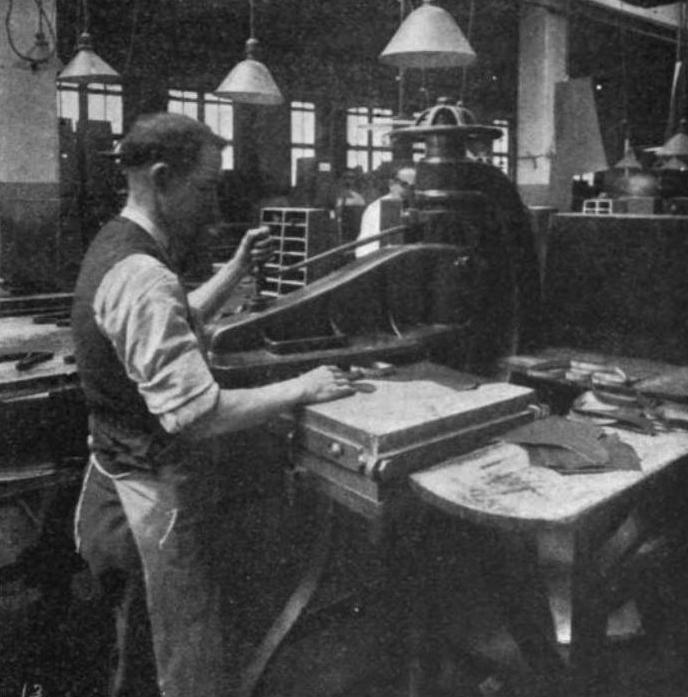

industries, the process is known as clicking and the machine may be referred to as a ''clicking machine''. When a ''dinking die'' or ''dinking machine'' is used, the process is known as dinking. Commonly produced items using this process include gasket

Some seals and gaskets

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to c ...

s, label

A label (as distinct from signage) is a piece of paper, plastic film, cloth, metal, or other material affixed to a container or product. Labels are most often affixed to packaging and containers using an adhesive, or sewing when affix ...

s, tokens, corrugated box

A box (plural: boxes) is a container with rigid sides used for the storage or transportation of its contents. Most boxes have flat, parallel, rectangular sides (typically rectangular prisms). Boxes can be very small (like a matchbox) or v ...

es, and envelope

An envelope is a common packaging item, usually made of thin, flat material. It is designed to contain a flat object, such as a letter (message), letter or Greeting card, card.

Traditional envelopes are made from sheets of paper cut to one o ...

s.

Die cutting started as a process of cutting leather for the shoe industry in the mid-19th century. It is now sophisticated enough to cut through just one layer of a laminate

Simulated flight (using image stack created by μCT scanning) through the length of a knitting needle that consists of laminated wooden layers: the layers can be differentiated by the change of direction of the wood's vessels

Shattered windshi ...

, so it is now used on labels, postage stamps

A postage stamp is a small piece of paper issued by a post office, postal administration, or other authorized vendors to customers who pay postage (the cost involved in moving, insuring, or registering mail). Then the stamp is affixed to the ...

, and other stickers; this type of die cutting is known as '.

Die cutting can be done on either flatbed or rotary press

A rotary printing press is a printing press in which the images to be printed are curved around a cylinder. Printing can be done on various substrates, including paper, cardboard, and plastic. Substrates can be sheet feed or unwound on a contin ...

es. Rotary die cutting is often done inline with printing

Printing is a process for mass reproducing text and images using a master form or template. The earliest non-paper products involving printing include cylinder seals and objects such as the Cyrus Cylinder and the Cylinders of Nabonidus. The ...

. The primary difference between rotary die cutting and flatbed die cutting is that the flatbed is not as fast but the tools are cheaper. This process lends itself to smaller production runs where it is not as easy to absorb the added cost of a rotary die.

Rotary die cutting

Rotary die cutting is die cutting using a cylindrical die on a rotary press and may be known as a rotary die cutter or RDC. A long sheet or web of material will be fed through the press into an area known as a "station" which holds a rotary tool that will cut out shapes, make perforations or creases, or even cut the sheet or web into smaller parts. A series ofgear

A gear or gearwheel is a rotating machine part typically used to transmit rotational motion and/or torque by means of a series of teeth that engage with compatible teeth of another gear or other part. The teeth can be integral saliences or ...

s will force the die to rotate at the same speed as the rest of the press, ensuring that any cuts the die makes line up with the printing on the material. The machines used for this process can incorporate multiple "stations" that die cut a particular shape in the material. In each of these stations lie one or more of these geared tools or printing cylinders, and some machines use automatic eye registration to make sure the cuts and/or printing are lined up with one another when lower tolerances are required.

Dies used in rotary die cutting are either solid engraved

Engraving is the practice of incising a design on a hard, usually flat surface by cutting grooves into it with a burin. The result may be a decorated object in itself, as when silver, gold, steel, or glass are engraved, or may provide an inta ...

dies, adjustable dies, or magnetic plate tooling. Engraved dies have a much higher tolerance and are machined

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which util ...

out of a solid steel bar normally made out of tool steel. Adjustable dies have removable blades that can be easily replaced with other blades, either due to wear or to cut a different material, while magnetic plate tooling has a cylinder that has magnets placed in it, and an engraved metal plate is attached or wrapped around the base cylinder holding onto it by the force of the magnets.

Dinking

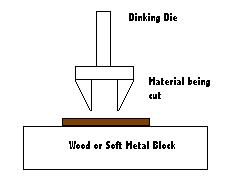

Dinking is a manufacturing process. Dinking uses special dies called dinking dies, which are hollow cutters. The edges of the dies are usually beveled about 20° and sharpened. The material is punched through into a wood or soft metal block in order to not dull the edges.American Machinists' Handbook and Dictionary of Shop Terms by Fred H. Colvin and Frank A Stanley 1914 The die may be pressed into the material with a hammer or a mechanical press.Fundamentals of Manufacturing By Philip D. Rufe 2001.See also

* Cutting plotter *Postage stamp separation

For postage stamps, separation is the means by which individual stamps are made easily detachable from each other.

Methods of separation include:

# perforation: cutting rows and columns of small holes

# rouletting: small horizontal and vert ...

* Steel rule die

References

Bibliography

* {{Authority control Graphic design Industrial processes Metal forming Packaging industry Printing devices