|

Micro-mechanics Of Failure

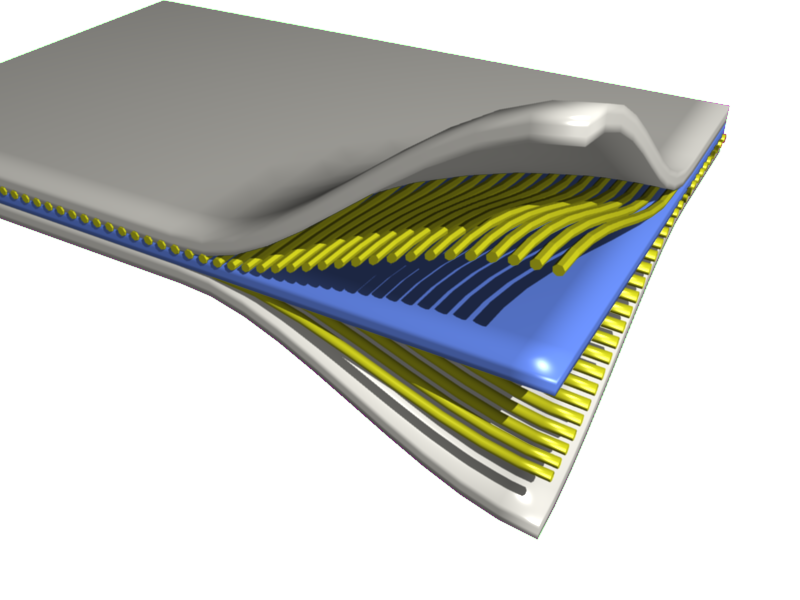

The theory of micro-mechanics of failure aims to explain the material failure, failure of fibre-reinforced plastic, continuous fiber reinforced composites by micro-scale analysis of stresses within each constituent material (such as fiber and matrix), and of the stresses at the interfaces between those constituents, calculated from the macro stresses at the ply level. As a completely mechanics-based failure theory, the theory is expected to provide more accurate analyses than those obtained with phenomenological models such as Tsai-Wu failure criterion, Tsai-Wu and Hashin failure criteria, being able to distinguish the critical constituent in the critical ply in a composite laminate. Basic concepts The basic concept of the micro-mechanics of failure (MMF) theory is to perform a hierarchy of micromechanical analyses, starting from mechanical behavior of constituents (the fiber, the matrix, and the interface), then going on to the mechanical behavior of a ply, of a laminate, and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hierarchy Of Micromechanics-based Analysis Procedure For Composite Structures

A hierarchy (from Ancient Greek, Greek: , from , 'president of sacred rites') is an arrangement of items (objects, names, values, categories, etc.) that are represented as being "above", "below", or "at the same level as" one another. Hierarchy is an important concept in a wide variety of fields, such as architecture, philosophy, design, mathematics, computer science, organizational theory, systems theory, systematic biology, and the social sciences (especially political science). A hierarchy can link entities either directly or indirectly, and either vertically or diagonally. The only direct links in a hierarchy, insofar as they are hierarchical, are to one's immediate superior or to one of one's subordinates, although a system that is largely hierarchical can also incorporate alternative hierarchies. Hierarchical links can extend "vertically" upwards or downwards via multiple links in the same direction, following a path (graph theory), path. All parts of the hierarchy that are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Linear Elasticity

Linear elasticity is a mathematical model of how solid objects deform and become internally stressed by prescribed loading conditions. It is a simplification of the more general nonlinear theory of elasticity and a branch of continuum mechanics. The fundamental assumptions of linear elasticity are infinitesimal strains — meaning, "small" deformations — and linear relationships between the components of stress and strain — hence the "linear" in its name. Linear elasticity is valid only for stress states that do not produce yielding. Its assumptions are reasonable for many engineering materials and engineering design scenarios. Linear elasticity is therefore used extensively in structural analysis and engineering design, often with the aid of finite element analysis. Mathematical formulation Equations governing a linear elastic boundary value problem are based on three tensor partial differential equations for the balance of linear momentum and six in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanics

Mechanics () is the area of physics concerned with the relationships between force, matter, and motion among Physical object, physical objects. Forces applied to objects may result in Displacement (vector), displacements, which are changes of an object's position relative to its environment. Theoretical expositions of this branch of physics has its origins in Ancient Greece, for instance, in the writings of Aristotle and Archimedes (see History of classical mechanics and Timeline of classical mechanics). During the early modern period, scientists such as Galileo Galilei, Johannes Kepler, Christiaan Huygens, and Isaac Newton laid the foundation for what is now known as classical mechanics. As a branch of classical physics, mechanics deals with bodies that are either at rest or are moving with velocities significantly less than the speed of light. It can also be defined as the physical science that deals with the motion of and forces on bodies not in the quantum realm. History ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Christensen Failure Criterion

The Christensen failure criterion is a material failure theory for isotropic materials that attempts to span the range from ductile to brittle materials. It has a two-property form calibrated by the uniaxial tensile and compressive strengths T \left (\sigma_T\right ) and C \left (\sigma_C\right ). The theory was developed by Stanford professor Richard. M. Christensen and first published in 1997. Description The Christensen failure criterion is composed of two separate subcriteria representing competitive failure mechanisms. When expressed in principal stress components, it is given by : ;Polynomial invariants failure criterion For 0\le\frac\le1 ;Coordinated Fracture Criterion For 0\le \frac\le \frac The geometric form of () is that of a paraboloid in principal stress space. The fracture criterion () (applicable only over the partial range 0 ≤ T/C ≤ 1/2 ) cuts slices off the paraboloid, leaving three flattened elliptical surfaces on it. The fracture cutof ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Material Failure Theory

Material failure theory is an interdisciplinary field of materials science and solid mechanics which attempts to predict the conditions under which solid materials fail under the action of external loads. The failure of a material is usually classified into brittle failure (fracture) or ductile failure ( yield). Depending on the conditions (such as temperature, state of stress, loading rate) most materials can fail in a brittle or ductile manner or both. However, for most practical situations, a material may be classified as either brittle or ductile. In mathematical terms, failure theory is expressed in the form of various failure criteria which are valid for specific materials. Failure criteria are functions in stress or strain space which separate "failed" states from "unfailed" states. A precise physical definition of a "failed" state is not easily quantified and several working definitions are in use in the engineering community. Quite often, phenomenological failure ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strength Of Materials

Strength may refer to: Personal trait *Physical strength, as in people or animals *Character strengths like those listed in the Values in Action Inventory *The exercise of willpower Physics * Mechanical strength, the ability to withstand an applied stress or load without structural failure ** Compressive strength, the capacity to withstand axially directed pushing forces **Tensile strength, the maximum stress while being stretched or pulled before necking ** Shear strength, the ability to withstand shearing * Strength (explosive), the ability of an explosive to move surrounding material * Field strength, the magnitude of a field's vector * Signal strength, in telecommunications *Strength (material), the behavior of solid objects subject to stresses and strains Music * Strength (American band), a band from Portland, Oregon * Strength (Japanese band), a band from Sendai, Miyagi, Japan * ''Strength'' (The Alarm album), 1985 * ''Strength'' (Enuff Z'nuff album), 1991 *''Stre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Material

A composite or composite material (also composition material) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Composite materials with more than one distinct layer are called ''composite laminates''. Typical engineered composite materials are made up of a binding agent forming the ''matrix'' and a Filler (materials), filler material (particulates or fibres) giving ''substance'', e.g.: * Concrete, reinforced concrete and masonry with cement, lime or Mortar (masonry), mortar (which is itself a composite material) as a binder * Composite wood such as glulam and plywood with wood glue as a binder * Reinforced plastics, such as fiberglass and fibre-rein ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Macaulay Brackets

Macaulay brackets are a notation used to describe the ramp function :\ = \begin 0, & x < 0 \\ x, & x \ge 0. \end A popular alternative transcription uses angle brackets, ''viz.'' . Introduction to Aerospace Structures. Department of Aerospace Engineering Sciences, University of Colorado at Boulder Another commonly used notation is + or + for the positive part of , which avoids conflicts with for set notation [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress (mechanics)

In continuum mechanics, stress is a physical quantity that describes forces present during deformation. For example, an object being pulled apart, such as a stretched elastic band, is subject to ''tensile'' stress and may undergo elongation. An object being pushed together, such as a crumpled sponge, is subject to ''compressive'' stress and may undergo shortening. The greater the force and the smaller the cross-sectional area of the body on which it acts, the greater the stress. Stress has dimension of force per area, with SI units of newtons per square meter (N/m2) or pascal (Pa). Stress expresses the internal forces that neighbouring particles of a continuous material exert on each other, while ''strain'' is the measure of the relative deformation of the material. For example, when a solid vertical bar is supporting an overhead weight, each particle in the bar pushes on the particles immediately below it. When a liquid is in a closed container under pressure, each ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compressive Strength

In mechanics, compressive strength (or compression strength) is the capacity of a material or Structural system, structure to withstand Structural load, loads tending to reduce size (Compression (physics), compression). It is opposed to ''tensile strength'' which withstands loads tending to elongate, resisting Tension (physics), tension (being pulled apart). In the study of strength of materials, compressive strength, tensile strength, and shear strength can be analyzed independently. Some materials fracture at their compressive strength limit; others Plasticity (physics), deform irreversibly, so a given amount of Deformation (engineering), deformation may be considered as the limit for compressive load. Compressive strength is a key value for Structural engineering, design of structures. Compressive strength is often measured on a universal testing machine. Measurements of compressive strength are affected by the specific test method and conditions of measurement. Compressive s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Von Mises Yield Criterion

In continuum mechanics, the maximum distortion energy criterion (also von Mises yield criterion) states that yielding of a ductile material begins when the second invariant of deviatoric stress J_2 reaches a critical value. It is a part of plasticity theory that mostly applies to ductile materials, such as some metals. Prior to yield, material response can be assumed to be of a linear elastic, nonlinear elastic, or viscoelastic In materials science and continuum mechanics, viscoelasticity is the property of materials that exhibit both Viscosity, viscous and Elasticity (physics), elastic characteristics when undergoing deformation (engineering), deformation. Viscous mate ... behavior. In materials science and engineering, the von Mises yield criterion is also formulated in terms of the von Mises stress or equivalent tensile stress, \sigma_\text. This is a scalar value of stress that can be computed from the Cauchy stress tensor. In this case, a material is said to start y ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coefficient Of Thermal Expansion

Thermal expansion is the tendency of matter to increase in length, area, or volume, changing its size and density, in response to an increase in temperature (usually excluding phase transitions). Substances usually contract with decreasing temperature (thermal contraction), with rare exceptions within limited temperature ranges ('' negative thermal expansion''). Temperature is a monotonic function of the average molecular kinetic energy of a substance. As energy in particles increases, they start moving faster and faster, weakening the intermolecular forces between them and therefore expanding the substance. When a substance is heated, molecules begin to vibrate and move more, usually creating more distance between themselves. The relative expansion (also called strain) divided by the change in temperature is called the material's coefficient of linear thermal expansion and generally varies with temperature. Prediction If an equation of state is available, it can be used t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |