bucket tappet on:

[Wikipedia]

[Google]

[Amazon]

A tappet or valve lifter is a

A tappet or valve lifter is a

In an

In an

A

A

A tappet or valve lifter is a

A tappet or valve lifter is a valve train

A valvetrain is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combus ...

component which converts rotational motion into linear motion in activating a valve

A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or Slurry, slurries) by opening, closing, or partially obstructing various passageways. Valves are technically Pip ...

. It is most commonly found in internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal comb ...

s, where it converts the rotational motion of the camshaft into linear motion of intake and exhaust valves, either directly or indirectly.

An earlier use of the term was for part of the valve gear in beam engine

A beam engine is a type of steam engine where a pivoted overhead Beam (structure), beam is used to apply the force from a vertical piston to a vertical connecting rod. This configuration, with the engine directly driving a pump, was first used b ...

s beginning in 1715. The term is also used for components in pneumatic cylinder

Pneumatic cylinder, also known as air cylinder, is a mechanical device which uses the power of compressed gas to produce a force in a reciprocating linear motion.

Like in a hydraulic cylinder, something forces a piston to move in the desired ...

s and weaving loom.

History

The first recorded use of the term tappet is as part of thevalve gear

The valve gear of a steam engine is the mechanism that operates the inlet and exhaust valves to admit steam into the cylinder and allow exhaust steam to escape, respectively, at the correct points in the cycle. It can also serve as a reversing ...

in the 1715 Newcomen engine

The atmospheric engine was invented by Thomas Newcomen in 1712, and is sometimes referred to as the Newcomen fire engine (see below) or Newcomen engine. The engine was operated by condensing steam being drawn into the cylinder, thereby creating ...

, an early form of steam engine. Early versions of the Newcomen engines from 1712 had manually operated valves, but by 1715 this repetitive task had been automated through the use of tappets. The beam of the engine had a vertical 'plug rod' hung from it, alongside the cylinder. Adjustable blocks or 'tappets' were attached to this rod and as the beam moved up and down, the tappets pressed against long levers or 'horns' attached to the engine's valves, working the cycle of steam and injection water valves to operate the engine.

This operation by tappets on a plug rod continued into the early twentieth century with the Cornish engine

A Cornish engine is a type of steam engine developed in Cornwall, England, mainly for pumping water from a mine. It is a form of beam engine that uses steam at a higher pressure than the earlier engines designed by James Watt. The engines were ...

.

From the 19th century onwards, most steam engines used slide valve

The slide valve is a rectilinear valve used to control the admission of steam into and emission of exhaust from the cylinder of a steam engine.

Use

In the 19th century, most steam locomotives used slide valves to control the flow of steam into ...

s or piston valves, which do not require the use of tappets.

internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal comb ...

, a tappet (also called a 'valve lifter' or 'cam follower') is the component which converts the rotation of the camshaft into vertical motion to open and close an intake or exhaust valve

A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or Slurry, slurries) by opening, closing, or partially obstructing various passageways. Valves are technically Pip ...

.

The principal types of tappets used in automotive engines are solid, hydraulic

Hydraulics () is a technology and applied science using engineering, chemistry, and other sciences involving the mechanical properties and use of liquids. At a very basic level, hydraulics is the liquid counterpart of pneumatics, which concer ...

, and roller.

To reduce wear from the rotating camshaft, tappets are usually circular and allowed, or even encouraged, to rotate in place. This minimizes wear caused by the camshaft contacting the same point on the base of the tappet each valve cycle, which can result in grooving. However, in some relatively small engines with many cylinders (such as the Daimler '250' V8 engine), the tappets were small and non-rotating.

The base of most plain tappets is given a slight convex

Convex or convexity may refer to:

Science and technology

* Convex lens, in optics

Mathematics

* Convex set, containing the whole line segment that joins points

** Convex polygon, a polygon which encloses a convex set of points

** Convex polytop ...

profile to soften contact of the leading edge of the camshaft lobe.

Alternatives

An alternative to the tappet is the “finger follower”, which is a pivoting beam that is used to convert the camshaft rotation into opening and closing of a valve. Finger followers are used in some high-performancedual overhead camshaft

An overhead camshaft (OHC) engine is a piston engine in which the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combusti ...

(DOHC) engines, most commonly in motorcycles and sports cars.

Adjusting valve clearance

On most overhead valve (OHV) engines, proper clearance between the camshaft and tappet is achieved by turning a set screw in the end of the rocker arm that contacts the end of the pushrod until a desired gap is achieved using afeeler gauge

A feeler gauge is a tool used to measure gap widths. Feeler gauges are mostly used in engineering to measure the clearance between two parts.

Description

They consist of a number of small lengths of steel of different thicknesses with measureme ...

. Too large a gap results in wear from misaligned parts and compromised engine performance, and too small can lead to bent pushrods or burnt valves.

A locknut secures the set screw-in place. Loose set screws can cause catastrophic engine failure, which has led to fatal aircraft crashes.

On some OHV engines in the 1960s, such as the Ford Taunus V4 engine

The Ford Taunus V4 engine is a 60° V4 piston engine with one balance shaft, introduced by Ford Motor Company in Germany in 1962. The German V4 was built in the Cologne plant and powered the Ford Taunus and German versions of the Consul, Capri, ...

and Opel CIH engine, the tappet adjustment was done by setting the height of the rocker pivot point (rather than the typical method of a rocker-end adjustment screw). On the 1965-1970 versions of the Opel CIH engine with solid tappets, the tappet adjustment was conducted with the engine running.

Hydraulic tappets

A

A hydraulic tappet

A hydraulic tappet, also known as a hydraulic valve lifter or hydraulic lash adjuster, is a device for maintaining zero valve clearance in an internal combustion engine. Conventional solid valve lifters require regular adjusting to maintain a ...

, also known as a "hydraulic valve lifter" and "hydraulic lash adjuster", contains a small hydraulic piston that becomes filled with pressurised engine oil. The piston acts as a hydraulic spring that automatically adjusts the tappet clearance according to the oil pressure. Although the movements of the piston are small and infrequent, they are sufficient to make the valve actuation self-adjusting so that there is no need to manually adjust the clearance of the tappets.

Hydraulic tappets depend on a supply of clean oil at the appropriate pressure. When starting a cold engine, with low oil pressure, hydraulic tappets are often noisy for a few seconds, until they position themselves correctly.

Roller tappets

Early automotive engines used a roller at the contact point with the camshaft, however as engine speeds increased, 'flat tappets' with plain ends became far more common than tappets with rollers. However in recent times, roller tappets and rocker arms with roller tappet ends have made a resurgence due to the lower friction providing greater efficiency and reducing drag.Valvetrain layouts

In asidevalve engine

A flathead engine, also known as a sidevalve engine''American Rodder'', 6/94, pp.45 & 93. or valve-in-block engine, is an internal combustion engine with its poppet valves contained within the engine block, instead of in the cylinder head, as ...

— a common design for car engines until the 1950s— the valves are mounted at the sides of the cylinder and face upwards. This means that the camshaft could be placed directly beneath the valves, without the need for a rocker. With lower cylinder blocks, the tappets could drive the valves directly without needing even a push rod. Sidevalve engines also required regular adjustment of the tappet clearance, and in this case it was the tappets themselves that were adjusted directly. Small access plates were provided on the sides of the cylinder block, giving access to the gap between the valves and tappets. Some tappets had a threaded adjuster, but simpler engines could be adjusted by grinding down the ends of the valve stem directly. As the tappet adjustment always consisted of expanding the clearance (re-grinding valves into their valve seats during de-coking makes them sit lower, thus reducing the tappet clearance), adjustment by shortening the valve stems was a viable method. Eventually the valves would be replaced entirely, a relatively common operation for engines of this era.

In a pushrod engine

An overhead valve engine, abbreviated (OHV) and sometimes called a pushrod engine, is a piston engine whose valves are located in the cylinder head above the combustion chamber. This contrasts with flathead (or "sidevalve") engines, where the va ...

(OHV), the tappets are located down in the engine block

In an internal combustion engine, the engine block is the structure that contains the cylinders and other components. The engine block in an early automotive engine consisted of just the cylinder block, to which a separate crankcase was attach ...

and operate long, thin pushrod

A valvetrain is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combu ...

s which transfer the motion (via the rocker arms) to the valves located at the top of the engine.

In a single overhead camshaft

An overhead camshaft (OHC) engine is a piston engine in which the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combusti ...

(SOHC) engine, the tappets are integrated into the design of the rocker arms as one piece, since the camshaft interacts with the rocker arm directly. Mass-production of SOHC engines for passenger cars became more common in the 1970s, in the form of crossflow cylinder head

A crossflow cylinder head is a cylinder head that features the intake and exhaust ports on opposite sides. The gases can be thought to flow across the head. This is in contrast to reverse-flow cylinder head designs that have the ports on the sam ...

s with overhead rockers located directly above a single overhead camshaft, as a more efficient design which could be cost-effectively manufactured. The 1970-2001 Ford Pinto engine

The Ford Pinto engine was the unofficial name for a four-cylinder internal combustion engine built by Ford Europe. In Ford sales literature, it was referred to as the EAO or OHC engine and because it was designed to the metric system, it was some ...

was one of the first mass-production engines to use an SOHC design with a toothed cambelt. In this configuration, the rockers combine the function of sliding tappet, rocker and adjustment device. Adjustment of the valve clearance was usually by a threaded stud at the valve end of the rocker. The linear sliding tappet side often had a high rate of wear and demanded careful lubrication with oil containing zinc additives. A relatively uncommon design of an SOHC camshaft with four valves per cylinder was first used in the 1973-1980 Triumph Dolomite Sprint inline-four engine, which used a camshaft with 8 lobes that actuated the 16 valves via a clever arrangement of rocker arms.

Double overhead camshaft

An overhead camshaft (OHC) engine is a piston engine in which the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combus ...

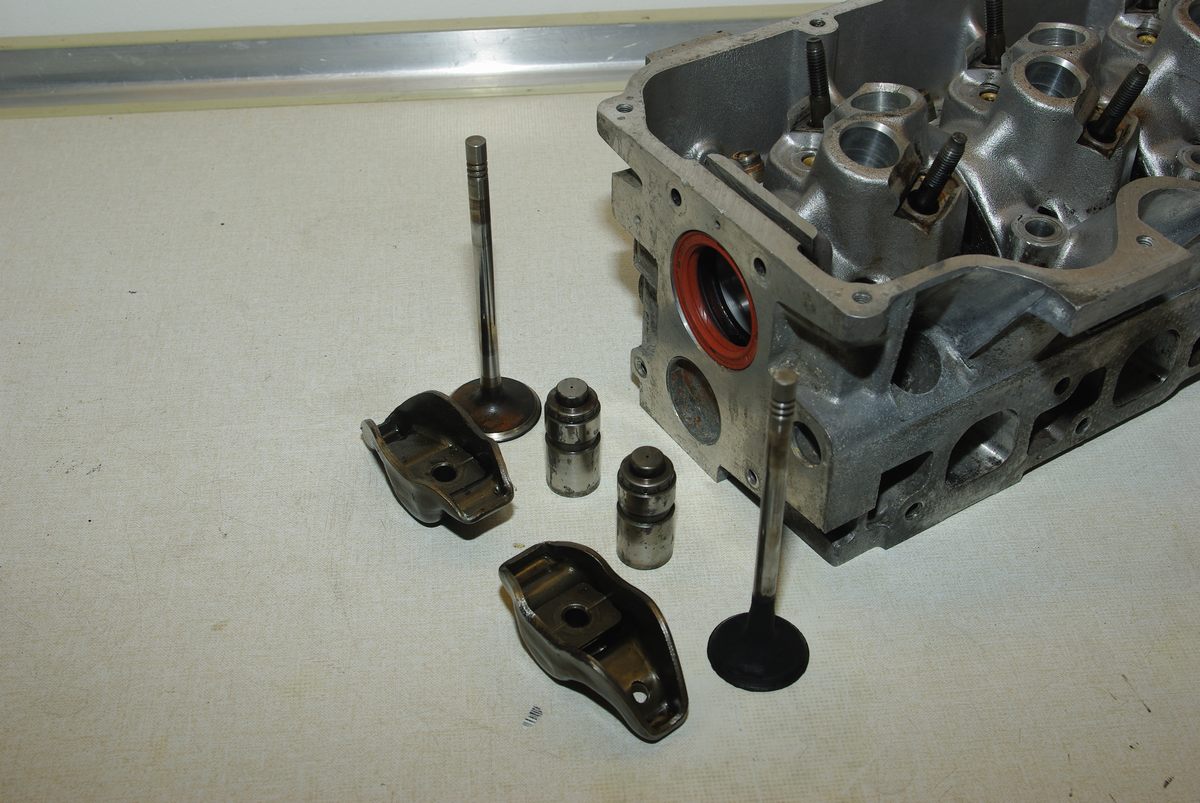

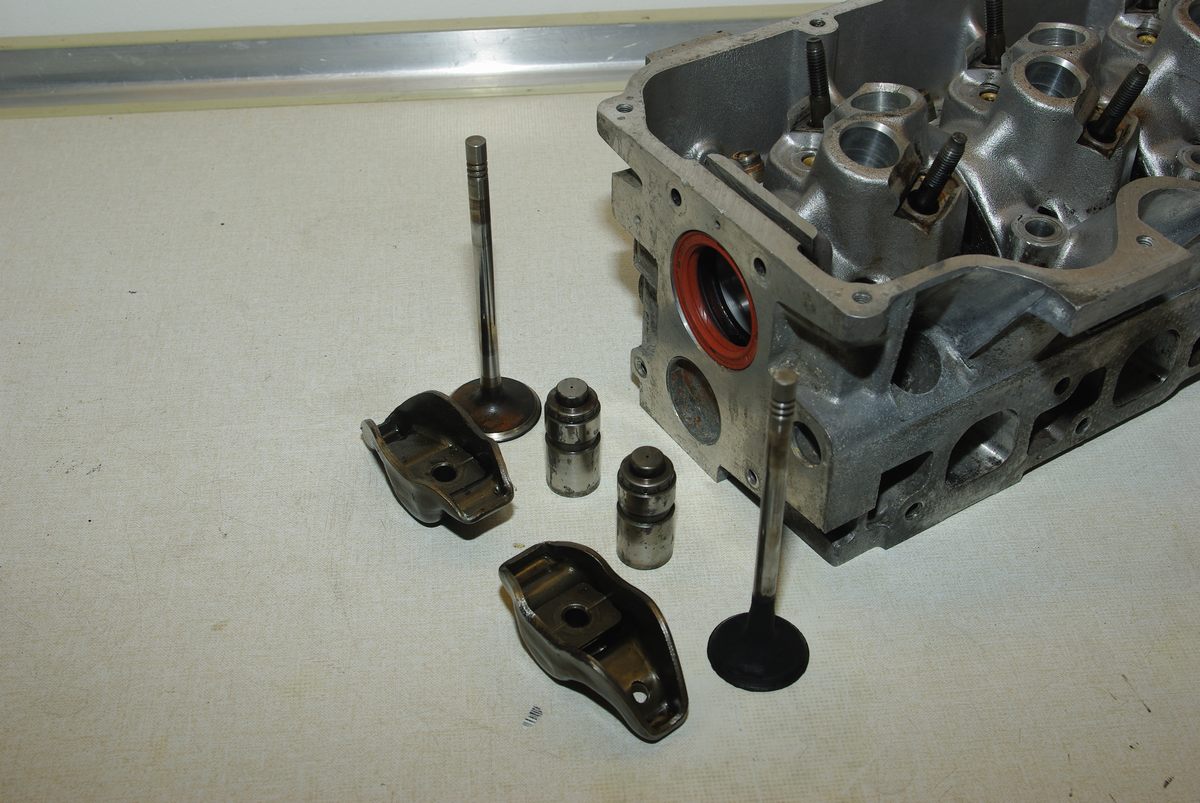

(DOHC) engines were first developed as high performance aircraft and racing engines, with the camshafts mounted directly over the valves and driving them through a simple 'bucket tappet'. Most engines used a crossflow cylinder head with the valves in two rows in line with their corresponding camshaft. The tappet clearance adjustment is typically set using a small shim, located either above or below the tappet. Shims were made in a range of standard thicknesses and a mechanic would swap them to change the tappet gap. In early DOHC engines, the engine would first be assembled with a default shim of known thickness, then the gap measured. This measurement would be used to calculate the thickness of shim that would result in the desired gap. After installation of the new shim, the gaps would then be measured again to verify that the clearance was correct. As the camshaft had to be removed to change the shims, this was a very time consuming operation (especially since the position of the camshaft could vary slightly each time it was re-installed). Later engines used an improved design where the shims were located above the tappets, which allowed each shim to be changed without removing either the tappet or camshaft. A drawback of this design is that the rubbing surface of the tappet becomes the surface of the shim, which is a difficult problem of mass-production metallurgy. The first mass production engine to use this system was the 1966-2000 Fiat Twin Cam engine

Fiat Automobiles S.p.A., commonly known as simply Fiat ( , ; ), is an Italian automobile manufacturer. It became a part of Fiat Chrysler Automobiles in 2014 and, in 2021, became a subsidiary of Stellantis through its Italian division, Stellant ...

, followed by engines from Volvo and the water-cooled Volkswagens.

Other uses

The term 'tappet' is also used, obscurely, as a component of valve systems for other machinery, particularly as part of a bash valve inpneumatic cylinder

Pneumatic cylinder, also known as air cylinder, is a mechanical device which uses the power of compressed gas to produce a force in a reciprocating linear motion.

Like in a hydraulic cylinder, something forces a piston to move in the desired ...

s. Where a reciprocating action is produced, such as for a pneumatic drill or jackhammer

A jackhammer (pneumatic drill or demolition hammer in British English) is a pneumatic or electro-mechanical tool that combines a hammer directly with a chisel. It was invented by William McReavy, who then sold the patent to Charles Brady Ki ...

, the valve may be actuated by inertia

Inertia is the natural tendency of objects in motion to stay in motion and objects at rest to stay at rest, unless a force causes the velocity to change. It is one of the fundamental principles in classical physics, and described by Isaac Newto ...

or by the movement of the working piston. As the piston hammers back and forth, it impacts a small tappet, which in turn moves the air valve and so reverses the flow of air to the piston.

In weaving looms, a tappet is a mechanism which helps form the shed or opening in the warp threads (long direction) of the material through

which the weft threads (side to side or short direction) are passed. The tappets form the basic patterns in the material such as plain weave, twill, denim, or satin weaves. Harris tweed is still woven on looms in which tappets are still used.

See also

*List of auto parts

This is a list of auto parts, which are manufactured components of automobiles. This list reflects both fossil-fueled cars (using internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the c ...

References

{{Automotive engine Beam engines Engine valves Engine components Valvetrain