|

Strut Bar

A strut bar, strut brace, or strut tower brace (STB) is an automotive suspension accessory on a monocoque or unibody chassis to provide extra stiffness between the strut towers. With a MacPherson strut suspension system where the spring and shock absorber A shock absorber or damper is a mechanical or hydraulics, hydraulic device designed to absorb and Damping ratio, damp shock (mechanics), shock impulses. It does this by converting the kinetic energy of the shock into another form of energy (typic ... combine in one suspension unit, which also replaces the upper control arm, the entire vertical suspension load is transmitted to the top of the vehicle's strut tower. This is different from a double wishbone suspension where the spring and shock absorber may share the load separately. In general terms, a strut tower in a monocoque chassis is a reinforced portion of the inner wheel well and is not necessarily directly connected to the main chassis rails. For this reason, there ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strut Bar Ng Sentra

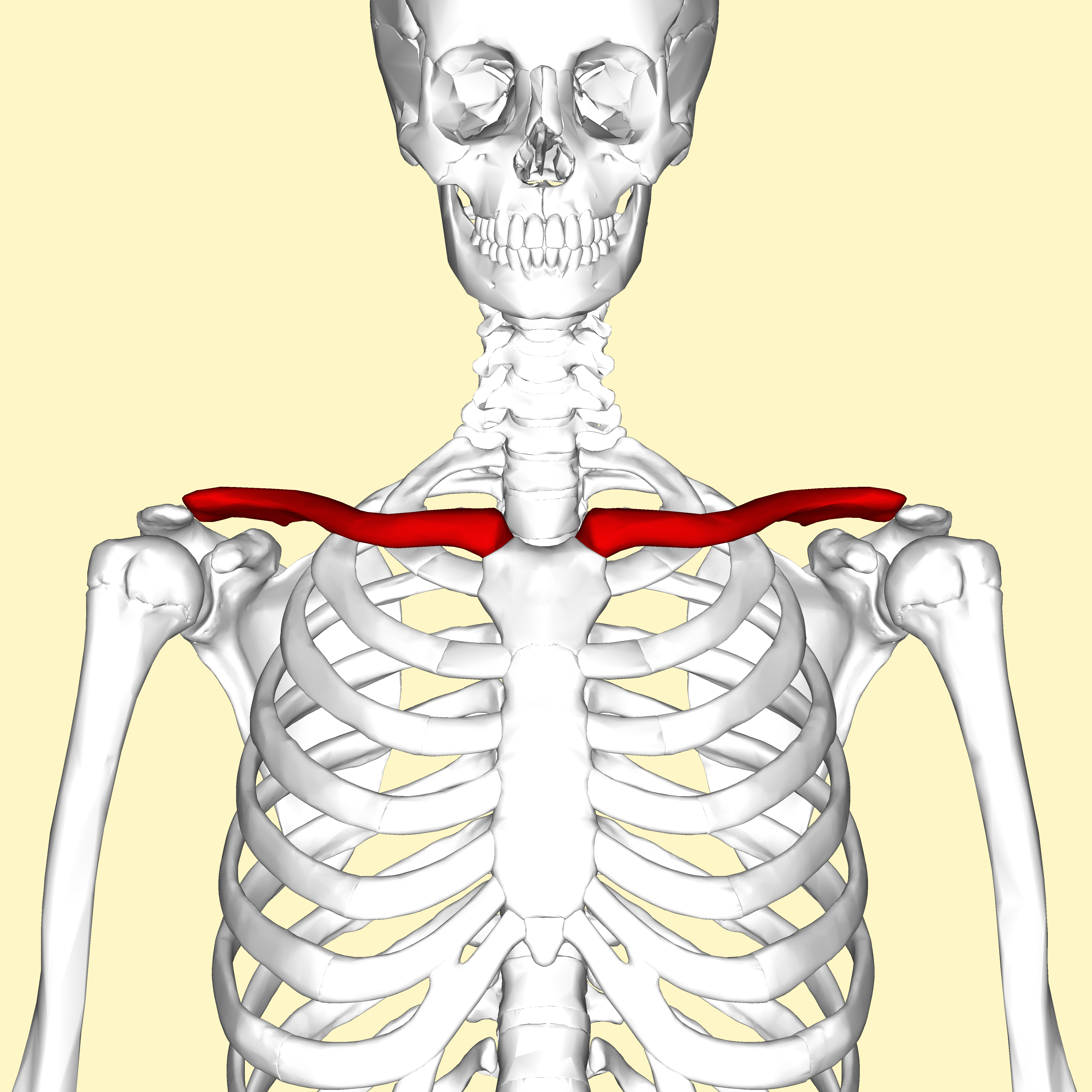

A strut is a structural component commonly found in engineering, aeronautics, architecture and anatomy. Struts generally work by resisting longitudinal compression, but they may also serve in tension. A stay is sometimes used as a synonym for strut, but some sources distinguish that struts are braces for holding compressive forces apart, while stays are braces for keeping stretching forces together. Human anatomy Part of the functionality of the clavicle is to serve as a strut between the scapula and sternum, resisting forces that would otherwise bring the upper limb close to the thorax. Keeping the upper limb away from the thorax is vital for its range of motion. Complete lack of clavicles may be seen in cleidocranial dysostosis, and the abnormal proximity of the shoulders to the median plane in cases of this genetic condition exemplifies the clavicle's importance as a strut. Architecture and construction Strut is a common name in timber framing for a support or brace of sca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Suspension (vehicle)

Suspension is the system of tires, tire air, spring (device), springs, shock absorbers and Linkage (mechanical), linkages that connects a vehicle to its wheels and allows relative motion between the two. Suspension systems must support both road holding/Automobile handling, handling and ride quality, which are at odds with each other. The tuning of suspensions involves finding the right compromise. The suspension is crucial for maintaining consistent contact between the road wheel and the road surface, as all forces exerted on the vehicle by the road or ground are transmitted through the tires' contact patches. The suspension also protects the vehicle itself and any cargo or luggage from damage and wear. The design of front and rear suspension of a car may be different. History An early form of suspension on ox-drawn carts had the platform swing on iron chains attached to the wheeled frame of the carriage. This system remained the basis for most suspension systems unti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Monocoque

Monocoque ( ), also called structural skin, is a structural system in which loads are supported by an object's external skin, in a manner similar to an egg shell. The word ''monocoque'' is a French term for "single shell". First used for boats, a true monocoque carries both tensile and compressive forces within the skin and can be recognised by the absence of a load-carrying internal frame. Few metal aircraft other than those with milled skins can strictly be regarded as pure monocoques, as they use a metal shell or sheeting reinforced with frames riveted to the skin, but most wooden aircraft are described as monocoques, even though they also incorporate frames. By contrast, a semi-monocoque is a hybrid combining a tensile stressed skin and a compressive structure made up of longerons and ribs or frames. Other semi-monocoques, not to be confused with true monocoques, include vehicle unibodies, which tend to be composites, and inflatable shells or balloon tanks, both of whi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vehicle Frame

A vehicle frame, also historically known as its ''chassis'', is the main supporting structure of a motor vehicle to which all other components are attached, comparable to the skeleton of an organism. Until the 1930s, virtually every car had a structural frame separate from its body, known as ''body-on-frame'' construction. Both mass production of completed vehicles by a manufacturer using this method, epitomized by the Ford Model T, and supply of rolling chassis to coachbuilders for both mass production (as by Fisher Body in the United States) and to smaller firms (such as Hooper (coachbuilder), Hooper) for bespoke bodies and interiors was practiced. By the 1960s, unibody construction in passenger cars had become common, and the trend towards building unibody passenger cars continued over the ensuing decades. Nearly all trucks, buses, and most Pickup truck, pickups continue to use a separate frame as their chassis. Functions The main functions of a frame in a motor vehicle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chassis

A chassis (, ; plural ''chassis'' from French châssis ) is the load-bearing framework of a manufactured object, which structurally supports the object in its construction and function. An example of a chassis is a vehicle frame, the underpart of a motor vehicle, on which the body is mounted; if the running gear such as wheels and transmission, and sometimes even the driver's seat, are included, then the assembly is described as a rolling chassis. Examples Vehicles In the case of vehicles, the term ''rolling chassis'' means the frame plus the "running gear" like engine, transmission, drive shaft, differential, and suspension. The "rolling chassis" description originated from assembly production when an integrated chassis "rolled on its own tires" just before truck bodies were bolted to the frames near the end of the line. An underbody (sometimes referred to as " coachwork"), which is usually not necessary for the integrity of the structure, is built on the chassis to c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

MacPherson Strut

The MacPherson strut is a type of automotive suspension system that uses the top of a telescopic damper as the upper steering pivot. It is widely used in the front suspension of modern vehicles. The name comes from American automotive engineer Earle S. MacPherson, who invented and developed the design. History Earle S. MacPherson was appointed the chief engineer of Chevrolet's Light Car project in 1945. He was tasked with developing a new, smaller car for the immediate post-war market, an effort that led to the Chevrolet Cadet. The Cadet was poised to be a groundbreaking vehicle, and the three prototypes that had been built by 1946 displayed a wide range of innovations. One of these was a revolutionary new independent suspension system that featured what is now known as a MacPherson strut. The Cadet was slated to be the first production vehicle with MacPherson struts, but the project was cancelled in 1947 and never saw commercial production. This was in large part due to GM's ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spring (device)

A spring is a device consisting of an Elasticity (physics), elastic but largely rigid material (typically metal) bent or molded into a form (especially a coil) that can return into shape after being compressed or extended. Springs can Energy storage, store energy when compressed. In everyday use, the term most often refers to coil springs, but there are many different spring designs. Modern springs are typically manufactured from spring steel. An example of a non-metallic spring is the Bow (weapon), bow, made traditionally of flexible Taxus baccata, yew wood, which when Bow draw, drawn stores energy to propel an arrow. When a conventional spring, without stiffness variability features, is compressed or stretched from its resting position, it exerts an opposing force approximately proportional to its change in length (this approximation breaks down for larger deflections). The ''rate'' or ''spring constant'' of a spring is the change in the force it exerts, divided by the cha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shock Absorber

A shock absorber or damper is a mechanical or hydraulics, hydraulic device designed to absorb and Damping ratio, damp shock (mechanics), shock impulses. It does this by converting the kinetic energy of the shock into another form of energy (typically thermal energy, heat) which is then dissipated. Most shock absorbers are a form of dashpot (a damper which resists motion via viscous friction). Description Pneumatic and hydraulic shock absorbers are used in conjunction with cushions and springs. An automobile shock absorber contains spring-loaded check valves and orifices to control the flow of oil through an internal piston (see below). One design consideration, when designing or choosing a shock absorber, is where that energy will go. In most shock absorbers, energy is converted to heat inside the viscous fluid. In hydraulic cylinders, the hydraulic fluid heats up, while in Pneumatic cylinder, air cylinders, the hot air is usually exhausted to the atmosphere. In other types of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Double Wishbone Suspension

A double wishbone suspension is an independent suspension design for automobiles using two (occasionally parallel) wishbone-shaped arms to locate the wheel. Each wishbone or arm has two mounting points to the chassis and one joint at the knuckle. The shock absorber and coil spring mount to the wishbones to control vertical movement. Double wishbone designs allow the engineer to carefully control the motion of the wheel throughout suspension travel, controlling such parameters as camber angle, caster angle, toe pattern, roll center height, scrub radius, scuff ( mechanical abrasion), and more. Implementation The double-wishbone suspension can also be referred to as "double A-arms", though the arms themselves can be A-shaped or L-shaped. A single wishbone or A-arm can also be used in various other suspension types, such as variations of the MacPherson strut. The upper arm is usually shorter to induce negative camber as the suspension jounces (rises), and often this arrangement ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Body Roll

Body roll is the axial rotation of a vehicle’s body towards the outside of a turn. Body roll occurs because the compliance in vehicle suspension allows the vehicle body, which sits upon the suspension, to lean in the direction of the perceived centrifugal force acting upon the vehicle. Cause Vehicle suspension allows a vehicle’s wheels to move independently of its body. This smooths the ride for occupants and cargo while allowing the wheels to stay in contact with the ground over bumps. In a corner, the range of motion in the suspension allows the vehicle body to lean over toward the outside of the turn as the body tries to continue in a line tangential to the corner. Softer suspension with more travel will allow more body roll than harder suspension with less travel. Adverse effects Body roll allows a vehicle’s centre of mass to move towards the outside of the turn, increasing the load transfer to the outside wheels. This can cause understeer or oversteer to occur more e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Saab Sonett

The Saab Sonett is an automobile manufactured by Swedish automaker Saab between 1955 and 1957 and again between 1966 and 1974. The Sonett share its engines and other mechanical components with the Saab 93, 95 and 96 of the same era. It was mainly intended for the lucrative American export market and was only offered intermittently in the Swedish domestic market for the 1968 and 1972 model years. The first prototype, now known as the Sonett I, is a two-seat, open-top, lightweight roadster racer. Ten years later, the name was revived for the commercially distributed Sonett models II, V4, and III. __TOC__ Sonett I In the 1950s, Rolf Mellde—a Saab engine developer and race enthusiast—along with Lars Olov Olsson, Olle Lindkvist, and Gotta Svensson, designed a two-seat roadster prototype in a barn in Åsaka, near Trollhättan (the site of the main Saab manufacturing facility). The limited research-and-development project, with a total budget of only , first came to be kn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |