|

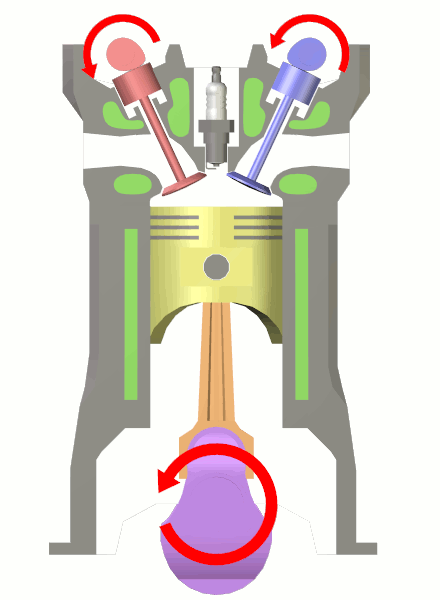

Scotch Yoke

The Scotch yoke (also known as slotted link mechanism) is a reciprocating motion mechanism, converting the linear motion of a slider into rotational motion, or vice versa. The piston or other reciprocating part is directly coupled to a sliding yoke with a slot that engages a pin on the rotating part. The location of the piston versus time is simple harmonic motion, i.e., a sine wave having constant amplitude and constant frequency, given a constant rotational speed. Applications This setup is most commonly used in control valve actuators in high-pressure oil and gas pipelines. Although not a common metalworking machine nowadays, crude shapers can use Scotch yokes. Almost all those use a Whitworth linkage, which gives a slow speed forward cutting stroke and a faster return. It has been used in various internal combustion engines, such as the Bourke engine, SyTech engine, and many hot air engines and steam engines. The term ''scotch yoke'' continues to be used when the sl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Yugo Escocés - Scotch Yoke Animation

Yugo (), also known as the Zastava Yugo, Zastava Koral (, sr-Cyrl, Застава Корал) and Yugo Koral, was a subcompact hatchback manufactured by Zastava Automobiles from 1980 until 2008, originally a Yugoslav corporation. Originally named the Zastava Jugo 45, various other names were also used over the car's long production run, like Yugo Tempo, Yugo Ciao, or Innocenti Koral. It was most commonly marketed as the Yugo 45/55/60/65, with the number referring to the car's maximum power. In the United States, it was sold as the Yugo GV (and sub-versions). Originally designed as a shortened variant of the Fiat 128, series production started in 1980. The Zastava Koral ''IN'', a facelifted model, was marketed until 2008, after which the production of all Zastava cars ended. Between 1980–2008, more than 794,000 Yugos were produced in total. The Yugo was marketed in the United States from 1985 to 1992 by Malcolm Bricklin, who asked Jerry Puchkoff to conceive and produce ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Bourke Engine

The Bourke engine was an attempt by Russell Bourke in the 1920s to improve the two-stroke internal combustion engine. Despite finishing his design and building several working engines, the onset of World War II, lack of test results, and the poor health of his wife compounded to prevent his engine from ever coming successfully to market. The main claimed virtues of the design are that it has only two moving parts, is lightweight, has two power pulses per revolution, and does not need oil mixed into the fuel. The Bourke engine is a two-stroke design, with one horizontally opposed piston assembly using two pistons that move in the same direction at the same time, so that their operations are 180 degrees out of phase. The pistons are connected to a Scotch yoke mechanism in place of the more usual crankshaft mechanism, thus the piston acceleration is perfectly sinusoidal. This causes the pistons to spend more time at top dead center than conventional engines. The incoming charg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

The Wolfram Demonstrations Project

The Wolfram Demonstrations Project is an open-source collection of interactive programmes called Demonstrations. It is hosted by Wolfram Research. At its launch, it contained 1300 demonstrations but has grown to over 10,000. The site won a Parents' Choice Award in 2008. Wolfram Research's staff organizes and edits the Demonstrations, which may be created by any user of Mathematica, then freely published and freely downloaded. Technology The Demonstrations run in Mathematica 6 or above and in Wolfram CDF Player, which is a free modified version of Wolfram Mathematica and available for Windows, Linux, and macOS and can operate as a web browser plugin. Demonstrations can also be embedded into a website. Each Demonstration page includes a snippet of JavaScript JavaScript (), often abbreviated as JS, is a programming language and core technology of the World Wide Web, alongside HTML and CSS. Ninety-nine percent of websites use JavaScript on the client side for webp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Otto Cycle Engine

An Otto cycle is an idealized thermodynamic cycle that describes the functioning of a typical spark ignition piston engine. It is the thermodynamic cycle most commonly found in automobile engines. The Otto cycle is a description of what happens to a gas as it is subjected to changes of pressure, temperature, volume, addition of heat, and removal of heat. The gas that is subjected to those changes is called the system. The system, in this case, is defined to be the fluid (gas) within the cylinder. Conversely, by describing the changes that take place within the system it also describes the system's effect on the environment. The purpose of the Otto cycle is to study the production of net work from the system that can propel a vehicle and its occupants in the environment. The Otto cycle is constructed from: :Top and bottom of the loop: a pair of quasi-parallel and isentropic processes (frictionless, adiabatic reversible). :Left and right sides of the loop: a pair of parallel i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Two-stroke Engine

A two-stroke (or two-stroke cycle) engine is a type of internal combustion engine that completes a Thermodynamic power cycle, power cycle with two strokes of the piston, one up and one down, in one revolution of the crankshaft in contrast to a four-stroke engine which requires four strokes of the piston in two crankshaft revolutions to complete a power cycle. During the stroke from bottom dead center to top dead center, the end of the exhaust/intake (or Scavenging (automotive), scavenging) is completed along with the compression of the mixture. The second stroke encompasses the combustion of the mixture, the expansion of the burnt mixture and, near bottom dead center, the beginning of the scavenging flows. Two-stroke engines often have a higher power-to-weight ratio than a four-stroke engine, since their power stroke occurs twice as often. Two-stroke engines can also have fewer moving parts, and thus be cheaper to manufacture and weigh less. In countries and regions with stringe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Connecting Rod

A connecting rod, also called a 'con rod', is the part of a reciprocating engine, piston engine which connects the piston to the crankshaft. Together with the crank (mechanism), crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston. In its most common form, in an internal combustion engine, it allows pivoting on the piston end and rotation on the shaft end. The predecessor to the connecting rod is a mechanic linkage used by water mills to convert rotating motion of the water wheel into reciprocating motion. The most common usage of connecting rods is in internal combustion engines or on steam engines. __TOC__ Origins A connecting rod crank has been found in the Celtic Oppida at Paule in Brittany, dated to 69 BC. The predecessor to the connecting length is the Linkage (mechanical), mechanical linkage used by List of Roman wa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Wrist Pin

In internal combustion engines, the gudgeon pin (English, wrist pin or piston pin US English) connects the piston to the connecting rod, and provides a bearing for the connecting rod to pivot upon as the piston moves.Nunney, Malcolm James (2007) "The Reciprocating Piston Petrol Engine: Gudgeon pins and their location" ''Light and heavy vehicle technology'' (4th ed.) Butterworth-Heinemann, Oxford, UKp. 28 In very early engine designs, including those driven by steam, and many very large stationary or marine engines, the gudgeon pin is located in a sliding crosshead that connects to the piston via a rod. A gudgeon is a pivot or journal. The origin of the word gudgeon is the Middle English word gojoun, which originated from the Middle French word goujon. Its first known use was in the 15th century.Webster's Seventh New Collegiate Dictionary, G & C Merriam Company, 1963, p. 370 Overview The gudgeon pin is typically a forged short hollow rod made of a steel alloy of high strength and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Top Dead Centre

In a reciprocating engine, the dead centre is the position of a piston in which it is either furthest from, or nearest to, the crankshaft. The former is known as top dead centre (TDC) while the latter is known as bottom dead centre (BDC). More generally, the dead centre is any position of a crank where the applied force is straight along its axis, meaning no turning force can be applied. Many sorts of machines are crank driven, including unicycles, bicycles, tricycles, various types of machine presses, gasoline engines, diesel engines, steam locomotives, and other steam engines. Crank-driven machines rely on the energy stored in a flywheel to overcome the dead centre, or are designed, in the case of multi-cylinder engines, so that dead centres can never exist on all cranks at the same time. A steam locomotive is an example of the latter, the connecting rods being arranged such that the dead centre for each cylinder occurs out of phase with the other one (or more) cylinders ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

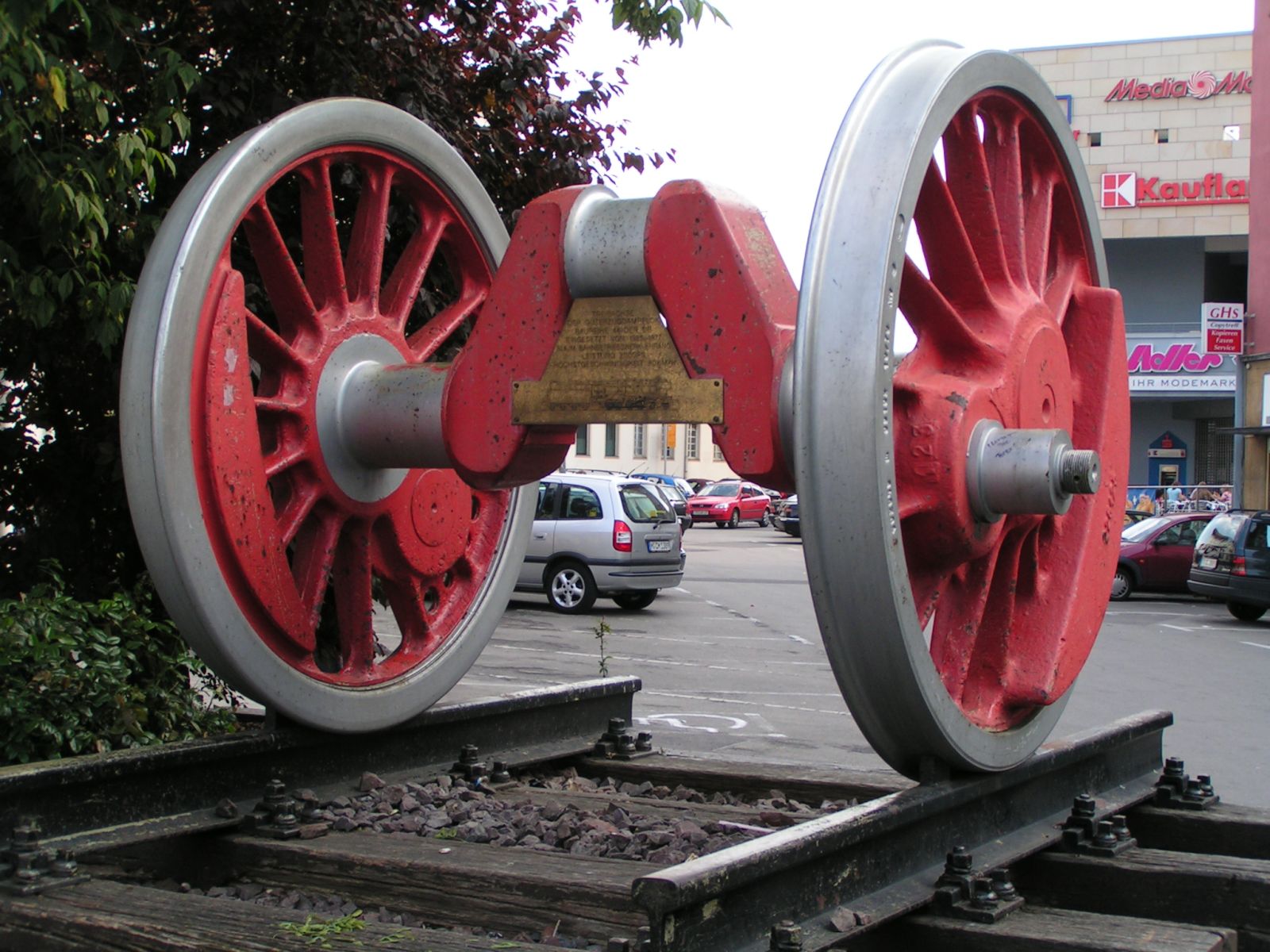

Driving Axle

On a steam locomotive, a driving wheel is a powered wheel which is driven by the locomotive's pistons (or turbine, in the case of a steam turbine locomotive). On a conventional, non-articulated locomotive, the driving wheels are all coupled together with side rods (also known as coupling rods); normally one pair is directly driven by the main rod (or connecting rod) which is connected to the end of the piston rod; power is transmitted to the others through the side rods. On diesel and electric locomotives, the driving wheels may be directly driven by the traction motors. Coupling rods are not usually used, and it is quite common for each axle to have its own motor. Jackshaft drive and coupling rods were used in the past (e.g. in the Swiss Crocodile locomotive) but their use is now confined to shunter locomotives. On an articulated locomotive or a duplex locomotive, driving wheels are grouped into sets with wheels within each set linked together. Diameter Driving wheel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Side Rod

A coupling rod or side rod connects the driving wheels of a locomotive. Steam locomotives in particular usually have them, but some Diesel locomotive, diesel and Electric locomotive, electric locomotives, especially older ones and switcher locomotive, shunter locomotives, also have them. The coupling rods transfer the power of drive to all wheels. Development Locomotion No. 1 was the first locomotive to employ coupling rods rather than Chain drive, chains. In the 1930s reliable roller bearing coupling rods were developed. Allowance for vertical motion In general, all railroad vehicles have Suspension (vehicle), spring suspension; without springs, irregularities in the track could lift wheels off the rail and cause impact damage to both rails and vehicles. Driving wheels are typically mounted so that they have around 1 inch (2.5 cm) of vertical motion. When there are only 2 coupled axles, this range of motion places only slight stress on the crank pins. With more axles, ho ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Crank Pin

A crankpin or crank pin, also known as a rod bearing journal, is a mechanical device in an engine which connects the crankshaft to the connecting rod for each cylinder. It has a cylindrical surface, to allow the crankpin to rotate relative to the "big end" of the connecting rod. The most common configuration is for a crankpin to serve one cylinder. However, many V engines have each crankpin shared by each pair of cylinders. Design The crankpin connects to the larger end of the connecting rod for each cylinder. This end of the connecting rod is called the "big end", as opposed to the "small end" or "little end" (which connects to the wrist/gudgeon pin in the piston). The bearing which allows the crankpin to rotate around its shaft is called the "rod bearing". In automotive engines, the most common type of rod bearing is the plain bearing, however bushings or roller bearings are also used in some engines. Configurations In a single-cylinder engine, straight engine or fla ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |