Combustion chambers on:

[Wikipedia]

[Google]

[Amazon]

A combustion chamber is part of an

In an

In an

Compression-ignition engines, such as

Compression-ignition engines, such as

internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal comb ...

in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process.

Internal combustion engines

In an

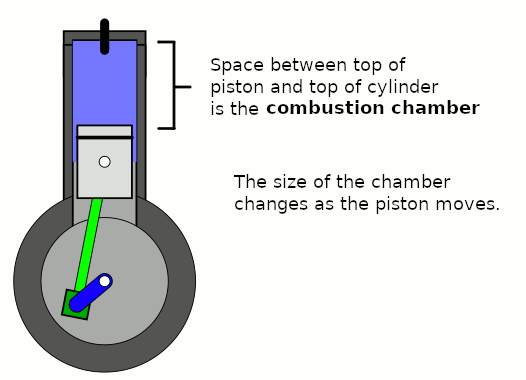

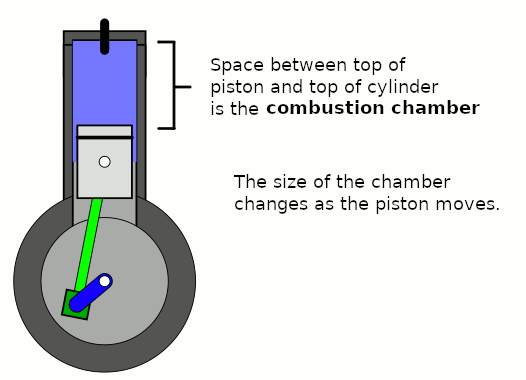

In an internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal comb ...

, the pressure caused by the burning air/fuel mixture applies direct force to part of the engine (e.g. for a piston engine, the force is applied to the top of the piston), which converts the gas pressure into mechanical energy

In physical sciences, mechanical energy is the sum of macroscopic potential and kinetic energies. The principle of conservation of mechanical energy states that if an isolated system is subject only to conservative forces, then the mechanical ...

(often in the form of a rotating output shaft). This contrasts an external combustion engine, where the combustion takes place in a separate part of the engine to where the gas pressure is converted into mechanical energy.

Spark-ignition engines

In spark ignition engines, such as petrol (gasoline) engines, the combustion chamber is usually located in thecylinder head

In a piston engine, the cylinder head sits above the cylinders, forming the roof of the combustion chamber. In sidevalve engines the head is a simple plate of metal containing the spark plugs and possibly heat dissipation fins. In more modern ...

. The engines are often designed such that the bottom of combustion chamber is roughly in line with the top of the engine block

In an internal combustion engine, the engine block is the structure that contains the cylinders and other components. The engine block in an early automotive engine consisted of just the cylinder block, to which a separate crankcase was attach ...

.

Modern engines with overhead valves

An overhead valve engine, abbreviated (OHV) and sometimes called a pushrod engine, is a piston engine whose valves are located in the cylinder head above the combustion chamber. This contrasts with flathead (or "sidevalve") engines, where the va ...

or overhead camshaft(s) use the top of the piston (when it is near top dead centre) as the bottom of the combustion chamber. Above this, the sides and roof of the combustion chamber include the intake valves, exhaust valves and spark plug. This forms a relatively compact combustion chamber without any protrusions to the side (i.e. all of the chamber is located directly above the piston). Common shapes for the combustion chamber are typically similar to one or more half-spheres (such as the hemi, pent-roof, wedge or kidney-shaped chambers).

The older flathead engine

A flathead engine, also known as a sidevalve engine''American Rodder'', 6/94, pp.45 & 93. or valve-in-block engine, is an internal combustion engine with its poppet valves contained within the engine block, instead of in the cylinder head, a ...

design uses a "bathtub"-shaped combustion chamber, with an elongated shape that sits above both the piston and the valves (which are located beside the piston). IOE engines combine elements of overhead valve and flathead engines; the intake valve is located above the combustion chamber, while the exhaust valve is located below it.

The shape of the combustion chamber, intake ports and exhaust ports are key to achieving efficient combustion and maximising power output. Cylinder heads are often designed to achieve a certain "swirl" pattern (rotational component to the gas flow) and turbulence

In fluid dynamics, turbulence or turbulent flow is fluid motion characterized by chaotic changes in pressure and flow velocity. It is in contrast to laminar flow, which occurs when a fluid flows in parallel layers with no disruption between ...

, which improves the mixing and increases the flow rate of gasses. The shape of the piston top also affects the amount of swirl.

Another design feature to promote turbulence for good fuel/air mixing is squish, where the fuel/air mix is "squished" at high pressure by the rising piston.

The location of the spark plug

A spark plug (sometimes, in British English, a sparking plug, and, colloquially, a plug) is a device for delivering electric current from an ignition system to the combustion chamber of a spark-ignition engine to ignite the compressed fuel/air ...

is also an important factor, since this is the starting point of the ''flame front'' (the leading edge of the burning gasses) which then travels downwards towards the piston. Good design should avoid narrow crevices where stagnant "end gas" can become trapped, reducing the power output of the engine and potentially leading to engine knocking

In spark-ignition internal combustion engines, knocking (also knock, detonation, spark knock, pinging or pinking) occurs when combustion of some of the air/fuel mixture in the cylinder does not result from propagation of the flame front ignite ...

. Most engines use a single spark plug per cylinder, however some (such as the 1986-2009 Alfa Romeo Twin Spark engine

Alfa Romeo Twin Spark (TS) technology was used for the first time in the Alfa Romeo Grand Prix car in 1914. In the early 1960s it was used in their race cars ( GTA, TZ) to enable it to achieve a higher power output from its engines. And in the e ...

) use two spark plugs per cylinder.

Compression-ignition engines

diesel engine

The diesel engine, named after the German engineer Rudolf Diesel, is an internal combustion engine in which Combustion, ignition of diesel fuel is caused by the elevated temperature of the air in the cylinder due to Mechanics, mechanical Compr ...

s, are typically classified as either:

* Direct injection, where the fuel is injected into the combustion chamber. Common varieties include unit direct injection and common rail injection.

* Indirect injection

Indirect injection in an internal combustion engine is fuel injection where fuel is not directly injected into the combustion chamber.

Gasoline engines equipped with indirect injection systems, wherein a fuel injector delivers the fuel at some p ...

, where the fuel is injected into a swirl chamber or pre-combustion chamber. The fuel ignites as it is injected into this chamber and the burning air/fuel mixture spreads into the main combustion chamber.

Direct injection engines usually give better fuel economy but indirect injection engines can use a lower grade of fuel.

Harry Ricardo

Sir Harry Ralph Ricardo (26 January 1885 – 18 May 1974) was an English engineer who was one of the foremost engine designers and researchers in the early years of the development of the internal combustion engine.

Among his many other works, ...

was prominent in developing combustion chambers for diesel engines, the best known being the ''Ricardo Comet''.

Gas turbine

In a continuous flow system, for example a jet engine combustor, the pressure is controlled and the combustion creates an increase in volume. The combustion chamber ingas turbine

A gas turbine or gas turbine engine is a type of Internal combustion engine#Continuous combustion, continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas gene ...

s and jet engines

A jet engine is a type of reaction engine, discharging a fast-moving jet (fluid), jet of heated gas (usually air) that generates thrust by jet propulsion. While this broad definition may include Rocket engine, rocket, Pump-jet, water jet, and ...

(including ramjet

A ramjet is a form of airbreathing jet engine that requires forward motion of the engine to provide air for combustion. Ramjets work most efficiently at supersonic speeds around and can operate up to .

Ramjets can be particularly appropriat ...

s and scramjet

A scramjet (supersonic combustion ramjet) is a variant of a ramjet airbreathing jet engine in which combustion takes place in supersonic airflow. As in ramjets, a scramjet relies on high vehicle speed to compress the incoming air forcefully b ...

s) is called the combustor

A combustor is a component or area of a gas turbine, ramjet, or scramjet engine where combustion takes place. It is also known as a burner, burner can, combustion chamber or flame holder. In a gas turbine engine, the ''combustor'' or combustion ...

.

The combustor is fed with high pressure air by the compression system, adds fuel and burns the mix and feeds the hot, high pressure exhaust into the turbine components of the engine or out the exhaust nozzle.

Different types of combustors exist, mainly:

* Can type: Can combustors are self-contained cylindrical combustion chambers. Each "can" has its own fuel injector, liner, interconnectors, casing. Each "can" get an air source from individual opening.

* Cannular type: Like the can type combustor, can annular combustors have discrete combustion zones contained in separate liners with their own fuel injectors. Unlike the can combustor, all the combustion zones share a common air casing.

* Annular type: Annular combustors do away with the separate combustion zones and simply have a continuous liner and casing in a ring (the annulus).

Rocket engine

If the gas velocity changes,thrust

Thrust is a reaction force described quantitatively by Newton's third law. When a system expels or accelerates mass in one direction, the accelerated mass will cause a force of equal magnitude but opposite direction to be applied to that ...

is produced, such as in the nozzle

A nozzle is a device designed to control the direction or characteristics of a fluid flow (specially to increase velocity) as it exits (or enters) an enclosed chamber or pipe (material), pipe.

A nozzle is often a pipe or tube of varying cross ...

of a rocket engine

A rocket engine is a reaction engine, producing thrust in accordance with Newton's third law by ejecting reaction mass rearward, usually a high-speed Jet (fluid), jet of high-temperature gas produced by the combustion of rocket propellants stor ...

.

Steam engines

Considering the definition of combustion chamber used for internal combustion engines, the equivalent part of asteam engine

A steam engine is a heat engine that performs Work (physics), mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a Cylinder (locomotive), cyl ...

would be the firebox, since this is where the fuel is burned. However, in the context of a steam engine, the term "combustion chamber" has also been used for a specific area between the firebox and the boiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, centra ...

. This extension of the firebox is designed to allow a more complete combustion of the fuel, improving fuel efficiency

Fuel efficiency (or fuel economy) is a form of thermal efficiency, meaning the ratio of effort to result of a process that converts chemical energy, chemical potential energy contained in a carrier (fuel) into kinetic energy or Mechanical work, w ...

and reducing build-up of soot and scale. The use of this type of combustion chamber is large steam locomotive engines, allows the use of shorter firetubes.

Micro combustion chambers

Micro combustion chambers are the devices in which combustion happens at a very small volume, due to which surface to volume ratio increases which plays a vital role in stabilizing the flame.See also

*Cylinder head

In a piston engine, the cylinder head sits above the cylinders, forming the roof of the combustion chamber. In sidevalve engines the head is a simple plate of metal containing the spark plugs and possibly heat dissipation fins. In more modern ...

* Engine displacement

Engine displacement is the measure of the cylinder volume swept by all of the pistons of a piston engine, excluding the combustion chambers. It is commonly used as an expression of an engine's size, and by extension as an indicator of the ...

* Combustor

A combustor is a component or area of a gas turbine, ramjet, or scramjet engine where combustion takes place. It is also known as a burner, burner can, combustion chamber or flame holder. In a gas turbine engine, the ''combustor'' or combustion ...

* Variable compression ratio

References

{{DEFAULTSORT:Combustion Chamber Engine technology Locomotive parts Gas turbine technology