|

Rocker Arm

A rocker arm is a valvetrain component that typically transfers the motion of a pushrod in an overhead valve engine, overhead valve internal combustion engine to the corresponding intake/exhaust poppet valve, valve. Rocker arms in automobiles are typically made from stamped steel, or aluminum in higher-revving applications. Some rocker arms (called ''roller rockers'') include a bearing at the contact point, to reduce wear and friction there. Overview The most common use of a rocker arm is to transfer the up and down motion of a pushrod in an overhead valve engine, overhead valve (OHV) internal combustion engine to the corresponding intake/exhaust poppet valve, valve. In an OHV engine the camshaft located within the engine block below the cylinder bank(s) pushes the pushrod upwards. The top of the pushrod presses upwards on one side of the rocker arm located at the top of the cylinder head, which causes the rocker arm to pivot downward on the top of the valve, opening it. To redu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Škoda 120

120 may refer to: *120 (number), the number *AD 120, a year in the 2nd century AD *120 BC, a year in the 2nd century BC *120 film, a film format for still photography *120 (film), ''120'' (film), a 2008 film *120 (MBTA bus), a Massachusettes Bay Transport Authority bus route *120 (New Jersey bus), a New Jersey Transit bus route *120 (Kent) Construction Regiment, Royal Engineers * 120 volts, standard electrical mains voltage in several countries in the Americas *IdeaPad#IdeaPad 120 Series, Lenovo IdeaPad 120, a discontinued brand of notebook computers *Ching Chung stop (MTR digital station code 120), a Light Rail stop in Tuen Mun, Hong Kong *120 Lachesis, a main-belt asteroid *Škoda 120, a compact sedan 1/20 may refer to: * January 20 (month-day date notation) See also * Unbinilium, a hypothetical chemical element with atomic number 120 * CXX (other) {{Numberdis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Overhead Cam

An overhead camshaft (OHC) engine is a piston engine in which the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion chamber in the engine block. ''Single overhead camshaft'' (SOHC) engines have one camshaft per bank of cylinders. ''Dual overhead camshaft'' (DOHC, also known as "twin-cam") engines have two camshafts per bank. The first production car to use a DOHC engine was built in 1910. Use of DOHC engines slowly increased from the 1940s, leading to many automobiles by the early 2000s using DOHC engines. Design In an OHC engine, the camshaft is located at the top of the engine, above the combustion chamber. This contrasts the earlier overhead valve engine (OHV) and flathead engine configurations, where the camshaft is located down in the engine block. The valves in both OHC and OHV engines are located above the combustion chamber; however an O ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pushrod

A valvetrain is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gases out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines, in order from oldest to newest, are: * Flathead engine: A single camshaft and the valves are located in the engine block below the cylinder or cylinder bank. * Overhead valve engine: A single camshaft remains in the block below the cylinder(s), however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: Both the valves and one or more camshafts are located in the cylinder head above the cylinders or cylinder banks. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Poppet Valve

A poppet valve (also sometimes called mushroom valve) is a valve typically used to control the timing and quantity of petrol (gas) or vapour flow into or out of an engine, but with many other applications. It consists of a hole or open-ended chamber, usually round or oval in cross-section, and a plug, usually a disk shape on the end of a shaft known as a valve stem. The working end of this plug, the valve face, is typically ground at a 45┬░ bevel to seal against a corresponding valve seat ground into the rim of the chamber being sealed. The shaft travels through a valve guide to maintain its alignment. A pressure differential on either side of the valve can assist or impair its performance. In exhaust applications higher pressure against the valve helps to seal it, and in intake applications lower pressure helps open it. Etymology The word poppet shares etymology with "puppet": it is from the Middle English ''popet'' ("youth" or "doll"), from Middle French ''poupette'', whic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Auto Parts

This is a list of auto parts, which are manufactured components of automobiles. This list reflects both fossil-fueled cars (using internal combustion engine An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal comb ...s) and electric vehicles; the list is not exhaustive. Many of these parts are also used on other motor vehicles such as trucks and buses. Car body and main parts Body components, including trim Vehicle door, Doors Windows Low voltage/auxiliary electrical system and electronics Audio/video devices Cameras Low voltage electrical supply system Gauge (instrument), Gauges and meters Ignition system Automotive lighting, Lighting and signaling system Sensors Starting system Electrical switches Wiring harnesses Miscellaneous ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states: * no minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium, zirconium, or any other element to be added to obtain a desired alloying effect; * the specified minimum for copper does not exceed 0.40%; * or the specified maximum for any of the following elements does not exceed: manganese 1.65%; silicon 0.60%; and copper 0.60%. As the carbon content percentage rises, steel has the ability to become harder and stronger through heat treating; however, it becomes less ductile. Regardless of the heat treatment, a higher carbon content reduces weldability. In carbon steels, the higher carbon content lowers the melting point. The term may be used to reference steel that is not stainless steel; in this use carbon steel may include alloy st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cast Iron

Cast iron is a class of ironÔÇôcarbon alloys with a carbon content of more than 2% and silicon content around 1ÔÇô3%. Its usefulness derives from its relatively low melting temperature. The alloying elements determine the form in which its carbon appears: Cast iron#White cast iron, white cast iron has its carbon combined into an iron carbide named cementite, which is very hard, but brittle, as it allows cracks to pass straight through; Grey iron, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and Ductile iron, ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing. Carbon (C), ranging from 1.8 to 4 wt%, and silicon (Si), 1ÔÇô3 wt%, are the main alloying elements of cast iron. Iron alloys with lower carbon content are known as steel. Cast iron tends to be brittle, except for malleable iron, malleable cast irons. With its relatively low melting point, g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

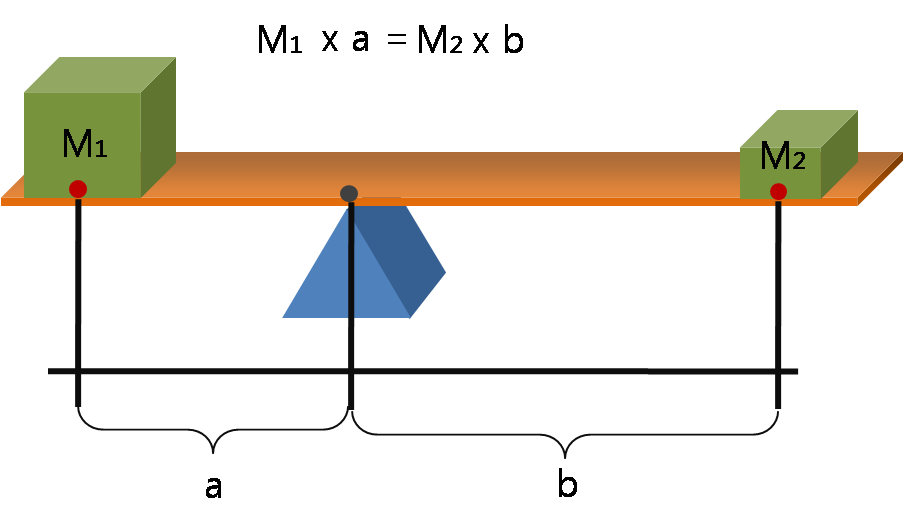

Fulcrum (mechanics)

A lever is a simple machine consisting of a beam or rigid rod pivoted at a fixed hinge, or '' fulcrum''. A lever is a rigid body capable of rotating on a point on itself. On the basis of the locations of fulcrum, load, and effort, the lever is divided into three types. It is one of the six simple machines identified by Renaissance scientists. A lever amplifies an input force to provide a greater output force, which is said to provide leverage, which is mechanical advantage gained in the system, equal to the ratio of the output force to the input force. As such, the lever is a mechanical advantage device, trading off force against movement. Etymology The word "lever" entered English around 1300 from . This sprang from the stem of the verb ''lever'', meaning "to raise". The verb, in turn, goes back to , itself from the adjective ''levis'', meaning "light" (as in "not heavy"). The word's primary origin is the Proto-Indo-European stem , meaning "light", "easy", or "nimble", amo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reciprocating Weight

The moment of inertia, otherwise known as the mass moment of inertia, angular/rotational mass, second moment of mass, or most accurately, rotational inertia, of a rigid body is defined relatively to a rotational axis. It is the ratio between the torque applied and the resulting angular acceleration about that axis. It plays the same role in rotational motion as mass does in linear motion. A body's moment of inertia about a particular axis depends both on the mass and its distribution relative to the axis, increasing with mass and distance from the axis. It is an extensive (additive) property: for a point mass the moment of inertia is simply the mass times the square of the perpendicular distance to the axis of rotation. The moment of inertia of a rigid composite system is the sum of the moments of inertia of its component subsystems (all taken about the same axis). Its simplest definition is the second moment of mass with respect to distance from an axis. For bodies constr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stamping (metalworking)

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and Die (manufacturing), die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly fed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined. St ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Camshaft

A camshaft is a shaft that contains a row of pointed cams in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems and early electric motor speed controllers. Camshafts in piston engines are usually made from steel or cast iron, and the shape of the cams greatly affects the engine's characteristics. History Trip hammers are one of the early uses of a form of cam to convert rotating motion, e.g. from a waterwheel, into the reciprocating motion of a hammer used in forging or to pound grain. Evidence for these exists back to the Han dynasty in China, and they were widespread by the medieval period. Camshafts were first described by Ismail al-Jazari in 1206. Once the rotative version of the steam engine was developed in the late 18th century, the operation of the valve gear was usually by an eccentric, which turned the rotation of the crankshaft i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ball (bearing)

Bearing balls are special highly spherical and smooth balls, most commonly used in ball bearings, but also used as components in things like freewheel mechanisms. The balls themselves are commonly referred to as ball bearings. This is an example of a synecdoche. The balls come in many different ''grades''. These grades are defined by bodies such as the American Bearing Manufacturers Association (ABMA), a body which sets standards for the precision of bearing balls. They are manufactured in machines designed specially for the job. In 2008, the United States produced 5.778 billion bearing balls. Grade Bearing balls are manufactured to a specific grade, which defines its geometric tolerance (engineering), tolerances. The grades range from 2000 to 3, where the smaller the number the higher the precision. Grades are written "GXXXX", i.e. grade 100 would be "G100". Lower grades also have fewer defects, such as flats, pits, soft spots, and cuts. The surface smoothness is measured in tw ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |