|

Flow Stress

In materials science the flow stress, typically denoted as Yf (or \sigma_\text), is defined as the instantaneous value of stress required to continue plastically deforming a material - to keep it flowing. It is most commonly, though not exclusively, used in reference to metals. On a stress-strain curve, the flow stress can be found anywhere within the plastic regime; more explicitly, a flow stress can be found for any value of strain between and including yield point (\sigma_\text) and excluding fracture (\sigma_\text): \sigma_\text \leq Y_\text < \sigma_\text. The flow stress changes as deformation proceeds and usually increases as strain accumulates due to , although the flow stress could decrease due to any recovery process. In |

Materials Science

Materials science is an interdisciplinary field of researching and discovering materials. Materials engineering is an engineering field of finding uses for materials in other fields and industries. The intellectual origins of materials science stem from the Age of Enlightenment, when researchers began to use analytical thinking from chemistry, physics, and engineering to understand ancient, phenomenological observations in metallurgy and mineralogy. Materials science still incorporates elements of physics, chemistry, and engineering. As such, the field was long considered by academic institutions as a sub-field of these related fields. Beginning in the 1940s, materials science began to be more widely recognized as a specific and distinct field of science and engineering, and major technical universities around the world created dedicated schools for its study. Materials scientists emphasize understanding how the history of a material (''processing'') influences its struc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Work Hardening

Work hardening, also known as strain hardening, is the process by which a material's load-bearing capacity (strength) increases during plastic (permanent) deformation. This characteristic is what sets ductile materials apart from brittle materials. Work hardening may be desirable, undesirable, or inconsequential, depending on the application. This strengthening occurs because of dislocation movements and dislocation generation within the crystal structure of the material. Many non-brittle metals with a reasonably high melting point as well as several polymers can be strengthened in this fashion. Alloys not amenable to heat treatment, including low-carbon steel, are often work-hardened. Some materials cannot be work-hardened at low temperatures, such as indium, however others can be strengthened only via work hardening, such as pure copper and aluminum. Undesirable work hardening An example of undesirable work hardening is during machining when early passes of a cutter inadver ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Continuum Mechanics

Continuum mechanics is a branch of mechanics that deals with the deformation of and transmission of forces through materials modeled as a ''continuous medium'' (also called a ''continuum'') rather than as discrete particles. Continuum mechanics deals with ''deformable bodies'', as opposed to rigid bodies. A continuum model assumes that the substance of the object completely fills the space it occupies. While ignoring the fact that matter is made of atoms, this provides a sufficiently accurate description of matter on length scales much greater than that of inter-atomic distances. The concept of a continuous medium allows for intuitive analysis of bulk matter by using differential equations that describe the behavior of such matter according to physical laws, such as mass conservation, momentum conservation, and energy conservation. Information about the specific material is expressed in constitutive relationships. Continuum mechanics treats the physical properties of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

John Wiley & Sons

John Wiley & Sons, Inc., commonly known as Wiley (), is an American Multinational corporation, multinational Publishing, publishing company that focuses on academic publishing and instructional materials. The company was founded in 1807 and produces books, Academic journal, journals, and encyclopedias, in print and electronically, as well as online products and services, training materials, and educational materials for undergraduate, graduate, and continuing education students. History The company was established in 1807 when Charles Wiley opened a print shop in Manhattan. The company was the publisher of 19th century American literary figures like James Fenimore Cooper, Washington Irving, Herman Melville, and Edgar Allan Poe, as well as of legal, religious, and other non-fiction titles. The firm took its current name in 1865. Wiley later shifted its focus to scientific, Technology, technical, and engineering subject areas, abandoning its literary interests. Wiley's son Joh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strain (materials Science)

In mechanics, strain is defined as relative deformation, compared to a position configuration. Different equivalent choices may be made for the expression of a strain field depending on whether it is defined with respect to the initial or the final configuration of the body and on whether the metric tensor or its dual is considered. Strain has dimension of a length ratio, with SI base units of meter per meter (m/m). Hence strains are dimensionless and are usually expressed as a decimal fraction or a percentage. Parts-per notation is also used, e.g., parts per million or parts per billion (sometimes called "microstrains" and "nanostrains", respectively), corresponding to μm/m and nm/m. Strain can be formulated as the spatial derivative of displacement: \boldsymbol \doteq \cfrac\left(\mathbf - \mathbf\right) = \boldsymbol'- \boldsymbol, where is the identity tensor. The displacement of a body may be expressed in the form , where is the reference position of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strain Hardening Exponent

The strain hardening exponent (also called the strain hardening index), usually denoted n, is a measured parameter that quantifies the ability of a material to become stronger due to strain hardening. Work hardening, Strain hardening (work hardening) is the process by which a material's load-bearing capacity increases during plastic (permanent) Strain (mechanics), strain, or Deformation (engineering), deformation. This characteristic is what sets ductile materials apart from brittle materials. The uniaxial tension test is the primary experimental method used to directly measure a material's Stress–strain curve, stress–strain behavior, providing valuable insights into its strain-hardening behavior. The strain hardening exponent is sometimes regarded as a constant and occurs in forging and Forming (metalworking), forming calculations as well as the formula known as the Hollomon equation (after John Herbert Hollomon Jr.) who originally posited it as: \sigma=K\epsilon^nJ. H. Ho ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Homologous Temperature

Homologous temperature expresses the thermodynamic temperature of a material as a fraction of the thermodynamic temperature of its melting point (i.e. using the Kelvin scale): T_H = \frac For example, the homologous temperature of lead at room temperature (25 °C) is approximately 0.50 (TH = T/Tmp = 298 K/601 K = 0.50). Significance of the homologous temperature The homologous temperature of a substance is useful for determining the rate of steady state creep (diffusion-dependent deformation). A higher homologous temperature results in an exponentially higher rate of diffusion dependent deformation. Additionally, for a given fixed homologous temperature, two materials with different melting points would have similar diffusion-dependent deformation behaviour. For example, solder (Tmp = 456 K) at 115 °C would have comparable mechanical properties to copper (Tmp = 1358 K) at 881 °C, because they would both be at 0.85Tmp despite being at diff ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Composition

A chemical composition specifies the identity, arrangement, and ratio of the chemical elements making up a compound by way of chemical and atomic bonds. Chemical formulas can be used to describe the relative amounts of elements present in a compound. For example, the chemical formula for water is H2O: this means that each molecule of water is constituted by 2 atoms of hydrogen (H) and 1 atom of oxygen (O). The chemical composition of water may be interpreted as a 2:1 ratio of hydrogen atoms to oxygen atoms. Different types of chemical formulas are used to convey composition information, such as an empirical or molecular formula. Nomenclature can be used to express not only the elements present in a compound but their arrangement within the molecules of the compound. In this way, compounds will have unique names which can describe their elemental composition. Composite mixture The chemical composition of a mixture can be defined as the distribution of the individual substance ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

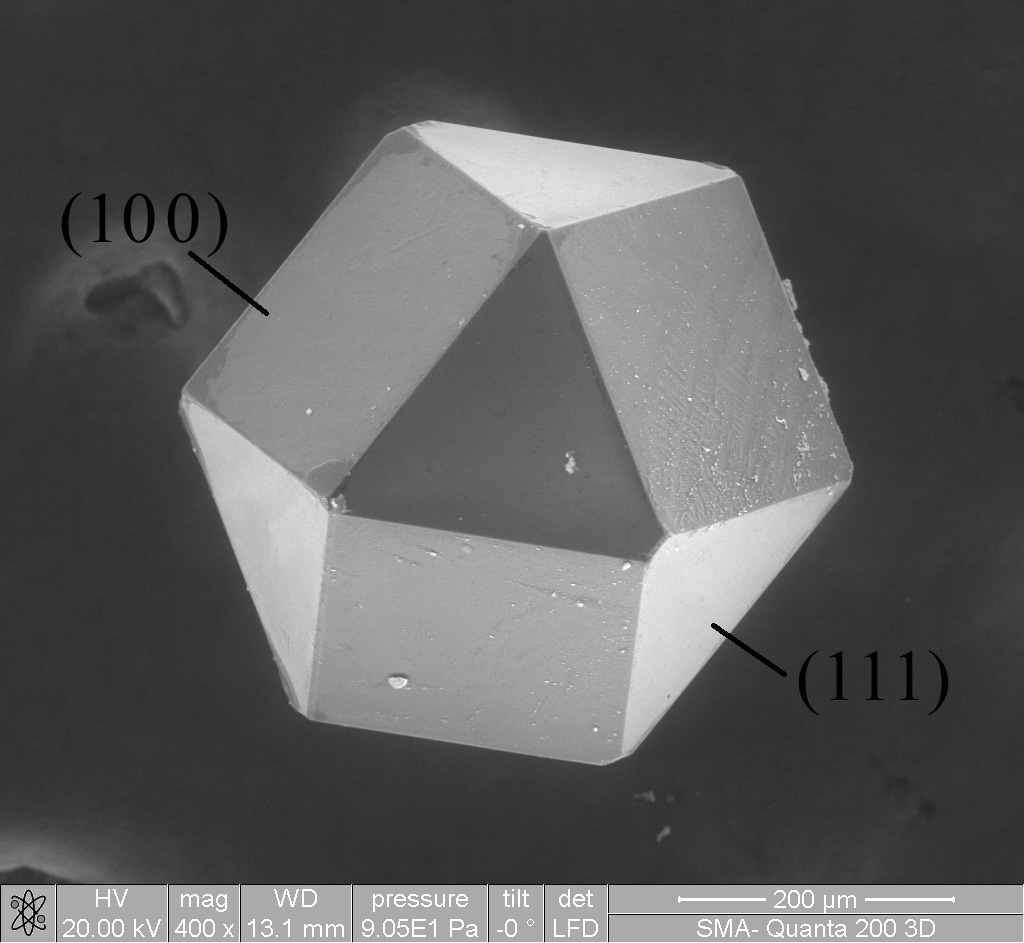

Crystal Structure

In crystallography, crystal structure is a description of ordered arrangement of atoms, ions, or molecules in a crystalline material. Ordered structures occur from intrinsic nature of constituent particles to form symmetric patterns that repeat along the principal directions of three-dimensional space in matter. The smallest group of particles in a material that constitutes this repeating pattern is the unit cell of the structure. The unit cell completely reflects the symmetry and structure of the entire crystal, which is built up by repetitive translation of the unit cell along its principal axes. The translation vectors define the nodes of the Bravais lattice. The lengths of principal axes/edges, of the unit cell and angles between them are lattice constants, also called ''lattice parameters'' or ''cell parameters''. The symmetry properties of a crystal are described by the concept of space groups. All possible symmetric arrangements of particles in three-dimensional space ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grain Size

Grain size (or particle size) is the diameter of individual grains of sediment, or the lithified particles in clastic rocks. The term may also be applied to other granular materials. This is different from the crystallite size, which refers to the size of a single crystal inside a particle or grain. A single grain can be composed of several crystals. Granular material can range from very small colloidal particles, through clay, silt, sand, gravel, and cobbles, to boulders. Krumbein phi scale Size ranges define limits of classes that are given names in the Wentworth scale (or Udden–Wentworth scale named after geologists Chester K. Wentworth and Johan A. Udden) used in the United States. The Krumbein ''phi'' (φ) scale, a modification of the Wentworth scale created by W. C. Krumbein in 1934, is a logarithmic scale computed by the equation :\varphi=-\log_2, where :\varphi is the Krumbein phi scale, :D is the diameter In geometry, a diameter of a circle i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |