|

Fusion Bonded Epoxy Coating

Fusion bonded epoxy coating, also known as fusion-bond epoxy powder coating and commonly referred to as FBE coating, is an epoxy-based powder coating that is widely used to protect steel pipe used in pipeline construction from corrosion. It is also commonly used to protect reinforcing bars (though being phased out as of 2005) and on a wide variety of piping connections, valves etc. FBE coatings are thermoset polymer coatings. They come under the category of ''protective coatings'' in paints and coating nomenclature. The name ''fusion-bond epoxy'' is due to resigning cross-link and the application method, which is different from a conventional paint. In 2020 the market size was quoted at 12 billion dollars. The resin and hardener components in the dry powder FBE stock remain unreacted at normal storage conditions. At typical coating application temperatures, usually in the range of , the contents of the powder melt and transform to a liquid form. The liquid FBE film wets and flo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Epoxy

Epoxy is the family of basic components or Curing (chemistry), cured end products of epoxy Resin, resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also collectively called ''epoxy''. The IUPAC name for an epoxide group is an oxirane. Epoxy resins may be reacted (cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (sometimes called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as Curing (chemistry), curing. Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of application ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mil (imperial)

A thousandth of an inch is a derived unit of length in a system of units using inches. Equal to of an inch, a thousandth is commonly called a thou (used for both singular and plural) or, particularly in North America, a mil (plural mils). The words are shortened forms of the English and Latin words for "thousand" ( in Latin). In international engineering contexts, confusion can arise because ''mil'' is a formal unit name in North America but ''mil'' or ''mill'' is also a common colloquial clipped form of millimetre. The units are considerably different: a millimetre is approximately 39 mils. Contexts of use The thou, or mil, is most commonly used in engineering and manufacturing in non-metric countries. For example, in specifying: * The thickness of items such as paper, film, foil, wires, paint coatings, latex gloves, plastic sheeting, and fibers ** For example, most plastic ID cards are about in thickness. ** Card stock thickness in the United States, where mils are also ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rebar

Rebar (short for reinforcement bar or reinforcing bar), known when massed as reinforcing steel or steel reinforcement, is a tension device added to concrete to form ''reinforced concrete'' and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has low tensile strength. Rebar usually consists of steel bars which significantly increase the tensile strength of the structure. Rebar surfaces feature a continuous series of ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage. The most common type of rebar is carbon steel, typically consisting of hot-rolled round bars with deformation patterns embossed into its surface. Steel and concrete have similar coefficients of thermal expansion, so a concrete structural member reinforced with steel will experience minimal differential stress as the temperature changes. Other readily available types of rebar are manufacture ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint, which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then Powder coating#Curing, cured under heat or with ultraviolet light. The powder may be a thermoplastic or a thermosetting polymer. It is usually used to create a thick, tough finish that is more durable than conventional paint. Powder coating is mainly used for coating of metal objects, particularly those subject to rough use. Advancements in powder coating technology like UV-curable powder coatings allow for other materials such as plastics, composites, Carbon-fiber reinforced polymer, carbon fiber, and medium-density fibreboard (MDF) to be powder coated, as little heat or oven dwell time is required to process them. History, properties, and uses of powder coating The powder coating process was invented around 1945 by Daniel Gustin and received US Patent 2 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

DCVG

DCVG (direct current voltage gradient) is a survey technique used for assessing the effectiveness of corrosion protection on buried steel structures. In particular, oil and natural gas pipelines are routinely monitored using this technique to help locate coating faults and highlight deficiencies in their cathodic protection (CP) strategies. History The DCVG method was invented by Australian John Mulvany, an ex Telecom engineer, in the early 1980s. This technique was used by Telecom Australia to identify damaged insulation on buried metallic cable. At that time Santos in Adelaide was keen to use coating defect techniques for buried pipelines suffering corrosion in the Moomba area. John Leeds, a professional corrosion engineer, was employed by Santos to engage companies with relevant expertise. Initially international companies using the "CIPS" and "Pearson" technique were engaged. Ike Solomon and Matthew Wong of Wilson Walton International engaged John Mulvaney to modify the DCVG ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engineering is the field dedicated to controlling and preventing corrosion. In the most common use of the word, this means electrochemical oxidation of metal in reaction with an oxidant such as oxygen, hydrogen, or hydroxide. Rusting, the formation of red-orange iron oxides, is a well-known example of electrochemical corrosion. This type of corrosion typically produces oxides or salts of the original metal and results in a distinctive coloration. Corrosion can also occur in materials other than metals, such as ceramics or polymers, although in this context, the term "degradation" is more common. Corrosion degrades the useful properties of materials and structures including mechanical strength, appearance, and permeability to liquids and ga ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cathodic Protection

Cathodic protection (CP; ) is a technique used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. A simple method of protection connects the metal to be protected to a more easily corroded " sacrificial metal" to act as the anode. The sacrificial metal then corrodes instead of the protected metal. For structures such as long pipelines, where passive galvanic cathodic protection is not adequate, an external DC electrical power source is used to provide sufficient current. Cathodic protection systems protect a wide range of metallic structures in various environments. Common applications are: steel water or fuel pipelines and steel storage tanks such as home water heaters; steel pier piles; ship and boat hulls; offshore oil platforms and onshore oil well casings; offshore wind farm foundations and metal reinforcement bars in concrete buildings and structures. Another common application is in galvanized steel, in which a sacrif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rohm & Haas

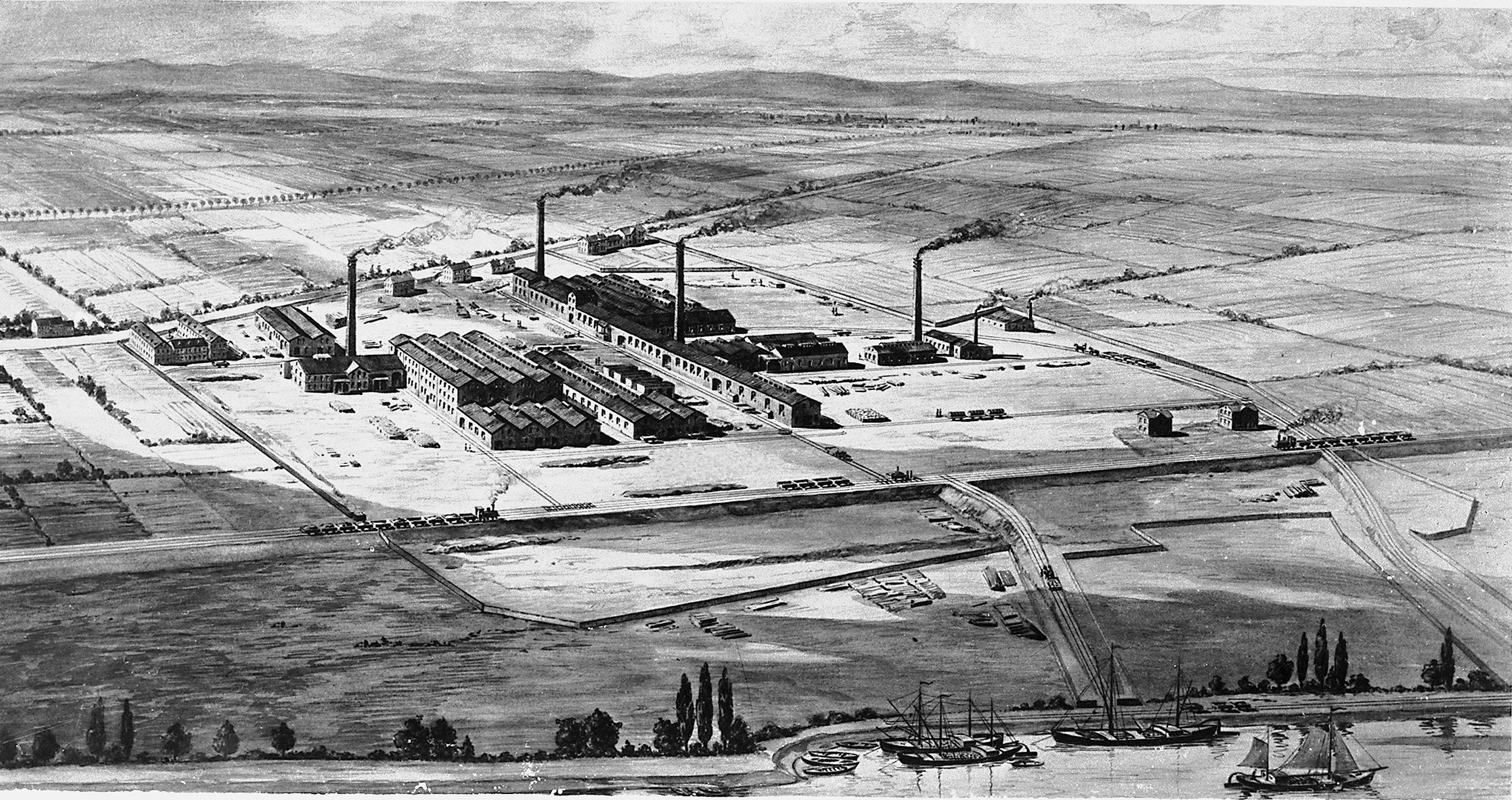

Rohm and Haas Company is a US manufacturer of specialty chemicals for end use markets such as building and construction, electronic devices, packaging, household and personal care products. Headquartered in Philadelphia, the company is organized into three business groups of Specialty Materials, Performance Materials and Electronic Materials, and also has two stand-alone businesses of Powder Coatings and Salt. Formerly a Fortune 500 Company, Rohm and Haas employs more than 17,000 people in 27 countries, with its last sales revenue reported as an independent company at US$8.9 billion. Dow Chemical Company bought Rohm and Haas for $15 billion in 2009. History The company was founded in Esslingen, Germany, by Dr. Otto Röhm and Mr. Otto Haas in 1907. Haas moved to Philadelphia and began the American side of the business on September 1, 1909, from an office on Front Street, while Otto Röhm remained in Germany to run a company that would eventually become Röhm GmbH. Röhm im ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

BASF

BASF SE (), an initialism of its original name , is a European Multinational corporation, multinational company and the List of largest chemical producers, largest chemical producer in the world. Its headquarters are located in Ludwigshafen, Germany. BASF comprises subsidiary, subsidiaries and joint ventures in more than 80 countries, operating six integrated production sites and 390 other production sites across Europe, Asia, Australia, the Americas and Africa. BASF has customers in over 190 countries and supplies products to a wide variety of industries. Despite its size and global presence, BASF has received relatively little public attention since it abandoned the manufacture and sale of BASF-branded consumer electronics products in the 1990s. The company began as a dye manufacturer in 1865. Fritz Haber worked with Carl Bosch, one of its employees, to invent the Haber-Bosch, Haber-Bosch process by 1912, after which the company grew rapidly. In 1925, the company merged with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Akzo Nobel

Akzo Nobel N.V., stylised as AkzoNobel, is a Dutch multinational company which creates paints and performance coatings for both industry and consumers worldwide. Headquartered in Amsterdam, the company has activities in more than 150 countries. AkzoNobel is the world's third-largest paint manufacturer by revenue after Sherwin-Williams and PPG Industries. History AkzoNobel has a long history of mergers and divestments. Parts of the current company can be traced back to 17th-century companies. History and formation of Akzo Akzo was formed in 1969 as merger of Algemene Kunstzijde Unie (General Artificial Silk Union; AKU) and Koninklijke Zout Organon (Royal Salt Organon; KZO). The AKU was formed in 1929 when the Vereinigte Glanzstoff-Fabriken (est. 1899) and Nederlandse Kunstzijdefabriek (ENKA, est. 1911) merged, forming Algemene Kunstzijde Unie (AKU). The latter faced, amongst others, technical problems in the manufacturing of synthetic fibers. Its founder, Jacques Coenraad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Axalta Coating Systems

Axalta Coating Systems Ltd., also known as simply Axalta, is an American company specializing in coatings in a wide variety of industrial applications, materials and sectors, including automotive paints. The company is based in Philadelphia, Pennsylvania, and incorporated in Bermuda. Axalta develops and manufactures coatings for light and commercial vehicles, industrial, and refinish applications. The firm does business in 130 countries, has nearly 13,000 employees, and has more than 100,000 customers. Axalta traces its origins to the German firm Herberts Gmbh, which began in 1866 coating carriages before moving to automotive painting. Through later mergers the company became DuPont Performance Coatings (DPC), part of the American DuPont chemical empire, and was rebranded as Axalta Coating Systems after being purchased by The Carlyle Group in 2013. Axalta went public on the New York Stock Exchange in November 2014 and since then has become fully independent. Carlyle Group exit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jotun (company)

Jotun is a Norwegian multinational chemicals company dealing mainly in decorative paints and performance coatings (marine, protective and powder coatings). It is one of the world's largest manufacturers of paints and coating products. Jotun manufactures paints and varnishes for marine and industrial purposes, synthetic resins, floor coverings, polyurethane foam, heavy-duty coatings, binders, unsaturated polyesters, glass-fiber reinforced polyester pipes, tanks, and more. Jotun merged with three other paint producers in 1971 and became not only Norway's largest paint producer but also one of the largest companies in Norway. As of January 2021, the company has a presence in more than 100 countries around the world, with more than 10,000 employees, 67 companies in 45 countries, and 40 production facilities in 21 countries. As of 2021, Jotun had about 10,300 employees including one thousand employees within Norway. It operated 40 factories in 21 countries and is represented in 120 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |