|

Duralumin

Duralumin (also called duraluminum, duraluminium, duralum, dural(l)ium, or dural) is a trade name for one of the earliest types of age hardening, age-hardenable aluminium–copper alloys. The term is a combination of ''Düren'' and ''aluminium'' . Its use as a trade name is obsolete. Today the term mainly refers to aluminium-copper alloys, designated as the 2000 series by the international alloy designation system (IADS), as with 2014 aluminium alloy, 2014 and 2024 aluminium alloy, 2024 alloys used in airframe fabrication. Duralumin was developed in 1909 in Germany. Duralumin is known for its strength and hardness, making it suitable for various applications, especially in the aviation and aerospace industry. However, it is susceptible to corrosion, which can be mitigated by using alclad-duralum materials. History Duralumin was developed by the German metallurgist Alfred Wilm at private military-industrial laboratory (Center for Scientific-Technical Research) in Neubabelsberg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminium–copper Alloys

Aluminium–copper alloys (AlCu) are Aluminium alloy, aluminium alloys that consist largely of aluminium (Al) and traces of copper (Cu) as the main Alloy, alloying elements. Important grades also contain additives of magnesium, iron, nickel and silicon (AlCu(Mg, Fe, Ni, Si)), often manganese is also included to increase strength (see aluminium–manganese alloys). The main area of application is aircraft construction. The alloys have medium to high strength and can be Precipitation hardening, age hardened. They are both . Also available as cast alloy. Their susceptibility to corrosion and their poor weldability are disadvantageous. Duralumin is the oldest variety in this group and goes back to Alfred Wilm, who discovered it in 1903. Aluminium could only be used as a widespread construction material thanks to the aluminium–copper alloys, as pure aluminium is much too soft for this and other hardenable alloys such as aluminium–magnesium–silicon alloys (AlMgSi) or the naturally h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alfred Wilm

Alfred Wilm (25 June 1869 – 6 August 1937) was a German metallurgist who invented the alloy Al-(3.5%-5.5%)Cu-Mg-Mn, now known as Duralumin which is used extensively in aircraft. Research Work Whilst working in private military-industrial laboratory (Center for Scientific-Technical Research) in Neubabelsberg in 1901, Wilm discovered age hardening, in particular age hardening of aluminium alloys. This discovery was made after hardness measurements on Al-Cu alloy specimens were serendipitously found to increase in hardness at room temperature. This increase in hardness was identified after his measurements were interrupted by a weekend, and when they were resumed on the Monday the hardness had increased. By 1906, Wilm had developed an alloy – Al-(3.5–5.5%)Cu-Mg-Mn (Mg and Mn were < 1%), for which a patent was filed. Later this patent was purchased and the alloy marketed as |

Aluminium Alloy

An aluminium alloy ( UK/IUPAC) or aluminum alloy ( NA; see spelling differences) is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to their low melting points, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.I. J. Polmear, ''Light Alloys'', A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alclad

Alclad is a corrosion-resistant aluminium sheet formed from high-purity aluminium surface layers metallurgically bonded (rolled onto) to high-strength aluminium alloy core material. It has a melting point of about . Alclad is a trademark of Alcoa but the term is also used generically. Since the late 1920s, Alclad has been produced as an aviation-grade material, being first used by the sector in the construction of the ZMC-2 airship. The material has significantly more resistance to corrosion than most aluminium-based alloys, for only a modest increase in weight, making Alclad attractive for building various elements of aircraft, such as the fuselage, structural members, skin, and cowling. Accordingly, it became a relatively popular material for aircraft manufacturing. Details The material was described in NACA-TN-259 of August 1927, as "a new corrosion resistant aluminium product which is markedly superior to the present strong alloys. Its use should result in greatly increased ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engineering is the field dedicated to controlling and preventing corrosion. In the most common use of the word, this means electrochemical oxidation of metal in reaction with an oxidant such as oxygen, hydrogen, or hydroxide. Rusting, the formation of red-orange iron oxides, is a well-known example of electrochemical corrosion. This type of corrosion typically produces oxides or salts of the original metal and results in a distinctive coloration. Corrosion can also occur in materials other than metals, such as ceramics or polymers, although in this context, the term "degradation" is more common. Corrosion degrades the useful properties of materials and structures including mechanical strength, appearance, and permeability to liquids and ga ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

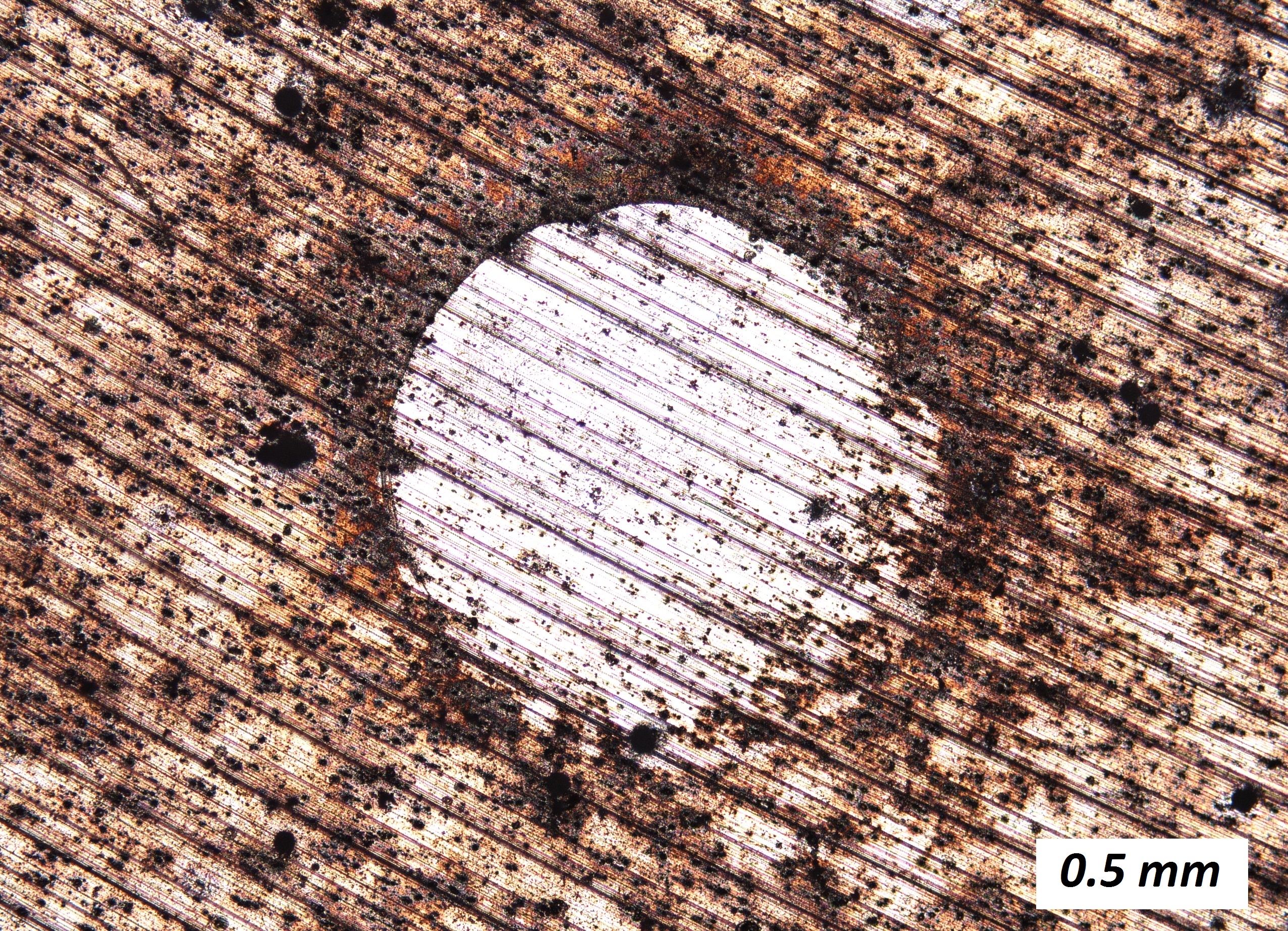

Precipitation Hardening

Precipitation hardening, also called age hardening or particle hardening, is a heat treatment technique used to increase the yield strength of malleable materials, including most structural alloys of aluminium, magnesium, nickel, titanium, and some steels, stainless steels, and duplex stainless steel. In superalloys, it is known to cause yield strength anomaly providing excellent high-temperature strength. Precipitation hardening relies on changes in solid solubility with temperature to produce fine particles of an impurity phase, which impede the movement of dislocations, or defects in a crystal's lattice. Since dislocations are often the dominant carriers of plasticity, this serves to harden the material. The impurities play the same role as the particle substances in particle-reinforced composite materials. Just as the formation of ice in air can produce clouds, snow, or hail, depending upon the thermal history of a given portion of the atmosphere, precipitation in solids ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking

Metalworking is the process of shaping and reshaping metals in order to create useful objects, parts, assemblies, and large scale structures. As a term, it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges, down to precise engine parts and delicate jewellery. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to and including highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

2011 Aluminium Alloy

Eleven or 11 may refer to: *11 (number) * One of the years 11 BC, AD 11, 1911, 2011 Literature * ''Eleven'' (novel), a 2006 novel by British author David Llewellyn *''Eleven'', a 1970 collection of short stories by Patricia Highsmith *''Eleven'', a 2004 children's novel in The Winnie Years by Lauren Myracle *''Eleven'', a 2008 children's novel by Patricia Reilly Giff *''Eleven'', a short story by Sandra Cisneros Music *Eleven (band), an American rock band * Eleven: A Music Company, an Australian record label *Up to eleven, an idiom from popular culture, coined in the movie ''This Is Spinal Tap'' Albums * ''11'' (The Smithereens album), 1989 * ''11'' (Ua album), 1996 * ''11'' (Bryan Adams album), 2008 * ''11'' (Sault album), 2022 * ''Eleven'' (Harry Connick, Jr. album), 1992 * ''Eleven'' (22-Pistepirkko album), 1998 * ''Eleven'' (Sugarcult album), 1999 * ''Eleven'' (B'z album), 2000 * ''Eleven'' (Reamonn album), 2010 * ''Eleven'' (Martina McBride album), 2011 * ''Eleven'' (Mr Fogg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machinability

Machinability is the ease with which a metal can be cut ( machined) permitting the removal of the material with a satisfactory finish at low cost.Degarmo, p. 542. Materials with good machinability (free-machining materials) require little power to cut, can be cut quickly, easily obtain a good finish, and do not cause significant wear on the tooling. Factors that typically improve a material's performance often degrade its machinability, presenting a significant engineering challenge. Machinability can be difficult to predict due to the large number of variables involved in the machining process. Two sets of factors are the condition and physical properties of the work materials. The condition of the work material includes at least eight factors: microstructure, grain size, heat treatment, chemical composition, fabrication, hardness, yield strength, and tensile strength.Schneider, "Machinability." Physical properties are those of the individual material groups, such as the modu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

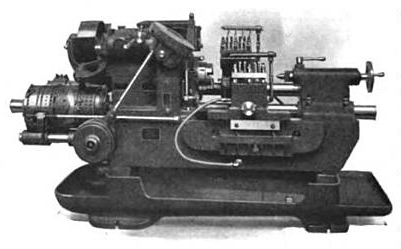

Screw Machine (automatic Lathe)

In metalworking and woodworking, an automatic lathe is a lathe with an automatically controlled cutting process. Automatic lathes were first developed in the 1870s and were mechanically controlled. From the advent of NC and CNC in the 1950s, the term automatic lathe has generally been used for only mechanically controlled lathes, although some manufacturers (e.g., DMG Mori and Tsugami) market Swiss-type CNC lathes as 'automatic'. CNC has not yet entirely displaced mechanically automated lathes, as although no longer in production, many mechanically automated lathes remain in service. General nomenclature The term "automatic lathe" is still often used in manufacturing in its earlier sense, referring to automated lathes of non- CNC types. The first automatic lathes were mechanically automated and controlled by cams or tracers and pantographs. Thus, before electronic automation via numerical control, the "automatic" in the term "automatic machine tool" always referred implic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manganese

Manganese is a chemical element; it has Symbol (chemistry), symbol Mn and atomic number 25. It is a hard, brittle, silvery metal, often found in minerals in combination with iron. Manganese was first isolated in the 1770s. It is a transition metal with a multifaceted array of industrial alloy uses, particularly in stainless steels. It improves strength, workability, and resistance to wear. Manganese oxide is used as an oxidising agent, as a rubber additive, and in glass making, fertilisers, and ceramics. Manganese sulfate can be used as a fungicide. Manganese is also an essential human dietary element, important in macronutrient metabolism, bone formation, and free radical defense systems. It is a critical component in dozens of proteins and enzymes. It is found mostly in the bones, but also the liver, kidneys, and brain. In the human brain, the manganese is bound to manganese metalloproteins, most notably glutamine synthetase in astrocytes. Manganese is commonly found in labo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |