|

Slag (welding)

Welding slag is a form of slag, or glass, vitreous material produced as a byproduct of some arc welding processes, most specifically shielded metal arc welding (also known as stick welding), submerged arc welding, and flux-cored arc welding. Slag is formed when flux (metallurgy), flux, the solid shielding material used in the welding process, melts in or on top of the weld zone (also known as Dross). Slag is the solidified remaining flux after the weld area cools.Modern Welding Technology (6th Edition), Howard B. Cary& Scott Helzer, 2004, __TOC__ Flux Welding flux is a combination of carbonate and silicate materials used in welding processes to shield the weld from atmospheric gases. When the heat of the weld zone reaches the flux, the flux melts and outgasses. The gases produced push the atmospheric gas back, preventing oxidation (and reactions with nitrogen). The melted flux covers the molten metal in the weld zone. Flux materials are chosen so that the density of the melted ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Submerged Arc Welding Schematic

Submerge (and its variants) means to be covered by something (usually a liquid), such as being underwater: * Submerged arc welding * Submerged continent * Submerged forest * Submerged floating tunnel * Submerged specific gravity * Submergent coastline * Submergent plant * Submersible * Submersible bridge * Submersible drilling rig * Submersible mixer * Submersisphaeria, submerged fungi genus * Ceratophyllum submersum, submerged, free-floating, aquatic plant * the action of a submarine of diving below the surface of water Submerge, Submerged, or Submersed may also refer to: * ''Submerge'', 1998 album by the Japanese alternative rock band Coaltar of the Deepers * Submerge (nightclub), Indian nightclub * ''Submerged'' (2000 film), a 2000 film * ''Submerged'' (2005 film), a 2005 film * ''Submerged'' (2016 film), a 2016 film * ''Submerged'' (video game), a 2015 video game * ''Submerged'', a one-act play written in 1929 by Clay Shaw and Herman Stuart Cottman * ''Subme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wire Brush

A wire brush is a tool consisting of a brush whose bristles are made of wire, most often steel wire. The steel used is generally a medium- to high-carbon variety and very hard and springy. Other wire brushes feature bristles made from brass or stainless steel, depending on application. Wires in a wire brush can be held together by epoxy, staples, or other binding. Wire brushes usually either have a handle of wood or plastic (for handheld use) or are formed into a wheel for use on angle grinders, bench grinders, pistol-grip drill motors, or other power tools. Uses The wire brush is primarily an abrasive implement, used for cleaning rust and removing paint. It is also used to clean surfaces and to create a better conductive area for attaching electrical connections, such as those between car battery posts and their connectors, should they accumulate a build-up of grime and dirt. When cleaning stainless steel, it is advisable to use a stainless steel bristle wire brush ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Angle Grinder

An angle grinder, also known as a side grinder or disc grinder, is a handheld power tool used for grinding (abrasive cutting) and polishing. History The high-speed angle grinder was invented in 1954 by German company Ackermann + Schmitt ( FLEX-Elektrowerkzeuge GmbH) in Steinheim an der Murr. Naming In German, Dutch, Slovak, Czech, Polish, Croatian, Romanian, Hungarian, Bulgarian and Latvian, an angle grinder is colloquially called a "flex", and in Italy and in Spanish-speaking countries it is sometimes called "flexible". In Switzerland it is known as "Perles" from a popular brand of cutting tools. In Polish it is also known as "kątówka" or "gumówka" (= the rubber thing), which refers to the elasticity of certain types of disks. However they are never made out of true rubber due to fire hazard. In Russian, it is known as "болгарка" ("bolgarka") (literally "Bulgarian" of the feminine gender), since the first angle grinders in the USSR were Bulgarian made. Design ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hammer

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nail (fastener), nails into wood, to shape metal (as with a forge), or to crush Rock (geology), rock. Hammers are used for a wide range of driving, shaping, breaking and non-destructive striking applications. Traditional disciplines include carpentry, blacksmithing, war hammer, warfare, and mallet percussion, percussive musicianship (as with a gong). Hammering is use of a hammer in its strike capacity, as opposed to pry bar, prying with a secondary claw or grappling with a secondary hook. Carpentry and blacksmithing hammers are generally wielded from a stationary stance against a stationary target as gripped and propelled with one arm, in a lengthy downward plane (geometry), planar arc—downward to add kinetic energy to the impact—pivoting mainly around the shoulder and elbo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

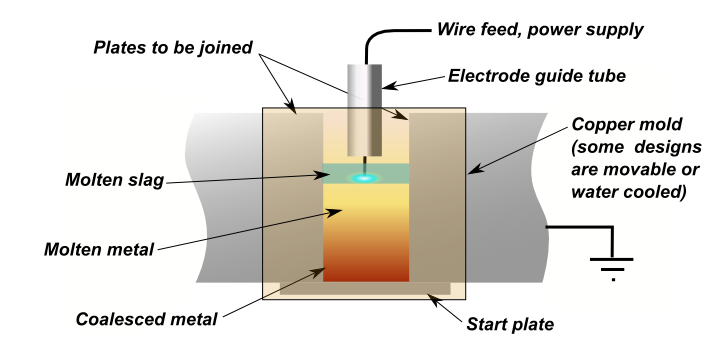

Electroslag

Electroslag welding (ESW) is a highly productive, single pass welding process for thick (greater than 25 mm up to about 300 mm) materials in a vertical or close to vertical position. (ESW) is similar to electrogas welding, but the main difference is the arc starts in a different location. An electric arc is initially struck by wire that is fed into the desired weld location and then flux is added. Additional flux is added until the molten slag, reaching the tip of the electrode, extinguishes the arc. The wire is then continuously fed through a consumable guide tube (can oscillate if desired) into the surfaces of the metal workpieces and the filler metal are then melted using the electrical resistance of the molten slag to cause coalescence. The wire and tube then move up along the workpiece while a copper retaining shoe that was put into place before starting (can be water-cooled if desired) is used to keep the weld between the plates that are being welded. Electroslag ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

X-ray

An X-ray (also known in many languages as Röntgen radiation) is a form of high-energy electromagnetic radiation with a wavelength shorter than those of ultraviolet rays and longer than those of gamma rays. Roughly, X-rays have a wavelength ranging from 10 Nanometre, nanometers to 10 Picometre, picometers, corresponding to frequency, frequencies in the range of 30 Hertz, petahertz to 30 Hertz, exahertz ( to ) and photon energies in the range of 100 electronvolt, eV to 100 keV, respectively. X-rays were discovered in 1895 in science, 1895 by the German scientist Wilhelm Röntgen, Wilhelm Conrad Röntgen, who named it ''X-radiation'' to signify an unknown type of radiation.Novelline, Robert (1997). ''Squire's Fundamentals of Radiology''. Harvard University Press. 5th edition. . X-rays can penetrate many solid substances such as construction materials and living tissue, so X-ray radiography is widely used in medical diagnostics (e.g., checking for Bo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding Defect

In metalworking, a welding defect is any flaw that compromises the usefulness of a wikt:weldment, weldment. There are many different types of welding defects, which are classified according to ISO 6520, while acceptable limits for welds are specified in ISO 5817 and ISO 10042. Major causes According to the American Society of Mechanical Engineers (ASME), the causes of welding defects can be classified as follows: 41% poor process conditions, 32% operator error, 12% using the wrong technique, 10% incorrect consumables, and 5% bad weld grooves. Hydrogen embrittlement Residual stresses The magnitude of residual stress caused by the heating, and subsequent cooling, from welding can be roughly calculated using: :E \alpha \Delta T Where E is Young's modulus, \alpha is the coefficient of thermal expansion, and \Delta T is the temperature change. This approximates for steel. Types Cracks Arc strikes An arc strike is a discontinuity resulting from an arc consisting of any local ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

FCAW Drawing

Flux-cored arc welding (FCAW or FCA) is a semi-automatic or automatic arc welding process. FCAW requires a continuously-fed consumable tubular electrode containing a flux (metallurgy), flux and a constant-voltage or, less commonly, a constant-Electric current, current welding power supply. An externally supplied shielding gas is sometimes used, but often the flux itself is relied upon to generate the necessary protection from the atmosphere, producing both gaseous protection and liquid slag (welding), slag protecting the weld. Types One type of FCAW requires no shielding gas. This is made possible by the flux core in the tubular consumable electrode. However, this core contains more than just flux. It also contains various ingredients that when exposed to the high temperatures of welding generate a shielding gas for protecting the arc. This type of FCAW is attractive because it is portable and generally has good penetration into the base metal. Also, windy conditions need not be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slag

The general term slag may be a by-product or co-product of smelting (pyrometallurgical) ores and recycled metals depending on the type of material being produced. Slag is mainly a mixture of metal oxides and silicon dioxide. Broadly, it can be classified as ferrous (co-products of processing iron and steel), ferroalloy (a by-product of ferroalloy production) or non-ferrous/ base metals (by-products of recovering non-ferrous materials like copper, nickel, zinc and phosphorus). Within these general categories, slags can be further categorized by their precursor and processing conditions (e.g., blast furnace slags, air-cooled blast furnace slag, granulated blast furnace slag, basic oxygen furnace slag, and electric arc furnace slag). Slag generated from the EAF process can contain toxic metals, which can be hazardous to human and environmental health. Due to the large demand for ferrous, ferralloy, and non-ferrous materials, slag production has increased throughout the years des ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SMAW Weld Area

SMAW may refer to: *Mk 153 Shoulder-Launched Multipurpose Assault Weapon, or SMAW for short *Shielded metal arc welding Shielded metal arc welding (SMAW), also known as manual metal arc welding (MMA or MMAW), flux shielded arc welding or informally as stick welding, is a manual arc welding process that uses a consumable electrode covered with a flux to lay the we ..., the arc welding process that uses electrodes with a coated covering called flux {{disambig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flux (metallurgy)

In metallurgy, a flux is a chemical reducing agent, flowing agent, or purifying agent. Fluxes may have more than one function at a time. They are used in both extractive metallurgy and metal joining. Some of the earliest known fluxes were sodium carbonate, potash, charcoal, coke, borax, lime, lead sulfide and certain minerals containing phosphorus. Iron ore was also used as a flux in the smelting of copper. These agents served various functions, the simplest being a reducing agent, which prevented oxides from forming on the surface of the molten metal, while others absorbed impurities into slag, which could be scraped off molten metal. Fluxes are also used in foundries for removing impurities from molten nonferrous metals such as aluminium, or for adding desirable trace elements such as titanium. As reducing agents, fluxes facilitate soldering, brazing, and welding by removing oxidation from the metals to be joined. In some applications molten flux also serves as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |