|

Quick Response Manufacturing

Quick response manufacturing (QRM) is an approach to manufacturing which emphasizes the beneficial effect of reducing internal and external lead times. Description Shorter lead times improve quality, reduce cost and eliminate non-value-added waste within the organization while simultaneously increasing the organization's competitiveness and market share by serving customers better and faster. The time-based framework of QRM accommodates strategic variability such as offering custom-engineered products while eliminating dysfunctional variability such as rework and changing due dates. For this reason, companies making products in low or varying volumes have used QRM as an alternative or to complement other strategies such as Lean Manufacturing, Total quality management, Six Sigma or Kaizen. However, the benefits of QRM are still mooted and contested by experts around. Many opposers of QRM criticize its approach being very "marketing-style" rather than academic or statistical. Histor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of the secondary sector of the economy. The term may refer to a range of human activity, from handicraft to high-tech, but it is most commonly applied to industrial design, in which raw materials from the primary sector are transformed into finished goods on a large scale. Such goods may be sold to other manufacturers for the production of other more complex products (such as aircraft, household appliances, furniture, sports equipment or automobiles), or distributed via the tertiary industry to end users and consumers (usually through wholesalers, who in turn sell to retailers, who then sell them to individual customers). Manufacturing engineering is the field of engineering that designs and optimizes the manufacturing process, or the steps through which raw materials are transformed i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Queuing Theory

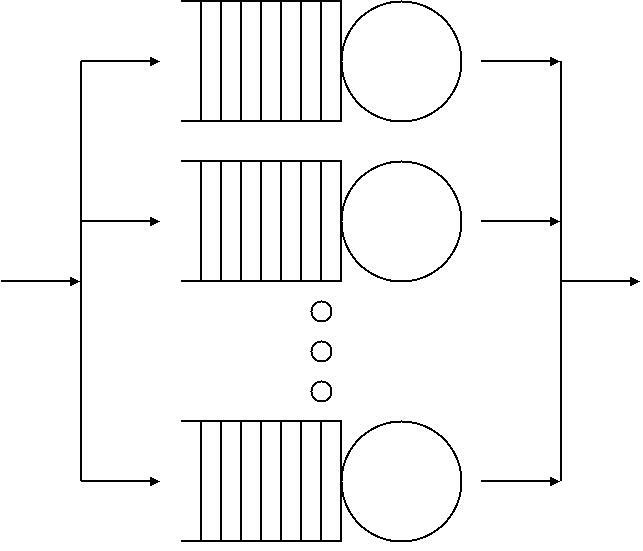

Queueing theory is the mathematical study of waiting lines, or queues. A queueing model is constructed so that queue lengths and waiting time can be predicted. Queueing theory is generally considered a branch of operations research because the results are often used when making business decisions about the resources needed to provide a service. Queueing theory has its origins in research by Agner Krarup Erlang, who created models to describe the system of incoming calls at the Copenhagen Telephone Exchange Company. These ideas were seminal to the field of teletraffic engineering and have since seen applications in telecommunications, traffic engineering, computing, project management, and particularly industrial engineering, where they are applied in the design of factories, shops, offices, and hospitals. Spelling The spelling "queueing" over "queuing" is typically encountered in the academic research field. In fact, one of the flagship journals of the field is '' Queuein ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Business Process Reengineering

Business process re-engineering (BPR) is a business management strategy originally pioneered in the early 1990s, focusing on the analysis and design of workflows and business processes within an organization. BPR aims to help organizations fundamentally rethink how they do their work in order to improve customer service, cut operational costs, and become world-class competitors.Business Process Re-engineering Assessment Guide United States General Accounting Office, May 1997. BPR seeks to help companies radically restructure their organizations by focusing on the ground-up design of their business processes. According to early BPR proponent Thomas H. Davenport (1990), a business process is a set of log ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Supply Chain Management

In commerce, supply chain management (SCM) deals with a system of procurement (purchasing raw materials/components), operations management, logistics and marketing channels, through which raw materials can be developed into finished products and delivered to their end customers. A more narrow definition of supply chain management is the "design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronising supply with demand and measuring performance globally". This can include the movement and storage of raw materials, work-in-process inventory, finished goods, and end to end order fulfilment from the point of origin to the point of consumption. Interconnected, interrelated or interlinked networks, channels and node businesses combine in the provision of products and services required by end customers in a supply chain. SCM is the br ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

HAN University Of Applied Sciences

The HAN University of Applied Sciences, mostly referred to as HAN, is one of the largest universities of applied sciences in the Netherlands. It offers bachelor's and master's degree programs to over 35,000 students. HAN is a knowledge institute for higher education and research in the Dutch province of Gelderland, with campuses in Arnhem and Nijmegen. History In the 1980s there were many small universities of applied sciences in the Netherlands. The government at the time believed this was inefficient, both in terms of the financing and organizing of education. In 1983 the government pushed smaller universities of applied sciences to mergeThe Netherlands Association of Universities of Applied Sciencesagreed, and gradually more and more universities of applied sciences in Arnhem and Nijmegen merged. On 1 February 1996, the HAN conglomerate was finally established and it became a large, broad-based educational institution. Since then the number of students has grown while costs ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

National Oilwell Varco

NOV Inc., formerly National Oilwell Varco, is an American multinational corporation based in Houston, Texas. It is a worldwide provider of equipment and components used in oil and gas drilling and production operations, oilfield services, and supply chain integration services to the upstream oil and gas industry. The company conducts operations in more than 500 locations across six continents, operating through two reporting segments: Energy Equipment and Energy Products and Services. NOV. Retrieved on September 17,2024. "New Releases." History Background NOV's two main predecessors, Oilwell Supply and National Supply, were founded in ...[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Merrill A

Merrill may refer to: Places in the United States *Merrill Field, Anchorage, Alaska *Merrill, Iowa * Merrill, Maine * Merrill, Michigan * Merrill, Mississippi, an unincorporated community near Lucedale in George County *Merrill, Oregon *Merrill, Wisconsin * Merrill (town), Wisconsin * Merrill Township, Michigan *Merrill Township, North Dakota *Merrill College at the University of California, Santa Cruz People *Merrill (given name) *Merrill (surname) Other uses *Merrill (company), a division of Bank of America *Skidmore, Owings and Merrill, architectural firm * USS ''Merrill'' (DD-976) *Nine men's morris, a strategy board game also called ''Merrills'' * Merrill (crater) * Merrill, a companion character in ''Dragon Age II'' See also * Merril Merril is a given name and surname. Notable people with the name include: * Judith Merril (1923–1997), American and Canadian science fiction writer * Merril Anthony (1909–1967), Guyanese cricketer * Merril Bainbridge (born 1968), Austra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fast Fit

Fast fit (often capitalized and written as Fast Fit,) refers to a method of handling the shipping and sampling processes typical of multinational organizations who primarily manufacture offshore, specifically in the fashion and textile industry. Fast Fit centers on the sharing of 360-degree, annotatable images intended to reduce the costs and lead times associated with shipping physical samples. The term is particularly prevalent among companies that fit the Fast Fashion model, as Fast Fit is considered to be a vital component in the reduction of time between design inspiration and final production of a garment or product. Philosophy Relationship to Fast Fashion The goal of Fast Fashion (a philosophy that drives high street retailers and brands like Zara, H&M, Topshop, Benetton, American Apparel and Peacocks) is to create demand for – and deliver to market – garments "closer to trend" and at a lower price point than was possible using traditional design, sampling, manu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sweatshop

A sweatshop or sweat factory is a cramped workplace with very poor and/or illegal working conditions, including little to no breaks, inadequate work space, insufficient lighting and ventilation, or uncomfortably or dangerously high or low temperatures. The work may be difficult, tiresome, dangerous, climatically challenging, or underpaid. Employees in sweatshops may work long hours with unfair wages, regardless of laws mandating overtime pay or a minimum wage; child labor laws may also be violated. Women make up 85 to 90% of sweatshop workers and may be forced by employers to take birth control and routine pregnancy tests to avoid supporting maternity leave or providing health benefits. The Fair Labor Association's "2006 Annual Public Report" inspected factories for FLA compliance in 18 countries including Bangladesh, El Salvador, Colombia, Guatemala, Malaysia, Thailand, Tunisia, Turkey, China, India, Vietnam, Honduras, Indonesia, Brazil, Mexico, and the United States. The U.S. De ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fast Fashion

Fast fashion is the business model of replicating recent catwalk trends and High fashion, high-fashion designs, mass production, mass-producing them at a low cost, and bringing them to retail quickly while demand is at its highest. The term ''fast fashion'' is also used generically to describe the products of this business model, particularly clothing and footwear. Retailers who employ the fast fashion strategy include Fashion Nova, Primark, H&M, Shein, and Zara (retailer), Zara, all of which have become large multinationals by driving high turnover of inexpensive seasonal and trendy clothing that appeals to fashion-conscious consumers. Fast fashion grew during the late 20th century as Clothing industry, manufacturing of clothing became less expensive—the result of more efficient supply chains, new quick response manufacturing methods, and greater reliance on low-cost labor from the apparel manufacturing industries of South Asia, South, Southeast Asia, Southeast, and East Asia, w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kanban

Kanban ( meaning signboard) is a scheduling system for lean manufacturing (also called just-in-time manufacturing, abbreviated JIT). Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. The system takes its name from the cards that track production within a factory. Kanban is also known as the ''Toyota nameplate system'' in the automotive industry. A goal of the kanban system is to limit the buildup of excess inventory at any point in production. Limits on the number of items waiting at supply points are established and then reduced as inefficiencies are identified and removed. Whenever a limit is exceeded, this points to an inefficiency that should be addressed. In kanban, problem areas are highlighted by measuring lead time and cycle time of the full process and process steps. One of the main benefits of kanban is to establish an upper limit to work in process (commonly referred as "WIP") inventory to avoid overcapacity. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Enterprise Resource Planning

Enterprise resource planning (ERP) is the integrated management of main business processes, often in real time and mediated by software and technology. ERP is usually referred to as a category of business management software—typically a suite of integrated applications—that an organization can use to collect, store, manage and interpret data from many business activities. ERP systems can be local-based or cloud-based. Cloud-based applications have grown in recent years due to the increased efficiencies arising from information being readily available from any location with Internet access. ERP differs from integrated business management systems by including planning all resources that are required in the future to meet business objectives. This includes plans for getting suitable staff and manufacturing capabilities for future needs. ERP provides an integrated and continuously updated view of the core business processes using common databases maintained by a database manag ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |