|

Exhaust Brake

An exhaust brake is a means of slowing a diesel engine by closing off the exhaust path from the engine, causing the exhaust gases to be compressed in the exhaust manifold, and in the cylinder. Since the exhaust is being compressed, and there is no fuel being applied, the engine slows down the vehicle: the crankshaft and hence the wheels work against the pistons to compress the exhaust. The amount of braking torque generated is usually directly proportional to the back pressure of the engine. Exhaust brakes are manufactured by many companies. The brakes vary in design, but essentially operate as described above. More advanced exhaust brakes have exhaust pressure modulation (EPM) that controls the back pressure which in turn improves the braking performance across a range of engine speeds. Description An exhaust brake is a valve which essentially creates a back-pressure in the exhaust system, which applies enough force onto the engine's pistons to slow the engine. In most cases ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel Engine

The diesel engine, named after the German engineer Rudolf Diesel, is an internal combustion engine in which Combustion, ignition of diesel fuel is caused by the elevated temperature of the air in the cylinder due to Mechanics, mechanical Compression (physics), compression; thus, the diesel engine is called a compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine (gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Introduction Diesel engines work by compressing only air, or air combined with residual combustion gases from the exhaust (known as exhaust gas recirculation, "EGR"). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases air temperature inside the Cylinder (engine), cylinder so that atomised diesel fuel injected into the combustion chamber ignites. The torque a dies ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust Manifold

In automotive engineering, an exhaust manifold collects the exhaust gases from multiple cylinders into one pipe. The word ''manifold'' comes from the Old English word ''manigfeald'' (from the Anglo-Saxon ''manig'' anyand ''feald'' old and refers to the folding together of multiple inputs and outputs (in contrast, an inlet or intake manifold ''supplies'' air ''to'' the cylinders). Exhaust manifolds are generally simple cast iron or stainless steel units which collect engine exhaust gas from multiple cylinders and deliver it to the exhaust pipe. For many engines, there are aftermarket tubular exhaust manifolds known as headers in American English, as extractor manifolds in British and Australian English, and simply as "tubular manifolds" in British English. These consist of individual exhaust headpipes for each cylinder, which then usually converge into one tube called a collector. Headers that do not have collectors are called zoomie headers. The most common types of afterm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder (engine)

In an engine, the cylinder is the space in which a piston travels. The inner surface of the cylinder is formed from either a thin metallic liner (also called "sleeve") or a surface coating applied to the engine block. A piston is seated inside each cylinder by several metal piston rings, which also provide seals for compression and the lubricating oil. The piston rings do not actually touch the cylinder walls, instead they ride on a thin layer of lubricating oil. Steam engines The cylinder in a steam engine is made pressure-tight with end covers and a piston; a valve distributes the steam to the ends of the cylinder. Cylinders were cast in cast iron and later in steel. The cylinder casting can include other features such as valve ports and mounting feet. Internal combustion engines The cylinder is the space through which the piston travels, propelled by the energy generated from the combustion of the air/fuel mixture in the combustion chamber. In an air-cooled e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Torque

In physics and mechanics, torque is the rotational analogue of linear force. It is also referred to as the moment of force (also abbreviated to moment). The symbol for torque is typically \boldsymbol\tau, the lowercase Greek letter ''tau''. When being referred to as moment of force, it is commonly denoted by . Just as a linear force is a push or a pull applied to a body, a torque can be thought of as a twist applied to an object with respect to a chosen point; for example, driving a screw uses torque to force it into an object, which is applied by the screwdriver rotating around its axis to the drives on the head. Historical terminology The term ''torque'' (from Latin , 'to twist') is said to have been suggested by James Thomson and appeared in print in April, 1884. Usage is attested the same year by Silvanus P. Thompson in the first edition of ''Dynamo-Electric Machinery''. Thompson describes his usage of the term as follows: Today, torque is referred to using d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Back Pressure

Back pressure (or backpressure) is the term for a resistance to the desired flow of fluid through pipes. Obstructions or tight bends create backpressure via friction loss and pressure drop. In distributed systems in particular event-driven architecture, back pressure is a technique to regulate flow of data, ensuring that components do not become overwhelmed. Explanation A common example of backpressure is that caused by the exhaust system (consisting of the exhaust manifold, catalytic converter, muffler and connecting pipes) of an automotive four-stroke engine, which has a negative effect on engine efficiency, resulting in a decrease of power output that must be compensated by increasing fuel consumption. In a piston-ported two-stroke engine, however, the situation is more complicated, due to the need to prevent unburned fuel/air mixture from passing right through the cylinders into the exhaust. During the exhaust phase of the cycle, backpressure is even more undesirable ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

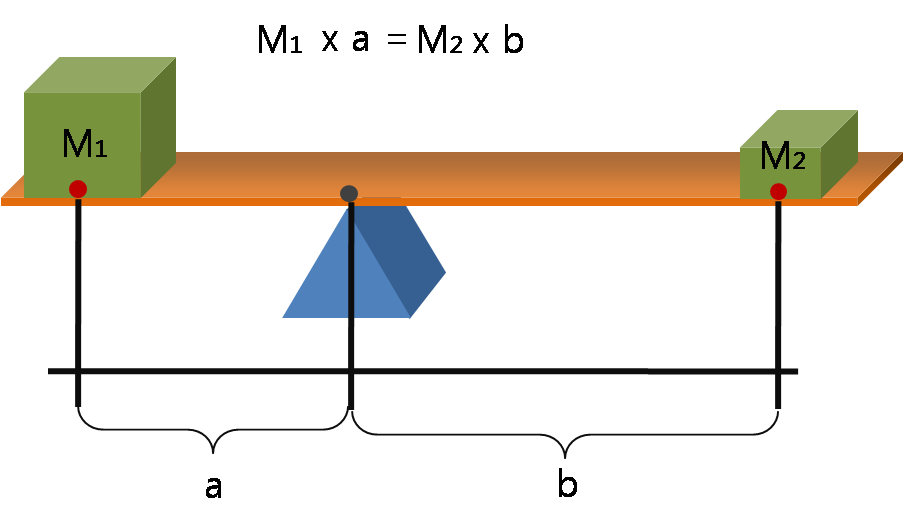

Lever

A lever is a simple machine consisting of a beam (structure), beam or rigid rod pivoted at a fixed hinge, or '':wikt:fulcrum, fulcrum''. A lever is a rigid body capable of rotating on a point on itself. On the basis of the locations of fulcrum, load, and effort, the lever is divided into Lever#Types of levers, three types. It is one of the six simple machines identified by Renaissance scientists. A lever amplifies an input force to provide a greater output force, which is said to provide leverage, which is mechanical advantage gained in the system, equal to the ratio of the output force to the input force. As such, the lever is a mechanical advantage device, trading off force against movement. Etymology The word "lever" entered English language, English around 1300 from . This sprang from the stem of the verb ''lever'', meaning "to raise". The verb, in turn, goes back to , itself from the adjective ''levis'', meaning "light" (as in "not heavy"). The word's primary origin is the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gear Ratio

A gear train or gear set is a machine element of a mechanical system formed by mounting two or more gears on a frame such that the teeth of the gears engage. Gear teeth are designed to ensure the Pitch circle diameter (gears), pitch circles of engaging gears roll on each other without slipping, providing a smooth transmission of rotation from one gear to the next. Features of gears and gear trains include: * The gear ratio of the pitch circles of mating gears defines the speed ratio and the mechanical advantage of the gear set. * A epicyclic gearing, planetary gear train provides high gear reduction in a compact package. * It is possible to design gear teeth for gears that are non-circular gear, non-circular, yet still transmit torque smoothly. * The speed ratios of chain drive, chain and belt (mechanical), belt drives are computed in the same way as gear ratios. See bicycle gearing. The transmission of rotation between contacting toothed wheels can be traced back to the Antikyt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compression Brake

A compression release engine brake, compression brake, or decompression brake is an engine braking mechanism installed on some diesel engines. When activated, it opens exhaust valves to the cylinders, right before the compression stroke ends, releasing the compressed gas trapped in the cylinders. The compression followed by the "wasteful" release consumes great amount of energy, effectively slowing the vehicle. Clessie Cummins was granted a patent for the engine compression brake in 1965, and the first company to manufacture them was Jacobs Vehicle Systems. Therefore, the brakes are commonly known as Jake brakes. Function When the driver releases the accelerator on a moving vehicle powered by an internal combustion engine, the vehicle's forward momentum continues to turn the engine's crankshaft. Most diesel engines do not have a throttle body, so regardless of the throttle setting, air is always drawn into the cylinders (excluding the valve fitted to certain diesels, such ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jake Brake

A compression release engine brake, compression brake, or decompression brake is an engine braking mechanism installed on some diesel engines. When activated, it opens 4-stroke cycle engine valves#Internal combustion engine, exhaust valves to the cylinders, right before the compression stroke ends, releasing the compressed gas trapped in the cylinders. The compression followed by the "wasteful" release consumes great amount of energy, effectively slowing the vehicle. Clessie Cummins was granted a patent for the engine compression brake in 1965, and the first company to manufacture them was Jacobs Vehicle Systems. Therefore, the brakes are commonly known as Jake brakes. Function When the driver releases the accelerator on a moving vehicle powered by an internal combustion engine, the vehicle's forward momentum continues to turn the engine's crankshaft. Most diesel engines do not have a throttle body, so regardless of the throttle setting, air is always drawn into the cylinders ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine Brake

Engine braking occurs when the retarding forces within an internal combustion engine are used to slow down a motor vehicle, as opposed to using additional external braking mechanisms such as friction brakes or magnetic brakes. The term is often confused with several other types of braking, most notably compression release engine brake, compression-release braking or "jake braking" which uses a different mechanism. Traffic regulations in many countries require trucks to always drive with an engaged gear, which in turn provides a certain amount of engine braking (viscous losses to the engine oil and air pumped through the engine and friction losses to the cylinder walls and bearings) when no accelerator pedal is applied. Engine braking in different engine types Gasoline engines The term "engine braking" refers to the braking effect that occurs in gasoline engines when the accelerator pedal is released. This causes fuel injection to cease and the throttle valve to close almost co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

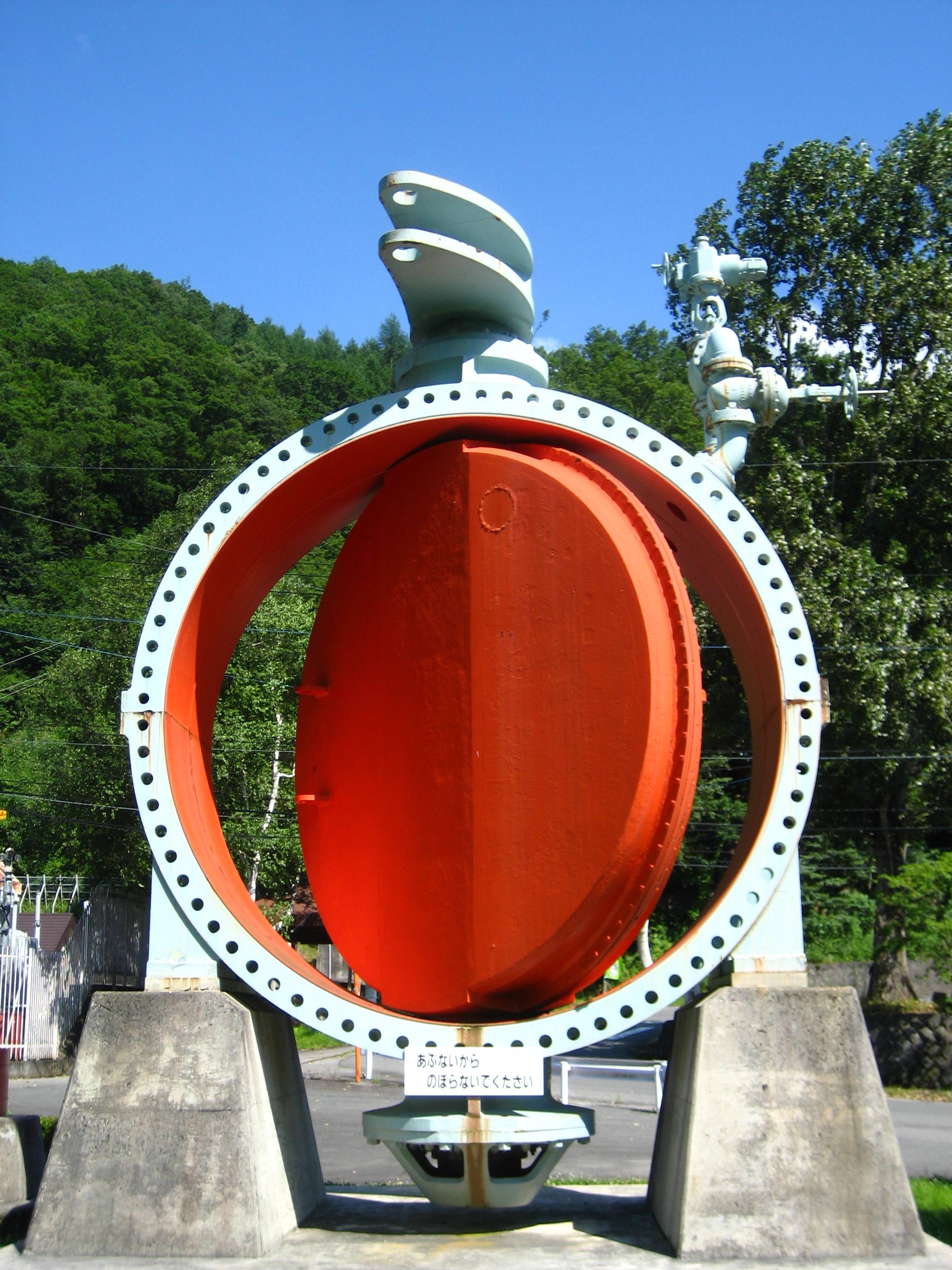

Butterfly Valve

A butterfly valve is a valve that isolates or regulates the flow of a fluid. The closing mechanism is a disk that rotates. Principle of operation Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they cost less than other valve designs, and are lighter weight so they need less support. The disc is positioned in the center of the pipe. A rod passes through the disc to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, so it induces a pressure drop, even when open. A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. Wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |