|

Fuel Pump

A Fuel pump is a component used in many liquid-fuelled engines (such as petrol/gasoline or diesel engines) to transfer the fuel from the fuel tank to the device where it is mixed with the intake air (such as the carburetor or fuel injector). Carbureted engines often use low-pressure mechanical pumps that are mounted on the engine. Fuel injected engines use either electric fuel pumps mounted inside the fuel tank (for lower pressure manifold injection systems) or high-pressure mechanical pumps mounted on the engine (for high-pressure direct injection systems). Some engines do not use any fuel pump at all. A low-pressure fuel supply used by a carbureted engine can be achieved through a gravity feed system, i.e. by simply mounting the tank higher than the carburetor. This method is commonly used in carbureted motorcycles, where the tank is usually directly above the engine. Low-pressure mechanical pumps On engines that use a carburetor (e.g. in older cars, lawnmowers a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Saab 90

The Saab 90 is a family car produced by Saab from September 1984 to 1987. It was manufactured at a facility in Uusikaupunki (Nystad), Finland, at that time owned by a joint venture with Finnish Valmet called Saab-Valmet. The 90 was a continuation of the Saab 99, and it was basically a Saab 99 from the B-pillar forward with the rear of a Saab 900 sedan. The 90, while easier to build than the 99, was still considerably more labour-intensive than the more modern 900. History When the production of the Saab 96 was completed in 1980, the head of Saab's passenger car division, Sten Wennlo, was under intense pressure to create a new base model for the European market. Also people at Saab-Valmet were concerned about the fate of the Saab 99, as its production took place entirely in Nystad. Saab-Valmet's first solution from 1983 was to weld the front end of a Saab 900 together with the rear end of a 99. When the product was shown to Wennlo, he stated that the principle was good, but ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cam (mechanism)

A cam is a rotating or sliding piece in a linkage (mechanical), mechanical linkage used especially in transforming rotary motion into linear motion. It is often a part of a rotating wheel (e.g. an eccentric wheel) or shaft (e.g. a cylinder with an irregular shape) that strikes a lever at one or more points on its circular path. The cam can be a simple tooth, as is used to deliver pulses of power to a steam hammer, for example, or an Eccentric (mechanism), eccentric disc or other shape that produces a smooth reciprocating (back and forth) motion in the ''Cam follower, follower'', which is a lever making contact with the cam. A cam timer is similar, and these were widely used for electric machine control (an electromechanical timer in a washing machine being a common example) before the advent of inexpensive electronics, microcontrollers, integrated circuits, programmable logic controllers and digital control. Camshaft The cam can be seen as a device that converts rotational mot ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pumps

A pump is a device that moves fluids (liquids or gases), or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic or pneumatic energy. Mechanical pumps serve in a wide range of applications such as pumping water from wells, aquarium filtering, pond filtering and aeration, in the car industry for water-cooling and fuel injection, in the energy industry for pumping oil and natural gas or for operating cooling towers and other components of heating, ventilation and air conditioning systems. In the medical industry, pumps are used for biochemical processes in developing and manufacturing medicine, and as artificial replacements for body parts, in particular the artificial heart and penile prosthesis. When a pump contains two or more pump mechanisms with fluid being directed to flow through them in series, it is called a ''multi-stage pump''. Terms such as ''two-stage'' or ''double-stage'' may be used to specifically describ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Auto Parts

This is a list of auto parts, which are manufactured components of automobiles. This list reflects both fossil-fueled cars (using internal combustion engine An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal comb ...s) and electric vehicles; the list is not exhaustive. Many of these parts are also used on other motor vehicles such as trucks and buses. Car body and main parts Body components, including trim Vehicle door, Doors Windows Low voltage/auxiliary electrical system and electronics Audio/video devices Cameras Low voltage electrical supply system Gauge (instrument), Gauges and meters Ignition system Automotive lighting, Lighting and signaling system Sensors Starting system Electrical switches Wiring harnesses Miscellaneous ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbopump

A turbopump is a fluid pump with two main components: a rotodynamic pump and a driving gas turbine, usually both mounted on the same shaft, or sometimes geared together. They were initially developed in Germany in the early 1940s. The most common purpose of a turbopump is to produce a high-pressure fluid for feeding a combustion chamber. While other use cases exist, they are most commonly found in liquid rocket engines. There are two common types of pumps used in turbopumps: a centrifugal pump, where the pumping is done by throwing fluid outward at high speed, or an axial-flow pump, where alternating rotating and static blades progressively raise the pressure of a fluid. Axial-flow pumps have small diameters but give relatively modest pressure increases. Although multiple compression stages are needed, axial flow pumps work well with low-density fluids. Centrifugal pumps are far more powerful for high-density fluids but require large diameters for low-density fluids. Histo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gasoline Direct Injection

Gasoline direct injection (GDI), also known as petrol direct injection (PDI), is a fuel injection system for internal combustion engines that run on gasoline (petrol) which injects fuel directly into the combustion chamber. This is distinct from manifold injection systems, which inject fuel into the intake manifold (inlet manifold) where it mixes with the incoming airstream before reaching the combustion chamber.. The use of GDI can help increase engine efficiency and specific power output as well as reduce exhaust emissions. The first GDI engine to reach production was introduced in 1925 for a low-compression truck engine. Several German cars used a Bosch mechanical GDI system in the 1950s, however usage of the technology remained rare until an electronic GDI system was introduced in 1996 by Mitsubishi for mass-produced cars. GDI has seen rapid adoption by the automotive industry in recent years, increasing in the United States from 2.3% of production for model year 2008 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

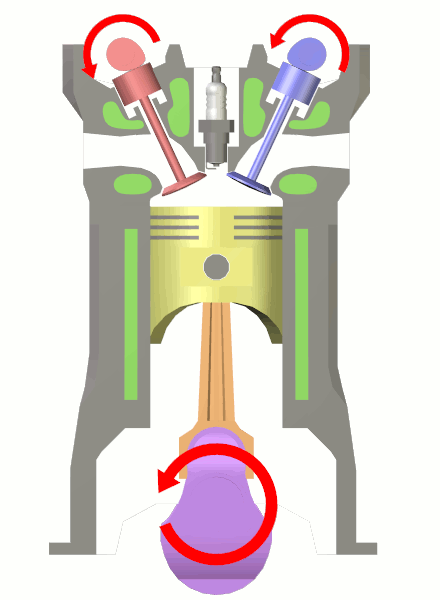

Camshaft

A camshaft is a shaft that contains a row of pointed cams in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems and early electric motor speed controllers. Camshafts in piston engines are usually made from steel or cast iron, and the shape of the cams greatly affects the engine's characteristics. History Trip hammers are one of the early uses of a form of cam to convert rotating motion, e.g. from a waterwheel, into the reciprocating motion of a hammer used in forging or to pound grain. Evidence for these exists back to the Han dynasty in China, and they were widespread by the medieval period. Camshafts were first described by Ismail al-Jazari in 1206. Once the rotative version of the steam engine was developed in the late 18th century, the operation of the valve gear was usually by an eccentric, which turned the rotation of the crankshaft i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

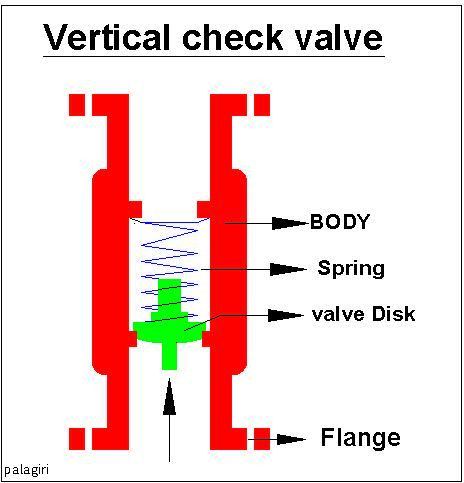

Check Valve

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction. Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of check valves used in a wide variety of applications. Check valves are often part of common household items. Although they are available in a wide range of sizes and costs, check valves generally are very small, simple, and inexpensive. Check valves work automatically and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem. The bodies (external shells) of most check valves are made of plastic or metal. An important concept in check valves is the cracking pressure which is the minimum differential upstream pressure between inlet and outlet at which the valve will operate ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rack And Pinion

rack and pinion is a type of linear actuator that comprises a circular gear (the '' pinion'') engaging a linear gear (the ''rack''). Together, they convert between rotational motion and linear motion: rotating the pinion causes the rack to be driven in a line. Conversely, moving the rack linearly will cause the pinion to rotate. The rack and pinion mechanism is used in rack railways, where the pinion mounted on a locomotive or a railroad car engages a rack usually placed between the rails, and helps to move the train up a steep gradient. It is also used in arbor presses and drill presses, where the pinion is connected to a lever and displaces a vertical rack (the ram). In pipelines and other industrial piping systems, a rack displaced by a linear actuator turns a pinion to open or close a valve. Stairlifts, lock gates, electric gates, and the mechanical steering mechanism of cars are other notable applications. The term "rack and pinion" may be used also when the rac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dead Centre (engineering)

In a reciprocating engine, the dead centre is the position of a piston in which it is either furthest from, or nearest to, the crankshaft. The former is known as top dead centre (TDC) while the latter is known as bottom dead centre (BDC). More generally, the dead centre is any position of a crank where the applied force is straight along its axis, meaning no turning force can be applied. Many sorts of machines are crank driven, including unicycles, bicycles, tricycles, various types of machine presses, gasoline engines, diesel engines, steam locomotives, and other steam engines. Crank-driven machines rely on the energy stored in a flywheel to overcome the dead centre, or are designed, in the case of multi-cylinder engines, so that dead centres can never exist on all cranks at the same time. A steam locomotive is an example of the latter, the connecting rods being arranged such that the dead centre for each cylinder occurs out of phase with the other one (or more) cylinders ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yanmar 2GM20

The Yanmar 2GM20 is a series of inboard marine diesel engines manufactured by the Japanese company Yanmar Co. Ltd. It is used in a wide range of sailboats and motorboats. The 2GM20 is out of production and has been superseded by the newer Yanmar 3YM20 series. Specifications It is a four-stroke, vertical, water-cooled diesel engine. It is built around two cylinders (hence the "2" in 2GM20) of 75 mm in diameter and 72 mm in stroke, adding up to 0.635 litres in displacement: each cylinder is roughly the size and volume of a 300 ml soft-drink can. The compression system uses a proprietary swirl-type pre-combustion chamber.Yanmar technical reference sheet The continuous rating output at the crankshaft is 11.8 kW, at 3400 revolutions per minute (rpm). The maximum output at the crankshaft is 13.4 kW, at 3600 rpm. The engine delivers roughly 16 horsepower, for a weight of about 114 kg. The engine is equipped with a starting motor (D.C. 12V, 1 k ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |