|

Kaizen

is a Japanese concept in business studies which asserts that significant positive results may be achieved due the cumulative effect of many, often small (and even trivial), improvements to all aspects of a company's operations. Kaizen is put into action by Continual improvement process, continuously improving every facet of a company's production and requires the participation of all employees from the CEO to assembly line workers. Kaizen also applies to processes, such as purchasing and logistics, that cross organizational boundaries into the supply chain. Kaizen aims to eliminate lean manufacturing, waste and redundancies. Kaizen may also be referred to as zero investment improvement (ZII) due to its utilization of existing resources. After being introduced by an Americans, American, Kaizen was first practiced in Economy of Japan, Japanese businesses after World War II, and most notably as part of The Toyota Way. It has since spread throughout the world and has been applied ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Economy Of Japan

The economy of Japan is a Developed country, highly developed mixed economy, often referred to as an East Asian model. According to the International Monetary Fund, IMF forecast for 2025, it will be the fifth-largest economy in the world List of countries by GDP (nominal), by nominal GDP as well as List of countries by GDP (PPP), by purchasing power parity (PPP) by the end of the year. It constituted 3.7% of the world's economy on a nominal basis in 2024. According to the same forecast, the country's List of countries by GDP (PPP) per capita, per capita GDP (PPP) will be $54,678 (2025). Due to a volatile currency exchange rate, Japan's nominal GDP as measured in American dollars fluctuates sharply. A founding member of the G7 and an early member of the OECD, Japan was the first country in Asia to achieve developed country status. In 2018, Japan was the fourth-largest in the world both List of countries by imports, as an importer and List of countries by exports, as an exporter. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Continual Improvement Process

A continual improvement process, also often called a continuous improvement process (abbreviated as CIP or CI), is an ongoing effort to improve products, services, or processes. These efforts can seek "incrementalism, incremental" improvement over time or "breakthrough" improvement all at once. Delivery (customer valued) processes are constantly evaluated and improved in the light of their efficiency, effectiveness and flexibility. Some see continual improvement processes as a meta-process for most management systems (such as business process management, quality management, project management, and program management). W. Edwards Deming, a pioneer of the field, saw it as part of the 'system' whereby feedback from the process and customer were evaluated against organisational goals. The fact that it can be called a management process does not mean that it needs to be executed by 'management'; but rather merely that it makes decisions about the implementation of the delivery process ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lean Thinking

Lean thinking is a management framework made up of a philosophy, practices and principles which aim to help practitioners improve efficiency and the quality of work. Lean thinking encourages whole organisation participation. The goal is to organise human activities to deliver more benefits to society and value to individuals while eliminating waste. History The term "lean thinking" was coined by mechanical engineer and MIT graduate student John Krafcik in 1988, who subsequently went on to run Google LLC's autonomous driving unit for many years. Principles Lean thinking is a way of thinking about an activity and seeing the waste inadvertently generated by the way the process is organized. It uses five key principles: *Value *Value streams *Flow *Pull *Perfection The aim of lean thinking is to create a lean culture, one that sustains growth by aligning customer satisfaction with employee satisfaction, and that offers innovative products or services profitably while minimizin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quality Management

Total quality management, Total Quality management (TQM), ensures that an organization, product, or service consistently performs as intended, as opposed to Quality Management, which focuses on work process and procedure standards. It has four main components: quality planning, quality assurance, quality control, and quality improvement. Customers recognize that quality is an important attribute when choosing and purchasing products and services. Suppliers can recognize that quality is an important differentiator of their offerings, and endeavor to compete on the quality of their products and the service they offer. Thus, quality management is focused both on product and service quality. Advancement In earlier periods, arts and crafts were led by Master craftsman, master craftspeople or artists who supervised studios, trained apprentices, and oversaw the product development process. With the advent of the Industrial Revolution, steam engines, and mass production, the role of crafts ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toyota Production System

The Toyota Production System (TPS) is an integrated socio-technical system, developed by Toyota, that comprises its management philosophy and practices. The TPS is a management system that organizes manufacturing and logistics for the automobile manufacturer, including interaction with suppliers and customers. The system is a major precursor of the more generic " lean manufacturing". Taiichi Ohno and Eiji Toyoda, Japanese industrial engineers, developed the system between 1948 and 1975. Originally called "Just-in-time production", it builds on the approach created by the founder of Toyota, Sakichi Toyoda, his son Kiichiro Toyoda, and the engineer Taiichi Ohno. The principles underlying the TPS are embodied in The Toyota Way. Goals The main objectives of the TPS are to design out overburden ( muri) and inconsistency ( mura), and to eliminate waste ( muda). The most significant effects on process value delivery are achieved by designing a process capable of delivering the requi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Just-in-time Manufacturing

Lean manufacturing is a method of manufacturing goods aimed primarily at reducing times within the production system as well as response times from suppliers and customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to demand by only supplying goods that have been ordered and focus on efficiency, productivity (with a commitment to continuous improvement), and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow, and throughput times by further eliminating activities that do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service. Lean manufacturing (also known as agile manufacturing) is particularly related to the operational model impleme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lean Manufacturing

Lean manufacturing is a methods of production, method of manufacturing goods aimed primarily at reducing times within the Operations management#Production systems, production system as well as response times from suppliers and customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to Supply and demand, demand by only supplying goods that have been ordered and focus on efficiency, productivity (with a commitment to continuous improvement), and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing Cycle time variation, cycle, flow, and Throughput (business), throughput times by further eliminating activities that do not add any Value (economics), value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

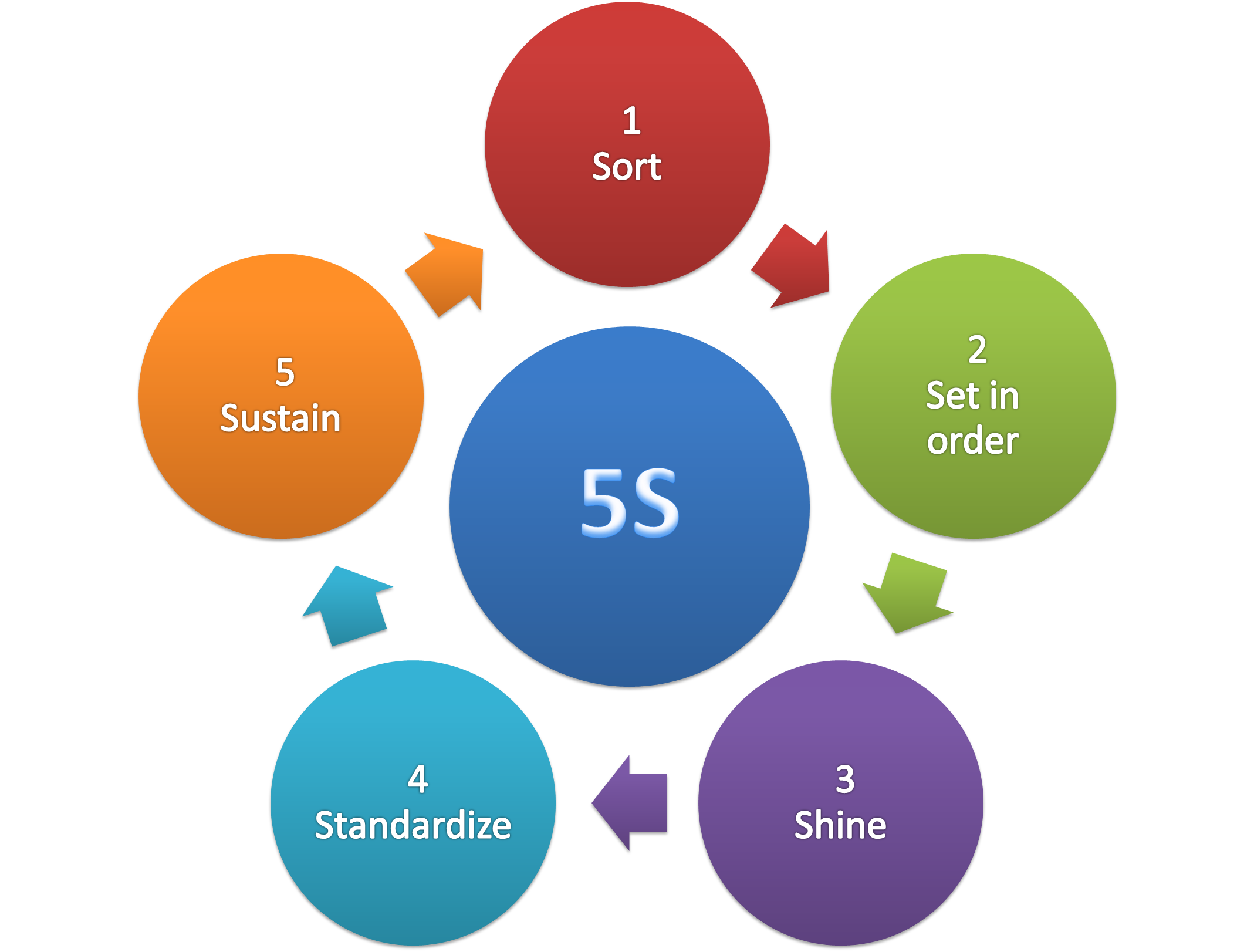

5S (methodology)

5S (Five S) is a workplace organization method that uses a list of five Japanese words: , , , , and . These have been translated as 'sort', 'set in order', 'shine', 'standardize', and 'sustain'. The list describes how to organize a work space for efficiency and effectiveness by identifying and sorting the items used, maintaining the area and items, and sustaining the new organizational system. The decision-making process usually comes from a dialogue about standardization, which builds understanding among employees of how they should do the work. In some organisations, 5S has become 6S, the sixth element being ''safety'' (''safe''). Other than a specific stand-alone methodology, 5S is frequently viewed as an element of a broader construct known as '' visual control'', '' visual workplace'', or ''visual factory''. Under those (and similar) terminologies, Western companies were applying underlying concepts of 5S before publication, in English, of the formal 5S methodology. For e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Muda (Japanese Term)

is a Japanese word meaning "futility", "uselessness", or "wastefulness", and is a key concept in lean process thinking such as in the Toyota Production System (TPS), denoting one of three types of deviation from optimal allocation of resources. The other types are known by the Japanese terms '' mura'' ("unevenness") and '' muri'' ("overload"). Waste in this context refers to the wasting of time or resources rather than wasteful by-products and should not be confused with waste reduction. From an end-customer's point of view, value-added work is any activity that produces goods or provides a service for which a customer is willing to pay; ''muda'' is any constraint or impediment that causes waste to occur. There are two types of muda: * ''Muda'' type I: non value-adding, but necessary for end-customers. These are usually harder to eliminate because while classified as non-value adding, they may still be necessary. * ''Muda'' type II: non value-adding and unnecessary for end ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

The Toyota Way

The Toyota Way is a set of principles defining the organizational culture of Toyota Motor Corporation. The company formalized the Toyota Way in 2001, after decades of academic research into the Toyota Production System and its implications for lean manufacturing as a methodology that other organizations could adopt. The two pillars of the Toyota Way are respect for people and continuous improvement. Jeffrey K. Liker popularized the philosophy in his 2004 book, ''The Toyota Way: 14 Management Principles from the World's Greatest Manufacturer.'' Subsequent research has explored the extent to which the Toyota Way can be applied in other contexts. Background The principles were first collated into a single document in the company's pamphlet "The Toyota Way 2001", to help codify the company's organizational culture. The philosophy was subsequently analyzed in the 2004 book ''The Toyota Way'' by industrial engineering researcher Jeffrey Liker and has received attention in business ad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Edwards Deming

William Edwards Deming (October 14, 1900 – December 20, 1993) was an American business theorist, composer, economist, industrial engineer, management consultant, statistician, and writer. Educated initially as an electrical engineer and later specializing in mathematical physics, he helped develop the sampling techniques still used by the United States Census Bureau and the Bureau of Labor Statistics. He is also known as the father of the quality movement and was hugely influential in post-WWII Japan, credited with revolutionizing Japan's industry and making it one of the most dominant economies in the world. He is best known for his theories of management. Overview Deming received a BS degree in electrical engineering from the University of Wyoming at Laramie (1921), an MS degree from the University of Colorado (1925), and a PhD from Yale University (1928). Both graduate degrees were in mathematics and physics. He had an internship at Western Electric's Hawthorne Wor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Just In Sequence

Just in sequence (JIS) is an inventory strategy that matches just in time (JIT) and complete fit in sequence with variation of assembly line production. Components and parts arrive at a production line right in time as scheduled before they get assembled. Feedback from the manufacturing line is used to coordinate transport to and from the process area. When implemented successfully, JIS improves a company's return on assets (ROA), without loss in flexibility, quality or overall efficiency. JIS is mainly implemented with car manufacture. JIS is sometimes called In-Line Vehicle Sequencing (ILVS). Just in sequence is just in time Just in sequence (JIS) is just one specialised strategy to achieve just in time (JIT). The process concept of JIT sees buffers at the production line as waste in capital bound. The aim is to eliminate buffers as much as possible at the expense of stability when disturbances arise. Just In Sequence is one of the most extreme applications of the concept, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |