conformal coating on:

[Wikipedia]

[Google]

[Amazon]

Conformal coating is a protective, breathable coating of thin polymeric film applied to

Conformal coating is a protective, breathable coating of thin polymeric film applied to

Precision analogue circuitry may suffer degraded accuracy if insulating surfaces become contaminated with ionic substances, such as fingerprint residues, that become mildly

Precision analogue circuitry may suffer degraded accuracy if insulating surfaces become contaminated with ionic substances, such as fingerprint residues, that become mildly

If the

If the

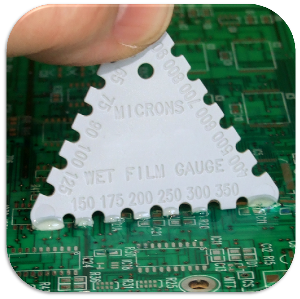

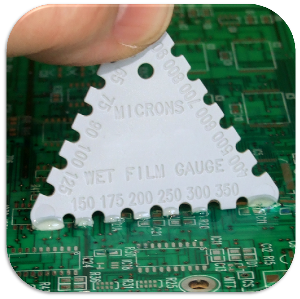

Wet film measurements are for conformal coatings where the dry film thickness can only be measured destructively or through the over-application of conformal coating. The wet film gauges are applied to the wet conformal coating; the teeth indicate the coating thickness.

Wet film measurements are for conformal coatings where the dry film thickness can only be measured destructively or through the over-application of conformal coating. The wet film gauges are applied to the wet conformal coating; the teeth indicate the coating thickness.

An alternative to wet film measurement is by using eddy currents. The system works by placing the test head on the surface of the conformal coating.

When liquid water is present, a pinhole can form in the coating. This is considered a defect and can be eliminated with appropriate steps and training. These techniques effectively "pot" or "conform" to components by completely covering them.

An alternative to wet film measurement is by using eddy currents. The system works by placing the test head on the surface of the conformal coating.

When liquid water is present, a pinhole can form in the coating. This is considered a defect and can be eliminated with appropriate steps and training. These techniques effectively "pot" or "conform" to components by completely covering them.

Traditionally, conformal coating inspection has been done manually. An inspector usually examines each PCB under a high-intensity, long-wave ultraviolet lamp. Recent developments in conformal coating

Traditionally, conformal coating inspection has been done manually. An inspector usually examines each PCB under a high-intensity, long-wave ultraviolet lamp. Recent developments in conformal coating

Conformal coating is a protective, breathable coating of thin polymeric film applied to

Conformal coating is a protective, breathable coating of thin polymeric film applied to printed circuit board

A printed circuit board (PCB), also called printed wiring board (PWB), is a Lamination, laminated sandwich structure of electrical conduction, conductive and Insulator (electricity), insulating layers, each with a pattern of traces, planes ...

s (PCBs). Conformal coatings are typically applied with 25–250 μm thickness on electronic circuitry to protect against moisture

Moisture is the presence of a liquid, especially water, often in trace amounts. Moisture is defined as water in the adsorbed or absorbed phase. Small amounts of water may be found, for example, in the air (humidity), in foods, and in some comme ...

and other substances.

Coatings can be applied in many ways, including brushing, spraying, dispensing, and dip coating. Many materials can be used as conformal coatings depending on manufacturer needs, such as acrylic, silicone

In Organosilicon chemistry, organosilicon and polymer chemistry, a silicone or polysiloxane is a polymer composed of repeating units of siloxane (, where R = Organyl group, organic group). They are typically colorless oils or elastomer, rubber ...

, urethane, and parylene. Many circuit board assembly firms apply a layer of transparent conformal coating to assemblies as an alternative to potting.

Conformal coatings are used to protect electronic components from possible environmental exposure; they allow moisture to escape but protect against contamination. More recently, conformal coatings are being used to reduce the formation of whiskers and to prevent current bleed between closely positioned components.

Applications

Precision analogue circuitry may suffer degraded accuracy if insulating surfaces become contaminated with ionic substances, such as fingerprint residues, that become mildly

Precision analogue circuitry may suffer degraded accuracy if insulating surfaces become contaminated with ionic substances, such as fingerprint residues, that become mildly conductive

In physics and electrical engineering, a conductor is an object or type of material that allows the flow of Electric charge, charge (electric current) in one or more directions. Materials made of metal are common electrical conductors. The flow ...

in higher humidity. A suitably chosen material coating can reduce the effects of mechanical stress and vibrations on the circuit and its ability to perform in extreme temperatures.

For example, in a chip-on-board assembly process, a silicon die is mounted on the board with an adhesive or soldering

Soldering (; ) is a process of joining two metal surfaces together using a filler metal called solder. The soldering process involves heating the surfaces to be joined and melting the solder, which is then allowed to cool and solidify, creatin ...

process, and then it is electrically connected by wire bonding, typically with 25.4 μm diameter gold

Gold is a chemical element; it has chemical symbol Au (from Latin ) and atomic number 79. In its pure form, it is a brightness, bright, slightly orange-yellow, dense, soft, malleable, and ductile metal. Chemically, gold is a transition metal ...

or aluminum

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

wire. The chip and the wire are delicate, so they are encapsulated in a version of the conformal coating called a blob top. This prevents accidental contact from damaging the wires or the chip. Another use of conformal coating is to increase the voltage

Voltage, also known as (electrical) potential difference, electric pressure, or electric tension, is the difference in electric potential between two points. In a Electrostatics, static electric field, it corresponds to the Work (electrical), ...

rating of a dense circuit assembly. An insulation coating can withstand a stronger electric voltage than air, particularly at high altitudes.

Excluding Parylene, most organic coatings are easily penetrated by water molecules. A coating preserves the performance of electronics primarily by preventing contaminants that can ionize, such as salts, from reaching circuit nodes and combining with water to form a microscopically thin electrolyte

An electrolyte is a substance that conducts electricity through the movement of ions, but not through the movement of electrons. This includes most soluble Salt (chemistry), salts, acids, and Base (chemistry), bases, dissolved in a polar solven ...

film. The coating is more effective if all surface contamination is removed first, using a highly repeatable industrial process such as vapor degreasing Vapor degreasing is a surface finishing process. It involves solvents in vapor form to cleanse the workpiece in preparation for further finishing operations.

Process

The acting principle behind the vapor degreaser process is that the solvents will ...

or semi-aqueous washing

Washing is a method of cleaning, usually with water and soap or detergent. Regularly washing and then rinsing both body and clothing is an essential part of good hygiene and health.

Often people use soaps and detergents to assist in the emulsific ...

. Pinholes would make contact with circuit nodes and form undesired conductive paths.

Methods

The coating material can be applied by brushing, spraying, dipping, or selective coating by robots. Nearly all modern conformal coatings contain a fluorescent dye to aid in vapor coverage inspection.Brush coating

Brush coating works by coating the material onto the board and is suitable for low-volume application. The finish is thick and tends to be subject to defects such as bubbles.Spray application coating

Spray coating can be completed with a spray aerosol or spray gun and is suitable for low- and medium-volume processing. The coating application may be limited due to 3D effects. The masking requirements have less penetration. This method can be used in spray booths for medium-scale production.Conformal coating dipping

If the

If the printed circuit board

A printed circuit board (PCB), also called printed wiring board (PWB), is a Lamination, laminated sandwich structure of electrical conduction, conductive and Insulator (electricity), insulating layers, each with a pattern of traces, planes ...

(PCB) is designed appropriately, it can be the highest volume technique. However, the coating penetrates everywhere, including beneath devices, so many PCB designs are unsuitable for dipping.

An issue of thin tip coverage, where the material slumps around sharp edges, can be a problem, especially in a condensing atmosphere. This tip coverage effect can be addressed by either double-dipping the PCB or using several thin layers of atomized spraying.

Selective coating by machine

Selective coating by machine uses a needle and an atomized spray applicator, a non-atomized spray, or an ultrasonic valve technology that can move above the circuit board and spray the coating material in select areas. Flow rates and materialviscosity

Viscosity is a measure of a fluid's rate-dependent drag (physics), resistance to a change in shape or to movement of its neighboring portions relative to one another. For liquids, it corresponds to the informal concept of ''thickness''; for e ...

are programmed into the computer system, controlling the application so that the desired coating thickness is maintained. This method is effective for large volumes, provided that the PCB is designed for the method. There are limitations in the select coat process, such as capillary effects around low-profile connectors that absorb the coating accidentally.

The process quality of dip or dam-and-fill coating and non-atomized spray technology can be improved by applying and then releasing a vacuum while the assembly is submerged in the liquid resin. This forces the liquid resin into all crevices.

Solvent- and water-based conformal coatings

For standard solvent-based acrylics, air drying (film formation) is the normal process except where speed is essential. Heat curing can then be used, using batch or inline ovens with conveyors.UV conformal coatings

UV curing

UV curing (ultraviolet curing) is the process by which ultraviolet light initiates a photochemical reaction that generates a crosslinked network of polymers through radical polymerization or cationic polymerization. UV curing is adaptable to inkj ...

of conformal coatings is becoming important for high-volume users in fields such as automotive and consumer electronics. These coatings have thermal cycling resistance.

Moisture curing

In moisture curing, the applied resin coating is reactive to moisture in the atmosphere and polymerizes with exposure, creating a homogenized coating. The curing process can take up to a few days to complete.Thickness and measurement

Coating material (after curing) should have a thickness of when using acrylic resin, epoxy resin, or urethane resin. For silicone resin, the coating thickness recommended by the IPC standards is . There are several methods for measuring coating thickness, and they fall into two categories: wet film and dry film.Wet film conformal coating measurement

Wet film measurements are for conformal coatings where the dry film thickness can only be measured destructively or through the over-application of conformal coating. The wet film gauges are applied to the wet conformal coating; the teeth indicate the coating thickness.

Wet film measurements are for conformal coatings where the dry film thickness can only be measured destructively or through the over-application of conformal coating. The wet film gauges are applied to the wet conformal coating; the teeth indicate the coating thickness.

Dry film conformal coating thickness measurement

An alternative to wet film measurement is by using eddy currents. The system works by placing the test head on the surface of the conformal coating.

When liquid water is present, a pinhole can form in the coating. This is considered a defect and can be eliminated with appropriate steps and training. These techniques effectively "pot" or "conform" to components by completely covering them.

An alternative to wet film measurement is by using eddy currents. The system works by placing the test head on the surface of the conformal coating.

When liquid water is present, a pinhole can form in the coating. This is considered a defect and can be eliminated with appropriate steps and training. These techniques effectively "pot" or "conform" to components by completely covering them.

Inspection

Traditionally, conformal coating inspection has been done manually. An inspector usually examines each PCB under a high-intensity, long-wave ultraviolet lamp. Recent developments in conformal coating

Traditionally, conformal coating inspection has been done manually. An inspector usually examines each PCB under a high-intensity, long-wave ultraviolet lamp. Recent developments in conformal coating automated optical inspection

Automated optical inspection (AOI) is an automated visual inspection of printed circuit board (PCB) (or LCD, transistor) manufacture where a camera machine vision, autonomously scans the device under test for both catastrophic failure (e.g. missin ...

(AOI) have begun to use Automated Inspection Systems, which can be camera- or scanner-based.

Selection

Incorrect selection can affect long-term reliability of the circuit board as well as cause processing and cost problems. The most common standards for conformal coating are IPC A-610 and IPC-CC-830. These standards list indications of good and bad coverage and describe various failure mechanisms, such as dewetting. Another type of coating called parylene is applied with a vacuum deposition process at ambient temperature. Film coatings ranging from 0.100 to 76 μm can be applied in a single operation. The coating thickness is uniform, even on irregular surfaces. Desired contact points, such as battery contacts or connectors, must be covered with an air-tight mask to prevent the parylene from coating the contacts. Applying parylene is a batch process that does not lend itself to high-volume processing.Coating chemistry

Different materials offer unique properties that make them suitable for various applications. Below is a comparison of the properties of different conformal coating chemicals.References

{{DEFAULTSORT:Conformal Coating Printed circuit board manufacturing Coatings