|

Tellurium Copper

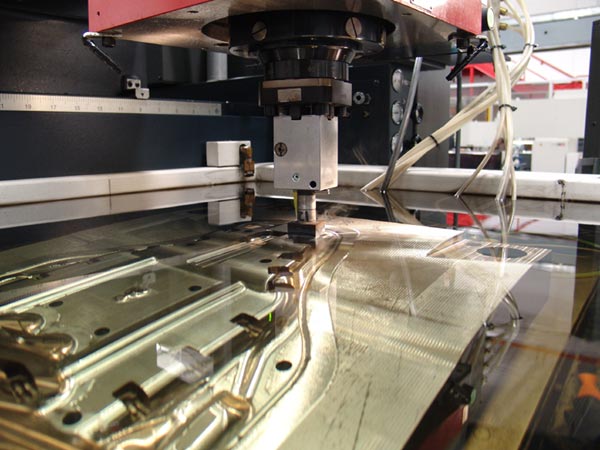

Tellurium copper is an alloy of copper and tellurium. Tellurium improves the machinability of copper. Overview Tellurium is usually added to copper to improve machinability ("free cutting"). ASTM specification B301 has 0.5% tellurium; at concentrations of up to 0.75% machinability is improved while electrical conductivity and hot working behavior is maintained. Mechanical properties are similar to ''tough pitch copper'', while machinability is similar to brass - the hardness of the alloy is increased by precipitation of the copper telluride: weissite. Tellurium copper is not suited to welding, but it can be welded with gas shielded arc welding or resistance welding. It can be readily soft soldered, silver soldered, or brazed. Tellurium copper can be used as the electrode in electrical discharge machining (EDM) - the alloy is used to replace copper when grinding wheel Grinding wheels are wheels that contain abrasive compounds for grinding and abrasive machining oper ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metal, metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have properties that differ from those of the pure elements from which they are made. The vast majority of metals used for commercial purposes are alloyed to improve their properties or behavior, such as increased strength, hardness or corrosion resistance. Metals may also be alloyed to reduce their overall cost, for instance alloys of gold and Copper(II) sulfate, copper. A typical example of an alloy is SAE 304 stainless steel, 304 grade stainless steel which is commonly used for kitchen utensils, pans, knives and forks. Sometime also known as 18/8, it as an alloy consisting broadly of 74% iron, 18% chromium and 8% nickel. The chromium and nickel alloying elements add strength and hardness to the majority iron element, but their main function is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Resistance Welding

Electric resistance welding (ERW) is a welding process in which metal parts in contact are permanently joined by heating them with an electric current, melting the metal at the joint. Electric resistance welding is widely used, for example, in manufacture of steel pipe and in assembly of bodies for automobiles. The electric current can be supplied to electrodes that also apply clamping pressure, or may be induced by an external magnetic field. The electric resistance welding process can be further classified by the geometry of the weld and the method of applying pressure to the joint: spot welding, seam welding, flash welding, projection welding, for example. Some factors influencing heat or welding temperatures are the proportions of the workpieces, the metal coating or the lack of coating, the electrode materials, electrode geometry, electrode pressing force, electric current and length of welding time. Small pools of molten metal are formed at the point of most electrical resista ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Telluride (chemistry)

The telluride ion is the anion Te2− and its derivatives. It is analogous to the other chalcogenide anions, the lighter O2−, S2−, and Se2−, and the heavier Po2−. In principle, Te2− is formed by the two-e− reduction of tellurium. The redox potential is −1.14 V. :Te(s) + 2 e− ↔ Te2− Although solutions of the telluride dianion have not been reported, soluble salts of bitelluride (TeH−) are known. Organic tellurides ''Tellurides'' also describe a class of organotellurium compounds formally derived from Te2−. An illustrative member is dimethyl telluride, which results from the methylation of telluride salts: :2 CH3I + Na2Te → (CH3)2Te + 2 NaI Dimethyl telluride is formed by the body when tellurium is ingested. Such compounds are often called telluroethers because they are structurally related to ethers with tellurium replacing oxygen, although the length of the C–Te bond is much longer than a C–O bond. C–Te–C angles tend to be c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding Wheel

Grinding wheels are wheels that contain abrasive compounds for grinding and abrasive machining operations. Such wheels are also used in grinding machines. The wheels are generally made with composite material. This consists of coarse-particle aggregate pressed and bonded together by a cementing matrix (called the ''bond'' in grinding wheel terminology) to form a solid, circular shape. Various profiles and cross sections are available depending on the intended usage for the wheel. They may also be made from a solid steel or aluminium disc with particles bonded to the surface. Today most grinding wheels are artificial composites made with artificial aggregates, but the history of grinding wheels began with natural composite stones, such as those used for millstones. The manufacture of these wheels is a precise and tightly controlled process, due not only to the inherent safety risks of a spinning disc, but also the composition and uniformity required to prevent that disc fro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrical Discharge Machining

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subject to an electric voltage. One of the electrodes is called the tool-electrode, or simply the or , while the other is called the workpiece-electrode, or . The process depends upon the tool and work piece not making physical contact. Extremely hard materials like carbides, ceramics, titanium alloys and heat treated tool steels that are very difficult to machine using conventional machining can be precisely machined by EDM. When the voltage between the two electrodes is increased, the intensity of the electric field in the volume between the electrodes becomes greater, causing electrical breakdown, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrode

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit (e.g. a semiconductor, an electrolyte, a vacuum or a gas). In electrochemical cells, electrodes are essential parts that can consist of a variety of materials (chemicals) depending on the type of cell. An electrode may be called either a cathode or anode according to the direction of the electric current, unrelated to the potential difference between electrodes. Michael Faraday coined the term "" in 1833; the word recalls the Greek ἤλεκτρον (, "amber") and ὁδός (, "path, way"). The electrophore, invented by Johan Wilcke in 1762, was an early version of an electrode used to study static electricity. Anode and cathode in electrochemical cells Electrodes are an essential part of any battery. The first electrochemical battery was devised by Alessandro Volta and was aptly named the Voltaic cell. This battery consisted of a stack of copper and zinc electrodes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brazing

Brazing is a metal-joining process in which two or more metal items are joined by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal. Brazing differs from welding in that it does not involve melting the work pieces. Brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. During the brazing process, the filler metal flows into the gap between close-fitting parts by capillary action. The filler metal is brought slightly above its melting ( liquidus) temperature while protected by a suitable atmosphere, usually a flux. It then flows over the base metal (in a process known as wetting) and is then cooled to join the work pieces together. Brazing joins the same or different metals with considerable strength. Process Brazing has many advantages over other metal-joining techniques, such as welding. Since brazing does not melt the base metal of the joi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silver Soldering

Brazing is a metal-joining process in which two or more metal items are joined by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal. Brazing differs from welding in that it does not involve melting the work pieces. Brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. During the brazing process, the filler metal flows into the gap between close-fitting parts by capillary action. The filler metal is brought slightly above its melting (liquidus) temperature while protected by a suitable atmosphere, usually a flux. It then flows over the base metal (in a process known as wetting) and is then cooled to join the work pieces together. Brazing joins the same or different metals with considerable strength. Process Brazing has many advantages over other metal-joining techniques, such as welding. Since brazing does not melt the base metal of the joint, i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Soft Solder

Solder (; NA: ) is a fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable for use as solder should have a lower melting point than the pieces to be joined. The solder should also be resistant to oxidative and corrosive effects that would degrade the joint over time. Solder used in making electrical connections also needs to have favorable electrical characteristics. Soft solder typically has a melting point range of , and is commonly used in electronics, plumbing, and sheet metal work. Alloys that melt between are the most commonly used. Soldering performed using alloys with a melting point above is called "hard soldering", "silver soldering", or brazing. In specific proportions, some alloys are eutectic — that is, the alloy's melting point is the lowest possible for a mixture of those components, and coi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melting, melt the parts together and allow them to cool, causing Fusion welding, fusion. Common alternative methods include solvent welding (of thermoplastics) using chemicals to melt materials being bonded without heat, and #Solid-state welding, solid-state welding processes which bond without melting, such as pressure, cold welding, and diffusion bonding. Metal welding is distinct from lower temperature bonding techniques such as brazing and soldering, which do not melt the base metal (parent metal) and instead require flowing a filler metal to solidify their bonds. In addition to melting the base metal in welding, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that can be stronger than the base material. Welding also requires a form of shield to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orange color. Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling silver used in jewelry, cupronickel used to make marine hardware and coins, and constantan used in strain gauges and thermocouples for temperature measurement. Copper is one of the few metals that can occur in nature in a directly usable, unalloyed metallic form. This means that copper is a native metal. This led to very early human use in several regions, from . Thousands of years later, it was the first metal to be smelted from sulfide ores, ; the first metal to be cast into a shape in a mold, ; and the first metal to be purposely alloyed with another metal, tin, to create bronze, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |