|

Profile Rolling

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes... Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel (I-beams, angle stock, channel stock), bar stock, and rails. Most steel mills ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Slitting Mill

Slitting Mill is a small village on the outskirts of Rugeley, Staffordshire. At the 2001 census, it had a population of 265. The village is within Rugeley civil parish In England, a civil parish is a type of administrative parish used for local government. It is a territorial designation which is the lowest tier of local government. Civil parishes can trace their origin to the ancient system of parishes, w ..., although it is a short distance from the rest of the town and has a distinct identity. Horns Pool is a popular local location for anglers. The village was known as Stonehouse, but towards the end of the 19th century its name was changed to Slitting Mill after the mills sited there during the 17th and 18th centuries. The slitting mills specialised in the production of nails. The Horns public house and St John the Baptist, Church of England are in the village. A water pumping station, owned by South Staffordshire Water, draws water from the ground beneath t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Electric Motors

An electric motor is a machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate Laplace force in the form of torque applied on the motor's shaft. An electric generator is mechanically identical to an electric motor, but operates in reverse, converting mechanical energy into electrical energy. Electric motors can be powered by direct current (DC) sources, such as from batteries or rectifiers, or by alternating current (AC) sources, such as a power grid, inverters or electrical generators. Electric motors may also be classified by considerations such as power source type, construction, application and type of motion output. They can be brushed or brushless, single-phase, two-phase, or three-phase, axial or radial flux, and may be air-cooled or liquid-cooled. Standardized electric motors provide power for industrial use. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Boulton And Watt

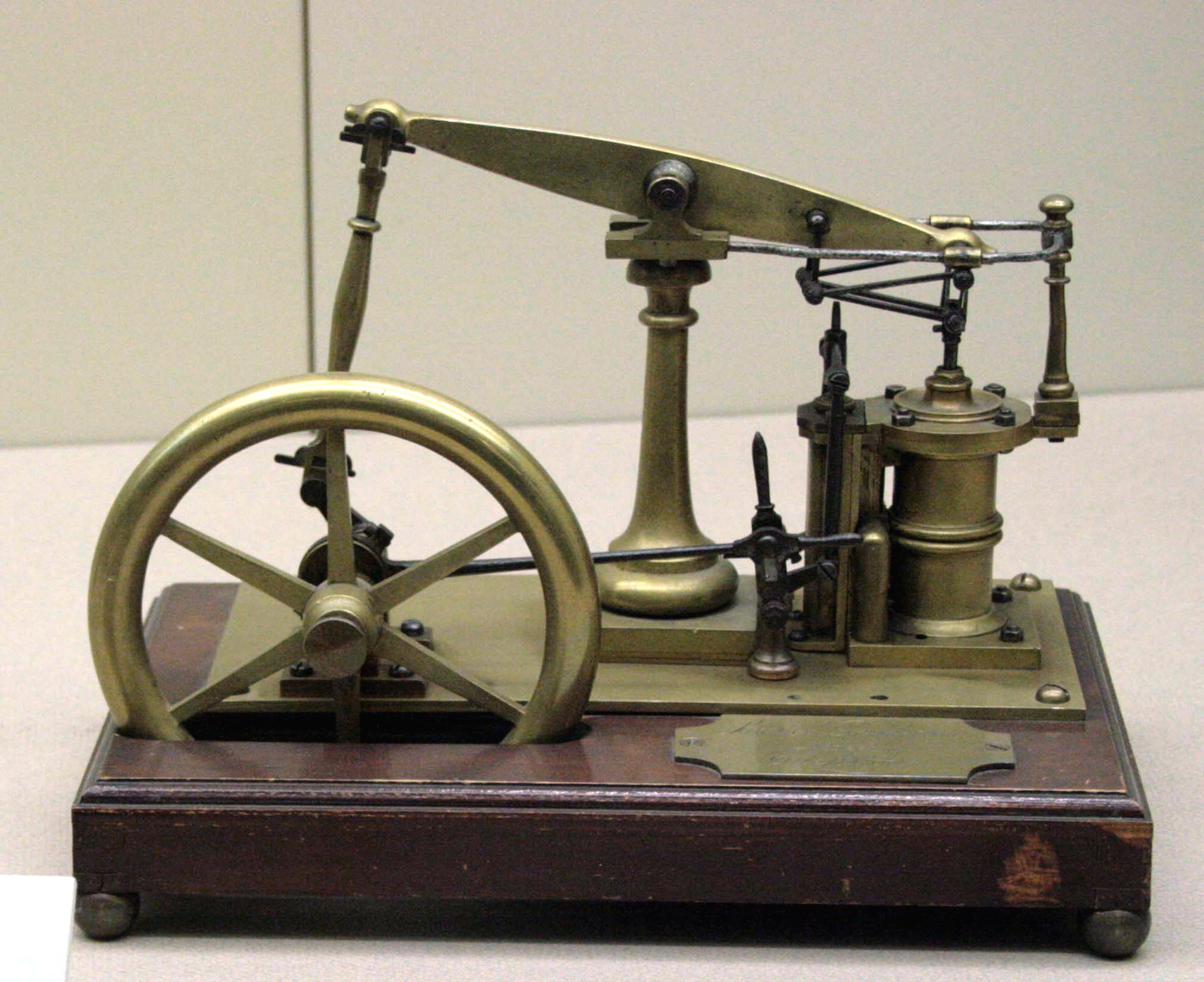

Boulton & Watt was an early British engineering and manufacturing firm in the business of designing and making marine and stationary steam engines. Founded in the English West Midlands around Birmingham in 1775 as a partnership between the English manufacturer Matthew Boulton and the Scottish engineer James Watt, the firm had a major role in the Industrial Revolution and grew to be a major producer of steam engines in the 19th century. The engine partnership The partnership was formed in 1775 to exploit Watt's patent for a steam engine with a separate condenser. This made much more efficient use of its fuel than the older Newcomen engine. Initially the business was based at the Soho Manufactory near Boulton's Soho House on the southern edge of the then-rural parish of Handsworth. However most of the components for their engines were made by others, for example the cylinders by John Wilkinson. In 1795, they began to make steam engines themselves at their Soho Foundry ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

John Wilkinson (industrialist)

John "Iron-Mad" Wilkinson (1728 – 14 July 1808) was an English industrialist who pioneered the manufacture of cast iron and the use of cast-iron goods during the Industrial Revolution. He was the inventor of a precision boring machine that could bore cast iron cylinders, such as cannon barrels and piston cylinders used in the steam engines of James Watt. His boring machine has been called the first machine tool. He also developed a blowing device for blast furnaces that allowed higher temperatures, increasing their efficiency, and helped sponsor the first iron bridge in Coalbrookdale. He is notable for his method of cannon boring, his techniques at casting iron and his work with the government of France to establish a cannon foundry. Biography Early life John Wilkinson was born in Little Clifton, Bridgefoot, Cumberland (now part of Cumbria), the eldest son of Isaac Wilkinson and Mary Johnson. Isaac was then the potfounder at the blast furnace there, one of the first ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Steam Engine

A steam engine is a heat engine that performs Work (physics), mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a Cylinder (locomotive), cylinder. This pushing force can be transformed by a connecting rod and Crank (mechanism), crank into rotational force for work. The term "steam engine" is most commonly applied to reciprocating engines as just described, although some authorities have also referred to the steam turbine and devices such as Hero's aeolipile as "steam engines". The essential feature of steam engines is that they are external combustion engines, where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term ''steam engine'' can refer to either complete steam plants (including Boiler (power generation), boilers etc.), such as railway steam locomot ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Water Wheels

A water wheel is a machine for converting the kinetic energy of flowing or falling water into useful forms of power, often in a watermill. A water wheel consists of a large wheel (usually constructed from wood or metal), with numerous blades or buckets attached to the outer rim forming the drive mechanism. Water wheels were still in commercial use well into the 20th century, although they are no longer in common use today. Water wheels are used for milling flour in gristmills, grinding wood into pulp for papermaking, hammering wrought iron, machining, ore crushing and pounding fibre for use in the manufacture of cloth. Some water wheels are fed by water from a mill pond, which is formed when a flowing stream is dammed. A channel for the water flowing to or from a water wheel is called a mill race. The race bringing water from the mill pond to the water wheel is a headrace; the one carrying water after it has left the wheel is commonly referred to as a tailrace. Waterwhee ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Christopher Polhem

Christopher Polhammar (18 December 1661 – 30 August 1751) better known as Christopher Polhem (), which he took after his ennoblement in 1716, was a Swedish scientist, inventor, and industrialist. He made significant contributions to the economic and industrial development of Sweden, particularly mining. He was ennobled by King Charles XII of Sweden for his contributions to Swedish technological development.Christopher Polhem Svenskt biografiskt lexicon Biography Polhem (Polhammar) was born on the island of in the village of Tingstäde, north-east of |

Tinplate

Tinplate consists of sheet metal, sheets of steel coated with a thin layer of tin to impede rust, rusting. Before the advent of cheap mild steel, the backing metal (known as "") was wrought iron. While once more widely used, the primary use of tinplate now is the manufacture of steel and tin cans, tin cans. In the tinning process, tinplate is made by rolling the steel (or formerly iron) in a rolling mill, removing any mill scale by pickling it in acid and then coating it with a thin layer of tin. Plates were once produced individually (or in small groups) in what became known as a ''pack mill''. In the late 1920s pack mills began to be replaced by ''strip mills'' which produced larger quantities more economically. Formerly, tinplate was used for tin ceiling, and holloware (cheap pots and pans), also known as tinware. The people who made tinware (metal spinning) were tinplate workers. For many purposes, tinplate has been replaced by galvanised metal, the base being treated with a z ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Blackplate

Blackplate is hot rolled or cold rolled,DIN 55405:2006-11 ''Verpackung - Terminologie - Begriffe'', Berlin: Beuth Verlag. non- descaled sheet steel or sheet iron.''Blackplate'' at www.merriam-webster.com. Retrieved 30 Apr 2017. Manufacture and properties Blackplate is made of non- iron or and is annealed on open flames or in an annealing box. Its dark appearance is caused by its reaction with the surrounding air.[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Pontypool

Pontypool ( ) is a town and the administrative centre of the county borough of Torfaen, within the Historic counties of Wales, historic boundaries of Monmouthshire (historic), Monmouthshire in South Wales. , it has a population of 29,062. Location It is situated on the Afon Lwyd river in the county borough of Torfaen. Located at the eastern edge of the South Wales coalfields, Pontypool grew around industries including iron and steel production, coal mining, and the growth of the railways. A rather artistic manufacturing industry which also flourished here alongside heavy industry was Japanning, a type of lacquer ware. Pontypool covers several areas, hamlets, villages and towns including New Inn, Torfaen, New Inn, Griffithstown, Sebastopol (Panteg.) Abersychan, Cwmffrwdoer, Pontnewynydd, Trevethin, Penygarn, Torfaen, Penygarn, Wainfelin, Tranch, Brynwern, Pontymoile, Blaendare, Cwmynyscoy, Talywain, Garndiffaith, Pentwyn, Torfaen, Pentwyn, and Varteg. History The name of the to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |