|

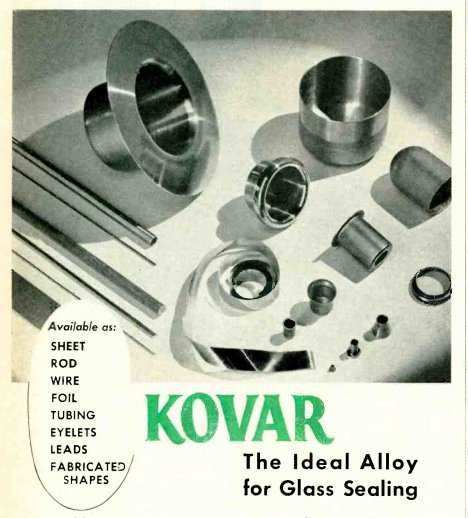

Kovar

Kovar (trademark of CRS Holdings, inc., Delaware) is a nickel–cobalt ferrous alloy compositionally identical to Fernico 1, designed to have substantially the same thermal expansion characteristics as borosilicate glass (≈ between , to ≈ at 800 °C) to allow a tight mechanical joint between the two materials over a range of temperatures. It finds application in glass-to-metal seals in scientific apparatus, and conductors entering glass envelopes of electronic parts such as vacuum tubes (valves), X-ray and microwave tubes and some lightbulbs. Kovar was invented to meet the need for a reliable glass-to-metal seal, which is required in electronic devices such as light bulbs, vacuum tubes, cathode-ray tubes, and in vacuum systems in chemistry and other scientific research. Most metals cannot seal to glass because their coefficient of thermal expansion is not the same as glass; as the joint cools after fabrication the stresses due to the different expansion rates o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coefficient Of Thermal Expansion

Thermal expansion is the tendency of matter to increase in length, area, or volume, changing its size and density, in response to an increase in temperature (usually excluding phase transitions). Substances usually contract with decreasing temperature (thermal contraction), with rare exceptions within limited temperature ranges ('' negative thermal expansion''). Temperature is a monotonic function of the average molecular kinetic energy of a substance. As energy in particles increases, they start moving faster and faster, weakening the intermolecular forces between them and therefore expanding the substance. When a substance is heated, molecules begin to vibrate and move more, usually creating more distance between themselves. The relative expansion (also called strain) divided by the change in temperature is called the material's coefficient of linear thermal expansion and generally varies with temperature. Prediction If an equation of state is available, it can be used t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vacuum Tube

A vacuum tube, electron tube, thermionic valve (British usage), or tube (North America) is a device that controls electric current flow in a high vacuum between electrodes to which an electric voltage, potential difference has been applied. It takes the form of an evacuated tubular envelope of glass or sometimes metal containing electrodes connected to external connection pins. The type known as a thermionic tube or thermionic valve utilizes thermionic emission of electrons from a hot cathode for fundamental Electronics, electronic functions such as signal amplifier, amplification and current Rectifier, rectification. Non-thermionic types such as vacuum phototubes achieve electron emission through the photoelectric effect, and are used for such purposes as the detection of light and measurement of its intensity. In both types the electrons are accelerated from the cathode to the anode by the electric field in the tube. The first, and simplest, vacuum tube, the diode or Flem ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Young's Modulus

Young's modulus (or the Young modulus) is a mechanical property of solid materials that measures the tensile or compressive stiffness when the force is applied lengthwise. It is the modulus of elasticity for tension or axial compression. Young's modulus is defined as the ratio of the stress (force per unit area) applied to the object and the resulting axial strain (displacement or deformation) in the linear elastic region of the material. Although Young's modulus is named after the 19th-century British scientist Thomas Young, the concept was developed in 1727 by Leonhard Euler. The first experiments that used the concept of Young's modulus in its modern form were performed by the Italian scientist Giordano Riccati in 1782, pre-dating Young's work by 25 years. The term modulus is derived from the Latin root term '' modus'', which means ''measure''. Definition Young's modulus, E, quantifies the relationship between tensile or compressive stress \sigma (force per unit ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hardness

In materials science, hardness (antonym: softness) is a measure of the resistance to plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by Pressing (metalworking), pressing or abrasion (mechanical), abrasion. In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as sodium and metallic tin, or wood and common plastics. Macroscopic hardness is generally characterized by strong intermolecular bonds, but the behavior of solid materials under force is complex; therefore, hardness can be measured in different ways, such as scratch hardness, indentation hardness, and rebound hardness. Hardness is dependent on ductility, elasticity (physics), elastic stiffness, plasticity (physics), plasticity, deformation (mechanics), strain, strength of materials, strength, toughness, viscoelasticity, and viscosity. Common examples of hard matter are cer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reduction Of Area

Reduction, reduced, or reduce may refer to: Science and technology Chemistry * Reduction (chemistry), part of a reduction-oxidation (redox) reaction in which atoms have their oxidation state changed. ** Organic redox reaction, a redox reaction that takes place with organic compounds ** Ore reduction: see smelting Computing and algorithms * Reduction (complexity), a transformation of one problem into another problem * Reduction (recursion theory), given sets A and B of natural numbers, is it possible to effectively convert a method for deciding membership in B into a method for deciding membership in A? * Bit Rate Reduction, an audio compression method * Data reduction, simplifying data in order to facilitate analysis * Graph reduction, an efficient version of non-strict evaluation * L-reduction, a transformation of optimization problems which keeps the approximability features * Partial order reduction, a technique for reducing the size of the state-space to be searche ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Density

Density (volumetric mass density or specific mass) is the ratio of a substance's mass to its volume. The symbol most often used for density is ''ρ'' (the lower case Greek letter rho), although the Latin letter ''D'' (or ''d'') can also be used: \rho = \frac, where ''ρ'' is the density, ''m'' is the mass, and ''V'' is the volume. In some cases (for instance, in the United States oil and gas industry), density is loosely defined as its weight per unit volume, although this is scientifically inaccurate this quantity is more specifically called specific weight. For a pure substance, the density is equal to its mass concentration. Different materials usually have different densities, and density may be relevant to buoyancy, purity and packaging. Osmium is the densest known element at standard conditions for temperature and pressure. To simplify comparisons of density across different systems of units, it is sometimes replaced by the dimensionless quantity "relative den ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's outer and inner core. It is the fourth most abundant element in the Earth's crust, being mainly deposited by meteorites in its metallic state. Extracting usable metal from iron ores requires kilns or furnaces capable of reaching , about 500 °C (900 °F) higher than that required to smelt copper. Humans started to master that process in Eurasia during the 2nd millennium BC and the use of iron tools and weapons began to displace copper alloys – in some regions, only around 1200 BC. That event is considered the transition from the Bronze Age to the Iron Age. In the modern world, iron alloys, such as steel, stainless steel, cast iron and special steels, are by far the most common industrial metals, due to their mechan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hot Isostatic Pressing

Hot isostatic pressing (HIP) is a manufacturing process, used to reduce the porosity of metals and increase the density of many ceramic materials. This improves the material's mechanical properties and workability. The HIP process subjects a component to both elevated temperature and isostatic gas pressure within a high-pressure containment vessel, unlike the cold isostatic pressing (CIP), where the component is maintained at room temperature. The pressurizing gas most widely used is argon. An inert gas is used so that the material does not chemically react. The choice of metal can minimize negative effects of chemical reactions. Nickel, stainless or mild steel, or other metals can be chosen depending on the desired redox conditions. The chamber is heated, causing the pressure inside the vessel to increase. Many systems use associated gas pumping to achieve the necessary pressure level. Pressure is applied to the material from all directions (hence the term "isostatic"). For ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The atoms/molecules in the sintered material diffuse across the boundaries of the particles, fusing the particles together and creating a solid piece. Since the sintering temperature does not have to reach the melting point of the material, sintering is often chosen as the shaping process for materials with extremely high melting points, such as tungsten and molybdenum. The study of sintering in metallurgy, metallurgical powder-related processes is known as powder metallurgy. An example of sintering can be observed when ice cubes in a glass of water adhere to each other, which is driven by the temperature difference between the water and the ice. Examples of pressure-driven sintering are the compacting of snowfa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manganese

Manganese is a chemical element; it has Symbol (chemistry), symbol Mn and atomic number 25. It is a hard, brittle, silvery metal, often found in minerals in combination with iron. Manganese was first isolated in the 1770s. It is a transition metal with a multifaceted array of industrial alloy uses, particularly in stainless steels. It improves strength, workability, and resistance to wear. Manganese oxide is used as an oxidising agent, as a rubber additive, and in glass making, fertilisers, and ceramics. Manganese sulfate can be used as a fungicide. Manganese is also an essential human dietary element, important in macronutrient metabolism, bone formation, and free radical defense systems. It is a critical component in dozens of proteins and enzymes. It is found mostly in the bones, but also the liver, kidneys, and brain. In the human brain, the manganese is bound to manganese metalloproteins, most notably glutamine synthetase in astrocytes. Manganese is commonly found in labo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |