|

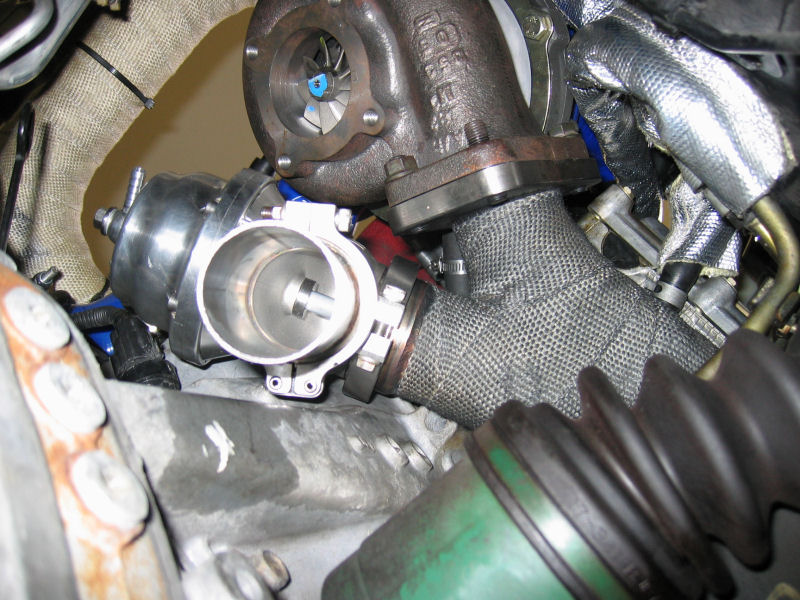

Variable Geometry Turbocharger

Variable-geometry turbochargers (VGTs), occasionally known as variable-nozzle turbochargers (VNTs), are a type of turbochargers, usually designed to allow the effective aspect ratio (A/R ratio) of the turbocharger to be altered as conditions change. This is done with the use of adjustable vanes located inside the turbine housing between the inlet and turbine, these vanes affect flow of gases towards the turbine. The benefit of the VGT is that the optimum aspect ratio at low engine speeds is very different from that at high engine speeds. If the aspect ratio is too large, the turbo will fail to create boost at low speeds; if the aspect ratio is too small, the turbo will choke the engine at high speeds, leading to high exhaust manifold pressures, high pumping losses, and ultimately lower power output. By altering the geometry of the turbine housing as the engine accelerates, the turbo's aspect ratio can be maintained at its optimum. Because of this, VGTs have a minimal amount of l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Acura RDX

Acura is the luxury vehicle, luxury and performance division of Japanese automaker Honda, based primarily in North America. The brand was launched on March 27, 1986, marketing luxury and performance automobiles. Acura sells cars in the United States, Canada, Mexico, Panama, and Kuwait. The company has also previously sold cars in Mainland China, Hong Kong, Russia, and Ukraine. Plans to introduce Acura to the Japanese domestic market in the late 2000s did not eventuate due to the 2008 financial crisis.2007 Mid-Year CEO Speech (Japanese) Establishing A Sales Channel from the Customer Viewpoint, 2. Accelerating our effort in Japan to strengthen the core characteristics that make Honda unique [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

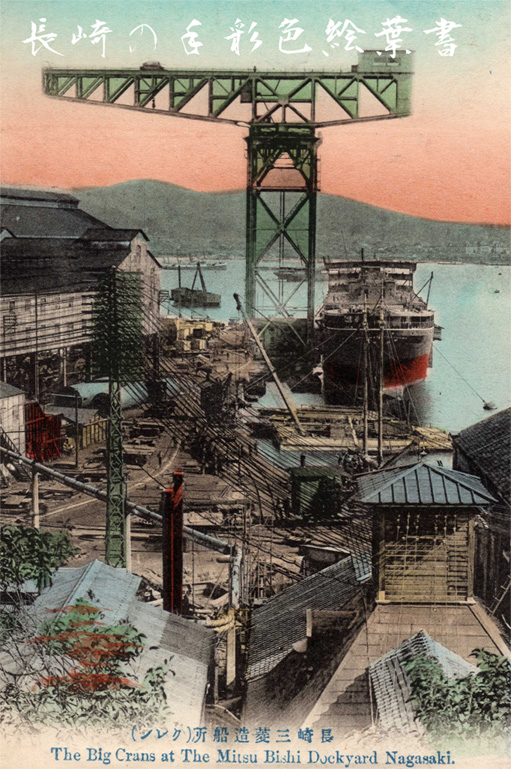

Mitsubishi Heavy Industries

is a Japanese Multinational corporation, multinational engineering, electrical equipment and electronics corporation headquartered in Tokyo, Japan. MHI is one of the core companies of the Mitsubishi Group and its automobile division is the predecessor of Mitsubishi Motors. MHI's products include aerospace and Automotive industry, automotive components, Air conditioning, air conditioners, elevators, Forklift, forklift trucks, Hydraulic machinery, hydraulic equipment, Printing, printing machines, missiles, tanks, Electric power system, power systems, ships, aircraft, Rail transport, railway systems, and space launch vehicles. Through its defense-related activities, it is the world's 23rd-largest defense contractor measured by 2011 defense revenues and the largest based in Japan. History In 1857, at the request of the Tokugawa Shogunate, a group of Dutch people, Dutch engineers were invited, including Dutch naval engineer Hendrik Hardes, and began work on the ''Nagasaki Yotetsu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

BorgWarner

BorgWarner Inc. is an American automotive and Electric vehicle, e-mobility supplier headquartered in Auburn Hills, Michigan. As of 2023, the company maintains production facilities and sites at 92 locations in 24 countries, and generates revenues of US$14.2 billion, while employing around 39,900 people. The company is one of the 25 List of the largest automotive suppliers, largest automotive suppliers in the world. History Early history Borg-Warner Corporation was formed out of several disparate manufacturers in the United States and abroad in 1928: Morse Equalizing Spring Company (industrial producer of Timing chain, automotive timing chains), Borg & Beck, Marvel-Schebler, Long Manufacturing (manufacturer of Radiator (engine cooling), automobile radiators), Warner Gear (producer of manual Transmission (mechanical device), transmissions) and Mechanics Universal Joint (producer of transmissions). Morse Equalizing Spring Company was the oldest forerunner, founded in 1880. 19 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Self-cleaning Oven

A self-cleaning or pyrolytic oven is an oven which uses high temperature (approximately ) to burn off leftovers from baking using pyrolysis, which uses no chemical agents. The oven can be powered by domestic (non-commercial) electricity or gas. Pyrolytic process Self-cleaning pyrolytic ovens reduce food soiling to ash with exposure to temperature around . The oven walls are coated with heat- and acid-resistant porcelain enamel. A self-cleaning oven is designed to stay locked until the high temperature process is completed. To prevent possible burn injuries, a mechanical interlock is used to keep the oven door locked and closed during and immediately after the high-temperature cleaning cycle, which lasts approximately three hours. Usually, the door can be opened after the temperature cools to approximately . Self-cleaning ovens usually have more insulation than standard ovens to reduce the possibility of fire. The insulation also reduces the amount of energy needed for normal co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel Particulate Filter

A diesel particulate filter (DPF) is a device designed to remove diesel exhaust#Particulates, diesel particulate matter or soot from the exhaust gas of a diesel engine.Tom Nash (May 2003) "Diesels: The Smoke is clearing", ''Motor '' Vol.199 No. 5, p. 54, Hearst Business Publishing Inc. Mode of action Wall-flow diesel particulate filters usually remove 85% or more of the soot, and under certain conditions can attain soot removal efficiencies approaching 100%. Some filters are single-use, intended for disposal and replacement once full of accumulated ash. Others are designed to burn off the accumulated particulate either passively through the use of a catalyst or by active means such as a fuel burner which heats the filter to soot combustion temperatures. This is accomplished by engine programming to run (when the filter is full) in a manner that elevates exhaust temperature, in conjunction with an extra fuel injector in the exhaust stream that injects fuel to react with a catalys ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust Brake

An exhaust brake is a means of slowing a diesel engine by closing off the exhaust path from the engine, causing the exhaust gases to be compressed in the exhaust manifold, and in the cylinder. Since the exhaust is being compressed, and there is no fuel being applied, the engine slows down the vehicle: the crankshaft and hence the wheels work against the pistons to compress the exhaust. The amount of braking torque generated is usually directly proportional to the back pressure of the engine. Exhaust brakes are manufactured by many companies. The brakes vary in design, but essentially operate as described above. More advanced exhaust brakes have exhaust pressure modulation (EPM) that controls the back pressure which in turn improves the braking performance across a range of engine speeds. Description An exhaust brake is a valve which essentially creates a back-pressure in the exhaust system, which applies enough force onto the engine's pistons to slow the engine. In most cases ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Efficiency

Fuel efficiency (or fuel economy) is a form of thermal efficiency, meaning the ratio of effort to result of a process that converts chemical energy, chemical potential energy contained in a carrier (fuel) into kinetic energy or Mechanical work, work. Overall fuel efficiency may vary per device, which in turn may vary per application, and this spectrum of variance is often illustrated as a continuous energy profile. Non-transportation applications, such as Industrial sector, industry, benefit from increased fuel efficiency, especially fossil fuel power plants or industries dealing with combustion, such as ammonia production during the Haber process. In the context of transport, fuel economy is the energy efficiency in transportation, energy efficiency of a particular vehicle, given as a ratio of distance traveled per unit of Motor fuel, fuel consumed. It is dependent on several factors including engine efficiency, transmission (mechanics), transmission design, and tire design. In ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Backpressure

Back pressure (or backpressure) is the term for a resistance to the desired flow of fluid through pipes. Obstructions or tight bends create backpressure via friction loss and pressure drop. In distributed systems in particular event-driven architecture, back pressure is a technique to regulate flow of data, ensuring that components do not become overwhelmed. Explanation A common example of backpressure is that caused by the exhaust system (consisting of the exhaust manifold, catalytic converter, muffler and connecting pipes) of an automotive four-stroke engine, which has a negative effect on engine efficiency, resulting in a decrease of power output that must be compensated by increasing fuel consumption. In a piston-ported two-stroke engine, however, the situation is more complicated, due to the need to prevent unburned fuel/air mixture from passing right through the cylinders into the exhaust. During the exhaust phase of the cycle, backpressure is even more undesir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust Gas Recirculation

In internal combustion engines, exhaust gas recirculation (EGR) is a nitrogen oxide () emissions reduction technique used in petrol engine, petrol/gasoline, diesel engines and some hydrogen internal combustion engine vehicle, hydrogen engines. EGR works by recirculating a portion of an engine's exhaust gas back to the engine cylinder (engine), cylinders. The exhaust gas displaces atmospheric air and reduces in the combustion chamber. Reducing the amount of oxygen reduces the amount of fuel that can burn in the cylinder thereby reducing peak in-cylinder temperatures. The actual amount of recirculated exhaust gas varies with the engine operating parameters. In the combustion cylinder, is produced by high-temperature mixtures of atmospheric nitrogen and oxygen, and this usually occurs at cylinder peak pressure. In a spark-ignition engine, an ancillary benefit of recirculating exhaust gases via an external EGR valve is an increase in efficiency, as charge dilution allows a large ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Charge Cooling

An intercooler is a heat exchanger used to cool a gas after compression. Often found in turbocharged engines, intercoolers are also used in air compressors, air conditioners, refrigeration and gas turbines. Internal combustion engines Most commonly used with turbocharged engines, an intercooler is used to counteract the heat of compression and heat soak in the pressurised intake air. By reducing the temperature of the intake air, the air becomes denser (allowing more fuel to be injected, resulting in increased power) and less likely to suffer from pre-ignition or knocking. Additional cooling can be provided by externally spraying a fine mist onto the intercooler surface, or even into the intake air itself, to further reduce intake charge temperature through evaporative cooling. Intercoolers can vary dramatically in size, shape and design, depending on the performance and space requirements of the system. Many passenger cars use either front-mounted intercoolers located i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wastegate

A wastegate is a valve that controls the flow of exhaust gases to the turbine wheel in a turbocharged engine system.Robson, D. (2018). Aircraft General Knowledge. Aviation Theory Centre Pty Ltd. . Diversion of exhaust gases regulates the turbine speed, which in turn regulates the rotating speed of the compressor. The primary function of the wastegate is to regulate the maximum boost pressure in turbocharger systems, to protect the engine and the turbocharger. One advantage of installing a remote mount wastegate to a free-float (or non-wastegate) turbo includes an allowance for a smaller area over radius (A/R) turbine housing, resulting in less lag time before the turbo begins to spool and create boost. One of the earliest usage of a modern wastegate was in the Saab 99 Turbo 1978, presented in 1977. Wastegate types External An external wastegate is a separate self-contained mechanism typically used with turbochargers that do not have internal wastegates. An external wastegate ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |