|

Wear Coefficient

The wear coefficient is a physical coefficient used to measure, characterize and correlate the wear of materials. Background Traditionally, the wear of materials has been characterized by weight loss and wear rate. However, studies have found that wear coefficient is more suitable. The reason being that it takes the wear rate, the applied load, and the hardness of the wear pin into account. Although, measurement variations by an order of 10-1 have been observed, the variations can be minimized if suitable precautions are taken. A wear volume versus distance curve can be divided into at least two regimes, the transient wear regime and the steady-state wear regime. The volume or weight loss is initially curvilinear. The wear rate per unit sliding distance in the transient wear regime decreases until it has reached a constant value in the steady-state wear regime. Hence the standard wear coefficient value obtained from a volume loss versus distance curve is a function of the slidin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Physical Coefficient

A physical coefficient is an important number that characterizes some physical property of a technical or scientific object. A coefficient also has a scientific reference which is the reliance on force. Stoichiometric coefficient of a chemical compound To find the coefficient of a chemical compound, you must balance the elements involved in it. For example, water: H2O. It just so happens that hydrogen (H) and oxygen (O) are both diatomic molecules, thus we have H2 and O2. To form water, one of the O atoms breaks off from the O2 molecule and react with the H2 compound to form H2O. But, there is one oxygen atom left. It reacts with another H2 molecule. Since it took two of each atom to balance the compound, we put the coefficient 2 in front of H2O: 2 H2O. The total reaction is thus 2 H2 + O2 → 2 H2O. Examples of physical coefficients # '' Coefficient of thermal expansion'' (thermodynamics) (dimensionless) - Relates the change in temperature to the change in a material's ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wear

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical (e.g., erosion) or chemical (e.g., corrosion). The study of wear and related processes is referred to as tribology. Wear in machine elements, together with other processes such as fatigue and creep, causes functional surfaces to degrade, eventually leading to material failure or loss of functionality. Thus, wear has large economic relevance as first outlined in the Jost Report. Abrasive wear alone has been estimated to cost 1-4% of the gross national product of industrialized nations. Wear of metals occurs by plastic displacement of surface and near-surface material and by detachment of particles that form wear debris. The particle size may vary from millimeters to nanometers. This process may occur by contact with other metals, nonmetallic solids, flowing liquids, solid particles or liquid droplets entrained in flowing gasses. The wear rate is affected by f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

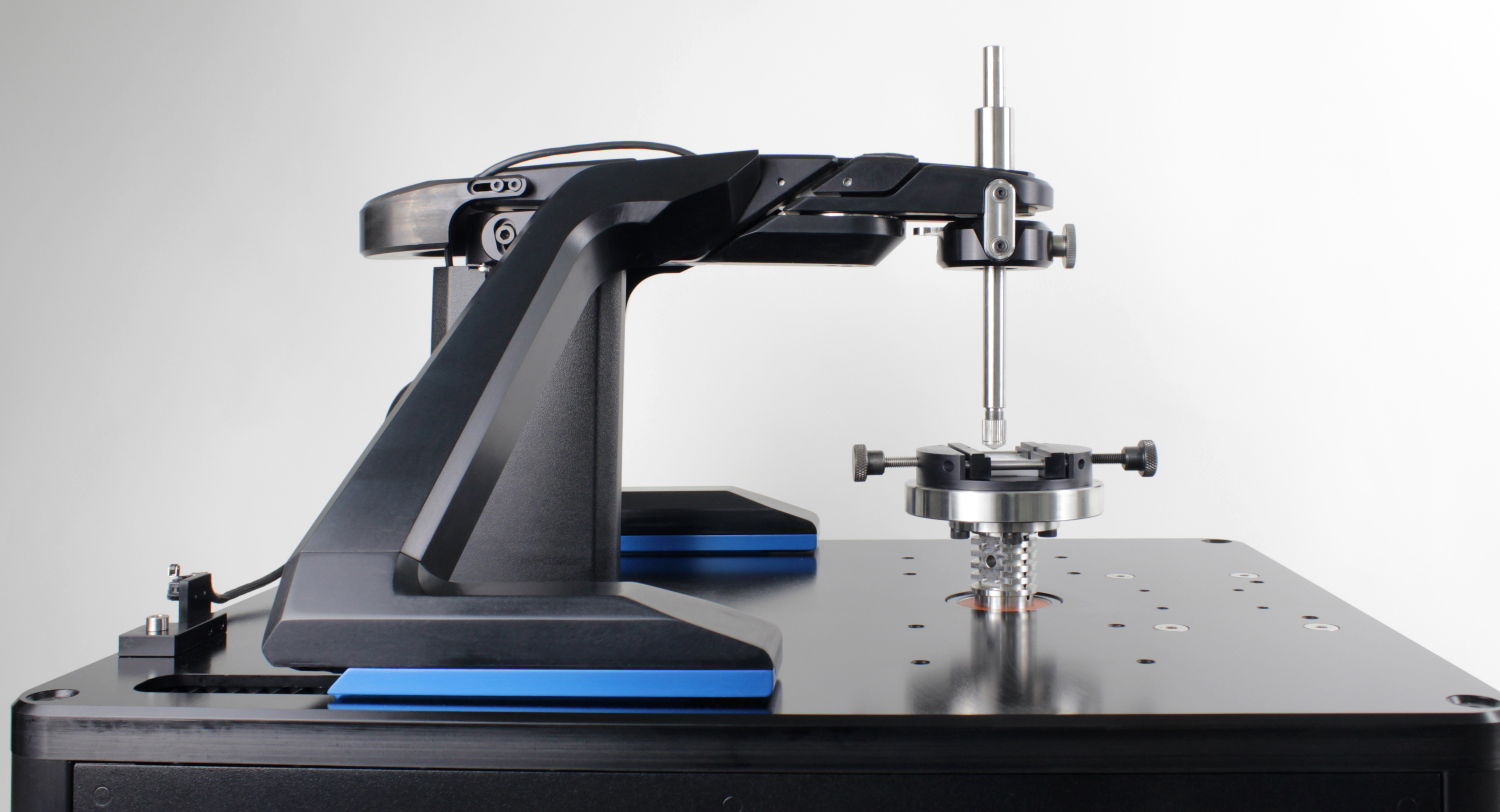

Tribometer

A tribometer is an instrument that measures tribological quantities, such as coefficient of friction, friction force, and wear volume, between two surfaces in contact. It was invented by the 18th century Dutch scientist Musschenbroek A tribotester is the general name given to a machine or device used to perform tests and simulations of wear, friction and lubrication which are the subject of the study of tribology. Often tribotesters are extremely specific in their function and are fabricated by manufacturers who desire to test and analyze the long-term performance of their products. An example is that of orthopedic implant manufacturers who have spent considerable sums of money to develop tribotesters that accurately reproduce the motions and forces that occur in human hip joints so that they can perform accelerated wear tests of their products. Theory A simple tribometer is described by a hanging mass and a mass resting on a horizontal surface, connected to each other ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Curvilinear Coordinates

In geometry, curvilinear coordinates are a coordinate system for Euclidean space in which the coordinate lines may be curved. These coordinates may be derived from a set of Cartesian coordinates by using a transformation that is locally invertible (a one-to-one map) at each point. This means that one can convert a point given in a Cartesian coordinate system to its curvilinear coordinates and back. The name ''curvilinear coordinates'', coined by the French mathematician Lamé, derives from the fact that the coordinate surfaces of the curvilinear systems are curved. Well-known examples of curvilinear coordinate systems in three-dimensional Euclidean space (R3) are cylindrical and spherical coordinates. A Cartesian coordinate surface in this space is a coordinate plane; for example ''z'' = 0 defines the ''x''-''y'' plane. In the same space, the coordinate surface ''r'' = 1 in spherical coordinates is the surface of a unit sphere, which is curved. The formalism of curvil ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

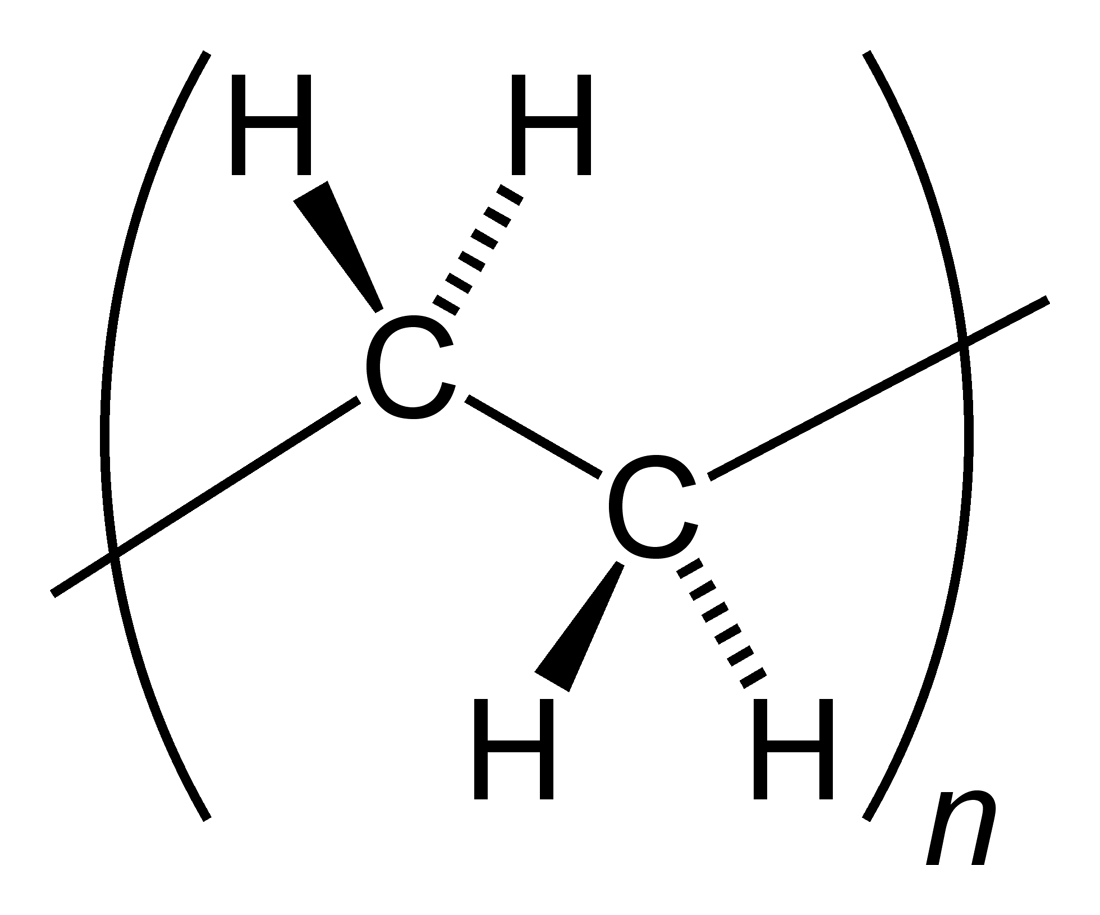

Polyethylene

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging (plastic bags, plastic films, geomembranes and containers including bottles, etc.). , over 100 million tonnes of polyethylene resins are being produced annually, accounting for 34% of the total plastics market. Many kinds of polyethylene are known, with most having the chemical formula (C2H4)''n''. PE is usually a mixture of similar polymers of ethylene, with various values of ''n''. It can be ''low-density'' or ''high-density'': low-density polyethylene is extruded using high pressure () and high temperature (), while high-density polyethylene is extruded using low pressure () and low temperature (). Polyethylene is usually thermoplastic, but it can be modified to become thermosetting instead, for example, in cross-linked polyethylene. History Polyethylene was first synthesized by the German ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Poly(methyl Methacrylate)

Poly(methyl methacrylate) (PMMA) belongs to a group of materials called engineering plastics. It is a transparent thermoplastic. PMMA is also known as acrylic, acrylic glass, as well as by the trade names and brands Crylux, Plexiglas, Acrylite, Astariglas, Lucite, Perclax, and Perspex, among several others ( see below). This plastic is often used in sheet form as a lightweight or shatter-resistant alternative to glass. It can also be used as a casting resin, in inks and coatings, and for many other purposes. Although not a type of familiar silica-based glass, the substance, like many thermoplastics, is often technically classified as a type of glass, in that it is a non-crystalline vitreous substance—hence its occasional historic designation as ''acrylic glass''. Chemically, it is the synthetic polymer of methyl methacrylate. It was developed in 1928 in several different laboratories by many chemists, such as William Chalmers, Otto Röhm, and Walter Bauer, and first brou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Allotropes Of Iron

At atmospheric pressure, three allotropic forms of iron exist, depending on temperature: alpha iron (α-Fe), gamma iron (γ-Fe), and delta iron (δ-Fe). At very high pressure, a fourth form exists, called epsilon iron (ε-Fe). Some controversial experimental evidence suggests the existence of a fifth high-pressure form that is stable at very high pressures and temperatures. The phases of iron at atmospheric pressure are important because of the differences in solubility of carbon, forming different types of steel. The high-pressure phases of iron are important as models for the solid parts of planetary cores. The inner core of the Earth is generally assumed to consist essentially of a crystalline iron-nickel alloy with ε structure. The outer core surrounding the solid inner core is believed to be composed of liquid iron mixed with nickel and trace amounts of lighter elements. Standard pressure allotropes Alpha iron (α-Fe) Below 912 °C (1,674 °F), iron has a b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polytetrafluoroethylene

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications. It is one of the best-known and widely applied PFAS. The commonly known brand name of PTFE-based composition is Teflon by Chemours, a spin-off from DuPont, which originally discovered the compound in 1938. Polytetrafluoroethylene is a fluorocarbon solid, as it is a high- molecular-weight polymer consisting wholly of carbon and fluorine. PTFE is hydrophobic: neither water nor water-containing substances wet PTFE, as fluorocarbons exhibit only small London dispersion forces due to the low electric polarizability of fluorine. PTFE has one of the lowest coefficients of friction of any solid. Polytetrafluoroethylene is used as a non-stick coating for pans and other cookware. It is non-reactive, partly because of the strength of carbon–fluorine bonds, so it is often used in containers and pipework for reactive and corrosive chemicals. Where used as a lubri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Beryllium Copper

Beryllium copper (BeCu), also known as copper beryllium (CuBe), beryllium bronze, and spring copper, is a copper alloy with 0.5–3% beryllium but can contain other elements as well. Beryllium copper combines high strength with non-magnetic and non-sparking qualities. It has excellent metalworking, forming, and machining properties. It has many specialized applications in tools for hazardous environments, musical instruments, precision measurement devices, bullets, and aerospace. Beryllium alloys present a toxic inhalation hazard during manufacture. Properties Beryllium copper is a ductile, weldable, and machinable alloy. Like pure copper, it is resistant to non-oxidizing acids (such as hydrochloric acid and carbonic acid) and plastic decomposition products, to abrasive wear, and to galling. It can be heat-treated for increased strength, durability, and electrical conductivity. Beryllium copper attains the greatest strength (up to ) of any copper-based alloy. It ha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tool Steel

Tool steel is any of various carbon steels and alloy steels that are particularly well-suited to be made into tools and tooling, including cutting tools, dies, hand tools, knives, and others. Their suitability comes from their distinctive hardness, resistance to abrasion and deformation, and their ability to hold a cutting edge at elevated temperatures. As a result, tool steels are suited for use in the shaping of other materials, as for example in cutting, machining, stamping, or forging. With a carbon content between 0.5% and 1.5%, tool steels are manufactured under carefully controlled conditions to produce the required quality. The presence of carbides in their matrix plays the dominant role in the qualities of tool steel. The four major alloying elements that form carbides in tool steel are: tungsten, chromium, vanadium and molybdenum. The rate of dissolution of the different carbides into the austenite form of the iron determines the high-temperature performance of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states: * no minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium, zirconium, or any other element to be added to obtain a desired alloying effect; * the specified minimum for copper does not exceed 0.40%; * or the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65%; silicon 0.60%; copper 0.60%. The term ''carbon steel'' may also be used in reference to steel which is not stainless steel; in this use carbon steel may include alloy steels. High carbon steel has many different uses such as milling machines, cutting tools (such as chisels) and high strength wires. These applications require a much finer microstructure, which improves the toughness. Carbon steel is a popular met ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brinell Scale

The Brinell scale characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science. History Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The large size of indentation and possible damage to test-piece limits its usefulness. However, it also had the useful feature that the hardness value divided by two gave the approximate UTS in ksi for steels. This feature contributed to its early adoption over competing hardness tests. Test details The typical test uses a diameter steel ball as an indenter with a force. For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The indentation is measured and hardness calculated as: :\operatorname=\frac where: :BHN = Brinell Hard ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |