|

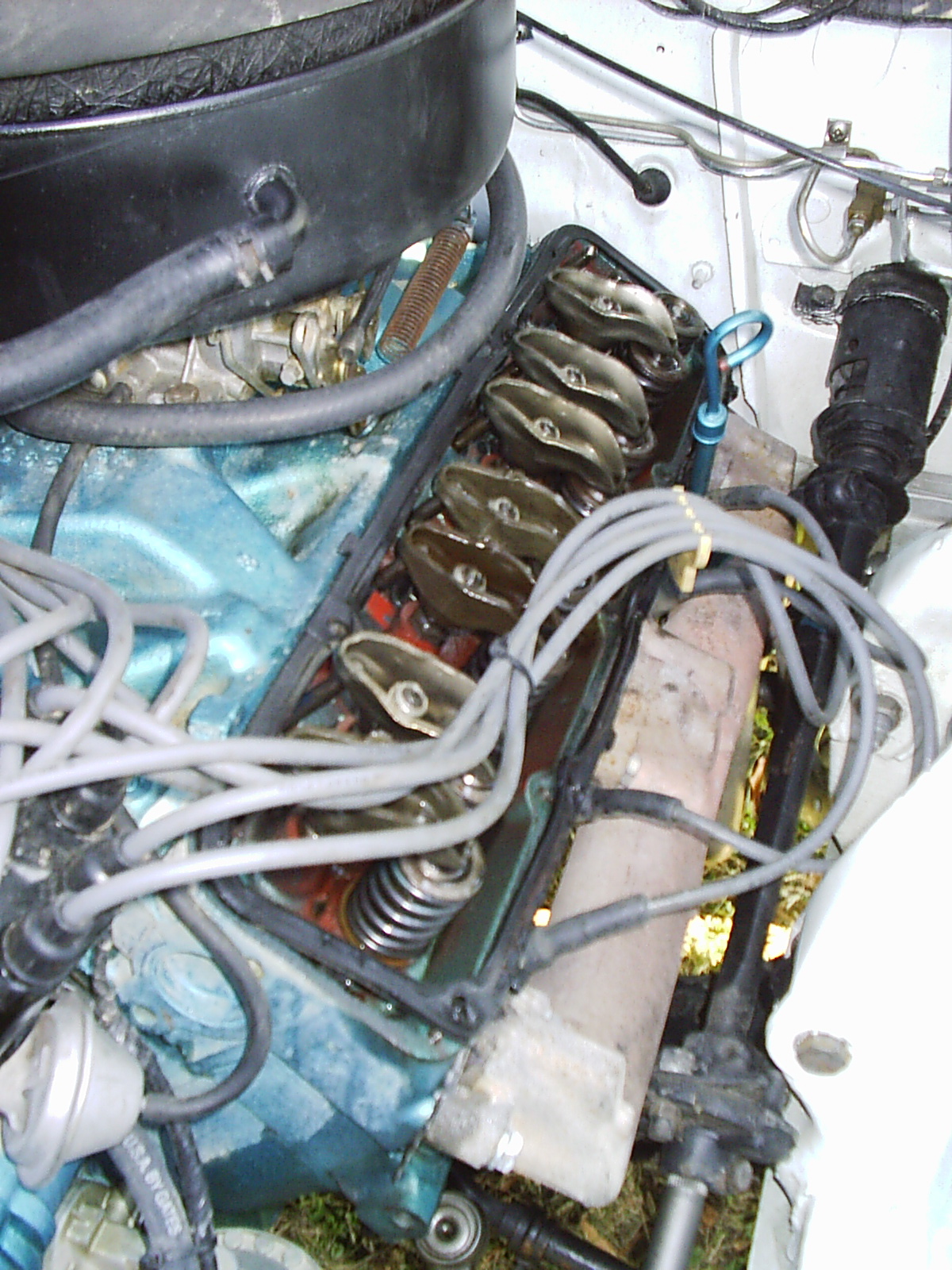

Pushrods

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gasses out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines - in order from oldest to newest - are: * Flathead engine: The camshaft and the valves are located in the engine block below the combustion chamber. * Overhead valve engine: The camshaft remains in the block, however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: The valves and camshaft(s) are in the cylinder head above the combustion chamber. Components The valvetrain consists of all the compo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Overhead Valve Engine

An overhead valve (OHV) engine, sometimes called a ''pushrod engine'', is a piston engine whose valves are located in the cylinder head above the combustion chamber. This contrasts with earlier flathead engines, where the valves were located below the combustion chamber in the engine block. Although an overhead camshaft (OHC) engine also has overhead valves, the common usage of the term "overhead valve engine" is limited to engines where the camshaft is located in the engine block. In these traditional OHV engines, the motion of the camshaft is transferred using pushrods (hence the term "pushrod engine") and rocker arms to operate the valves at the top of the engine. Some early intake-over-exhaust engines used a hybrid design combining elements of both side-valves and overhead valves. History Predecessors The first internal combustion engines were based on steam engines and therefore used slide valves. This was the case for the first Otto engine, which was first s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flathead Engine

A flathead engine, also known as a sidevalve engine''American Rodder'', 6/94, pp.45 & 93. or valve-in-block engine is an internal combustion engine with its poppet valves contained within the engine block, instead of in the cylinder head, as in an overhead valve engine. Flatheads were widely used internationally by automobile manufacturers from the late 1890s until the mid-1950s but were replaced by more efficient overhead valve and overhead camshaft engines. They are currently experiencing a revival in low-revving aero-engines such as the D-Motor. The side-valve design The valve gear comprises a camshaft sited low in the cylinder block which operates the poppet valves via tappets and short pushrods (or sometimes with no pushrods at all). The flathead system obviates the need for further valvetrain components such as lengthy pushrods, rocker arms, overhead valves or overhead camshafts. The sidevalves are typically adjacent, sited on one side of the cylinder(s), though ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Timing Belt (camshaft)

In a piston engine, either a timing belt (also called a ''cambelt'') or timing chain or set of timing gears is used to synchronize the rotation of the crankshaft and the camshaft. This synchronisation ensures that the engine's valves open and close at the correct times in relation to the position of the pistons. Design In most piston engines, the camshaft(s) are mechanically connected to the crankshaft. The crankshaft drives the camshaft (via a timing belt, timing chain or pushrods), which in turn actuates the intake and exhaust valves. These valves allow the engine to inhale air (or an air/fuel mixture) and exhale the exhaust gasses. The most common devices to transfer the drive are toothed rubber belts, metal timing chains or a set of gears. The teeth of the belt/chain/gears mesh with both the crankshaft and camshaft(s), thereby synchronising their motion. In many older overhead valve engines, the camshaft is located in the block near the crankshaft, therefore a simple g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pushrod

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gasses out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines - in order from oldest to newest - are: * Flathead engine: The camshaft and the valves are located in the engine block below the combustion chamber. * Overhead valve engine: The camshaft remains in the block, however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: The valves and camshaft(s) are in the cylinder head above the combustion chamber. Components The valvetrain consists of all the c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tappet

A tappet is most commonly a component in an internal combustion engine which converts the rotating motion of the camshaft into linear motion of the valves, either directly or indirectly. An earlier use of the term was for part of the valve gear in beam engines beginning in 1715. The term is also used for components in pneumatic cylinders and weaving loom. __TOC__ Beam engines The first recorded use of the term tappet is as part of the valve gear in the 1715 Newcomen engine, an early form of steam engine. Early versions of the Newcomen engines from 1712 had manually operated valves, but by 1715 this repetitive task had been automated through the use of tappets. The beam of the engine had a vertical 'plug rod' hung from it, alongside the cylinder. Adjustable blocks or 'tappets' were attached to this rod and as the beam moved up and down, the tappets pressed against long levers or 'horns' attached to the engine's valves, working the cycle of steam and injection water valves ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valve Float

Valve float is an adverse condition which can occur at high engine speeds when the poppet valves in an internal combustion engine valvetrain do not properly follow the closure phase of the cam lobe profile. This reduces engine efficiency and performance. There is also a significant risk of severe engine damage due to valve spring damage, and/or pistons contacting the valves, and/or catastrophic lifter and cam lobe failure, especially with roller lifters. Similar conditions 'Valve lift' is intentional, using a controlled valve float to increase lift and duration of the valve open cycle. In some motorsports there are rules that limit camshaft lift, provoking this type of exploitation. Properly optimizing the system avoids undue stresses to the camshaft lobes and tappets. 'Valve bounce' is a related condition where the valve does not stay seated because of the combined effects of the valve's inertia and resonance of metallic valve springs that reduce the closing force and allow t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Overhead Camshaft Engine

An overhead camshaft (OHC) engine is a piston engine where the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion chamber in the engine block. ''Single overhead camshaft'' (SOHC) engines have one camshaft per bank of cylinders. ''Dual overhead camshaft'' (DOHC, also known as "twin-cam".) engines have two camshafts per bank. The first production car to use a DOHC engine was built in 1910. Use of DOHC engines slowly increased from the 1940s, leading to many automobiles by the early 2000s using DOHC engines. Design In an OHC engine, the camshaft is located at the top of the engine, above the combustion chamber. This contrasts the earlier overhead valve engine (OHV) and flathead engine configurations, where the camshaft is located down in the engine block. The valves in both OHC and OHV engines are located above the combustion chamber; however an O ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Head

In an internal combustion engine, the cylinder head (often abbreviated to simply "head") sits above the cylinder (engine), cylinders and forms the roof of the combustion chamber. In sidevalve engines, the head is a simple sheet of metal; whereas in more modern overhead valve engine, overhead valve and overhead camshaft engine, overhead camshaft engines, the cylinder head is a more complicated block often containing inlet and exhaust passages, coolant passages, Poppet_valve#Usage_in_internal_combustion_engines, valves, camshafts, spark plugs and Fuel_injection#Direct_injection, fuel injectors. Most straight engines have a single cylinder head shared by all of the cylinders and most V engines have two cylinder heads (one per bank of cylinders). Design A summary of engine designs is shown below, in chronological order for automobile usage. Sidevalve engines In a flathead engine, flathead (''sidevalve'') engine, all of the valvetrain components are cam-in-block, contained wi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Camless Piston Engine

A camless or free-valve piston engine is an engine that has poppet valves operated by means of electromagnetic, hydraulic, or pneumatic actuators instead of conventional cams. Actuators can be used to both open and close valves, or to open valves closed by springs or other means. Camshafts normally have one lobe per valve, with a fixed valve duration and lift. Although many modern engines use camshaft phasing, adjusting the lift and valve duration in a working engine is more difficult. Some manufacturers use systems with more than one cam lobe, but this is still a compromise as only a few profiles can be in operation at once. This is not the case with the camless engine, where lift and valve timing can be adjusted freely from valve to valve and from cycle to cycle. It also allows multiple lift events per cycle and, indeed, no events per cycle—switching off the cylinder entirely. Camless development Camless valve trains have long been investigated by several companies, including ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high- temperature and high- pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons (piston engine), turbine blades ( gas turbine), a rotor (Wankel engine), or a nozzle (jet engine). This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. This replaced the external combustion engine for applications where the weight or size of an engine was more important. The first commercially successful internal combustion engine was created by Étienne Lenoir around 1860, and the first modern internal combustion engine, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tappet

A tappet is most commonly a component in an internal combustion engine which converts the rotating motion of the camshaft into linear motion of the valves, either directly or indirectly. An earlier use of the term was for part of the valve gear in beam engines beginning in 1715. The term is also used for components in pneumatic cylinders and weaving loom. __TOC__ Beam engines The first recorded use of the term tappet is as part of the valve gear in the 1715 Newcomen engine, an early form of steam engine. Early versions of the Newcomen engines from 1712 had manually operated valves, but by 1715 this repetitive task had been automated through the use of tappets. The beam of the engine had a vertical 'plug rod' hung from it, alongside the cylinder. Adjustable blocks or 'tappets' were attached to this rod and as the beam moved up and down, the tappets pressed against long levers or 'horns' attached to the engine's valves, working the cycle of steam and injection water valves ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)

.jpg)