|

Methane Reformer

A methane reformer is a device based on steam reforming, autothermal reforming or partial oxidation and is a type of chemical synthesis which can produce pure hydrogen gas from methane using a catalyst. There are multiple types of reformers in development but the most common in industry are autothermal reforming (ATR) and steam methane reforming (SMR). Most methods work by exposing methane to a catalyst (usually nickel) at high temperature and pressure. Steam reforming Steam reforming (SR), sometimes referred to as steam methane reforming (SMR) uses an external source of hot gas to heat tubes in which a catalytic reaction takes place that converts steam and lighter hydrocarbons such as methane, biogas or refinery feedstock into hydrogen and carbon monoxide (syngas). Syngas reacts further to give more hydrogen and carbon dioxide in the reactor. The carbon oxides are removed before use by means of pressure swing adsorption (PSA) with molecular sieves for the final purification. The P ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steam Reforming

Steam reforming or steam methane reforming (SMR) is a method for producing syngas (hydrogen and carbon monoxide) by reaction of hydrocarbons with water. Commonly, natural gas is the feedstock. The main purpose of this technology is often hydrogen production, although syngas has multiple other uses such as production of Ammonia production, ammonia or methanol. The reaction is represented by this equilibrium: :CH4 + H2O CO + 3 H2 The reaction is strongly endothermic (Δ''H''SR = 206 kJ/mol). Hydrogen produced by steam reforming is termed grey hydrogen, 'grey' hydrogen when the waste carbon dioxide is released to the atmosphere and blue hydrogen, 'blue' hydrogen when the carbon dioxide is (mostly) captured and stored geologically—see carbon capture and storage. Zero carbon green hydrogen, 'green' hydrogen is produced by Thermochemical cycle, thermochemical water splitting, using solar thermal, low- or zero-carbon electricity or waste heat, or electrolysis, using low- or zero-carb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bar (unit)

The bar is a metric unit of pressure defined as 100,000 Pa (100 kPa), though not part of the International System of Units (SI). A pressure of 1 bar is slightly less than the current average atmospheric pressure on Earth at sea level (approximately 1.013 bar). By the barometric formula, 1 bar is roughly the atmospheric pressure on Earth at an altitude of 111 metres at 15 °C. The bar and the millibar were introduced by the Norwegian meteorologist Vilhelm Bjerknes, who was a founder of the modern practice of weather forecasting, with the bar defined as one megadyne per square centimetre. The SI brochure, despite previously mentioning the bar, now omits any mention of it.. The bar has been legally recognised in countries of the European Union since 2004. British Standard BS 350:2004 ''Conversion Factors for Units''. The US National Institute of Standards and Technology (NIST) deprecates its use except for "limited use in meteorology" and lists ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Cells

A fuel cell is an electrochemical cell that converts the chemical energy of a fuel (often hydrogen) and an oxidizing agent (often oxygen) into electricity through a pair of redox reactions. Fuel cells are different from most batteries in requiring a continuous source of fuel and oxygen (usually from air) to sustain the chemical reaction, whereas in a battery the chemical energy usually comes from substances that are already present in the battery. Fuel cells can produce electricity continuously for as long as fuel and oxygen are supplied. The first fuel cells were invented by Sir William Grove in 1838. The first commercial use of fuel cells came almost a century later following the invention of the hydrogen–oxygen fuel cell by Francis Thomas Bacon in 1932. The alkaline fuel cell, also known as the Bacon fuel cell after its inventor, has been used in NASA space programs since the mid-1960s to generate power for satellites and space capsules. Since then, fuel cells hav ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

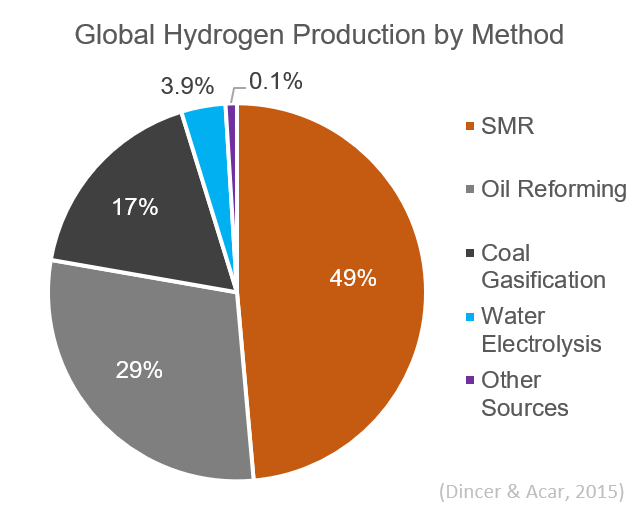

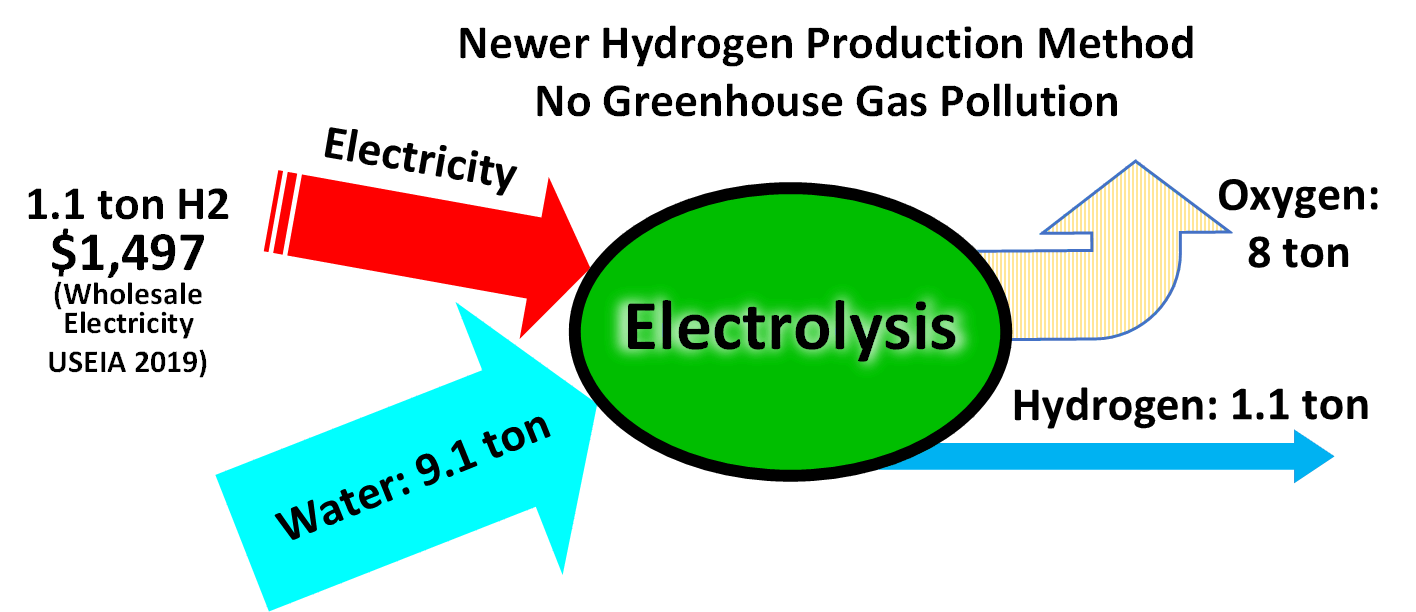

Hydrogen Production

Hydrogen gas is produced by several industrial methods. Nearly all of the world's current supply of hydrogen is created from fossil fuels. Article in press. Most hydrogen is ''gray hydrogen'' made through steam methane reforming. In this process, hydrogen is produced from a chemical reaction between steam and methane, the main component of natural gas. Producing one tonne of hydrogen through this process emits 6.6–9.3 tonnes of carbon dioxide. When carbon capture and storage is used to remove a large fraction of these emissions, the product is known as ''blue hydrogen''. ''Green hydrogen'' is usually understood to be produced from Renewable energy, renewable electricity via electrolysis of water. Less frequently, definitions of ''green hydrogen'' include hydrogen produced from other low-emission sources such as Biomass (energy), biomass. Producing green hydrogen is currently more expensive than producing gray hydrogen, and the efficiency of energy conversion is inherently low. O ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Looping Reforming And Gasification

Chemical looping reforming (CLR) and gasification (CLG) are the operations that involve the use of gaseous carbonaceous feedstock and solid carbonaceous feedstock, respectively, in their conversion to syngas in the chemical looping scheme. The typical gaseous carbonaceous feedstocks used are natural gas and reducing tail gas, while the typical solid carbonaceous feedstocks used are coal and biomass. The feedstocks are partially oxidized to generate syngas using metal oxide oxygen carriers as the oxidant. The reduced metal oxide is then oxidized in the regeneration step using air. The syngas is an important intermediate for generation of such diverse products as electricity, chemicals, hydrogen, and liquid fuels. The motivation for developing the CLR and CLG processes lies in their advantages of being able to avoid the use of pure oxygen in the reaction, thereby circumventing the energy intensive air separation requirement in the conventional methane reformer, reforming and gasifica ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Partial Oxidation

Partial oxidation (POX) is a type of chemical reaction. It occurs when a substoichiometric fuel-air mixture is partially combusted in a reformer, creating a hydrogen-rich syngas which can then be put to further use, for example in a fuel cell. A distinction is made between ''thermal partial oxidation'' (TPOX) and ''catalytic partial oxidation'' (CPOX). Principle Partial oxidation is a technically mature process in which natural gas or a heavy hydrocarbon fuel (heating oil) is mixed with a limited amount of oxygen in an exothermic process. * General reaction: + \frac\mathit -> \mathit + \frac\mathitH2 * Idealized reaction for heating oil: + 6O2 -> + 12H2 * Idealized reaction for coal: + 12O2 -> + 6H2 The formulas given for coal and heating oil show only a typical representative of these complex fuels. Water may be added to lower the combustion temperature and reduce soot formation. Yields are below stoichiometric due to some fuel being fully combusted to carbon dioxide and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

PROX

PROX is an acronym for PReferential OXidation, that refers to the preferential oxidation of carbon monoxide in a gas mixture by a catalyst. It is intended to remove trace amounts of CO from H2/CO/CO2 mixtures produced by steam reforming and water-gas shift. An ideal PROX catalyst preferentially oxidizes carbon monoxide (CO) using a heterogeneous catalyst placed upon a ceramic support. Catalysts include metals such as platinum, platinum/iron, platinum/ruthenium, gold nanoparticles as well as novel copper oxide/ceramic conglomerate catalysts. Motivation This reaction is a considerable subject area of research with implications for fuel cell design. Its main utility lies in the removal of carbon monoxide (CO) from the fuel cell's feed gas. CO poisons the catalyst of most low-temperature fuel cells. Carbon monoxide is often produced as a by-product from steam reforming of hydrocarbons, which produces hydrogen and CO. It is possible to consume most of the CO by reacting it with steam ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reformed Methanol Fuel Cell

Reformed Methanol Fuel Cell (RMFC) or Indirect Methanol Fuel Cell (IMFC) systems are a subcategory of proton-exchange fuel cells where, the fuel, methanol (CH3OH), is reformed, before being fed into the fuel cell. RMFC systems offer advantages over direct methanol fuel cell (DMFC) systems including higher efficiency, smaller cell stacks, less requirement on methanol purity, no water management, better operation at low temperatures, and storage at sub-zero temperatures because methanol is a liquid from and as there is no liquid methanol-water mixture in the cells which can destroy the membrane of DMFC in case of frost. The reason for the high efficiency of RMFC in contrast to DMFC is that hydrogen containing gas is fed to the fuel cell stack instead of methanol and overpotential (power loss for catalytic conversion) on anode is much lower for hydrogen than for methanol. The tradeoff is that RMFC systems operate at hotter temperatures and therefore need more advanced heat man ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Gas

Industrial gases are the gaseous materials that are Manufacturing, manufactured for use in Industrial sector, industry. The principal gases provided are nitrogen, oxygen, carbon dioxide, argon, hydrogen, helium and acetylene, although many other gases and mixtures are also available in gas cylinders. The industry producing these gases is also known as industrial gas, which is seen as also encompassing the supply of equipment and technology to produce and use the gases. Their production is a part of the wider chemical Industry (where industrial gases are often seen as "specialty chemicals"). Industrial gases are used in a wide range of industries, which include petroleum industry, oil and gas, petrochemicals, chemical industry, chemicals, electric power industry, power, mining, steelmaking, metals, Environmentalism, environmental protection, medicine, Pharmaceutical drug, pharmaceuticals, biotechnology, food Industry, food, Water industry, water, fertilizers, nuclear power, electr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Catalytic Reforming

Catalytic reforming is a chemical process used to convert petroleum naphtha, naphthas from crude oil into liquid products called reformates, which are premium "blending stocks" for high-octane gasoline. The process converts low-octane linear hydrocarbons (paraffins) into branched alkanes (isoparaffins) and cyclic naphthenes, which are then partially dehydrogenated to produce high-octane aromatic hydrocarbons. The dehydrogenation also produces significant amounts of byproduct hydrogen gas, which is fed into other refinery processes such as hydrocracking. A side reaction is hydrogenolysis, which produces light hydrocarbons of lower value, such as methane, ethane, propane and butanes. In addition to a gasoline blending stock, reformate is the main source of aromatic bulk chemicals such as benzene, toluene, xylene and ethylbenzene, which have diverse uses, most importantly as raw materials for conversion into plastics. However, the benzene content of reformate makes it carcinogenic, w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dimethyl Ether

Dimethyl ether (DME; also known as methoxymethane) is the organic compound with the formula CH3OCH3, (sometimes ambiguously simplified to C2H6O as it is an isomer of ethanol). The simplest ether, it is a colorless gas that is a useful precursor to other organic compounds and an aerosol propellant that is currently being demonstrated for use in a variety of fuel applications. Dimethyl ether was first synthesised by Jean-Baptiste Dumas and Eugene Péligot in 1835 by distillation of methanol and sulfuric acid. Production Approximately 50,000 tons were produced in 1985 in Western Europe by dehydration of methanol:Manfred Müller, Ute Hübsch, "Dimethyl Ether" in Ullmann's Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim, 2005. : The required methanol is obtained from synthesis gas ( syngas). Other possible improvements call for a dual catalyst system that permits both methanol synthesis and dehydration in the same process unit, with no methanol isolation and purificatio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Biofuel

Biofuel is a fuel that is produced over a short time span from Biomass (energy), biomass, rather than by the very slow natural processes involved in the formation of fossil fuels such as oil. Biofuel can be produced from plants or from agricultural, domestic or industrial Biodegradable waste, bio waste. Biofuels are mostly used for transportation, but can also be used for heating and electricity. Biofuels (and bioenergy, bio energy in general) are regarded as a renewable energy source. The use of biofuel has been subject to criticism regarding the "food vs fuel" debate, varied assessments of their Sustainable biofuel, sustainability, and ongoing deforestation and biodiversity loss as a result of biofuel production. In general, biofuels emit fewer greenhouse gas emissions when burned in an engine and are generally considered carbon-neutral fuels as the carbon emitted has been captured from the atmosphere by the crops used in production. However, life-cycle assessments of biofue ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |