Bell Brothers on:

[Wikipedia]

[Google]

[Amazon]

''Cleveland Ironstone. Outline of the Main Or Thick Stratified Bed, Its Discovery, Application, And Results, In Connection with the Iron-Works in the North of England''

Transactions of the North of England Institute of Mining Engineers 5 1856-57, 165-223

Hidden Teesside: Webb House, Bell Brothers Offices, Middlesbrough

North Yorkshire County Council Archives: Bell Of Rounton Grange Records

(Watercolours by John Bell (ca 1814–1886) of Port Clarence Ironworks under construction ca 1853) {{Good article Ironworks and steelworks in England Chemical companies of the United Kingdom Manufacturing companies based in Newcastle upon Tyne Steam engine manufacturers 1809 establishments in England Manufacturing companies established in 1809 1931 disestablishments in England Manufacturing companies disestablished in 1931 British companies established in 1809 1931 mergers and acquisitions British companies disestablished in 1931

Losh, Wilson and Bell, later Bells, Goodman, then Bells, Lightfoot and finally Bell Brothers, was a leading

/ref> In 1807, the Loshes opened an

/ref> Around 1821, George Stephenson was briefly a partner in the Walker Ironworks.

In 1827 a

In 1827 a

William Arthur Bone, 1912. In 1838, a second mill for rolling rails was added, run by the engineer John Vaughan (who went on to found On 25 January 1851, Lowthian Bell left the partnership with William Losh, Thomas Wilson, Catherine Bell, Thomas Bell and John Bell. The business at that time was described in the

On 25 January 1851, Lowthian Bell left the partnership with William Losh, Thomas Wilson, Catherine Bell, Thomas Bell and John Bell. The business at that time was described in the

tunnels. In 1871 the firm made pumping and winding engines for Seghill Colliery. In 1875 it made machinery to condense smoke and gases for Clyde Lead Works of Glasgow.

Northeast England

North East England, commonly referred to simply as the North East within England, is one of nine official regions of England. It consists of County Durham , Northumberland, Tyne and Wear and part of northern North Yorkshire. It is the least ...

manufacturing company, founded in 1809 by the partners William Losh

William Losh (1770 in Carlisle – 4 August 1861, in Ellison Place, Newcastle) was a chemist and industrialist who is credited with introducing the Leblanc process for the manufacture of alkali to the United Kingdom.

Life and work

Losh worked in ...

, Thomas Wilson, and Thomas Bell.

The firm was founded at Newcastle-upon-Tyne

Newcastle upon Tyne, or simply Newcastle ( , Received Pronunciation, RP: ), is a City status in the United Kingdom, cathedral city and metropolitan borough in Tyne and Wear, England. It is England's northernmost metropolitan borough, located o ...

with an ironworks

An ironworks or iron works is an industrial plant where iron is smelted and where heavy iron and steel products are made. The term is both singular and plural, i.e. the singular of ''ironworks'' is ''ironworks''.

Ironworks succeeded bloome ...

and an alkali

In chemistry, an alkali (; from the Arabic word , ) is a basic salt of an alkali metal or an alkaline earth metal. An alkali can also be defined as a base that dissolves in water. A solution of a soluble base has a pH greater than 7.0. The a ...

works nearby at Walker. The alkali works were the first in England to make soda using the Leblanc process

The Leblanc process was an early industrial process for making ''soda ash'' ( sodium carbonate) used throughout the 19th century, named after its inventor, Nicolas Leblanc. It involved two stages: making sodium sulfate from sodium chloride, fol ...

; the ironworks was the first to use Cleveland Ironstone, presaging the 1850s boom in ironmaking on Teesside

Teesside () is an urban area around the River Tees in North East England. Straddling the border between County Durham and North Yorkshire, it spans the boroughs of Borough of Middlesbrough, Middlesbrough, Borough of Stockton-on-Tees, Stockton ...

.

The so-called discoverer of Cleveland Ironstone, the mining engineer John Vaughan, ran a rolling mill for the company before leaving to found the major rival firm Bolckow Vaughan

Bolckow, Vaughan & Co., Ltd was an English steelmaking, ironmaking and mining company founded in 1864, based on the partnership since 1840 of its two founders, Henry Bolckow and John Vaughan (ironmaster), John Vaughan. The firm drove the dramat ...

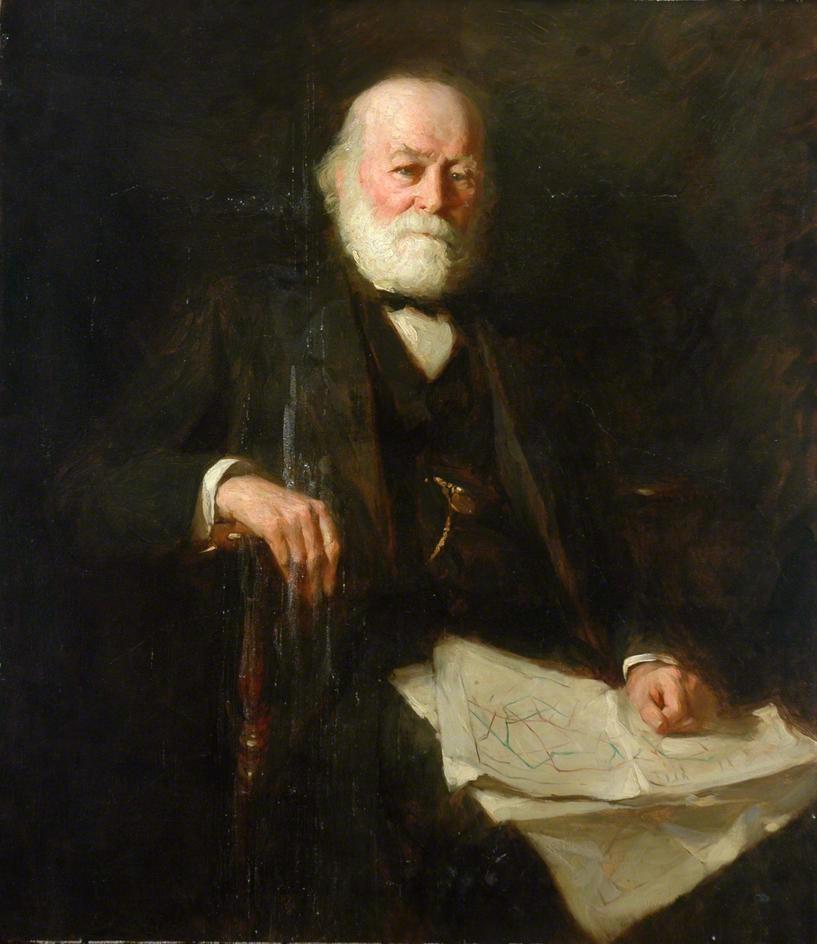

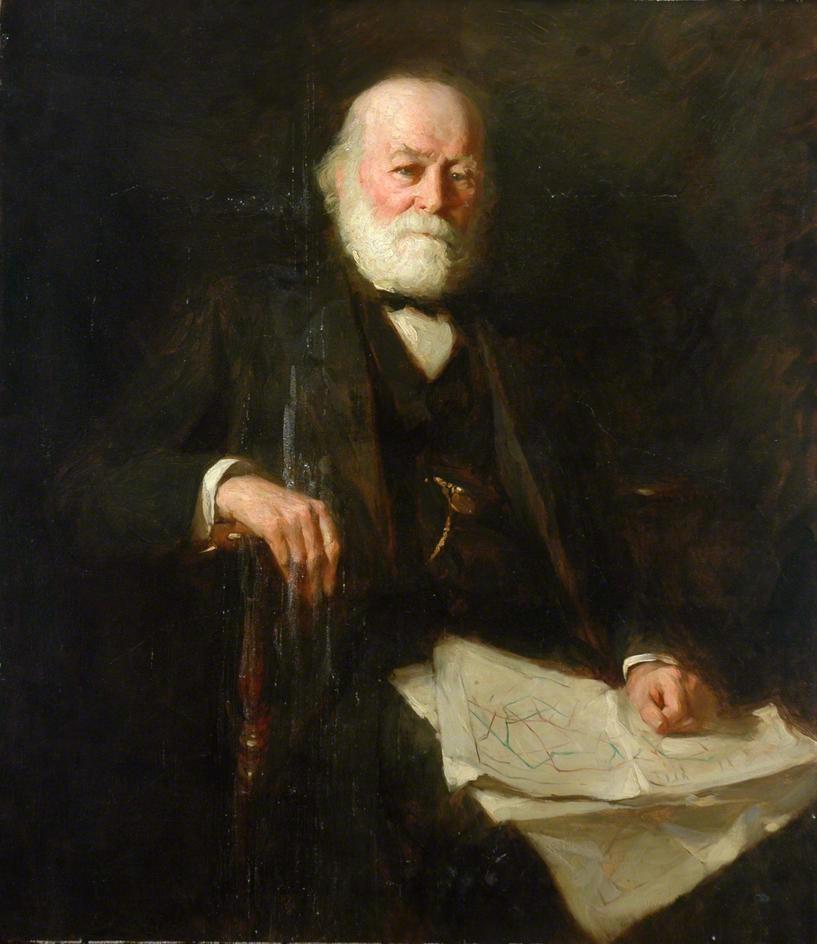

. The other key figure in the company was Lowthian Bell

Sir Isaac Lowthian Bell, 1st Baronet, FRS (18 February 1816 – 20 December 1904) was a British ironmaster and Liberal Party politician from Washington, County Durham. He was described as being "as famous in his day as Isambard Kingdom Brunel".

...

, son of Thomas Bell; he became perhaps the best known ironmaster

An ironmaster is the manager, and usually owner, of a forge or blast furnace for the processing of iron. It is a term mainly associated with the period of the Industrial Revolution, especially in Great Britain.

The ironmaster was usually a larg ...

in England.

As Bell Brothers, the firm continued until 1931, when it was taken over by rival Dorman Long

Dorman Long & Co was a UK steel producer, later diversifying into bridge building. The company was once listed on the London Stock Exchange.

History

The company was founded by Arthur Dorman and Albert de Lande Long when they acquired '' ...

.

History

Founders

The company was named afterWilliam Losh

William Losh (1770 in Carlisle – 4 August 1861, in Ellison Place, Newcastle) was a chemist and industrialist who is credited with introducing the Leblanc process for the manufacture of alkali to the United Kingdom.

Life and work

Losh worked in ...

, Thomas Wilson, and Thomas Bell.

William Losh (1770 Carlisle–4 August 1861, Ellison Place, Newcastle) came from a rich family that owned coal mines in Northeast England

North East England, commonly referred to simply as the North East within England, is one of nine official regions of England. It consists of County Durham , Northumberland, Tyne and Wear and part of northern North Yorkshire. It is the least ...

. He was educated in Hamburg, and trained in Newcastle, Sweden and France. He married Alice Wilkinson of Carlisle on 1 March 1798 at Gateshead. He was a friend of the explorer Alexander von Humboldt

Friedrich Wilhelm Heinrich Alexander von Humboldt (14 September 1769 – 6 May 1859) was a German polymath, geographer, natural history, naturalist, List of explorers, explorer, and proponent of Romanticism, Romantic philosophy and Romanticism ...

and a one-time business partner of rail pioneer George Stephenson

George Stephenson (9 June 1781 – 12 August 1848) was an English civil engineer and Mechanical engineering, mechanical engineer during the Industrial Revolution. Renowned as the "Father of Railways", Stephenson was considered by the Victoria ...

. His brother James Losh was also a partner in the firm, and kept a diary recording his anxieties about the firm during the Napoleonic wars

{{Infobox military conflict

, conflict = Napoleonic Wars

, partof = the French Revolutionary and Napoleonic Wars

, image = Napoleonic Wars (revision).jpg

, caption = Left to right, top to bottom:Battl ...

.

Thomas Wilson (1773–9 May 1858) of Low Fell

Low Fell is a suburb of Gateshead situated in the Metropolitan Borough of Gateshead in Tyne and Wear, England. Built predominantly on sandstone, grindstone and clay, it is bordered by Sheriff Hill/ Deckham to the east, Saltwell/Bensham to the ...

, Gateshead

Gateshead () is a town in the Gateshead Metropolitan Borough of Tyne and Wear, England. It is on the River Tyne's southern bank. The town's attractions include the twenty metre tall Angel of the North sculpture on the town's southern outskirts, ...

joined the Losh, Lubbin counting house. In 1807, Wilson became a partner and the firm took the name Losh, Wilson and Bell. In 1810 he married Mrs Fell of Kirklinton.

Thomas Bell, (5 March 1784 – 20 April 1845) partner, was married to Katherine Lowthian of Newbiggin, Cumberland on 25 March 1815. Bell's father was a blacksmith

A blacksmith is a metalsmith who creates objects primarily from wrought iron or steel, but sometimes from #Other metals, other metals, by forging the metal, using tools to hammer, bend, and cut (cf. tinsmith). Blacksmiths produce objects such ...

.

Origins: from alkali to iron

The firm's origins can be traced back to 1790 when Archibald Dundonald, with John and William Losh, experimented on producing soda fromsalt

In common usage, salt is a mineral composed primarily of sodium chloride (NaCl). When used in food, especially in granulated form, it is more formally called table salt. In the form of a natural crystalline mineral, salt is also known as r ...

. In about 1793 they opened a works at Bells Close, near Newcastle. Dundonald sent William Losh to Paris to study Nicolas Leblanc

Nicolas Leblanc (; December 6, 1742 – January 16, 1806) was a French chemist and surgeon who discovered how to manufacture soda ash from common salt.

Earlier days

Leblanc was born in Ivoy le Pré, Cher, France on 6 December 1742. His f ...

's process for making soda from salt.Grace's Guide: Walker Ironworks/ref> In 1807, the Loshes opened an

alkali

In chemistry, an alkali (; from the Arabic word , ) is a basic salt of an alkali metal or an alkaline earth metal. An alkali can also be defined as a base that dissolves in water. A solution of a soluble base has a pH greater than 7.0. The a ...

works at Walker, Newcastle upon Tyne

Walker is a residential suburb and electoral ward in the south-east of Newcastle upon Tyne, in the county of Tyne and Wear, England.

History

The place-name 'Walker' is first attested in 1242, where it appears as ''Waucre''. This means 'wall-car ...

, Northumberland. It was the first in England to use the Leblanc process

The Leblanc process was an early industrial process for making ''soda ash'' ( sodium carbonate) used throughout the 19th century, named after its inventor, Nicolas Leblanc. It involved two stages: making sodium sulfate from sodium chloride, fol ...

. Dundonald left the partnership and the business continued as Walker Alkali Works.

Losh, Wilson & Bell's first ironworks

An ironworks or iron works is an industrial plant where iron is smelted and where heavy iron and steel products are made. The term is both singular and plural, i.e. the singular of ''ironworks'' is ''ironworks''.

Ironworks succeeded bloome ...

was founded in 1809 at Walker, beside the alkali works, carrying out a mixture of engineering work but not building steam engine

A steam engine is a heat engine that performs Work (physics), mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a Cylinder (locomotive), cyl ...

s. By 1818, George Stephenson

George Stephenson (9 June 1781 – 12 August 1848) was an English civil engineer and Mechanical engineering, mechanical engineer during the Industrial Revolution. Renowned as the "Father of Railways", Stephenson was considered by the Victoria ...

's original wooden wagonway was completely relaid with cast-iron edge-rails made in collaboration between Stephenson, who owned the patent, and Losh, Wilson and Bell.Institution of Mechanical Engineers Past Presidents/ref> Around 1821, George Stephenson was briefly a partner in the Walker Ironworks.

Wealth

In 1827 a

In 1827 a rolling mill

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is simi ...

capable of 100 tons of bar iron per week was installed at the Walker Ironworks; in the same year, Losh, Wilson and Bell's Walker foundry was listed in Parson and White's gazetteer of Durham and Northumberland as a steam engine manufacturer. In 1833, the iron puddling process was installed at Walker. In 1835, while working as an inspector of construction on the Whitby & Pickering Railway, Thomas Wilson noted the presence of ironstone

Ironstone is a sedimentary rock, either deposited directly as a ferruginous sediment or created by chemical replacement, that contains a substantial proportion of an iron ore compound from which iron (Fe) can be smelted commercially.

Not to be c ...

in a railway cutting at Grosmont, and arranged for drift mine

Drift mining is either the mining of an ore deposit by Underground mining (hard rock), underground methods, or the working of coal seams accessed by adits driven into the surface outcrop of the coal bed. A drift mine is an underground mine in whic ...

s to exploit the find; the new railway carried the ore to Whitby

Whitby is a seaside town, port and civil parish in North Yorkshire, England. It is on the Yorkshire Coast at the mouth of the River Esk, North Yorkshire, River Esk and has a maritime, mineral and tourist economy.

From the Middle Ages, Whitby ...

. In that year, at the age of nineteen, Thomas Bell's son Lowthian Bell

Sir Isaac Lowthian Bell, 1st Baronet, FRS (18 February 1816 – 20 December 1904) was a British ironmaster and Liberal Party politician from Washington, County Durham. He was described as being "as famous in his day as Isambard Kingdom Brunel".

...

entered the firm's Newcastle office under his father. In 1836 he joined his father at the firm's ironworks at Walker.The Peerage: Bell, Sir Isaac LowthianWilliam Arthur Bone, 1912. In 1838, a second mill for rolling rails was added, run by the engineer John Vaughan (who went on to found

Bolckow Vaughan

Bolckow, Vaughan & Co., Ltd was an English steelmaking, ironmaking and mining company founded in 1864, based on the partnership since 1840 of its two founders, Henry Bolckow and John Vaughan (ironmaster), John Vaughan. The firm drove the dramat ...

); he strongly influenced Lowthian Bell to become an ironmaster

An ironmaster is the manager, and usually owner, of a forge or blast furnace for the processing of iron. It is a term mainly associated with the period of the Industrial Revolution, especially in Great Britain.

The ironmaster was usually a larg ...

. In the same year, '' The Athenaeum Journal'' reported that the Losh, Wilson & Bell works was manufacturing tin

Tin is a chemical element; it has symbol Sn () and atomic number 50. A silvery-colored metal, tin is soft enough to be cut with little force, and a bar of tin can be bent by hand with little effort. When bent, a bar of tin makes a sound, the ...

and iron plate in large quantities, along with iron bars for making railway-carriage wheels. The firm's adjacent alkali works was one of several such operations on the Tyne that were collectively producing more than 250 tons of crystallised soda and about 100 tons of soda ash weekly. The journal called William Losh "the father of soda-making on the Tyne" and described him as the head of the firm (although it was a partnership).

In 1842, the shortage of pig iron

Pig iron, also known as crude iron, is an intermediate good used by the iron industry in the production of steel. It is developed by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with si ...

persuaded Bell to install its own blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure.

In a ...

for smelting mill cinder; this was a key decision, enabling the firm to expand. Only two years later, in 1844, the firm installed a second furnace at Walker for Cleveland Ironstone from Grosmont, six years before the boom in Cleveland iron when Vaughan

Vaughan ( ) (2022 population 344,412) is a city in Ontario, Canada. It is located in the Regional Municipality of York, just north of Toronto. Vaughan was the fastest-growing municipality in Canada between 1996 and 2006 with its population increa ...

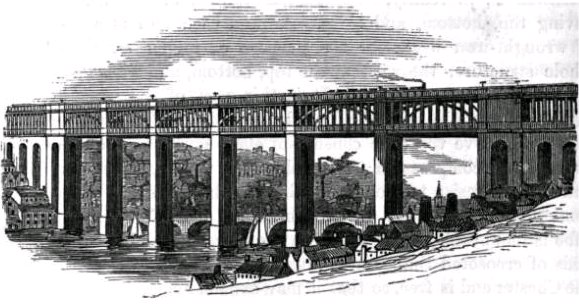

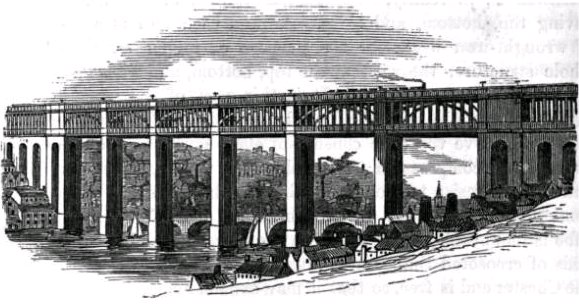

and Marley discovered ironstone in the Eston Hills in 1850. From 1849, Losh, Wilson and Bell were subcontractors on the Newcastle-Gateshead High Level Bridge High Level Bridge may refer to:

* Detroit–Superior High Level Bridge, road and former tramway bridge over the Cuyahoga River in Cleveland, Ohio.

* High Level Bridge, River Tyne, road and railway bridge between Newcastle upon Tyne and Gateshead ...

, responsible for constructing the bridge approaches.

On 25 January 1851, Lowthian Bell left the partnership with William Losh, Thomas Wilson, Catherine Bell, Thomas Bell and John Bell. The business at that time was described in the

On 25 January 1851, Lowthian Bell left the partnership with William Losh, Thomas Wilson, Catherine Bell, Thomas Bell and John Bell. The business at that time was described in the London Gazette

London is the capital and largest city of both England and the United Kingdom, with a population of in . Its wider metropolitan area is the largest in Western Europe, with a population of 14.9 million. London stands on the River Tha ...

as "Iron Manufacturers, and Ship and Insurance Brokers, under the style or firm of Losh, Wilson, and Bell". He went on to have a career in chemistry and politics, becoming a member of parliament among many other distinctions.

On 8 October 1855, there was a serious boiler explosion

A boiler explosion is a catastrophic failure of a boiler.

There are two types of boiler explosions. One type is a failure of the pressure parts of the steam and water sides. There can be many different causes, such as failure of the safety val ...

at the Walker Iron Works, which killed at least seven workers. According to a contemporary account, the boiler "unfurled like a sail, was blown upwards, carrying with it two roofings of the sheds, and blowing down two furnaces, with their chimneys, and scattering the molten metal and red hot bricks around, while one end of it was hurled into the midst of the works, and the other about 200 yards over the hill top, into the lumber-yard".

All the dead were aged between 19 and 33, and the event created something of a sensation at the time. In 1857, John Marley

John Marley (born Mortimer Leon Marlieb; October 17, 1907 – May 22, 1984) was an American actor and theatre director. He won the Volpi Cup for Best Actor at the 29th Venice International Film Festival for his performance in John Cassavetes' ' ...

, in his account of the Cleveland Ironstone, described the Bell Ironworks as follows:John Marley, ''Cleveland Ironstone'', 1857.These iron-works, situate on the Tyne, and belonging to Messrs. Losh, Wilson, & Bell, originally consisted of only one furnace, being the first blast furnace that was specially erected for this bed of ironstone (in connection with Scotch, and other ores, for mixing), viz., about the year 1842 or 1843, and which ironstone was purchased from the aforesaid mines belonging to Mrs. Clark, in theWhitby Whitby is a seaside town, port and civil parish in North Yorkshire, England. It is on the Yorkshire Coast at the mouth of the River Esk, North Yorkshire, River Esk and has a maritime, mineral and tourist economy. From the Middle Ages, Whitby ...district, the first cargo being sent in June or July, 1843, since which time these works have been increased by one extra furnace, built for the Whitby district ironstone in 1844, and by other three t Port Clarence">Port_Clarence.html" ;"title="t Port Clarence">t Port Clarencefor the north part of Cleveland, about 1852, making now a total of five furnaces.

Bells, Goodman

From 1869 at the latest, the company owning the Walker Engine Works was Bells, Goodman & Co. In that year the firm made the tunnelling shield and iron castings to line the Tower Subway">Tower subway The Tower Subway is a tunnel beneath the River Thames in central London, between Tower Hill on the north bank of the river and Vine Lane (off Tooley Street) on the south. In 1869 a circular tunnel was dug through the London clay using a cast ir ...Bells, Lightfoot

In 1875, the Bells, Goodman partnership was dissolved when Alfred Goodman retired. The firm became known as Bells, Lightfoot & Co. In 1876 it supplied a 90" Cornish beam engine for Springhead Pumping Station near Anlaby in the East Riding of Yorkshire; it had an unusual box-section wrought iron beam, and continued running until 1952. On 30 November 1876, Thomas Bell Lightfoot, Managing Partner, was granted a patent for his developments on machines for squeezing metals into shape. However, on 28 August 1883, Thomas Bell moved to Bilbao, Spain, where he continued to describe himself as an Ironmaster, and by mutual consent his partnership with Henry Bell and Thomas Bell the younger was dissolved. The deed was witnessed on 7 December 1883.Bell Brothers

By 1873, Bell Brothers owned 9 coal mines in County Durham and Yorkshire. There were 10 mines in 1882; in 1888 the "Clarence Salt Works" was also recorded. In 1896 and 1902 the company had 11 mines. In 1914 there are 12; in 1921 there are 14. The 1881–1891Arts and Crafts

The Arts and Crafts movement was an international trend in the Decorative arts, decorative and fine arts that developed earliest and most fully in the British Isles and subsequently spread across the British Empire and to the rest of Europe and ...

classical style Bell Brothers office building at Zetland Road in Middlesbrough was designed by architect Philip Webb

Philip Speakman Webb (12 January 1831 – 17 April 1915) was a British architect and designer sometimes called the Father of Arts and Crafts Architecture. His use of vernacular architecture demonstrated his commitment to "the art of common ...

; it was his only commercial development. According to English Heritage

English Heritage (officially the English Heritage Trust) is a charity that manages over 400 historic monuments, buildings and places. These include prehistoric sites, a battlefield, medieval castles, Roman forts, historic industrial sites, Lis ...

it is architecturally the most important building in Middlesbrough.

In 1903, Lowthian Bell, then aged 87, sold a majority holding of the Bell companies to the rival firm Dorman Long

Dorman Long & Co was a UK steel producer, later diversifying into bridge building. The company was once listed on the London Stock Exchange.

History

The company was founded by Arthur Dorman and Albert de Lande Long when they acquired '' ...

. It was not a comfortable merger. Bell Brothers, along with the plate maker Consett Iron Company

The Consett Iron Company Ltd was an industrial business based in the Consett area of County Durham in the United Kingdom. The company owned coal mines and limestone quarries, and manufactured iron and steel. It was registered on 4 April 1864 a ...

and another family ironmaking firm of Northeast England, Bolckow Vaughan

Bolckow, Vaughan & Co., Ltd was an English steelmaking, ironmaking and mining company founded in 1864, based on the partnership since 1840 of its two founders, Henry Bolckow and John Vaughan (ironmaster), John Vaughan. The firm drove the dramat ...

,

Further, as regards the Bells and the Dormans,

Bell Brothers was recorded in the ''Colliery Year Book and Coal Trades Directory'' of 1923 as having an annual output of 600,000 tons of coal for coking and manufacturing. Sir Hugh Bell was chairman and managing director; Arthur Dorman and Charles Dorman were directors. That same year, Bell Brothers, described in ''The Sydney Morning Herald

''The Sydney Morning Herald'' (''SMH'') is a daily Tabloid (newspaper format), tabloid newspaper published in Sydney, Australia, and owned by Nine Entertainment. Founded in 1831 as the ''Sydney Herald'', the ''Herald'' is the oldest continuous ...

'' as "owners of coal and ironstone mines and blast furnaces and rolling mills", was finally merged completely with Dorman Long. Sir Arthur Dorman was chairman; both Hugh Bell and his son Maurice Bell were among the directors. When Arthur Dorman died in 1931, Hugh Bell, aged 87, briefly became chairman of 'Dorman versus Bell'; he died on 29 June 1931.

Wages and social conditions

John Roby Leifchild wrote a report in 1842 for the Children's Employment Commission entitled "Employment of Children and Young Persons in the Collieries, Lead Mines, and Iron Works of Northumberland and the North of Durham; and on the Condition, Treatment, and Education of such Children and Young Persons". Leifchild found that Losh, Wilson & Bell paid its workers 30 to 36 shillings per week for a scrap-puddler; £2 5 shillings per week for a pudler; 18 shillings per week for a plate mill-furnace man; and 25 shillings per week for an engineman. The boiler engineer's family of wife and four children spent 18 shillings per week on provisions and 3 shillings per week on rent, leaving only 4 shillings for all other expenditure. In sport, an iron puddler, Robert Chambers of the company's Walker works, won the sculling championship at the 1857 Thames Regatta. The heavy work stirring the iron was said to have strengthened his arms and shoulders. Chambers also won the return match, held on the Tyne on 19 April 1859, even after a collision with a moored boat left him a hundred yards behind.Whitehead, Ian. ''The Sporting Tyne, A History of Professional Rowing'', Portcullis, 2002.See also

*Hartley Colliery disaster

The Hartley Colliery disaster (also known as the Hartley Pit disaster or Hester Pit disaster) was a coal mining accident in Northumberland, England, that occurred on 16 January 1862 and resulted in the deaths of 204 men and children. The beam o ...

References

Bibliography

* * * Marley, J''Cleveland Ironstone. Outline of the Main Or Thick Stratified Bed, Its Discovery, Application, And Results, In Connection with the Iron-Works in the North of England''

Transactions of the North of England Institute of Mining Engineers 5 1856-57, 165-223

External links

Hidden Teesside: Webb House, Bell Brothers Offices, Middlesbrough

North Yorkshire County Council Archives: Bell Of Rounton Grange Records

(Watercolours by John Bell (ca 1814–1886) of Port Clarence Ironworks under construction ca 1853) {{Good article Ironworks and steelworks in England Chemical companies of the United Kingdom Manufacturing companies based in Newcastle upon Tyne Steam engine manufacturers 1809 establishments in England Manufacturing companies established in 1809 1931 disestablishments in England Manufacturing companies disestablished in 1931 British companies established in 1809 1931 mergers and acquisitions British companies disestablished in 1931