|

Value Network Analysis

Value network analysis (VNA) is a methodology for understanding, using, visualizing, optimizing internal and external value networks and complex economic ecosystems.Biem, Alain, and Nathan Caswell. "A Value Network Model for Strategic Analysis." ''HICSS. 2008.'' The methods include visualizing sets of relationships from a dynamic whole systems perspective. Robust network analysis approaches are used for understanding value conversion of financial and non-financial assets, such as intellectual capital, into other forms of value. Allee, Verna. "Value Network Analysis and Value Conversion of Tangible and Intangible Assets." Journal of Intellectual Capital. Publisher: Emerald Insights, Year: 2008, Volume: 9, Issue: 1, Page: 5 - 24, Digital Object Identifier: The value conversion question is critical in both social exchange theory that considers the cost/benefit returns of informal exchanges and more classical views of exchange value where there is concern with conversion of value in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Value Network

There is no agreed upon definition of value network. A general definition that subsumes the other definitions is that a value network is a network of roles linked by interactions in which '' economic entities'' engage in both tangible and intangible exchanges to achieve economic or social good. This definition is similar to one given by Verna Allee. Definitions Different definitions provide different perspectives on the general concept of a value network. Christensen Clayton Christensen defines a value network as: "The collection of upstream suppliers, downstream channels to market, and ancillary providers that support a common business model within an industry. When would-be disruptors enter into existing value networks, they must adapt their Business models to conform to the value network and therefore fail at disruption because they become co-opted." Fjeldstad and Stabell: Value configurations Fjeldstad and Stabell define a value network as one of three ways b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Value Added

Value added is a term in economics for calculating the difference between market value of a product or service, and the sum value of its constituents. It is relatively expressed by the supply-demand curve for specific units of sale. Value added is distinguished from the accounting term added value which measures only the financial profits earned upon transformational processes for specific items of sale that are available on the market. In business, ''total value added'' is calculated by tabulating the ''unit value added'' (measured by summing unit profit — the difference between sale price and production cost, unit depreciation cost, and unit labor cost) per each unit sold. Thus, total value added is equivalent to revenue minus intermediate consumption. Value added is a higher portion of revenue for integrated companies (e.g. manufacturing companies) and a lower portion of revenue for less integrated companies (e.g. retail companies); total value added is very nearly ap ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Value Shop

A value shop is an organization designed to solve customer or client problems, rather than creating value by producing output from an input of raw materials. The principles of value shops were first conceptualized by Thompson in 1967, and properly defined by Charles B. Stabell and Øystein D. Fjeldstad of the Norwegian School of Management in 1998, who also created the name. Compared to Michael Porter's concept of the value chain, there is no sequential fixed set of activities or resources utilized to create value. Each problem is treated uniquely and activities and resources are allocated specifically to cater to the problem in question. According to the research of Stabell and Fjeldstad, the value configuration analysis (1998), five main generic activities are carried out in the organization: * Problem Finding and acquisition * Problem Solving * Choice of problem solution * Execution of solution * Control and evaluation Value is created in the shop by several mechanisms allow ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Value Network

There is no agreed upon definition of value network. A general definition that subsumes the other definitions is that a value network is a network of roles linked by interactions in which '' economic entities'' engage in both tangible and intangible exchanges to achieve economic or social good. This definition is similar to one given by Verna Allee. Definitions Different definitions provide different perspectives on the general concept of a value network. Christensen Clayton Christensen defines a value network as: "The collection of upstream suppliers, downstream channels to market, and ancillary providers that support a common business model within an industry. When would-be disruptors enter into existing value networks, they must adapt their Business models to conform to the value network and therefore fail at disruption because they become co-opted." Fjeldstad and Stabell: Value configurations Fjeldstad and Stabell define a value network as one of three ways b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

System Dynamics

System dynamics (SD) is an approach to understanding the nonlinear behaviour of complex systems over time using stocks, flows, internal feedback loops, table functions and time delays. Overview System dynamics is a methodology and mathematical modeling technique to frame, understand, and discuss complex issues and problems. Originally developed in the 1950s to help corporate managers improve their understanding of industrial processes, SD is currently being used throughout the public and private sector for policy analysis and design. Convenient graphical user interface (GUI) system dynamics software developed into user friendly versions by the 1990s and have been applied to diverse systems. SD models solve the problem of simultaneity (mutual causation) by updating all variables in small time increments with positive and negative feedbacks and time delays structuring the interactions and control. The best known SD model is probably the 1972 ''The Limits to Growth''. This model fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

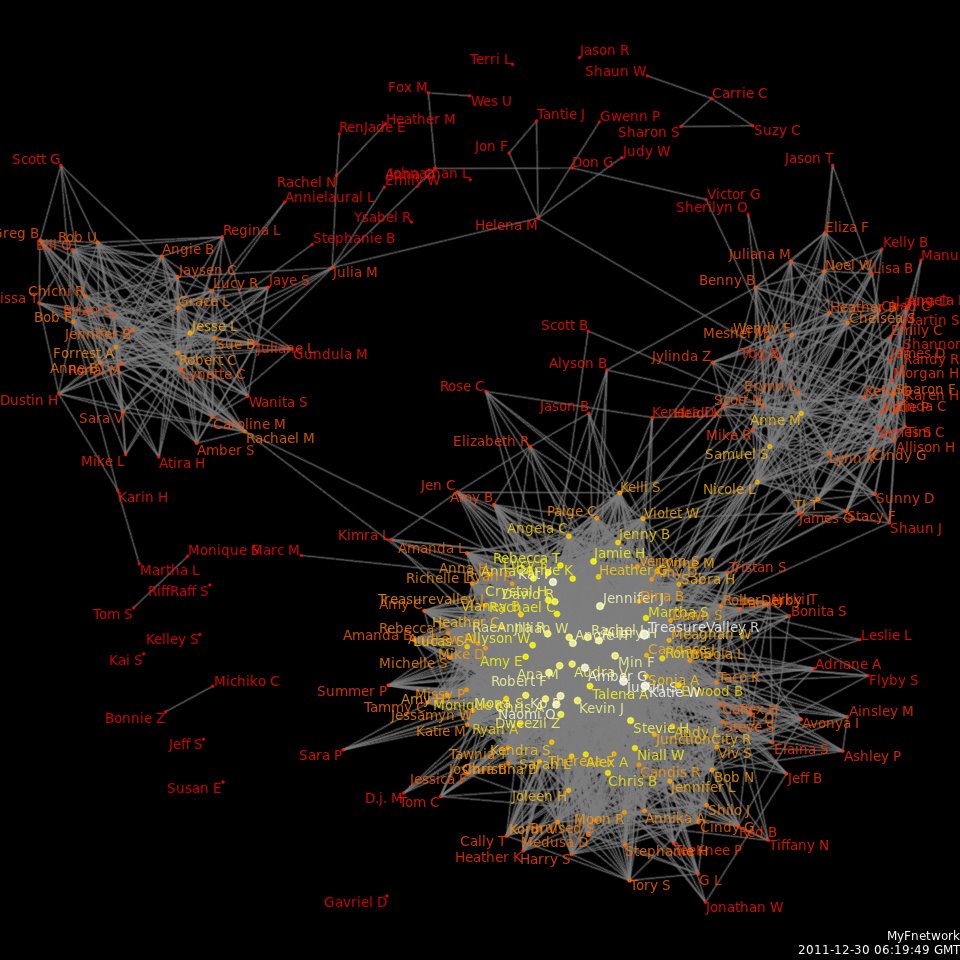

Social Network Analysis

Social network analysis (SNA) is the process of investigating social structures through the use of networks and graph theory. It characterizes networked structures in terms of ''nodes'' (individual actors, people, or things within the network) and the ''ties'', ''edges'', or ''links'' (relationships or interactions) that connect them. Examples of social structures commonly visualized through social network analysis include social media networks, meme proliferation, information circulation, friendship and acquaintance networks, business networks, knowledge networks, difficult working relationships, collaboration graphs, kinship, disease transmission, and sexual relationships. These networks are often visualized through '' sociograms'' in which nodes are represented as points and ties are represented as lines. These visualizations provide a means of qualitatively assessing networks by varying the visual representation of their nodes and edges to reflect attributes of inter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Business Process Management

Business process management (BPM) is the discipline in which people use various methods to Business process discovery, discover, Business process modeling, model, Business analysis, analyze, measure, improve, optimize, and Business process automation, automate business processes. Any combination of methods used to manage a company's business processes is BPM. Processes can be structured and repeatable or unstructured and variable. Though not required, enabling technologies are often used with BPM. As an approach, BPM sees processes as important assets of an organization that must be understood, managed, and developed to announce and deliver value-added products and services to clients or customers. This approach closely resembles other total quality management or continual improvement process methodologies. ISO 9000:2015 promotes the process approach to managing an organization. ...promotes the adoption of a process approach when developing, implementing and improving the effe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Business Process Reengineering

Business process re-engineering (BPR) is a business management strategy originally pioneered in the early 1990s, focusing on the analysis and design of workflows and business processes within an organization. BPR aims to help organizations fundamentally rethink how they do their work in order to improve customer service, cut operational costs, and become world-class competitors.Business Process Re-engineering Assessment Guide United States General Accounting Office, May 1997. BPR seeks to help companies radically restructure their organizations by focusing on the ground-up design of their business processes. According to early BPR proponent Thomas H. Davenport (1990), a business process is a set of log ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Workflow

Workflow is a generic term for orchestrated and repeatable patterns of activity, enabled by the systematic organization of resources into processes that transform materials, provide services, or process information. It can be depicted as a sequence of operations, the work of a person or group, the work of an organization of staff, or one or more simple or complex mechanisms. From a more abstract or higher-level perspective, workflow may be considered a view or representation of real work. The flow being described may refer to a document, service, or product that is being transferred from one step to another. Workflows may be viewed as one fundamental building block to be combined with other parts of an organization's structure such as information technology, teams, projects and hierarchies. Historical development The development of the concept of a workflow occurred above a series of loosely defined, overlapping eras. Beginnings in manufacturing The modern history of wor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Six Sigma

Six Sigma (6σ) is a set of techniques and tools for process improvement. It was introduced by American engineer Bill Smith while working at Motorola in 1986. Six Sigma strategies seek to improve manufacturing quality by identifying and removing the causes of defects and minimizing variability in manufacturing and business processes. This is done by using empirical and statistical quality management methods and by hiring people who serve as Six Sigma experts. Each Six Sigma project follows a defined methodology and has specific value targets, such as reducing pollution or increasing customer satisfaction. The term ''Six Sigma'' originates from statistical quality control, a reference to the fraction of a normal curve that lies within six standard deviations of the mean, used to represent a defect rate. History Motorola pioneered Six Sigma, setting a "six sigma" goal for its manufacturing business. It registered Six Sigma as a service mark on June 11, 1991 (); on December 28, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lean Manufacturing

Lean manufacturing is a methods of production, method of manufacturing goods aimed primarily at reducing times within the Operations management#Production systems, production system as well as response times from suppliers and customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to Supply and demand, demand by only supplying goods that have been ordered and focus on efficiency, productivity (with a commitment to continuous improvement), and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing Cycle time variation, cycle, flow, and Throughput (business), throughput times by further eliminating activities that do not add any Value (economics), value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Value Chain

A value chain is a progression of activities that a business or firm performs in order to deliver goods and services of Value (economics), value to an end customer. The concept comes from the field of business management and was first described by Michael Porter in his 1985 best-seller, ''Competitive Advantage: Creating and Sustaining Superior Performance''. According to the OECD Secretary-General , the emergence of global value chains (GVCs) in the late 1990s provided a catalyst for accelerated change in the landscape of international investment and trade, with major, far-reaching consequences on governments as well as enterprises . Role of the business unit According to Porter, the appropriate level for constructing a value chain is the business unit within a business,Michael E. Porter (1985) Competitive advantage: creating and sustaining superior performance. The Free Press not a division (business), business division or the company as a whole. Porter is concerned that analy ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |