Curing (chemistry) on:

[Wikipedia]

[Google]

[Amazon]

Curing is a chemical process employed in

During the curing process, single monomers and oligomers, mixed with or without a curing agent, react to form a tridimensional polymeric network.

In the very first part of the reaction branches of molecules with various architectures are formed, and their

During the curing process, single monomers and oligomers, mixed with or without a curing agent, react to form a tridimensional polymeric network.

In the very first part of the reaction branches of molecules with various architectures are formed, and their

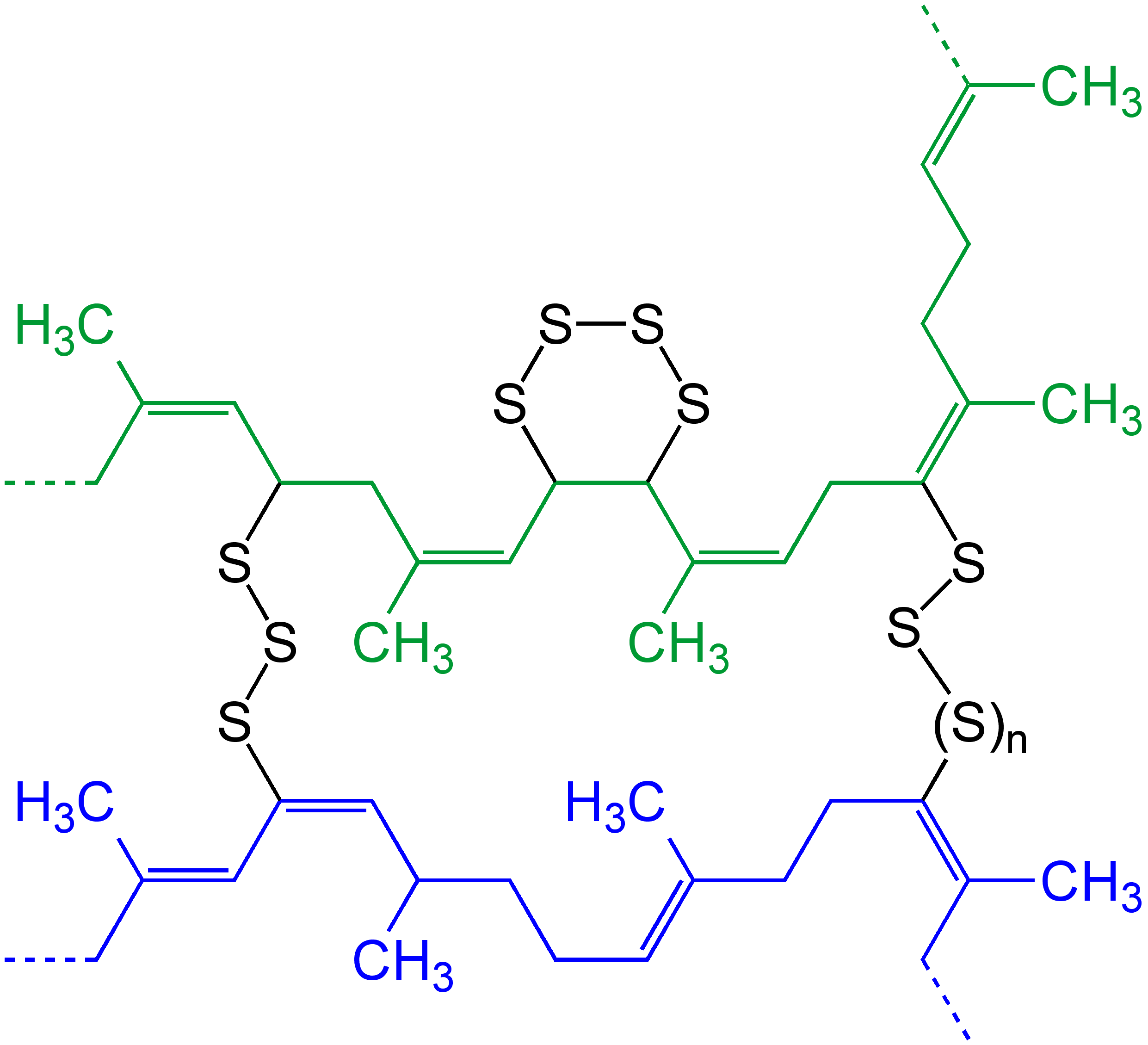

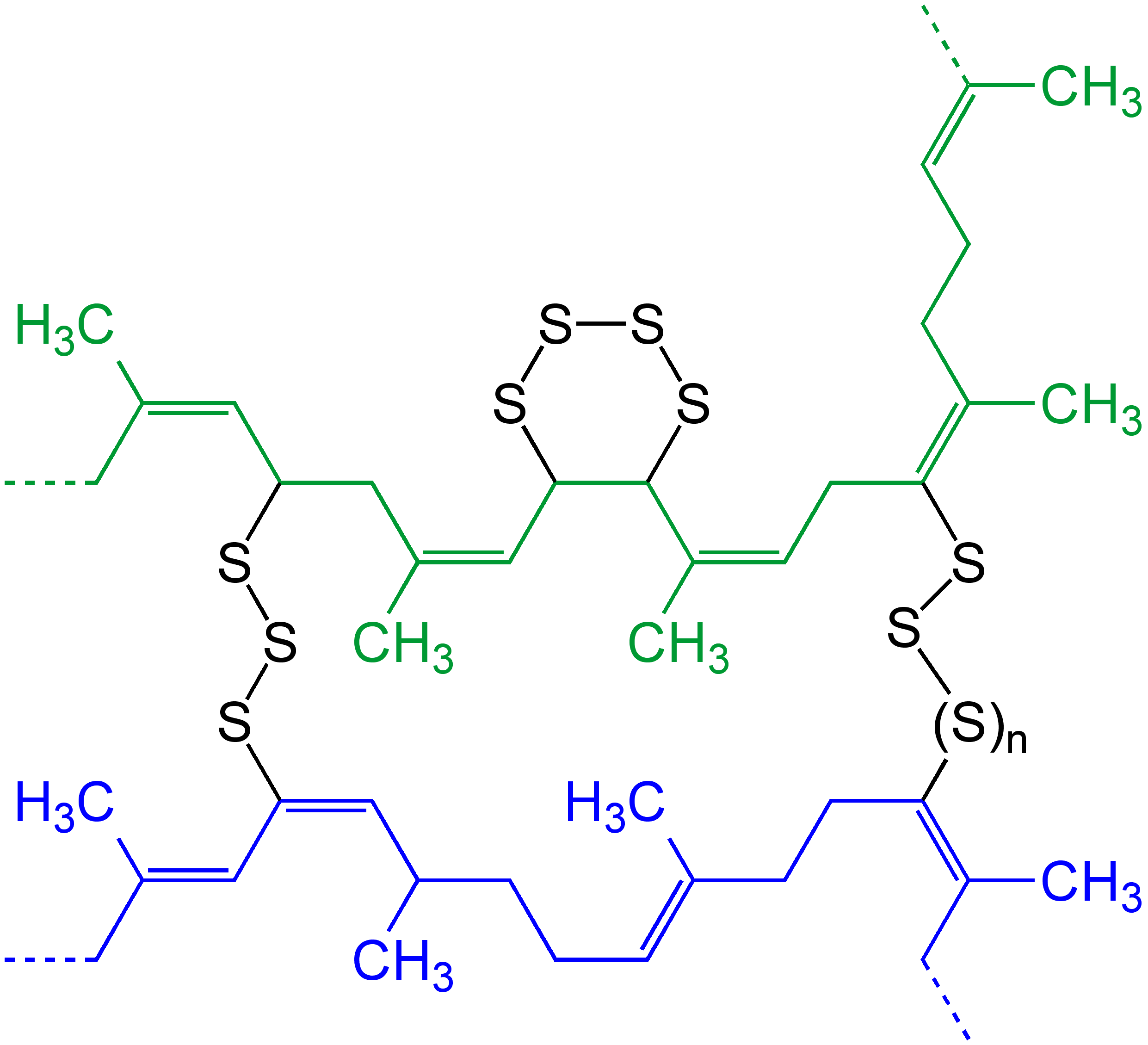

Figure 3: Simplified chemical reactions associated with curing of a drying oil. In the first step, the diene undergoes autoxidation to give a hydroperoxide. In the second step, the hydroperoxide combines with another unsaturated side chain to generate a crosslink.

Epoxy, Epoxy resins are typically cured by the use of additives, often called hardeners. Polyamines are often used. The amine groups ring-open the epoxide rings.

In rubber, the curing is also induced by the addition of a crosslinker. The resulting process is called

Figure 3: Simplified chemical reactions associated with curing of a drying oil. In the first step, the diene undergoes autoxidation to give a hydroperoxide. In the second step, the hydroperoxide combines with another unsaturated side chain to generate a crosslink.

Epoxy, Epoxy resins are typically cured by the use of additives, often called hardeners. Polyamines are often used. The amine groups ring-open the epoxide rings.

In rubber, the curing is also induced by the addition of a crosslinker. The resulting process is called

A simple way to monitor the change in viscosity, and thus, the extent of the reaction, in a curing process is to measure the variation of the

A simple way to monitor the change in viscosity, and thus, the extent of the reaction, in a curing process is to measure the variation of the

polymer chemistry

Polymer chemistry is a sub-discipline of chemistry that focuses on the structures, chemical synthesis, and chemical and physical properties of polymers and macromolecules. The principles and methods used within polymer chemistry are also applic ...

and process engineering that produces the toughening or hardening of a polymer

A polymer () is a chemical substance, substance or material that consists of very large molecules, or macromolecules, that are constituted by many repeat unit, repeating subunits derived from one or more species of monomers. Due to their br ...

material by cross-linking of polymer chains. Even if it is strongly associated with the production of thermosetting polymers, the term "curing" can be used for all the processes where a solid product is obtained from a liquid solution, such as with PVC plastisols.

Curing process

molecular weight

A molecule is a group of two or more atoms that are held together by Force, attractive forces known as chemical bonds; depending on context, the term may or may not include ions that satisfy this criterion. In quantum physics, organic chemi ...

increases in time with the extent of the reaction until the network size is equal to the size of the system. The system has lost its solubility

In chemistry, solubility is the ability of a chemical substance, substance, the solute, to form a solution (chemistry), solution with another substance, the solvent. Insolubility is the opposite property, the inability of the solute to form su ...

and its viscosity

Viscosity is a measure of a fluid's rate-dependent drag (physics), resistance to a change in shape or to movement of its neighboring portions relative to one another. For liquids, it corresponds to the informal concept of ''thickness''; for e ...

tends to infinite. The remaining molecule

A molecule is a group of two or more atoms that are held together by Force, attractive forces known as chemical bonds; depending on context, the term may or may not include ions that satisfy this criterion. In quantum physics, organic chemi ...

s start to coexist with the macroscopic network until they react with the network creating other crosslinks. The crosslink density increases until the system reaches the end of the chemical reaction.

Curing can be induced by heat, radiation, electron beams, or chemical additives. To quote from IUPAC

The International Union of Pure and Applied Chemistry (IUPAC ) is an international federation of National Adhering Organizations working for the advancement of the chemical sciences, especially by developing nomenclature and terminology. It is ...

: curing "might or might not require mixing with a chemical curing agent". Thus, two broad classes are curing induced by chemical additives (also called curing agents, hardeners) and curing in the absence of additives. An intermediate case involves a mixture of resin and additives that requires external stimulus (light, heat, radiation) to induce curing.

The curing methodology depends on the resin and the application. Particular attention is paid to the shrinkage induced by the curing. Usually small values of shrinkage (2–3%) are desirable.

Curing induced by additives

Figure 3: Simplified chemical reactions associated with curing of a drying oil. In the first step, the diene undergoes autoxidation to give a hydroperoxide. In the second step, the hydroperoxide combines with another unsaturated side chain to generate a crosslink.

Epoxy, Epoxy resins are typically cured by the use of additives, often called hardeners. Polyamines are often used. The amine groups ring-open the epoxide rings.

In rubber, the curing is also induced by the addition of a crosslinker. The resulting process is called

Figure 3: Simplified chemical reactions associated with curing of a drying oil. In the first step, the diene undergoes autoxidation to give a hydroperoxide. In the second step, the hydroperoxide combines with another unsaturated side chain to generate a crosslink.

Epoxy, Epoxy resins are typically cured by the use of additives, often called hardeners. Polyamines are often used. The amine groups ring-open the epoxide rings.

In rubber, the curing is also induced by the addition of a crosslinker. The resulting process is called sulfur vulcanization

Sulfur vulcanization is a chemical process for converting natural rubber or related polymers into materials of varying hardness, elasticity, and mechanical durability by heating them with sulfur or sulfur-containing compounds. Sulfur forms cros ...

. Sulfur breaks down to form polysulfide cross-links (bridges) between sections of the polymer chains. The degree of crosslinking determines the rigidity and durability, as well as other properties of the material.

Paints and varnishes commonly contain oil drying agents, usually metallic soaps that catalyze cross-linking of the unsaturated drying oil

Drying is a mass transfer process consisting of the removal of water or another solvent by evaporation from a solid, semi-solid or liquid. This process is often used as a final production step before selling or packaging products. To be conside ...

s that largely comprise them. When paint is described as "drying" it is in fact hardening by crosslinking. Oxygen atoms serve as the crosslinks, analogous to the role played by sulfur in the vulcanization of rubber.

Curing without additives

In the case ofconcrete

Concrete is a composite material composed of aggregate bound together with a fluid cement that cures to a solid over time. It is the second-most-used substance (after water), the most–widely used building material, and the most-manufactur ...

, curing entails the formation of silicate crosslinks. The process is not induced by additives.

In many cases, the resin is provided as a solution or mixture with a thermally-activated catalyst, which induces crosslinking but only upon heating. For example, some acrylate-based resins are formulated with dibenzoyl peroxide. Upon heating the mixture, the peroxide converts to a free radical, which adds to an acrylate, initiating crosslinking.

Some organic resins are cured with heat. As heat is applied, the viscosity

Viscosity is a measure of a fluid's rate-dependent drag (physics), resistance to a change in shape or to movement of its neighboring portions relative to one another. For liquids, it corresponds to the informal concept of ''thickness''; for e ...

of the resin drops before the onset of crosslinking, whereupon it increases as the constituent oligomers interconnect. This process continues until a tridimensional network of oligomer chains is created – this stage is termed gelation. In terms of processability of the resin

A resin is a solid or highly viscous liquid that can be converted into a polymer. Resins may be biological or synthetic in origin, but are typically harvested from plants. Resins are mixtures of organic compounds, predominantly terpenes. Commo ...

this marks an important stage: before gelation the system is relatively mobile, after it the mobility is very limited, the micro-structure of the resin and the composite material

A composite or composite material (also composition material) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a ...

is fixed and severe diffusion limitations to further cure are created. Thus, in order to achieve vitrification

Vitrification (, via French ') is the full or partial transformation of a substance into a glass, that is to say, a non- crystalline or amorphous solid. Glasses differ from liquids structurally and glasses possess a higher degree of connectivity ...

in the resin, it is usually necessary to increase the process temperature after gelation.

When catalysts are activated by ultraviolet radiation

Ultraviolet radiation, also known as simply UV, is electromagnetic radiation of wavelengths of 10–400 nanometers, shorter than that of visible light, but longer than X-rays. UV radiation is present in sunlight and constitutes about 10% of t ...

, the process is called UV cure.Gregory T. Carroll, Nicholas J. Turro and Jeffrey T. Koberstein (2010) ''Patterning Dewetting in Thin Polymer Films by Spatially Directed Photocrosslinking'' Journal of Colloid and Interface Science, Vol. 351, pp 556-560

Monitoring methods

Cure monitoring is, for example, an essential component for the control of the manufacturing process ofcomposite materials

A composite or composite material (also composition material) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a ...

.

The material, initially liquid

Liquid is a state of matter with a definite volume but no fixed shape. Liquids adapt to the shape of their container and are nearly incompressible, maintaining their volume even under pressure. The density of a liquid is usually close to th ...

, at the end of the process will be solid

Solid is a state of matter where molecules are closely packed and can not slide past each other. Solids resist compression, expansion, or external forces that would alter its shape, with the degree to which they are resisted dependent upon the ...

: viscosity

Viscosity is a measure of a fluid's rate-dependent drag (physics), resistance to a change in shape or to movement of its neighboring portions relative to one another. For liquids, it corresponds to the informal concept of ''thickness''; for e ...

is the most important property that changes during the process.

Cure monitoring relies on monitoring various physical or chemical properties.

Rheological analysis

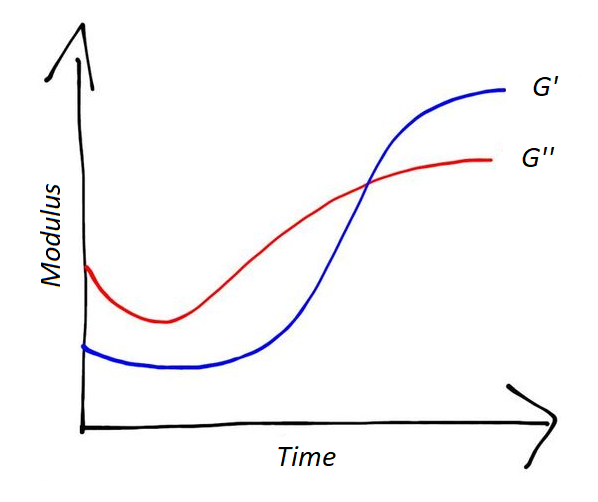

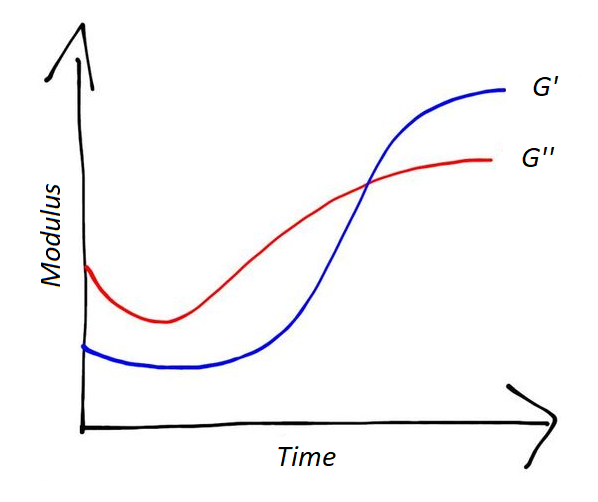

A simple way to monitor the change in viscosity, and thus, the extent of the reaction, in a curing process is to measure the variation of the

A simple way to monitor the change in viscosity, and thus, the extent of the reaction, in a curing process is to measure the variation of the elastic modulus

An elastic modulus (also known as modulus of elasticity (MOE)) is a quantity that describes an object's or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it.

Definition

The elastic modu ...

.

To measure the elastic modulus

An elastic modulus (also known as modulus of elasticity (MOE)) is a quantity that describes an object's or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it.

Definition

The elastic modu ...

of a system during curing, a rheometer can be used. With dynamic mechanical analysis, the storage modulus (G') and the loss modulus (G'') can be measured. The variation of G' and G" in time can indicate the extent of the curing reaction.

As shown in Figure 4, after an "induction time", G' and G" start to increase, with an abrupt change in slope. At a certain point they cross each other; afterwards, the rates of G' and G" decrease, and the moduli tend to a plateau. When they reach the plateau the reaction is concluded.

When the system is liquid, the storage modulus is very low: the system behaves like a liquid. Then the reaction continues and the system starts to react more like a solid: the storage modulus increases.

The degree of curing, , can be defined as follow:

The degree of curing starts from zero (at the beginning of the reaction) and grows until one (the end of the reaction). The slope of the curve changes with time and has his maximum about at half of the reaction.

Thermal analysis

If the reactions occurring during crosslinking are exothermic, the crosslinking rate can be related to the heat released during the process. The higher the number of bonds created, the higher is the heat released in the reaction. At the end of the reaction, no more heat will be released. To measure the heat flow differential scanning calorimetry can be used. Assuming that each bond formed during the crosslinking releases the same amount of energy, the degree of curing, , can be defined as follows: where is the heat released up to a certain time , is the instantaneous rate of heat and is the total amount of heat released in , when the reaction finishes. Also in this case the degree of curing goes from zero (no bonds created) to one (no more reactions occur) with a slope that changes in time and has its maximum about at half of the reaction.Dielectrometric analysis

Conventional dielectrometry is carried out typically in a parallel plate configuration of thedielectric

In electromagnetism, a dielectric (or dielectric medium) is an Insulator (electricity), electrical insulator that can be Polarisability, polarised by an applied electric field. When a dielectric material is placed in an electric field, electric ...

sensor

A sensor is often defined as a device that receives and responds to a signal or stimulus. The stimulus is the quantity, property, or condition that is sensed and converted into electrical signal.

In the broadest definition, a sensor is a devi ...

( capacitance probe) and has the capability of monitoring the resin cure throughout the entire cycle, from the liquid to the rubber to the solid state. It is capable of monitoring phase separation in complex resin blends curing also within a fibrous perform. The same attributes belong to the more recent development of the dielectric technique, namely microdielectrometry.

Several versions of dielectric sensors are available commercially. The most suitable format for use in cure monitoring applications are the flat interdigital capacitive structures bearing a sensing grid on their surface. Depending on their design (specifically those on durable substrates) they have some reusability, while flexible substrate sensors can be used also in the bulk of the resin systems as embedded sensors.

Spectroscopic analysis

The curing process can be monitored by measuring changes in various parameters: *the concentration of specific reactive resin species using spectroscopic methods such as FTIR & Raman; *therefractive index

In optics, the refractive index (or refraction index) of an optical medium is the ratio of the apparent speed of light in the air or vacuum to the speed in the medium. The refractive index determines how much the path of light is bent, or refrac ...

or fluorescence

Fluorescence is one of two kinds of photoluminescence, the emission of light by a substance that has absorbed light or other electromagnetic radiation. When exposed to ultraviolet radiation, many substances will glow (fluoresce) with colore ...

of the resin (optical property);

*the internal resin strain (mechanical property) with the use of Fiber Bragg grating (FBG) sensors.

Ultrasonic analysis

Ultrasonic cure monitoring methods are based on the relationships between changes in the characteristics of propagatingultrasound

Ultrasound is sound with frequency, frequencies greater than 20 Hertz, kilohertz. This frequency is the approximate upper audible hearing range, limit of human hearing in healthy young adults. The physical principles of acoustic waves apply ...

and the real-time mechanical properties of a component, by measuring:

*ultrasonic time of flight, both in through-transmission and pulse-echo modes;

*natural frequency using impact excitation and laser

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word ''laser'' originated as an acronym for light amplification by stimulated emission of radi ...

-induced surface acoustic wave velocity measurement.

See also

* Vulcanization *Cross-link

In chemistry and biology, a cross-link is a bond or a short sequence of bonds that links one polymer chain to another. These links may take the form of covalent bonds or ionic bonds and the polymers can be either synthetic polymers or natural ...

References

* * *I.Partridge and G.Maistros, 'Dielectric Cure Monitoring for Process Control', Chapter 17, Vol. 5, Encyclopaedia of Composite Materials (2001), Elsevier Science, London, page 413 *P.Ciriscioli and G.Springer, 'Smart Autoclave cure in Composites', (1991), Technomic Publishing, Lancaster, PA. {{Authority control Polymer chemistry Chemical processes