|

Mixer Settler

Mixer settlers are a class of mineral process equipment used in the solvent extraction process. A mixer settler consists of a first stage that ''mixes'' the phases together followed by a quiescent ''settling'' stage that allows the phases to separate by gravity. Mixer A mixing chamber where a mechanical agitator brings in intimate contact the feed solution and the solvent to carry out the transfer of solute(s). The mechanical agitator is equipped with a motor which drives a mixing and pumping turbine. This turbine draws the two phases from the settlers of the adjacent stages, mixes them, and transfers this emulsion to the associated settler. The mixer may consists of one or multiple stages of mixing tanks. Common laboratory mixers consist of a single mixing stage, whereas industrial scale copper mixers may consist of up to three mixer stages where each stage performs a combined pumping and mixing action. Use of multiple stages allows a longer reaction time and also minimizes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

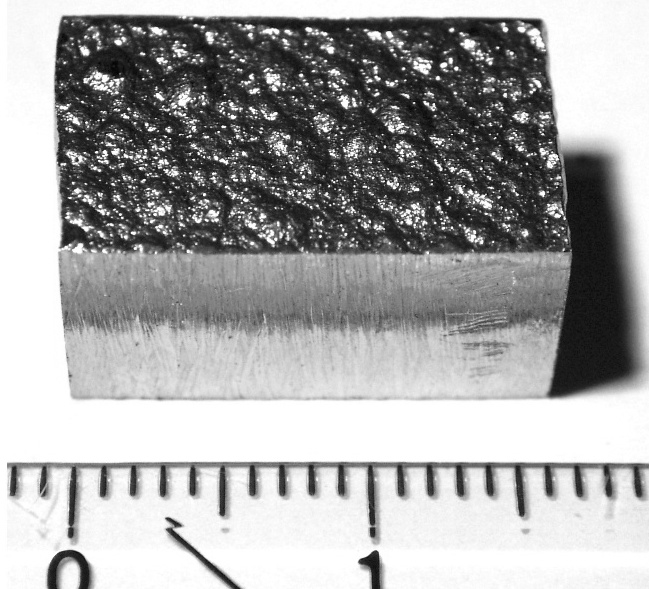

Copper Ore

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orange color. Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling silver used in jewelry, cupronickel used to make marine hardware and coins, and constantan used in strain gauges and thermocouples for temperature measurement. Copper is one of the few metals that can occur in nature in a directly usable, unalloyed metallic form. This means that copper is a native metal. This led to very early human use in several regions, from . Thousands of years later, it was the first metal to be smelted from sulfide ores, ; the first metal to be cast into a shape in a mold, ; and the first metal to be purposely alloyed with another metal, tin, to create bronze, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mineral Processing

Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling. Beneficiation is any process that improves (benefits) the economic value of the ore by removing the gangue minerals, which results in a higher grade product (ore concentrate) and a waste stream (tailings). There are many different types of beneficiation, with each step furthering the concentration of the original ore. Key is the concept of recovery (mineral processing), recovery, the mass (or equivalently molar) fraction of the valuable mineral (or metal) extracted from the ore and carried across to the concentrate. History Before the advent of heavy machinery, raw ore was broken up using hammers wielded by hand, a process called "''spalling''". Eventually, mechanical means were found to achieve this. For instance, stamp mills were being ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrometallurgy

Hydrometallurgy is a technique within the field of extractive metallurgy, the obtaining of metals from their ores. Hydrometallurgy uses solutions to recover metals from ores, concentrates, and recycled or residual materials. Usually the extracting solution is aqueous (water-based), often containing additives such as acids. In select cases, the extracting solvent is nonaqueous. Brent Hiskey "Metallurgy, Survey" in Kirk-Othmer Encyclopedia of Chemical Technology, 2000, Wiley-VCH, Weinheim. Processing techniques that complement hydrometallurgy are pyrometallurgy, vapour metallurgy, and molten salt electrometallurgy. Hydrometallurgy is typically divided into three general areas: *Leaching *Solution concentration and purification *Metal or metal compound recovery Leaching : Leaching (metallurgy), Leaching involves the use of aqueous solutions to extract metal from metal-bearing materials. The extracting solution is called a lixiviant. The lixiviant is optimized in terms of pH, ox ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solvent Extraction

A solvent (from the Latin language, Latin ''wikt:solvo#Latin, solvō'', "loosen, untie, solve") is a substance that dissolves a solute, resulting in a Solution (chemistry), solution. A solvent is usually a liquid but can also be a solid, a gas, or a supercritical fluid. Water is a solvent for Chemical polarity#Polarity of molecules, polar molecules, and the most common solvent used by living things; all the ions and proteins in a Cell (biology), cell are dissolved in water within the cell. Major uses of solvents are in paints, paint removers, inks, and dry cleaning. Specific uses for Organic compound, organic solvents are in dry cleaning (e.g. tetrachloroethylene); as paint thinners (toluene, turpentine); as nail polish removers and solvents of glue (acetone, methyl acetate, ethyl acetate); in spot removers (hexane, petrol ether); in detergents (D-limonene, citrus terpenes); and in perfumes (ethanol). Solvents find various applications in chemical, pharmaceutical, oil, and gas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrowinning

Electrowinning, also called electroextraction, is the electrodeposition of metals from their ores that have been put in solution via a process commonly referred to as leaching. Electrorefining uses a similar process to remove impurities from a metal. Both processes use electroplating on a large scale and are important techniques for the economical and straightforward purification of non-ferrous metals. The resulting metals are said to be ''electrowon''. In electrowinning, an electrical current is passed from an inert anode through a ''leach'' solution containing the dissolved metal ions so that the metal is recovered as it is reduced and deposited in an electroplating process onto the cathode. In electrorefining, the anode consists of the impure metal (e.g., copper) to be refined. The impure metallic anode is oxidized and the metal dissolves into solution. The metal ions migrate through the electrolyte towards the cathode where the pure metal is deposited. Insoluble solid impur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pregnant Leach Solution

Pregnant leach solution or pregnant liquor solution (PLS) is acidic metal-laden water generated from stockpile leaching and heap leaching. Pregnant leach solution is used in the solvent extraction and electrowinning (SX/EW) process. The portion of an original liquid that remains after other components have been dissolved by a solvent is called ''raffinate In chemical separation terminology, the raffinate (from French ''raffiner'', to refine) is a product which has had a component or components removed. The product having the removed materials is referred to as the extract. For example, in solvent e ...''. References Metallurgical processes {{Industry-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heap Leaching

Heap leaching is an industrial mining process used to extract precious metals, copper, uranium, and other compounds from ore using a series of chemical reactions that absorb specific minerals and re-separate them after their division from other earth materials. Similar to In situ leach, in situ mining, heap leach mining differs in that it places ore on a liner, then adds the chemicals via drip systems to the ore, whereas ''in situ'' mining lacks these liners and pulls pregnant solution up to obtain the minerals. Heap leaching is widely used in modern large-scale mining operations as it produces the desired concentrates at a lower cost compared to conventional processing methods such as flotation, agitation, and vat leaching. Additionally, dump leaching is an essential part of most copper mining operations and determines the quality grade of the produced material along with other factors Due to the profitability that the dump leaching has on the mining process, i.e. it can contri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrometallurgy

Hydrometallurgy is a technique within the field of extractive metallurgy, the obtaining of metals from their ores. Hydrometallurgy uses solutions to recover metals from ores, concentrates, and recycled or residual materials. Usually the extracting solution is aqueous (water-based), often containing additives such as acids. In select cases, the extracting solvent is nonaqueous. Brent Hiskey "Metallurgy, Survey" in Kirk-Othmer Encyclopedia of Chemical Technology, 2000, Wiley-VCH, Weinheim. Processing techniques that complement hydrometallurgy are pyrometallurgy, vapour metallurgy, and molten salt electrometallurgy. Hydrometallurgy is typically divided into three general areas: *Leaching *Solution concentration and purification *Metal or metal compound recovery Leaching : Leaching (metallurgy), Leaching involves the use of aqueous solutions to extract metal from metal-bearing materials. The extracting solution is called a lixiviant. The lixiviant is optimized in terms of pH, ox ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solvent Extraction

A solvent (from the Latin language, Latin ''wikt:solvo#Latin, solvō'', "loosen, untie, solve") is a substance that dissolves a solute, resulting in a Solution (chemistry), solution. A solvent is usually a liquid but can also be a solid, a gas, or a supercritical fluid. Water is a solvent for Chemical polarity#Polarity of molecules, polar molecules, and the most common solvent used by living things; all the ions and proteins in a Cell (biology), cell are dissolved in water within the cell. Major uses of solvents are in paints, paint removers, inks, and dry cleaning. Specific uses for Organic compound, organic solvents are in dry cleaning (e.g. tetrachloroethylene); as paint thinners (toluene, turpentine); as nail polish removers and solvents of glue (acetone, methyl acetate, ethyl acetate); in spot removers (hexane, petrol ether); in detergents (D-limonene, citrus terpenes); and in perfumes (ethanol). Solvents find various applications in chemical, pharmaceutical, oil, and gas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cobalt

Cobalt is a chemical element; it has Symbol (chemistry), symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. The free element, produced by reductive smelting, is a hard, lustrous, somewhat brittle, gray metal. Cobalt-based blue pigments (cobalt blue) have been used since antiquity for jewelry and paints, and to impart a distinctive blue tint to glass. The color was long thought to be due to the metal bismuth. Miners had long used the name ''kobold ore'' (German language, German for ''goblin ore'') for some of the blue pigment-producing minerals. They were so named because they were poor in known metals and gave off poisonous arsenic-containing fumes when smelted. In 1735, such ores were found to be reducible to a new metal (the first discovered since ancient times), which was ultimately named for the ''kobold''. Today, some cobalt is produced sp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lanthanide

The lanthanide () or lanthanoid () series of chemical elements comprises at least the 14 metallic chemical elements with atomic numbers 57–70, from lanthanum through ytterbium. In the periodic table, they fill the 4f orbitals. Lutetium (element 71) is also sometimes considered a lanthanide, despite being a d-block element and a transition metal. The informal chemical symbol Ln is used in general discussions of lanthanide chemistry to refer to any lanthanide. All but one of the lanthanides are f-block elements, corresponding to the filling of the 4f electron shell. Lutetium is a d-block element (thus also a transition metal), and on this basis its inclusion has been questioned; however, like its congeners scandium and yttrium in group 3, it behaves similarly to the other 14. The term rare-earth element or rare-earth metal is often used to include the stable group 3 elements Sc, Y, and Lu in addition to the 4f elements. All lanthanide elements form trivalent cations, Ln3+, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |