Deep reactive-ion etching on:

[Wikipedia]

[Google]

[Amazon]

Deep reactive-ion etching (DRIE) is a special subclass of

The Bosch process, named after the German company Robert Bosch GmbH which patented the process, also known as pulsed or time-multiplexed etching, alternates repeatedly between two modes to achieve nearly vertical structures:

# A standard, nearly isotropic plasma etch. The plasma contains some ions, which attack the wafer from a nearly vertical direction. Sulfur hexafluoride F6is often used for

The Bosch process, named after the German company Robert Bosch GmbH which patented the process, also known as pulsed or time-multiplexed etching, alternates repeatedly between two modes to achieve nearly vertical structures:

# A standard, nearly isotropic plasma etch. The plasma contains some ions, which attack the wafer from a nearly vertical direction. Sulfur hexafluoride F6is often used for  Each phase lasts for several seconds. The passivation layer protects the entire substrate from further chemical attack and prevents further etching. However, during the etching phase, the directional ions that bombard the substrate attack the passivation layer at the bottom of the trench (but not along the sides). They collide with it and sputter it off, exposing the substrate to the chemical etchant.

These etch/deposit steps are repeated many times over resulting in a large number of very small isotropic etch steps taking place only at the bottom of the etched pits. To etch through a 0.5 mm silicon wafer, for example, 100–1000 etch/deposit steps are needed. The two-phase process causes the sidewalls to undulate with an amplitude of about 100–500 nm. The cycle time can be adjusted: short cycles yield smoother walls, and long cycles yield a higher etch rate.

Each phase lasts for several seconds. The passivation layer protects the entire substrate from further chemical attack and prevents further etching. However, during the etching phase, the directional ions that bombard the substrate attack the passivation layer at the bottom of the trench (but not along the sides). They collide with it and sputter it off, exposing the substrate to the chemical etchant.

These etch/deposit steps are repeated many times over resulting in a large number of very small isotropic etch steps taking place only at the bottom of the etched pits. To etch through a 0.5 mm silicon wafer, for example, 100–1000 etch/deposit steps are needed. The two-phase process causes the sidewalls to undulate with an amplitude of about 100–500 nm. The cycle time can be adjusted: short cycles yield smoother walls, and long cycles yield a higher etch rate.

reactive-ion etching

Reactive-ion etching (RIE) is an etching (microfabrication), etching technology used in microfabrication. RIE is a type of dry etching which has different characteristics than Isotropic etching, wet etching. RIE uses chemical reaction, chemically ...

(RIE). It enables highly anisotropic

Anisotropy () is the structural property of non-uniformity in different directions, as opposed to isotropy. An anisotropic object or pattern has properties that differ according to direction of measurement. For example, many materials exhibit ver ...

etch process used to create deep penetration, steep-sided holes and trenches in wafers/substrates, typically with high aspect ratio

The aspect ratio of a geometry, geometric shape is the ratio of its sizes in different dimensions. For example, the aspect ratio of a rectangle is the ratio of its longer side to its shorter side—the ratio of width to height, when the rectangl ...

s. It was developed for microelectromechanical systems (MEMS), which require these features, but is also used to excavate trenches for high-density capacitor

In electrical engineering, a capacitor is a device that stores electrical energy by accumulating electric charges on two closely spaced surfaces that are insulated from each other. The capacitor was originally known as the condenser, a term st ...

s for DRAM and more recently for creating through-silicon vias ( TSVs) in advanced 3D wafer level packaging technology.

In DRIE, the substrate is placed inside a reactor, and several gases are introduced. A plasma is struck in the gas mixture which breaks the gas molecules into ions. The ions are accelerated towards, and react with the surface of the material being etched, forming another gaseous element. This is known as the chemical part of the reactive ion etching. There is also a physical part, if ions have enough energy, they can knock atoms out of the material to be etched without chemical reaction.

There are two main technologies for high-rate DRIE: cryogenic and Bosch, although the Bosch process is the only recognised production technique. Both Bosch and cryogenic processes can fabricate 90° (truly vertical) walls, but often the walls are slightly tapered, e.g. 88° ("reentrant") or 92° ("retrograde").

Another mechanism is sidewall passivation: SiOxFy functional group

In organic chemistry, a functional group is any substituent or moiety (chemistry), moiety in a molecule that causes the molecule's characteristic chemical reactions. The same functional group will undergo the same or similar chemical reactions r ...

s (which originate from sulphur hexafluoride and oxygen etch gases) condense on the sidewalls, and protect them from lateral etching. As a combination of these processes, deep vertical structures can be made.

Cryogenic process

In cryogenic-DRIE, the wafer is chilled to −110 °C (163 K). The low temperature slows down thechemical reaction

A chemical reaction is a process that leads to the chemistry, chemical transformation of one set of chemical substances to another. When chemical reactions occur, the atoms are rearranged and the reaction is accompanied by an Gibbs free energy, ...

that produces isotropic etching. However, ions continue to bombard upward-facing surfaces and etch them away. This process produces trenches with highly vertical sidewalls. The primary issues with cryo-DRIE is that the standard masks on substrates crack under the extreme cold, plus etch by-products have a tendency of depositing on the nearest cold surface, i.e. the substrate or electrode.

Bosch process

The Bosch process, named after the German company Robert Bosch GmbH which patented the process, also known as pulsed or time-multiplexed etching, alternates repeatedly between two modes to achieve nearly vertical structures:

# A standard, nearly isotropic plasma etch. The plasma contains some ions, which attack the wafer from a nearly vertical direction. Sulfur hexafluoride F6is often used for

The Bosch process, named after the German company Robert Bosch GmbH which patented the process, also known as pulsed or time-multiplexed etching, alternates repeatedly between two modes to achieve nearly vertical structures:

# A standard, nearly isotropic plasma etch. The plasma contains some ions, which attack the wafer from a nearly vertical direction. Sulfur hexafluoride F6is often used for silicon

Silicon is a chemical element; it has symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic lustre, and is a tetravalent metalloid (sometimes considered a non-metal) and semiconductor. It is a membe ...

.

# Deposition of a chemically inert passivation layer. (For instance, Octafluorocyclobutane 4F8source gas yields a substance similar to Teflon.)

Each phase lasts for several seconds. The passivation layer protects the entire substrate from further chemical attack and prevents further etching. However, during the etching phase, the directional ions that bombard the substrate attack the passivation layer at the bottom of the trench (but not along the sides). They collide with it and sputter it off, exposing the substrate to the chemical etchant.

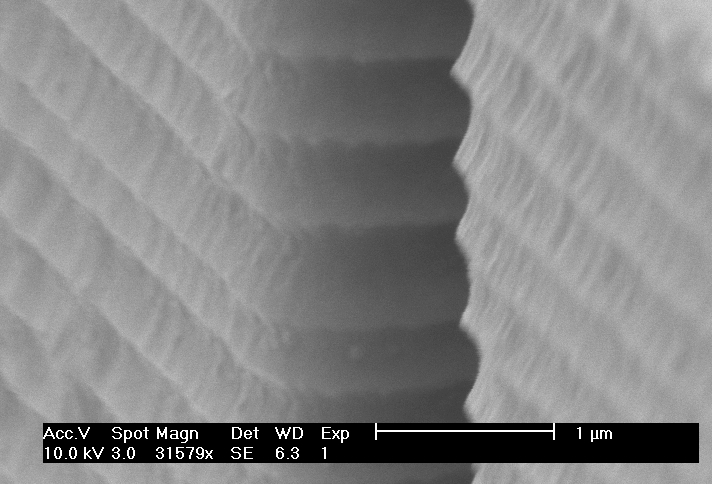

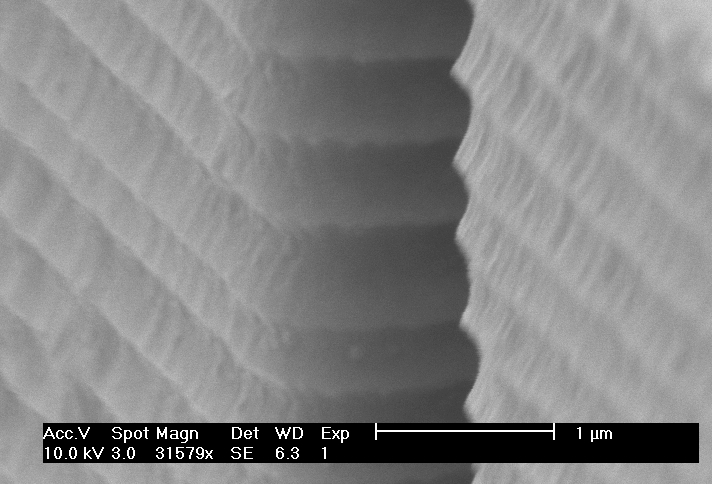

These etch/deposit steps are repeated many times over resulting in a large number of very small isotropic etch steps taking place only at the bottom of the etched pits. To etch through a 0.5 mm silicon wafer, for example, 100–1000 etch/deposit steps are needed. The two-phase process causes the sidewalls to undulate with an amplitude of about 100–500 nm. The cycle time can be adjusted: short cycles yield smoother walls, and long cycles yield a higher etch rate.

Each phase lasts for several seconds. The passivation layer protects the entire substrate from further chemical attack and prevents further etching. However, during the etching phase, the directional ions that bombard the substrate attack the passivation layer at the bottom of the trench (but not along the sides). They collide with it and sputter it off, exposing the substrate to the chemical etchant.

These etch/deposit steps are repeated many times over resulting in a large number of very small isotropic etch steps taking place only at the bottom of the etched pits. To etch through a 0.5 mm silicon wafer, for example, 100–1000 etch/deposit steps are needed. The two-phase process causes the sidewalls to undulate with an amplitude of about 100–500 nm. The cycle time can be adjusted: short cycles yield smoother walls, and long cycles yield a higher etch rate.

Applications

Etching depth typically depends on the application: * in DRAM memory circuits, capacitor trenches may be 10–20 μm deep, * in MEMS, DRIE is used for anything from a few micrometers to 0.5 mm. * in irregular chip dicing, DRIE is used with a novel hybrid soft/hard mask to achieve sub-millimeter etching to dice silicon dies into lego-like pieces with irregular shapes. * in flexible electronics, DRIE is used to make traditional monolithic CMOS devices flexible by reducing the thickness of silicon substrates to few to tens of micrometers. DRIE is distinguished from RIE by its etch depth. Practical etch depths for RIE (as used in IC manufacturing) would be limited to around 10 μm at a rate up to 1 μm/min, while DRIE can etch features much greater, up to 600 μm or more with rates up to 20 μm/min or more in some applications. DRIE of glass requires high plasma power, which makes it difficult to find suitable mask materials for truly deep etching. Polysilicon and nickel are used for 10–50 μm etched depths. In DRIE of polymers, Bosch process with alternating steps of SF6 etching and C4F8 passivation take place. Metal masks can be used, however they are expensive to use since several additional photo and deposition steps are always required. Metal masks are not necessary however on various substrates (Si p to 800 μm InP p to 40 μmor glass p to 12 μm if using chemically amplified negative resists. Gallium ion implantation can be used as etch mask in cryo-DRIE. Combined nanofabrication process of focused ion beam and cryo-DRIE was first reported by N Chekurov ''et al'' in their article "The fabrication of silicon nanostructures by local gallium implantation and cryogenic deep reactive ion etching".Precision machinery

DRIE has enabled the use of silicon mechanical components in high-end wristwatches. According to an engineer at Cartier, “There is no limit to geometric shapes with DRIE,”. With DRIE it is possible to obtain anaspect ratio

The aspect ratio of a geometry, geometric shape is the ratio of its sizes in different dimensions. For example, the aspect ratio of a rectangle is the ratio of its longer side to its shorter side—the ratio of width to height, when the rectangl ...

of 30 or more, meaning that a surface can be etched with a vertical-walled trench 30 times deeper than its width.

This has allowed for silicon components to be substituted for some parts which are usually made of steel, such as the hairspring. Silicon is lighter and harder than steel, which carries benefits but makes the manufacturing process more challenging.

See also

* Microelectromechanical systemsReferences