|

Shot Peening

Shot peening is a cold working process used to produce a compressive residual stress layer and modify the mechanical properties of metals and composites. It entails striking a surface with shot (round metallic, glass, or ceramic particles) with force sufficient to create plastic deformation."Shot Peening," ''Tool and Manufacturing Engineers Handbook'' (TMEH), Volume 3, Society of Manufacturing Engineers, 1985 In machining, shot peening is used to strengthen and relieve stress in components like steel automobile crankshafts and connecting rods. In architecture it provides a muted finish to metal. Shot peening is similar mechanically to sandblasting, though its purpose is not to remove material, but rather it employs the mechanism of plasticity to achieve its goal, with each particle functioning as a ball-peen hammer. Details Peening a surface spreads it plastically, causing changes in the mechanical properties of the surface. Its main application is to avoid the propagation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

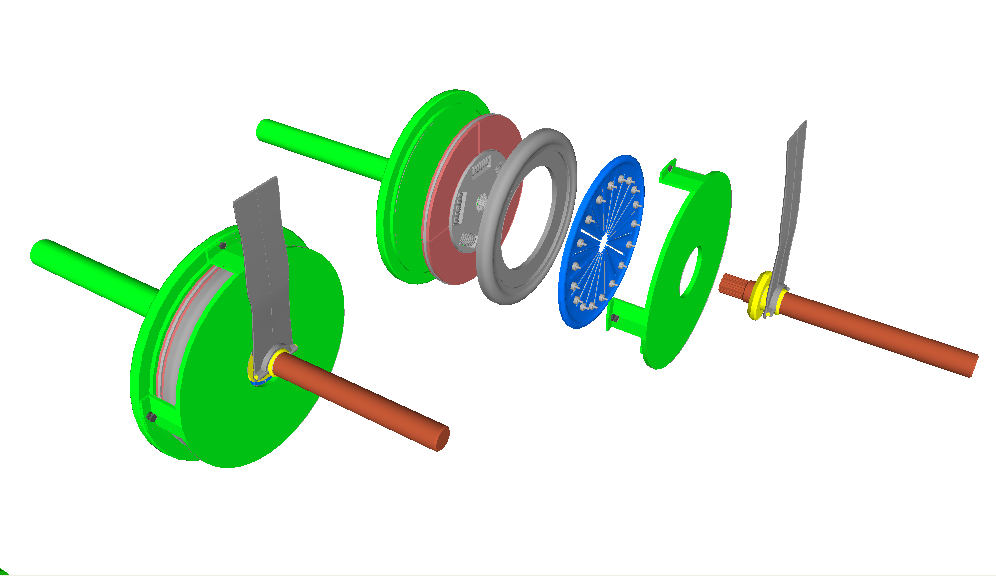

Almen Round

An Almen round is a thin round disk used to quantify the intensity of a shot peening process. Developed in 1994 by Rudolf Bosshard in Switzerland, it is a modification of the Almen strip method, which is used worldwide as a surface treatment testing method in the field of shot peening. The basic principle is the same, but due to the simple shape and minimized size, the Almen round is more suitable for automated processing and installation on dummy rigs. Also instead of the Almen block according SAE International, SAE J442, here a matching device is used and if connected to electronic processing unit, the Almen value according AMS-S-13165 (predecessor MIL-S-13165 Rev.C) can be evaluated in one run. Test specimen The Almen round is a circular cutting from an original Almen strip normally in material SAE 1070. It can be either of a "A", "C" or "N" type offered in various quality grades. The standard strip allows the splitting into four pieces rounds, which have a diameter of 18.7&nb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

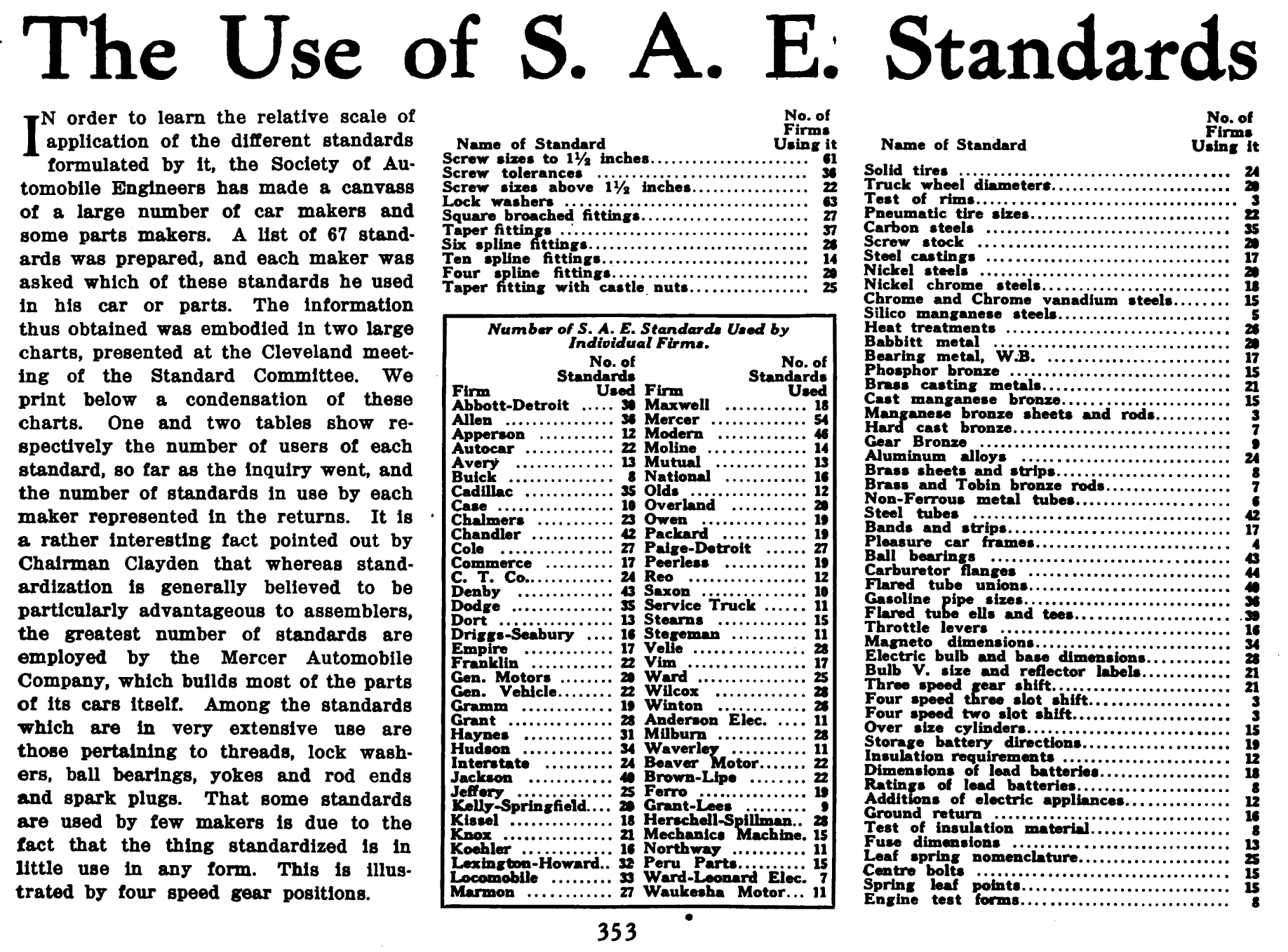

SAE International

SAE International is a global professional association and standards organization based in Warrendale, Pennsylvania, United States. Formerly the Society of Automotive Engineers, the organization adopted its current name in 2006 to reflect both its international membership and the increased scope of its activities beyond automotive engineering and the automotive industry to include aerospace and other transport industries, as well as commercial vehicles including autonomous vehicles such as self-driving cars, trucks, surface vessels, drones, and related technologies. SAE International has over 138,000 global members. Membership is granted to individuals, rather than companies. Aside from its standardization efforts, SAE International also devotes resources to projects and programs in STEM education, professional certification, and collegiate design competitions. History In the early 1900s there were dozens of automobile manufacturers in the United States, and many more w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mill Scale

Mill scale, often shortened to just scale, is the flaky surface of hot rolled steel, consisting of the mixed iron oxides iron(II) oxide (, wüstite), iron(III) oxide (, hematite), and iron(II,III) oxide (, magnetite). Mill scale is formed on the outer surfaces of plates, sheets or profiles when they are produced by passing red hot iron or steel billets through rolling mills. Mill scale is bluish-black in color. It is usually less than thick, and initially adheres to the steel surface and protects it from atmospheric corrosion provided no break occurs in this coating. Because it is electrochemically cathodic to steel, any break in the mill scale coating will cause accelerated corrosion of steel exposed at the break. Mill scale is thus a boon for a while, until its coating breaks due to handling of the steel product or due to any other mechanical cause. Mill scale becomes a nuisance when the steel is to be processed. Any paint applied over it is wasted, since it will come off ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbine

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced can be used for generating electrical power when combined with a generator.Munson, Bruce Roy, T. H. Okiishi, and Wade W. Huebsch. "Turbomachines." Fundamentals of Fluid Mechanics. 6th ed. Hoboken, NJ: J. Wiley & Sons, 2009. Print. A turbine is a turbomachine with at least one moving part called a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades so that they move and impart rotational energy to the rotor. Gas, steam, and water turbines have a casing around the blades that contains and controls the working fluid. Modern steam turbines frequently employ both reaction and impulse in the same unit, typically varying the degree of reaction and impulse from the blade root to its periphery. History Hero of Alexandria demonstrat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Suspension (vehicle)

Suspension is the system of tires, tire air, spring (device), springs, shock absorbers and Linkage (mechanical), linkages that connects a vehicle to its wheels and allows relative motion between the two. Suspension systems must support both road holding/Automobile handling, handling and ride quality, which are at odds with each other. The tuning of suspensions involves finding the right compromise. The suspension is crucial for maintaining consistent contact between the road wheel and the road surface, as all forces exerted on the vehicle by the road or ground are transmitted through the tires' contact patches. The suspension also protects the vehicle itself and any cargo or luggage from damage and wear. The design of front and rear suspension of a car may be different. History An early form of suspension on ox-drawn carts had the platform swing on iron chains attached to the wheeled frame of the carriage. This system remained the basis for most suspension systems unti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankshaft

A crankshaft is a mechanical component used in a reciprocating engine, piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating Shaft (mechanical engineering), shaft containing one or more crankpins, that are driven by the pistons via the connecting rods. The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting (metalworking), casting or machining process. Design The crankshaft is located within the engine block and held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration. A crankshaft is subjected to enormou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coil Spring

A tension coil spring A coil spring is a mechanical device that typically is used to store energy and subsequently release it, to absorb shock, or to maintain a force between contacting surfaces. It is made of an elastic material formed into the shape of a helix that returns to its natural length when unloaded. Under tension or compression, the material (wire) of a coil spring undergoes torsion. The spring characteristics therefore depend on the shear modulus. A coil spring may also be used as a torsion spring: in this case the spring as a whole is subjected to torsion about its helical axis. The material of the spring is thereby subjected to a bending moment, either reducing or increasing the helical radius. In this mode, it is the Young's modulus of the material that determines the spring characteristics. Spring rate A selection of conical coil springs Spring rate is the measurement of how much load (in pounds) a coil spring can hold until it compresses . The spring r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clutch

A clutch is a mechanical device that allows an output shaft to be disconnected from a rotating input shaft. The clutch's input shaft is typically attached to a motor, while the clutch's output shaft is connected to the mechanism that does the work. In a motor vehicle, the clutch acts as a mechanical linkage between the engine and transmission. By disengaging the clutch, the engine speed (RPM) is no longer determined by the speed of the driven wheels. Another example of clutch usage is in electric drills. The clutch's input shaft is driven by a motor and the output shaft is connected to the drill bit (via several intermediate components). The clutch allows the drill bit to either spin at the same speed as the motor (clutch engaged), spin at a lower speed than the motor (clutch slipping) or remain stationary while the motor is spinning (clutch disengaged). Types Dry clutch A ''dry clutch'' uses dry friction to transfer power from the input shaft to the output shaft, f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Camshaft

A camshaft is a shaft that contains a row of pointed cams in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems and early electric motor speed controllers. Camshafts in piston engines are usually made from steel or cast iron, and the shape of the cams greatly affects the engine's characteristics. History Trip hammers are one of the early uses of a form of cam to convert rotating motion, e.g. from a waterwheel, into the reciprocating motion of a hammer used in forging or to pound grain. Evidence for these exists back to the Han dynasty in China, and they were widespread by the medieval period. Camshafts were first described by Ismail al-Jazari in 1206. Once the rotative version of the steam engine was developed in the late 18th century, the operation of the valve gear was usually by an eccentric, which turned the rotation of the crankshaft i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gear

A gear or gearwheel is a rotating machine part typically used to transmit rotational motion and/or torque by means of a series of teeth that engage with compatible teeth of another gear or other part. The teeth can be integral saliences or cavities machined on the part, or separate pegs inserted into it. In the latter case, the gear is usually called a cogwheel. A cog may be one of those pegsDefinition of "cog" in the ''Oxford Learner's Dictionary'' online. Accessed on 2024-07-29.Definition of "cog" in the ''Merriam-Webster Dictionary'' online. Accessed on 2024-07-29. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chaos Theory

Chaos theory is an interdisciplinary area of Scientific method, scientific study and branch of mathematics. It focuses on underlying patterns and Deterministic system, deterministic Scientific law, laws of dynamical systems that are highly sensitive to initial conditions. These were once thought to have completely random states of disorder and irregularities. Chaos theory states that within the apparent randomness of chaotic complex systems, there are underlying patterns, interconnection, constant feedback loops, repetition, self-similarity, fractals and self-organization. The butterfly effect, an underlying principle of chaos, describes how a small change in one state of a deterministic nonlinear system can result in large differences in a later state (meaning there is sensitive dependence on initial conditions). A metaphor for this behavior is that a butterfly flapping its wings in Brazil can cause or prevent a tornado in Texas. Text was copied from this source, which is avai ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vibratory Finishing

Vibratory finishing is a type of mass finishing manufacturing Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of the secondary sector of the economy. The term may refer ... process used to deburr, radius, descale, burnish, clean, and brighten a large number of relatively small workpieces.Degarmo, p. 783. In this batch-type operation, specially shaped pellets of media and the workpieces are placed into the tub of a vibratory tumbler. The tub of the vibratory tumbler and all of its contents are then vibrated. The vibratory action causes the media to rub against the workpieces which yield the desired result. Depending on the application this can be either a dry or wet process. Unlike rotary tumbling this process can finish internal features, such as holes. It is also quicker and quieter. The process is performed in an open tub so the operat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |