|

Solder Sucker

In electronics, desoldering is the removal of solder and components from a circuit board for troubleshooting, repair, replacement, and salvage. Tools Desoldering tools and materials include the following: *Solder wick *Heat guns, also called hot air guns *Desoldering pump *Removal alloys *Removal fluxes *Heated soldering tweezers *Various picks and tweezers for tasks such as pulling at, holding, removing, and scraping components. *Vacuum and pressure pumps with specialized heater tips and nozzles *Rework stations, used to repair printed circuit board assemblies that fail factory test. Terminology is not totally standardised. Anything with a base unit with provision to maintain a stable temperature, pump air in either direction, etc., is often called a "station" (preceded by rework, soldering, desoldering, hot air); one, or sometimes more, tools may be connected to a station, e.g., a rework station may accommodate a soldering iron and hot air head. A soldering iron with a hollow ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vacuum Plunge

A vacuum (: vacuums or vacua) is space devoid of matter. The word is derived from the Latin adjective (neuter ) meaning "vacant" or "void". An approximation to such vacuum is a region with a gaseous pressure much less than atmospheric pressure. Physicists often discuss ideal test results that would occur in a ''perfect'' vacuum, which they sometimes simply call "vacuum" or free space, and use the term partial vacuum to refer to an actual imperfect vacuum as one might have in a laboratory or in outer space, space. In engineering and applied physics on the other hand, vacuum refers to any space in which the pressure is considerably lower than atmospheric pressure. The Latin term ''in vacuo'' is used to describe an object that is surrounded by a vacuum. The ''quality'' of a partial vacuum refers to how closely it approaches a perfect vacuum. Other things equal, lower gas pressure means higher-quality vacuum. For example, a typical vacuum cleaner produces enough suction to reduce ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder (engine), cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering Porting (engine)#Two-stroke porting, ports in the cylinder. __TOC__ Piston engines Internal combustion engines An internal combustion piston engine, internal combustion engine is acted upon by the pressure of the expanding combustion gases in the combustion chamber space at the top of the cylinder. This force then acts dow ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Via (electronics)

A via (Latin, 'path' or 'way') is an electrical connection between two or more metal layers of a printed circuit boards (PCB) or integrated circuit. Essentially a via is a small drilled hole that goes through two or more adjacent layers; the hole is plated with metal (often copper) that forms an electrical connection through the insulating layers. Vias are an important concern in PCB manufacturing. As vertical structures crossing multiple layers, they are specified differently from most of the design, which increases the chance for errors. They place the strictest demands on registration (how closely aligned different layers are). They are manufactured with different tooling from other features -- tooling that typically has looser tolerances. If either the hole or any layer is slightly out of place, the wrong electrical connections may be made; this may not be visible from the surface. After the hole is drilled, it must also be lined with conductive material, as opposed to simpl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Through-hole Technology

In electronics, through-hole technology (also spelled "thru-hole") is a manufacturing scheme in which leads on the components are inserted through holes drilled in printed circuit boards (PCB) and soldered to pads on the opposite side, either by manual assembly (hand placement) or by the use of automated insertion mount machines. History Through-hole technology almost completely replaced earlier electronics assembly techniques such as point-to-point construction. From the second generation of computers in the 1950s until surface-mount technology (SMT) became popular in the mid 1980s, every component on a typical PCB was a through-hole component. PCBs initially had tracks printed on one side only, later both sides, then multi-layer boards were in use. Through holes became plated-through holes (PTH) in order for the components to make contact with the required conductive layers. Plated-through holes are no longer required with SMT boards for making the component connectio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dual-Inline Package

In microelectronics, a dual in-line package (DIP or DIL) is an electronic component package with a rectangular housing and two parallel rows of electrical connecting pins. The package may be through-hole mounted to a printed circuit board (PCB) or inserted in a socket. The dual-inline format was invented by Don Forbes, Rex Rice and Bryant Rogers at Fairchild R&D in 1964, when the restricted number of leads available on circular transistor-style packages became a limitation in the use of integrated circuits. Increasingly complex circuits required more signal and power supply leads (as observed in Rent's rule); eventually microprocessors and similar complex devices required more leads than could be put on a DIP package, leading to development of higher-density chip carriers. Furthermore, square and rectangular packages made it easier to route printed-circuit traces beneath the packages. A DIP is usually referred to as a DIP''n'', where ''n'' is the total number of pins, and some ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Printed Circuit

A printed circuit board (PCB), also called printed wiring board (PWB), is a laminated sandwich structure of conductive and insulating layers, each with a pattern of traces, planes and other features (similar to wires on a flat surface) etched from one or more sheet layers of copper laminated onto or between sheet layers of a non-conductive substrate. PCBs are used to connect or "wire" components to one another in an electronic circuit. Electrical components may be fixed to conductive pads on the outer layers, generally by soldering, which both electrically connects and mechanically fastens the components to the board. Another manufacturing process adds vias, metal-lined drilled holes that enable electrical interconnections between conductive layers, to boards with more than a single side. Printed circuit boards are used in nearly all electronic products today. Alternatives to PCBs include wire wrap and point-to-point construction, both once popular but now rarely ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Capillary Action

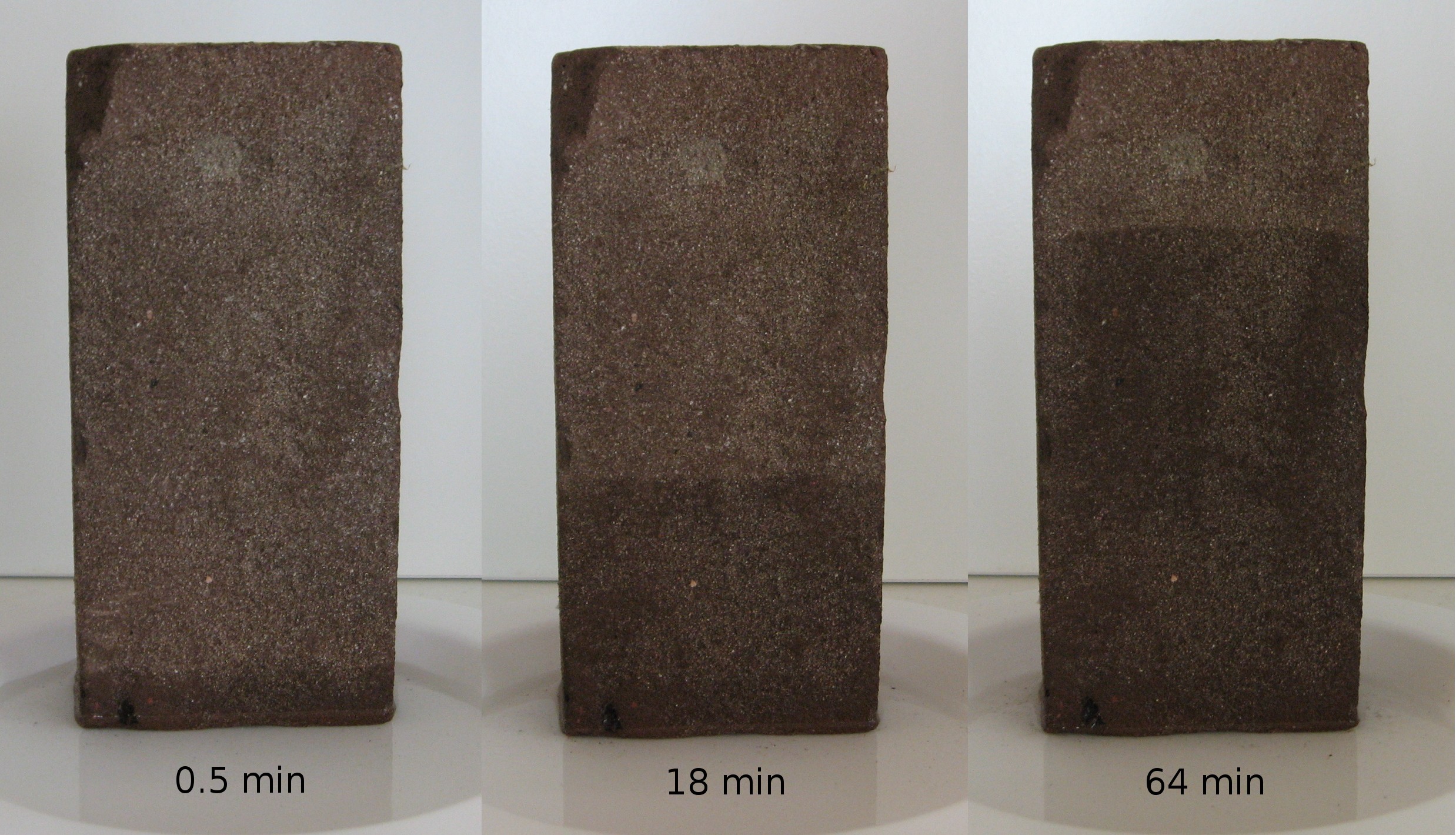

Capillary action (sometimes called capillarity, capillary motion, capillary rise, capillary effect, or wicking) is the process of a liquid flowing in a narrow space without the assistance of external forces like Gravitation, gravity. The effect can be seen in the drawing up of liquids between the hairs of a paint-brush, in a thin tube such as a Drinking straw, straw, in porous materials such as paper and plaster, in some non-porous materials such as clay and liquefied carbon fiber, or in a biological cell. It occurs because of intermolecular forces between the liquid and surrounding solid surfaces. If the diameter of the tube is sufficiently small, then the combination of surface tension (which is caused by Cohesion (chemistry), cohesion within the liquid) and Adhesion, adhesive forces between the liquid and container wall act to propel the liquid. Etymology Capillary comes from the Latin word capillaris, meaning "of or resembling hair". The meaning stems from the tiny, hairl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Soldering Iron

A soldering iron is a hand tool used in soldering. It supplies heat to melt solder so that it can flow into the joint between two workpieces. A soldering iron is composed of a heated metal tip (the ''bit'') and an insulated handle. Heating is often achieved electrically, by passing an electric current (supplied through an electrical cord or battery cables) through a resistive heating element. Cordless irons can be heated by combustion of gas stored in a small tank, often using a catalytic heater rather than a flame. Simple irons, less commonly used today than in the past, were simply a large copper ''bit'' on a handle, heated in a flame. Solder melts at approximately . Soldering irons are designed to reach a temperature range of . Soldering irons are most often used for installation, repairs, and limited production work in electronics assembly. High-volume production lines use other soldering methods.Bralla, James G. ''Handbook of Manufacturing Processes - How Products, Compon ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solder Wick-close Up-solder Impurities PNr°0112

Solder (; NA: ) is a fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable for use as solder should have a lower melting point than the pieces to be joined. The solder should also be resistant to oxidative and corrosive effects that would degrade the joint over time. Solder used in making electrical connections also needs to have favorable electrical characteristics. Soft solder typically has a melting point range of , and is commonly used in electronics, plumbing, and sheet metal work. Alloys that melt between are the most commonly used. Soldering performed using alloys with a melting point above is called "hard soldering", "silver soldering", or brazing. In specific proportions, some alloys are eutectic — that is, the alloy's melting point is the lowest possible for a mixture of those components, and coi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solder Flux

In metallurgy, a flux is a chemical reducing agent, flowing agent, or purifying agent. Fluxes may have more than one function at a time. They are used in both extractive metallurgy and metal joining. Some of the earliest known fluxes were sodium carbonate, potash, charcoal, coke, borax, lime, lead sulfide and certain minerals containing phosphorus. Iron ore was also used as a flux in the smelting of copper. These agents served various functions, the simplest being a reducing agent, which prevented oxides from forming on the surface of the molten metal, while others absorbed impurities into slag, which could be scraped off molten metal. Fluxes are also used in foundries for removing impurities from molten nonferrous metals such as aluminium, or for adding desirable trace elements such as titanium. As reducing agents, fluxes facilitate soldering, brazing, and welding by removing oxidation from the metals to be joined. In some applications molten flux also serves as a heat-t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rosin

Rosin (), also known as colophony or Greek pitch (), is a resinous material obtained from pine trees and other plants, mostly conifers. The primary components of rosin are diterpenoids, i.e., C20 carboxylic acids. Rosin consists mainly of resin acids, especially abietic acid. Rosin often appears as a semi-transparent, brittle substance that ranges in color from yellow to black and melts at stove-top temperatures. In addition to industrial applications such as in varnishes, adhesives, and sealing wax, rosin is used with string instruments on the bow hair to enhance its ability to grip and sound the strings, and it provides grip in various sports and activities. Rosin also serves as an ingredient in medicinal and pharmaceutical formulations and can cause contact dermatitis or occupational asthma in sensitive individuals. It is an FDA approved food additive. The name "colophony" originates from , Latin for "resin from Colophon" (), an ancient Ionic city. Properties R ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |