|

Rubber Pad Forming

Rubber pad forming (RPF) is a metalworking process where sheet metal is pressed between a die (manufacturing), die and a rubber block, made of polyurethane. Under pressure, the rubber and sheet metal are driven into the die and conform to its shape, forming the part. The rubber pads can have a general purpose shape, like a membrane. Alternatively, they can be machined in the shape of die or punch. Rubber pad forming is a deep drawing technique that is ideally suited for the production of small and medium-sized series. Deep drawing makes it possible to deform sheet metal in two directions, which offers great benefits in terms of function integration, weight reduction, cleanability and such. The disadvantage of regular deep drawing is that expensive tools consisting of an upper and lower mold are needed. Once these tools have been made, the variable costs are low, which makes regular deep drawing very suitable for large and very large numbers of products. Technique In the rubber p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rubber Press Animation

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds. Types of polyisoprene that are used as natural rubbers are classified as elastomers. Currently, rubber is harvested mainly in the form of the latex from the Hevea brasiliensis, Pará rubber tree (''Hevea brasiliensis'') or others. The latex is a sticky, milky and white colloid drawn off by making incisions in the bark and collecting the fluid in vessels in a process called "tapping". Manufacturers refine this latex into the rubber that is ready for commercial processing. Natural rubber is used extensively in many applications and products, either alone or in combination with other materials. In most of its useful forms, it has a large stretch ratio and high resilience and also is buoyant and water-proof. Industrial demand for rubber-like materials began to out ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

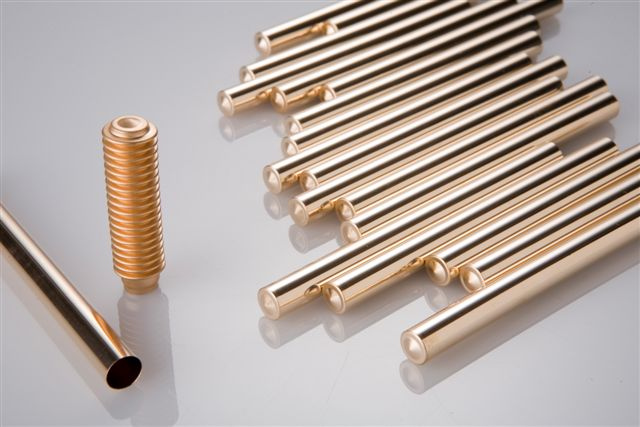

Metalworking

Metalworking is the process of shaping and reshaping metals in order to create useful objects, parts, assemblies, and large scale structures. As a term, it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges, down to precise engine parts and delicate jewellery. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to and including highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheet Metal

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil (metal), foil or Metal leaf, leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitting, roll slitter. In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its Sheet metal gauge, gauge. The larger the gauge number, the thinner the metal. Commonly used steel sheet metal ranges from 30 gauge (0.40 mm) to about 7 gauge (4.55 mm). Gauge differs between ferrous (Iron, iron-based) metals and nonferrous metals such as aluminum or copper. Copper thickness, for example ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die (manufacturing)

A die is a specialized machine tool used in manufacturing industries to cut and/or Forming (metalworking), form material to a desired shape or profile. ''Stamping (metalworking), Stamping dies'' are used with a machine press, press, as opposed to ''Draw plate, drawing dies'' (used in the manufacture of wire) and ''Die casting, casting dies'' (used in Molding (process), molding) which are not. Like molds, dies are generally customized to the item they are used to create. Products made with dies range from simple paper clips to complex pieces used in advanced technology. Continuous production, Continuous-feed laser cutting may displace the analogous die-based process in the automotive industry, among others. Die stamping Blanking and piercing are two Shearing (manufacturing), die cutting operations, and Bending (metalworking), bending is an example of a die forming operation. Die forming Forming operations work by deforming materials like sheet metal or plastic using force (Compre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rubber

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds. Types of polyisoprene that are used as natural rubbers are classified as elastomers. Currently, rubber is harvested mainly in the form of the latex from the Hevea brasiliensis, Pará rubber tree (''Hevea brasiliensis'') or others. The latex is a sticky, milky and white colloid drawn off by making incisions in the bark and collecting the fluid in vessels in a process called "tapping". Manufacturers refine this latex into the rubber that is ready for commercial processing. Natural rubber is used extensively in many applications and products, either alone or in combination with other materials. In most of its useful forms, it has a large stretch ratio and high resilience and also is buoyant and water-proof. Industrial demand for rubber-like materials began to out ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyurethane

Polyurethane (; often abbreviated PUR and PU) is a class of polymers composed of organic chemistry, organic units joined by carbamate (urethane) links. In contrast to other common polymers such as polyethylene and polystyrene, polyurethane term does not refer to the single type of polymer but a group of polymers. Unlike polyethylene and polystyrene, polyurethanes can be produced from a wide range of starting materials resulting in various polymers within the same group. This chemical variety produces polyurethanes with different chemical structures leading to many List of polyurethane applications, different applications. These include rigid and flexible foams, and coatings, adhesives, Potting (electronics), electrical potting compounds, and fibers such as spandex and polyurethane laminate (PUL). Foams are the largest application accounting for 67% of all polyurethane produced in 2016. A polyurethane is typically produced by reacting a polymeric isocyanate with a polyol. Since a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Deep Drawing

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses ( hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius. Deep drawing presses, especially in the Aerospace and Medical industries, require unparalleled accuracy and precision. Sheet hydroforming presses do complex draw work. Bed size, tonnage, stroke, speed, and more ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

8000 Ton Pers

8 (eight) is the natural number following 7 and preceding 9. Etymology English ''eight'', from Old English '', æhta'', Proto-Germanic ''*ahto'' is a direct continuation of Proto-Indo-European '' *oḱtṓ(w)-'', and as such cognate with Greek and Latin , both of which stems are reflected by the English prefix oct(o)-, as in the ordinal adjective ''octaval'' or ''octavary'', the distributive adjective is ''octonary''. The adjective ''octuple'' (Latin ) may also be used as a noun, meaning "a set of eight items"; the diminutive ''octuplet'' is mostly used to refer to eight siblings delivered in one birth. The Semitic numeral is based on a root ''*θmn-'', whence Akkadian ''smn-'', Arabic ''ṯmn-'', Hebrew ''šmn-'' etc. The Chinese numeral, written (Mandarin: ''bā''; Cantonese: ''baat''), is from Old Chinese ''*priāt-'', ultimately from Sino-Tibetan ''b-r-gyat'' or ''b-g-ryat'' which also yielded Tibetan '' brgyat''. It has been argued that, as the cardinal num ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Deep Drawing

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses ( hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius. Deep drawing presses, especially in the Aerospace and Medical industries, require unparalleled accuracy and precision. Sheet hydroforming presses do complex draw work. Bed size, tonnage, stroke, speed, and more ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Douglas Aircraft Co

Douglas may refer to: People * Douglas (given name) * Douglas (surname) Animals * Douglas (parrot), macaw that starred as the parrot ''Rosalinda'' in Pippi Longstocking * Douglas the camel, a camel in the Confederate Army in the American Civil War Businesses * Douglas Aircraft Company * Douglas (cosmetics), German cosmetics retail chain in Europe * Douglas Holding, former German company * Douglas (motorcycles), British motorcycle manufacturer Peerage and Baronetage * Duke of Douglas * Earl of Douglas, or any holder of the title * Marquess of Douglas, or any holder of the title * Douglas baronets Peoples * Clan Douglas, a Scottish kindred * Dougla people, West Indians of both African and East Indian heritage Places Australia * Douglas, Queensland, a suburb of Townsville * Douglas, Queensland (Toowoomba Region), a locality * Port Douglas, North Queensland, Australia * Shire of Douglas, in northern Queensland Canada * Douglas, New Brunswick * Douglas Parish, New Brunswick * Dou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydroforming

Hydroforming is a means of shaping ductile metals such as aluminium, brass, low alloy steel, and stainless steel into lightweight, structurally stiff and strong pieces. One of the largest applications of cost-effective hydroforming is the automotive industry, which makes use of the complex shapes made possible by hydroforming to produce stronger, lighter, and more rigid unibody structures for vehicles. This technique is particularly popular with the high-end sports car industry and is also frequently employed in the shaping of aluminium tubes for bicycle frames. Hydroforming is a specialized type of die forming that uses a high pressure hydraulic fluid to press room temperature working material into a die. To hydroform aluminium into a vehicle's frame rail, a hollow tube of aluminium is placed inside a negative mold that has the shape of the desired result. High pressure hydraulic pumps then inject fluid at very high pressure inside the aluminium tube which causes it to expand ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |